January 2008 31

ALTHOUGH IT’S virtually unknown in

the US, other than by historical-aviation

enthusiasts, the Stahlwerk Mark III was a

popular and successful sport aviation design

in Europe during the 1920s and 1930s.

Walter Rieseler designed the airplane in

1922, and it is sometimes referred to as the

Rieseler R III.

Rieseler, a gifted German airplane

pioneer and designer, has been all but

forgotten in aviation history in spite of his

numerous accomplishments. The Stahlwerk

Mark III was one of his earliest aircraft. He

became better known for his innovative

autogiros and was credited in 1935 with

designing and producing the world’s first

helicopter that featured twin counterrotating

blades.

In 1920 Rieseler, in partnership with his

brother, formed a small aircraft

manufacturing company in Breslau,

Germany, called Stahlwerk. The Mark III,

which was preceded by the Mark II and

Mark I, was offered for sale in 1922, and it

rapidly became popular among the sportaviation

community in Germany.

The Mark III was a small, single-place

design with a fuselage length of 17 feet

and a wingspan of 25 feet. It was

powered with several different air-cooled

engines, the most popular of which were

the Haacke HFM two-cylinder flat

opposed type that produced 26

horsepower and the Anzani three-cylinder

Fly the Stahlwerk indoors or out. The outrunner motor system is quiet and provides

enough power for a five-minute flight on a two-cell Li-Poly battery pack.

1922 Stahlwerk Mark III

BY BOB WALLACE

A semiscale

park flyer of

the golden-age

German sport

aircraft

radial that produced 30 horsepower.

The airplane’s maximum speed near sea

level was 66 mph, and it had a 62 mph

cruise speed. With its low wing loading the

Mark III had great short-field takeoff-andlanding

capabilities. It could be airborne in

slightly more than 100 feet, and it could be

put back on the ground in an even shorter

distance since its landing speed was just less

than 30 mph. Its large-diameter landing-gear

wheels were well suited to grass fields.

In 1923 a publicity seeker named

Antonius Raab made one of the Mark III’s

most publicized flights. He landed his

01sig1.QXD 11/19/07 1:14 PM Page 31

32 MODEL AVIATION

The constant-chord wing uses the same rib shape at each station. The flat-bottom

airfoil can be built on a flat surface with no fixturing required. Notice how the top

spars meet the wingtip.

It’s easier to install the rudder and elevator servos and control rods before the model

is covered. A 6-gram submicroservo with roughly 10 inch-ounce of torque is all that is

required.

Before sheeting the top of the fuselage, temporarily glue an incidence template in place

to build the wing support. Round all balsa parts before assembling the structure.

aircraft on the Unter den Linden, which is a

main thoroughfare in Berlin, Germany. The

police promptly arrested him.

At least one Mark III still exists. It is on

display at the Arlanda Aerospace Museum

in Stockholm, Sweden.

I selected the Stahlwerk Mark III as an

RC modeling project because it’s unique.

More importantly, it produced dimensions

and a planform that I hoped would result in

a model that would be easy to build and fly

and offer good flight characteristics.

Perhaps RC modelers who have never

built a stick-and-tissue-type model will find

this construction project to be one of interest

and give it a try. It uses simple, proven

building methods that require no unique

tools or building skills. Older modelers who

grew up eagerly constructing Comet and

Megow kits and chewing Lepage’s or

Ambroid glue off their fingers may find the

Mark III to be a trip down memory lane.

The intent in designing this model was to

keep it simple using inexpensive and readily

available construction materials most hobby

shops should have in stock. My Stahlwerk

Mark III is powered by a Baby Bullet

Double Cool Wind brushless outrunner

motor from CustomCDR.

CONSTRUCTION

As with any plans- or scratch-building

project, it helps to fabricate all the shaped or

formed parts before starting the assembly

Info

box

1922

Stahlwerk Mark III

Static shots by the author; flight shots by Lloyd Burnham

Type: Small vintage sport scale

Wingspan: 24 inches

Flying weight: 116 grams (4.1 ounces)

Wing area: 105 square inches

Length: 16.5 inches

Motor: Small microsize brushless

outrunner

Propeller: GWS 6 x 3

Battery: Two-cell, 300 mAh Li-Poly

Construction: Balsa and plywood

Covering/finish: Polyester tissue

(Litespan)

01sig1.QXD 11/19/07 1:18 PM Page 32

January 2008 33

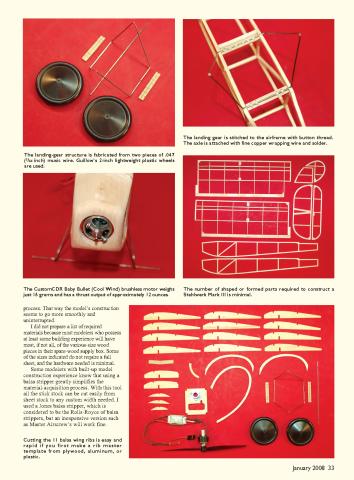

The landing gear is stitched to the airframe with button thread.

The axle is attached with fine copper wrapping wire and solder.

The CustomCDR Baby Bullet (Cool Wind) brushless motor weighs

just 16 grams and has a thrust output of approximately 12 ounces.

The number of shaped or formed parts required to construct a

Stahlwerk Mark III is minimal.

Cutting the 11 balsa wing ribs is easy and

rapid if you first make a rib master

template from plywood, aluminum, or

plastic.

The landing-gear structure is fabricated from two pieces of .047

(3/64 inch) music wire. Guillow’s 2-inch lightweight plastic wheels

are used.

process. That way the model’s construction

seems to go more smoothly and

uninterrupted.

I did not prepare a list of required

materials because most modelers who possess

at least some building experience will have

most, if not all, of the various-size wood

pieces in their spare-wood supply box. Some

of the sizes indicated do not require a full

sheet, and the hardware needed is minimal.

Some modelers with built-up model

construction experience know that using a

balsa stripper greatly simplifies the

material-acquisition process. With this tool

all the stick stock can be cut easily from

sheet stock to any custom width needed. I

used a Jones balsa stripper, which is

considered to be the Rolls-Royce of balsa

strippers, but an inexpensive version such

as Master Airscrew’s will work fine.

01sig2.QXD 11/19/07 2:03 PM Page 33

34 MODEL AVIATION

Although it is optional, you can give your model a more

scalelike appearance by adding 1/16 x 3/16 balsa to the landinggear

assembly legs.

The author made the decals on his Stahlwerk using a homecomputer

ink-jet printer and water-transfer decal sheets.

The tail surfaces are constructed from balsa stick and sheet stock. The curved perimeter pieces are made from laminated 1/32 balsa sheet.

Scale Documentation Sources

• www.histaviation.com/Mark_R_III_colour_profile.jpg

• http://aircraftwalkaround.hobbyvista.com/rieseler/rieseler.htm

• www.histaviation.com/Stahlwerk_Mark_III.html MA

—Bob Wallace

The number of shaped or formed parts required to construct a

Stahlwerk Mark III is minimal. Since the wing is a constantchord

type, cutting the 11 balsa wing ribs is easy and fast if you

make a master template from a scrap piece of 1/32 plywood, thin

sheet aluminum, or plastic.

The motor-mount former is cut from 1/8 light plywood. Its

height and width may vary a bit depending on what type of motor

you use and where that former will be positioned within the nose

portion of the fuselage.

The only other shaped parts that need to be cut are the 1/16

plywood tail skid, two 1/16 plywood landing-gear mounting

crossbraces, three 3/32 sheet top fuselage formers, and the 1/16

plywood wing-spar brace.

The main components are constructed directly over the plans

sheet placed on a flat building surface. Fledgling builders are

reminded to place a sheet of clear vinyl plastic (backing from

many heat-shrinkable film-type covering materials works well for

this) or good, old kitchen-variety waxed paper over the plans

sheet to permit easy separation of the assembled part from the

sheet.

Wing: To construct each wing panel, pin the 1/8 x 1/4 main spar in

place along with the 1/8 x 3/8 TE. Use the wing ribs to achieve the

proper lateral spacing. Pin all the wing ribs in place. Be sure to

cant the 1/8 center-section rib using the wing-dihedral-angle

template as a guide. Glue these pieces together with thin

cyanoacrylate adhesive, and then pin and glue the 1/8 x 1/4 LE and

01sig2.QXD 11/19/07 2:35 PM Page 34

Any lightweight film-type covering, such as silkspan, or tissue-type materials can be used.

A Williams Brothers 1/12th scale racing pilot bust was cut down to fit and painted.

Three Williams Brothers plastic Gnome engine cylinders (item 206) were trimmed

and mounted to resemble the Anzani engine used on most Stahlwerk Mark III aircraft

that were produced.

Using Litespan

requires that a heatsensitive

adhesive

be applied to the

various components

before covering.

two 3/32 square top spars in place.

Pin and glue the 1/8 x 1/4 wingtip pieces

in place. The two 3/32 square top spars are

cut at the outer W2 rib and angled

downward to the 1/8 x 1/4 tip; see Section BB

on the plans sheet.

Glue the gussets and 1/16 x 1/8 wing-strut

attachment pieces in place. It is easier to

install the center-section cockpit-recess 1/16

sheet trim pieces after the two wing panels

have been joined.

After both wing panels have been

fabricated, lightly block-sand the faces of

the canted center-section W1 ribs and trialfit

them to ensure that the indicated dihedral

angle (3/4 inch under each tip) is produced.

Glue the two wing panels together, and then

install the 1/16 plywood DB1 brace.

Install the 1/16 sheet cockpit-recess pieces

in the aft center-section recess. The

completed wing assembly can be sanded

and contoured to the indicated airfoil and

planform.

Tail: The tail surfaces are constructed from

balsa stick and sheet stock. The curved

perimeter pieces are made from laminated

1/32 balsa sheet.

Three pieces of 1/32 balsa sheet are glued

together, with the center piece positioned

cross-grain to provide additional strength,

and then the curved perimeter tail-surface

pieces are cut from this laminated balsa

sheet stock.

Fuselage: The basic fuselage is a box-type

structure that is composed primarily of 1/8

square balsa to make its open framework.

The two fuselage sides are constructed

directly over the plans sheet side view, and

then the various 1/8 square crossbraces are

installed using the plans sheet top view as a

guide.

As I mentioned, the size and position of

the 1/8 light-plywood motor bulkhead may

vary depending on what type of motor,

propeller mounting adapter, and motor

mount you choose. I also mentioned that I

used a Baby Bullet brushless motor, but a

January 2008 35

01sig2.QXD 11/19/07 2:36 PM Page 35

variety of other motors can be employed.

Mine weighs 16 grams and has a thrust output

of roughly 12 ounces using a 2S Li-Poly

battery source and 7-inch propeller.

After installing the motor-mount

bulkhead, 1/16 nose-sheeting inlays, and 1/8

scrap bulkhead gussets, fit and secure the

fuselage F1 and F2 top formers, 1/16 square

stringer, and 1/16 top sheeting.

To ensure that the wing-mounting pylon

structure is constructed at the proper

incidence angle and aligned correctly, use the

incidence template shown on the plans sheet

as a guide.

Using a piece of string or thread, along

with a couple pins or a flexible straightedge,

determine the fuselage centerline and lightly

mark it along the top sheeting between the F2

fuselage top formers. Pin the 1/8 sheet

incidence template onto the fuselage top

sheeting along the marked fuselage centerline

between the F2 formers.

Once the 1/8 x 1/4 wing-support portion of

the pylon is pinned in place on top of the

template, the 1/8 and 1/16 square pylon support

pieces can be cut, fitted (notching the top

sheeting as required), and glued in place.

Since the full-scale Stahlwerk’s pylon support

pieces were made from welded steel tubing, it

is easier to sand the 1/8 and 1/16 square pieces

round before cutting them and fitting them in

place.

36 MODEL AVIATION

Full-Size Plans Available—See Page 199

After you have glued the wing pylon

structure in place, remove and discard the

incidence template.

The landing-gear structure is fabricated

from two pieces of .047 (3/64 inch) music

wire. One piece is the 4-inch-long axle that

will ultimately be trimmed to accommodate

whatever type of wheel you choose. I used

Guillow’s 2-inch lightweight plastic wheels

on my Stahlwerk.

The main landing-gear structure is bent

to shape using the detail shown on the plans

sheet. Then the landing-gear structure is

mounted on the two 1/16 plywood

crossbraces using button thread and

cyanoacrylate adhesive.

A 1/16 cap piece of balsa is applied over

the laced-on landing-gear/plywood

crosspieces to provide a finished appearance

after being installed on the fuselage. The

axle is attached to the main landing gear

with fine copper wrapping wire and solder.

Although optional, you can attain a more

scalelike appearance by adding 1/16 x 3/16

balsa to the landing-gear-assembly legs. I did

this by cutting a small channel along the

balsa strips and then gluing them in place

with cyanoacrylate. After sanding a radius

on the legs, I painted the landing-gear

assembly with satin-finish black paint.

The fuselage bottom access hatch is

fabricated using the hatch detail shown on

the plans sheet, and it is held in place with a

small magnet. Glue the 1/4 sheet nose block

in place and sand the fuselage assembly to

the indicated contours.

Notch the fuselage to accept the 1/16

plywood tail skid, but do not permanently

install the tail skid until after you cover the

model. Also, it is easier to install the rudder

and elevator servos and control rods now

rather than after the model has been covered.

The wing struts are made from 3/32 x 3/16

balsa and have their edges rounded. The

wing, tail surfaces, and fuselage assembly

can be fine-sanded in preparation for

covering. Any minor surface imperfections

can be filled with lightweight filler.

Covering: Any lightweight film-type

covering, such as silkspan or tissue-type

materials, can be used to cover this model. I

used buff-colored Litespan, which is a

lightweight, heat-shrinkable polyester tissuetype

covering that closely resembles the

natural linen-type material used on many

aircraft during the 1920s, including the

Stahlwerk.

Using Litespan requires that a heatsensitive

adhesive be applied to the various

components before covering. I used Coverite

Balsarite. The adhesive is brushed onto the

various subassemblies wherever the

covering material needs to be heat-fastened.

Once the Balsarite has dried, the Litespan

can be applied in the same manner as any

other heat-shrinkable covering material. In

areas where covering material overlaps, the

joint needs to be coated with Balsarite.

The decals shown on my Stahlwerk were

made using a home-computer ink-jet printer

01sig2.QXD 11/19/07 2:04 PM Page 36

38 MODEL AVIATION

and water-transfer decal sheets. These decal

sheets are readily available at graphic-arts

supply outlets or from a variety of Internet

sources. The sheets I used were purchased on

eBay and cost roughly one dollar each.

I trimmed three Williams Brothers plastic

Gnome engine cylinders and mounted them

on my model to resemble the Anzani engine

that was used in most of the Stahlwerk Mark

IIIs. Although they are not true scale, the

World War I-era Gnome cylinders resemble

those on the Anzani; I do believe they

enhance the model’s overall scale

appearance.

To complete the power package I

equipped the Baby Bullet brushless motor

with a GWS 6 x 3 propeller (item

GW/EP6030), a Castle Creations

Thunderbird-9 ESC, and an Apache 7.4-volt,

300 mAh 20C Li-Poly battery pack. I used

an Airtronics RD6000 transmitter, and the

airborne radio system consisted of a Corona

RS410 single-conversion microreceiver and

two Blue Bird BMS-303 microservos.

I achieved the indicated CG on my model

by positioning the operating components as

shown on the plans sheet. My Stahlwerk,

ready to fly, weighed 116 grams (4.1

ounces).

Flying: A beautiful, mild spring day with

sunny skies and only a wisp of a breeze

proved to be ideal conditions for my

Stahlwerk’s test flights. Since our club flying

field is all grass, and the Stahlwerk is

equipped with relatively small-diameter

wheels, I decided to hand launch for the

maiden flight.

After a usual radio range check and final

inspection, it was flip-and-fly time. Standing

stationary with approximately two-thirds

throttle introduced, a light, straight-out toss

was all that was necessary for the Stahlwerk

to climb out nicely.

After gaining roughly 75 feet of altitude,

a few blips of right rudder and down-elevator

trim correction made the Stahlwerk fly hands

off. I spent the next several minutes flying

about, performing mild maneuvers at various

throttle settings to assess the model’s inflight

capabilities. It became apparent that a

bit more rudder and slightly less elevator

control-surface movement were needed.

The first landing was easy and

uneventful. With the motor throttled back to

approximately one-quarter power, I made a

shallow, gentle approach until the Stahlwerk

was a few feet above the grass surface. The

landing stall occurred predictably after

easing back the throttle to idle, which

resulted in a soft landing.

Since the Stahlwerk is a small,

lightweight aircraft with a low wing loading,

landing on grass could best be described as a

three-point plop rather than a conventional

landing. There is no rollout once the wheels

make contact with the grass!

After making the required controlsurface-

movement adjustments, I installed a

fresh battery pack and the Stahlwerk was

airborne again and flying quite nicely. It is

easy to fly and forgiving, with no bad in-

FLIGHT GLOW

■ Fully Automatic

■ No set-up, no servo reversal

■ Progressive heating

■ Full off at 1/4 throttle

■ Turn off with engine kill

■ Red LED when driver on

$39.95 plus shipping & handling

C-TRONICS,Inc. P.O. Box 192, Ramsey, NJ 07446 201 818-4289 www.c-tronicsinc.com

C-TRONICS ON BOARD GLOW DRIVERS

FLIGHT GLOW II

All of the features of

FLIGHT GLOW PLUS:

Tri-Color LED

Green–good driver battery

Orange–low driver battery

Red–driver on

Flashing Red–very low battery or

disconnected plug wire

Specify connector (Futaba, JR-Hitec-Airtronics) $49.95 plus shipping & handling

All units complete with plug connector and 1900 MA/HR battery

Work with single or twin engines* and twin cylinder*

(*requires additional battery and plug connector)

Dealer inquiries invited. Simple,Safe,Secure.

Visit our website

for full details

and to see our

other RC products!

01sig2.QXD 11/19/07 2:04 PM Page 38

flight characteristics. Its mild aerobatic

capability proved to be suitable for this type of

model. The well-built Baby Bullet proved to

be an ideal choice, with outstanding power.

Subsequent flights were in the 10- to 12-

minute range using an Apache two-cell, 300

mAh Li-Poly battery pack. The recommended

control-surface travel limits, in each direction,

are three-eights rudder and one-quarter

elevator. Those are suggested starting points,

and those who decide to build a Stahlwerk

may ultimately decide to alter them a bit to

suit their flying preferences.

Although I have not had the opportunity to

fly my Stahlwerk indoors, I am sure I will

when what is referred to as the “building

season” (winter) arrives in New England.

Since it is slow-flying, docile, and easy to fly,

it should be well suited for indoor flying.

The Stahlwerk is an easy-to-build sport-scale

model that is a bit different. It is well suited to

those who would like to try a traditional stickand-

tissue-type built-up model. Experienced

modelers who are looking for a project that

will renew pleasant memories of a time that

may well become known as the golden age of

model aviation should also find this to be a

worthy subject.

If I can be of help in answering any

questions relative to how I built my

Stahlwerk, I will be most willing to do so. My

address is 91 Sylvan St., Avon CT 06001. MA

Bob Wallace

[email protected]

Sources:

Baby Bullet Double Cool Wind motor:

CustomCDR

1215 Diamondback Dr. NE

Albuquerque NM 87113

www.customcdr.com

Castle Creations Thunderbird-9 ESC:

(913) 390-6939

www.castlecreations.com

Battery pack, servos, receiver, covering

material:

BP Hobbies

(732) 287-3933

www.bphobbies.com

Master Airscrew Balsa Stripper:

(916) 631-8385

www.masterairscrew.com

Jim Jones Design Balsa Stripper:

A2Z CNC

(877) 754-7465

www.a2zcnc.com/airplane.asp

Still Paying

a dollar for 4 screws?

Here’s a sensible

alternative from

Master Builder Assortment #5000

Retail price: $360.00

RTL price $129.95!

The Master Assortment is the most complete

model building hardware kit available anywhere

in the country. It contains the most often used

hardware for the average modeler.

• Socket Head Cap Screws

• Cowl and canopy Button Heads

• Socket Head Servo Screws

• Screws for landing gear

• Miscellaneous general purpose screws

• Nylon insert lock nuts

• Blind (T) nuts

• Hex nuts

• Lock washers

• Flat washers

• Organizers

• 1 telescoping magnetic screw grabber.

A total of 2,124 pieces!

RTL offers 10 other assortments and 500

individual hardware packs in small and large

quantities. Every fastener you need for model

building!

Join thousands of your fellow modelers. Visit

RTL Fasteners online. You’ll be glad you did!

RTL Fasteners

www.rtlfasteners.com

or call 800-239-6010

800 Battlefi eld Blvd. South, Suite 109

Chesapeake, VA 23322

40 MODEL AVIATION

01sig2.QXD 11/19/07 2:04 PM Page 40

Edition: Model Aviation - 2008/01

Page Numbers: 31,32,33,34,35,36,38,40

Edition: Model Aviation - 2008/01

Page Numbers: 31,32,33,34,35,36,38,40

January 2008 31

ALTHOUGH IT’S virtually unknown in

the US, other than by historical-aviation

enthusiasts, the Stahlwerk Mark III was a

popular and successful sport aviation design

in Europe during the 1920s and 1930s.

Walter Rieseler designed the airplane in

1922, and it is sometimes referred to as the

Rieseler R III.

Rieseler, a gifted German airplane

pioneer and designer, has been all but

forgotten in aviation history in spite of his

numerous accomplishments. The Stahlwerk

Mark III was one of his earliest aircraft. He

became better known for his innovative

autogiros and was credited in 1935 with

designing and producing the world’s first

helicopter that featured twin counterrotating

blades.

In 1920 Rieseler, in partnership with his

brother, formed a small aircraft

manufacturing company in Breslau,

Germany, called Stahlwerk. The Mark III,

which was preceded by the Mark II and

Mark I, was offered for sale in 1922, and it

rapidly became popular among the sportaviation

community in Germany.

The Mark III was a small, single-place

design with a fuselage length of 17 feet

and a wingspan of 25 feet. It was

powered with several different air-cooled

engines, the most popular of which were

the Haacke HFM two-cylinder flat

opposed type that produced 26

horsepower and the Anzani three-cylinder

Fly the Stahlwerk indoors or out. The outrunner motor system is quiet and provides

enough power for a five-minute flight on a two-cell Li-Poly battery pack.

1922 Stahlwerk Mark III

BY BOB WALLACE

A semiscale

park flyer of

the golden-age

German sport

aircraft

radial that produced 30 horsepower.

The airplane’s maximum speed near sea

level was 66 mph, and it had a 62 mph

cruise speed. With its low wing loading the

Mark III had great short-field takeoff-andlanding

capabilities. It could be airborne in

slightly more than 100 feet, and it could be

put back on the ground in an even shorter

distance since its landing speed was just less

than 30 mph. Its large-diameter landing-gear

wheels were well suited to grass fields.

In 1923 a publicity seeker named

Antonius Raab made one of the Mark III’s

most publicized flights. He landed his

01sig1.QXD 11/19/07 1:14 PM Page 31

32 MODEL AVIATION

The constant-chord wing uses the same rib shape at each station. The flat-bottom

airfoil can be built on a flat surface with no fixturing required. Notice how the top

spars meet the wingtip.

It’s easier to install the rudder and elevator servos and control rods before the model

is covered. A 6-gram submicroservo with roughly 10 inch-ounce of torque is all that is

required.

Before sheeting the top of the fuselage, temporarily glue an incidence template in place

to build the wing support. Round all balsa parts before assembling the structure.

aircraft on the Unter den Linden, which is a

main thoroughfare in Berlin, Germany. The

police promptly arrested him.

At least one Mark III still exists. It is on

display at the Arlanda Aerospace Museum

in Stockholm, Sweden.

I selected the Stahlwerk Mark III as an

RC modeling project because it’s unique.

More importantly, it produced dimensions

and a planform that I hoped would result in

a model that would be easy to build and fly

and offer good flight characteristics.

Perhaps RC modelers who have never

built a stick-and-tissue-type model will find

this construction project to be one of interest

and give it a try. It uses simple, proven

building methods that require no unique

tools or building skills. Older modelers who

grew up eagerly constructing Comet and

Megow kits and chewing Lepage’s or

Ambroid glue off their fingers may find the

Mark III to be a trip down memory lane.

The intent in designing this model was to

keep it simple using inexpensive and readily

available construction materials most hobby

shops should have in stock. My Stahlwerk

Mark III is powered by a Baby Bullet

Double Cool Wind brushless outrunner

motor from CustomCDR.

CONSTRUCTION

As with any plans- or scratch-building

project, it helps to fabricate all the shaped or

formed parts before starting the assembly

Info

box

1922

Stahlwerk Mark III

Static shots by the author; flight shots by Lloyd Burnham

Type: Small vintage sport scale

Wingspan: 24 inches

Flying weight: 116 grams (4.1 ounces)

Wing area: 105 square inches

Length: 16.5 inches

Motor: Small microsize brushless

outrunner

Propeller: GWS 6 x 3

Battery: Two-cell, 300 mAh Li-Poly

Construction: Balsa and plywood

Covering/finish: Polyester tissue

(Litespan)

01sig1.QXD 11/19/07 1:18 PM Page 32

January 2008 33

The landing gear is stitched to the airframe with button thread.

The axle is attached with fine copper wrapping wire and solder.

The CustomCDR Baby Bullet (Cool Wind) brushless motor weighs

just 16 grams and has a thrust output of approximately 12 ounces.

The number of shaped or formed parts required to construct a

Stahlwerk Mark III is minimal.

Cutting the 11 balsa wing ribs is easy and

rapid if you first make a rib master

template from plywood, aluminum, or

plastic.

The landing-gear structure is fabricated from two pieces of .047

(3/64 inch) music wire. Guillow’s 2-inch lightweight plastic wheels

are used.

process. That way the model’s construction

seems to go more smoothly and

uninterrupted.

I did not prepare a list of required

materials because most modelers who possess

at least some building experience will have

most, if not all, of the various-size wood

pieces in their spare-wood supply box. Some

of the sizes indicated do not require a full

sheet, and the hardware needed is minimal.

Some modelers with built-up model

construction experience know that using a

balsa stripper greatly simplifies the

material-acquisition process. With this tool

all the stick stock can be cut easily from

sheet stock to any custom width needed. I

used a Jones balsa stripper, which is

considered to be the Rolls-Royce of balsa

strippers, but an inexpensive version such

as Master Airscrew’s will work fine.

01sig2.QXD 11/19/07 2:03 PM Page 33

34 MODEL AVIATION

Although it is optional, you can give your model a more

scalelike appearance by adding 1/16 x 3/16 balsa to the landinggear

assembly legs.

The author made the decals on his Stahlwerk using a homecomputer

ink-jet printer and water-transfer decal sheets.

The tail surfaces are constructed from balsa stick and sheet stock. The curved perimeter pieces are made from laminated 1/32 balsa sheet.

Scale Documentation Sources

• www.histaviation.com/Mark_R_III_colour_profile.jpg

• http://aircraftwalkaround.hobbyvista.com/rieseler/rieseler.htm

• www.histaviation.com/Stahlwerk_Mark_III.html MA

—Bob Wallace

The number of shaped or formed parts required to construct a

Stahlwerk Mark III is minimal. Since the wing is a constantchord

type, cutting the 11 balsa wing ribs is easy and fast if you

make a master template from a scrap piece of 1/32 plywood, thin

sheet aluminum, or plastic.

The motor-mount former is cut from 1/8 light plywood. Its

height and width may vary a bit depending on what type of motor

you use and where that former will be positioned within the nose

portion of the fuselage.

The only other shaped parts that need to be cut are the 1/16

plywood tail skid, two 1/16 plywood landing-gear mounting

crossbraces, three 3/32 sheet top fuselage formers, and the 1/16

plywood wing-spar brace.

The main components are constructed directly over the plans

sheet placed on a flat building surface. Fledgling builders are

reminded to place a sheet of clear vinyl plastic (backing from

many heat-shrinkable film-type covering materials works well for

this) or good, old kitchen-variety waxed paper over the plans

sheet to permit easy separation of the assembled part from the

sheet.

Wing: To construct each wing panel, pin the 1/8 x 1/4 main spar in

place along with the 1/8 x 3/8 TE. Use the wing ribs to achieve the

proper lateral spacing. Pin all the wing ribs in place. Be sure to

cant the 1/8 center-section rib using the wing-dihedral-angle

template as a guide. Glue these pieces together with thin

cyanoacrylate adhesive, and then pin and glue the 1/8 x 1/4 LE and

01sig2.QXD 11/19/07 2:35 PM Page 34

Any lightweight film-type covering, such as silkspan, or tissue-type materials can be used.

A Williams Brothers 1/12th scale racing pilot bust was cut down to fit and painted.

Three Williams Brothers plastic Gnome engine cylinders (item 206) were trimmed

and mounted to resemble the Anzani engine used on most Stahlwerk Mark III aircraft

that were produced.

Using Litespan

requires that a heatsensitive

adhesive

be applied to the

various components

before covering.

two 3/32 square top spars in place.

Pin and glue the 1/8 x 1/4 wingtip pieces

in place. The two 3/32 square top spars are

cut at the outer W2 rib and angled

downward to the 1/8 x 1/4 tip; see Section BB

on the plans sheet.

Glue the gussets and 1/16 x 1/8 wing-strut

attachment pieces in place. It is easier to

install the center-section cockpit-recess 1/16

sheet trim pieces after the two wing panels

have been joined.

After both wing panels have been

fabricated, lightly block-sand the faces of

the canted center-section W1 ribs and trialfit

them to ensure that the indicated dihedral

angle (3/4 inch under each tip) is produced.

Glue the two wing panels together, and then

install the 1/16 plywood DB1 brace.

Install the 1/16 sheet cockpit-recess pieces

in the aft center-section recess. The

completed wing assembly can be sanded

and contoured to the indicated airfoil and

planform.

Tail: The tail surfaces are constructed from

balsa stick and sheet stock. The curved

perimeter pieces are made from laminated

1/32 balsa sheet.

Three pieces of 1/32 balsa sheet are glued

together, with the center piece positioned

cross-grain to provide additional strength,

and then the curved perimeter tail-surface

pieces are cut from this laminated balsa

sheet stock.

Fuselage: The basic fuselage is a box-type

structure that is composed primarily of 1/8

square balsa to make its open framework.

The two fuselage sides are constructed

directly over the plans sheet side view, and

then the various 1/8 square crossbraces are

installed using the plans sheet top view as a

guide.

As I mentioned, the size and position of

the 1/8 light-plywood motor bulkhead may

vary depending on what type of motor,

propeller mounting adapter, and motor

mount you choose. I also mentioned that I

used a Baby Bullet brushless motor, but a

January 2008 35

01sig2.QXD 11/19/07 2:36 PM Page 35

variety of other motors can be employed.

Mine weighs 16 grams and has a thrust output

of roughly 12 ounces using a 2S Li-Poly

battery source and 7-inch propeller.

After installing the motor-mount

bulkhead, 1/16 nose-sheeting inlays, and 1/8

scrap bulkhead gussets, fit and secure the

fuselage F1 and F2 top formers, 1/16 square

stringer, and 1/16 top sheeting.

To ensure that the wing-mounting pylon

structure is constructed at the proper

incidence angle and aligned correctly, use the

incidence template shown on the plans sheet

as a guide.

Using a piece of string or thread, along

with a couple pins or a flexible straightedge,

determine the fuselage centerline and lightly

mark it along the top sheeting between the F2

fuselage top formers. Pin the 1/8 sheet

incidence template onto the fuselage top

sheeting along the marked fuselage centerline

between the F2 formers.

Once the 1/8 x 1/4 wing-support portion of

the pylon is pinned in place on top of the

template, the 1/8 and 1/16 square pylon support

pieces can be cut, fitted (notching the top

sheeting as required), and glued in place.

Since the full-scale Stahlwerk’s pylon support

pieces were made from welded steel tubing, it

is easier to sand the 1/8 and 1/16 square pieces

round before cutting them and fitting them in

place.

36 MODEL AVIATION

Full-Size Plans Available—See Page 199

After you have glued the wing pylon

structure in place, remove and discard the

incidence template.

The landing-gear structure is fabricated

from two pieces of .047 (3/64 inch) music

wire. One piece is the 4-inch-long axle that

will ultimately be trimmed to accommodate

whatever type of wheel you choose. I used

Guillow’s 2-inch lightweight plastic wheels

on my Stahlwerk.

The main landing-gear structure is bent

to shape using the detail shown on the plans

sheet. Then the landing-gear structure is

mounted on the two 1/16 plywood

crossbraces using button thread and

cyanoacrylate adhesive.

A 1/16 cap piece of balsa is applied over

the laced-on landing-gear/plywood

crosspieces to provide a finished appearance

after being installed on the fuselage. The

axle is attached to the main landing gear

with fine copper wrapping wire and solder.

Although optional, you can attain a more

scalelike appearance by adding 1/16 x 3/16

balsa to the landing-gear-assembly legs. I did

this by cutting a small channel along the

balsa strips and then gluing them in place

with cyanoacrylate. After sanding a radius

on the legs, I painted the landing-gear

assembly with satin-finish black paint.

The fuselage bottom access hatch is

fabricated using the hatch detail shown on

the plans sheet, and it is held in place with a

small magnet. Glue the 1/4 sheet nose block

in place and sand the fuselage assembly to

the indicated contours.

Notch the fuselage to accept the 1/16

plywood tail skid, but do not permanently

install the tail skid until after you cover the

model. Also, it is easier to install the rudder

and elevator servos and control rods now

rather than after the model has been covered.

The wing struts are made from 3/32 x 3/16

balsa and have their edges rounded. The

wing, tail surfaces, and fuselage assembly

can be fine-sanded in preparation for

covering. Any minor surface imperfections

can be filled with lightweight filler.

Covering: Any lightweight film-type

covering, such as silkspan or tissue-type

materials, can be used to cover this model. I

used buff-colored Litespan, which is a

lightweight, heat-shrinkable polyester tissuetype

covering that closely resembles the

natural linen-type material used on many

aircraft during the 1920s, including the

Stahlwerk.

Using Litespan requires that a heatsensitive

adhesive be applied to the various

components before covering. I used Coverite

Balsarite. The adhesive is brushed onto the

various subassemblies wherever the

covering material needs to be heat-fastened.

Once the Balsarite has dried, the Litespan

can be applied in the same manner as any

other heat-shrinkable covering material. In

areas where covering material overlaps, the

joint needs to be coated with Balsarite.

The decals shown on my Stahlwerk were

made using a home-computer ink-jet printer

01sig2.QXD 11/19/07 2:04 PM Page 36

38 MODEL AVIATION

and water-transfer decal sheets. These decal

sheets are readily available at graphic-arts

supply outlets or from a variety of Internet

sources. The sheets I used were purchased on

eBay and cost roughly one dollar each.

I trimmed three Williams Brothers plastic

Gnome engine cylinders and mounted them

on my model to resemble the Anzani engine

that was used in most of the Stahlwerk Mark

IIIs. Although they are not true scale, the

World War I-era Gnome cylinders resemble

those on the Anzani; I do believe they

enhance the model’s overall scale

appearance.

To complete the power package I

equipped the Baby Bullet brushless motor

with a GWS 6 x 3 propeller (item

GW/EP6030), a Castle Creations

Thunderbird-9 ESC, and an Apache 7.4-volt,

300 mAh 20C Li-Poly battery pack. I used

an Airtronics RD6000 transmitter, and the

airborne radio system consisted of a Corona

RS410 single-conversion microreceiver and

two Blue Bird BMS-303 microservos.

I achieved the indicated CG on my model

by positioning the operating components as

shown on the plans sheet. My Stahlwerk,

ready to fly, weighed 116 grams (4.1

ounces).

Flying: A beautiful, mild spring day with

sunny skies and only a wisp of a breeze

proved to be ideal conditions for my

Stahlwerk’s test flights. Since our club flying

field is all grass, and the Stahlwerk is

equipped with relatively small-diameter

wheels, I decided to hand launch for the

maiden flight.

After a usual radio range check and final

inspection, it was flip-and-fly time. Standing

stationary with approximately two-thirds

throttle introduced, a light, straight-out toss

was all that was necessary for the Stahlwerk

to climb out nicely.

After gaining roughly 75 feet of altitude,

a few blips of right rudder and down-elevator

trim correction made the Stahlwerk fly hands

off. I spent the next several minutes flying

about, performing mild maneuvers at various

throttle settings to assess the model’s inflight

capabilities. It became apparent that a

bit more rudder and slightly less elevator

control-surface movement were needed.

The first landing was easy and

uneventful. With the motor throttled back to

approximately one-quarter power, I made a

shallow, gentle approach until the Stahlwerk

was a few feet above the grass surface. The

landing stall occurred predictably after

easing back the throttle to idle, which

resulted in a soft landing.

Since the Stahlwerk is a small,

lightweight aircraft with a low wing loading,

landing on grass could best be described as a

three-point plop rather than a conventional

landing. There is no rollout once the wheels

make contact with the grass!

After making the required controlsurface-

movement adjustments, I installed a

fresh battery pack and the Stahlwerk was

airborne again and flying quite nicely. It is

easy to fly and forgiving, with no bad in-

FLIGHT GLOW

■ Fully Automatic

■ No set-up, no servo reversal

■ Progressive heating

■ Full off at 1/4 throttle

■ Turn off with engine kill

■ Red LED when driver on

$39.95 plus shipping & handling

C-TRONICS,Inc. P.O. Box 192, Ramsey, NJ 07446 201 818-4289 www.c-tronicsinc.com

C-TRONICS ON BOARD GLOW DRIVERS

FLIGHT GLOW II

All of the features of

FLIGHT GLOW PLUS:

Tri-Color LED

Green–good driver battery

Orange–low driver battery

Red–driver on

Flashing Red–very low battery or

disconnected plug wire

Specify connector (Futaba, JR-Hitec-Airtronics) $49.95 plus shipping & handling

All units complete with plug connector and 1900 MA/HR battery

Work with single or twin engines* and twin cylinder*

(*requires additional battery and plug connector)

Dealer inquiries invited. Simple,Safe,Secure.

Visit our website

for full details

and to see our

other RC products!

01sig2.QXD 11/19/07 2:04 PM Page 38

flight characteristics. Its mild aerobatic

capability proved to be suitable for this type of

model. The well-built Baby Bullet proved to

be an ideal choice, with outstanding power.

Subsequent flights were in the 10- to 12-

minute range using an Apache two-cell, 300

mAh Li-Poly battery pack. The recommended

control-surface travel limits, in each direction,

are three-eights rudder and one-quarter

elevator. Those are suggested starting points,

and those who decide to build a Stahlwerk

may ultimately decide to alter them a bit to

suit their flying preferences.

Although I have not had the opportunity to

fly my Stahlwerk indoors, I am sure I will

when what is referred to as the “building

season” (winter) arrives in New England.

Since it is slow-flying, docile, and easy to fly,

it should be well suited for indoor flying.

The Stahlwerk is an easy-to-build sport-scale

model that is a bit different. It is well suited to

those who would like to try a traditional stickand-

tissue-type built-up model. Experienced

modelers who are looking for a project that

will renew pleasant memories of a time that

may well become known as the golden age of

model aviation should also find this to be a

worthy subject.

If I can be of help in answering any

questions relative to how I built my

Stahlwerk, I will be most willing to do so. My

address is 91 Sylvan St., Avon CT 06001. MA

Bob Wallace

[email protected]

Sources:

Baby Bullet Double Cool Wind motor:

CustomCDR

1215 Diamondback Dr. NE

Albuquerque NM 87113

www.customcdr.com

Castle Creations Thunderbird-9 ESC:

(913) 390-6939

www.castlecreations.com

Battery pack, servos, receiver, covering

material:

BP Hobbies

(732) 287-3933

www.bphobbies.com

Master Airscrew Balsa Stripper:

(916) 631-8385

www.masterairscrew.com

Jim Jones Design Balsa Stripper:

A2Z CNC

(877) 754-7465

www.a2zcnc.com/airplane.asp

Still Paying

a dollar for 4 screws?

Here’s a sensible

alternative from

Master Builder Assortment #5000

Retail price: $360.00

RTL price $129.95!

The Master Assortment is the most complete

model building hardware kit available anywhere

in the country. It contains the most often used

hardware for the average modeler.

• Socket Head Cap Screws

• Cowl and canopy Button Heads

• Socket Head Servo Screws

• Screws for landing gear

• Miscellaneous general purpose screws

• Nylon insert lock nuts

• Blind (T) nuts

• Hex nuts

• Lock washers

• Flat washers

• Organizers

• 1 telescoping magnetic screw grabber.

A total of 2,124 pieces!

RTL offers 10 other assortments and 500

individual hardware packs in small and large

quantities. Every fastener you need for model

building!

Join thousands of your fellow modelers. Visit

RTL Fasteners online. You’ll be glad you did!

RTL Fasteners

www.rtlfasteners.com

or call 800-239-6010

800 Battlefi eld Blvd. South, Suite 109

Chesapeake, VA 23322

40 MODEL AVIATION

01sig2.QXD 11/19/07 2:04 PM Page 40

Edition: Model Aviation - 2008/01

Page Numbers: 31,32,33,34,35,36,38,40

January 2008 31

ALTHOUGH IT’S virtually unknown in

the US, other than by historical-aviation

enthusiasts, the Stahlwerk Mark III was a

popular and successful sport aviation design

in Europe during the 1920s and 1930s.

Walter Rieseler designed the airplane in

1922, and it is sometimes referred to as the

Rieseler R III.

Rieseler, a gifted German airplane

pioneer and designer, has been all but

forgotten in aviation history in spite of his

numerous accomplishments. The Stahlwerk

Mark III was one of his earliest aircraft. He

became better known for his innovative

autogiros and was credited in 1935 with

designing and producing the world’s first

helicopter that featured twin counterrotating

blades.

In 1920 Rieseler, in partnership with his

brother, formed a small aircraft

manufacturing company in Breslau,

Germany, called Stahlwerk. The Mark III,

which was preceded by the Mark II and

Mark I, was offered for sale in 1922, and it

rapidly became popular among the sportaviation

community in Germany.

The Mark III was a small, single-place

design with a fuselage length of 17 feet

and a wingspan of 25 feet. It was

powered with several different air-cooled

engines, the most popular of which were

the Haacke HFM two-cylinder flat

opposed type that produced 26

horsepower and the Anzani three-cylinder

Fly the Stahlwerk indoors or out. The outrunner motor system is quiet and provides

enough power for a five-minute flight on a two-cell Li-Poly battery pack.

1922 Stahlwerk Mark III

BY BOB WALLACE

A semiscale

park flyer of

the golden-age

German sport

aircraft

radial that produced 30 horsepower.

The airplane’s maximum speed near sea

level was 66 mph, and it had a 62 mph

cruise speed. With its low wing loading the

Mark III had great short-field takeoff-andlanding

capabilities. It could be airborne in

slightly more than 100 feet, and it could be

put back on the ground in an even shorter

distance since its landing speed was just less

than 30 mph. Its large-diameter landing-gear

wheels were well suited to grass fields.

In 1923 a publicity seeker named

Antonius Raab made one of the Mark III’s

most publicized flights. He landed his

01sig1.QXD 11/19/07 1:14 PM Page 31

32 MODEL AVIATION

The constant-chord wing uses the same rib shape at each station. The flat-bottom

airfoil can be built on a flat surface with no fixturing required. Notice how the top

spars meet the wingtip.

It’s easier to install the rudder and elevator servos and control rods before the model

is covered. A 6-gram submicroservo with roughly 10 inch-ounce of torque is all that is

required.

Before sheeting the top of the fuselage, temporarily glue an incidence template in place

to build the wing support. Round all balsa parts before assembling the structure.

aircraft on the Unter den Linden, which is a

main thoroughfare in Berlin, Germany. The

police promptly arrested him.

At least one Mark III still exists. It is on

display at the Arlanda Aerospace Museum

in Stockholm, Sweden.

I selected the Stahlwerk Mark III as an

RC modeling project because it’s unique.

More importantly, it produced dimensions

and a planform that I hoped would result in

a model that would be easy to build and fly

and offer good flight characteristics.

Perhaps RC modelers who have never

built a stick-and-tissue-type model will find

this construction project to be one of interest

and give it a try. It uses simple, proven

building methods that require no unique

tools or building skills. Older modelers who

grew up eagerly constructing Comet and

Megow kits and chewing Lepage’s or

Ambroid glue off their fingers may find the

Mark III to be a trip down memory lane.

The intent in designing this model was to

keep it simple using inexpensive and readily

available construction materials most hobby

shops should have in stock. My Stahlwerk

Mark III is powered by a Baby Bullet

Double Cool Wind brushless outrunner

motor from CustomCDR.

CONSTRUCTION

As with any plans- or scratch-building

project, it helps to fabricate all the shaped or

formed parts before starting the assembly

Info

box

1922

Stahlwerk Mark III

Static shots by the author; flight shots by Lloyd Burnham

Type: Small vintage sport scale

Wingspan: 24 inches

Flying weight: 116 grams (4.1 ounces)

Wing area: 105 square inches

Length: 16.5 inches

Motor: Small microsize brushless

outrunner

Propeller: GWS 6 x 3

Battery: Two-cell, 300 mAh Li-Poly

Construction: Balsa and plywood

Covering/finish: Polyester tissue

(Litespan)

01sig1.QXD 11/19/07 1:18 PM Page 32

January 2008 33

The landing gear is stitched to the airframe with button thread.

The axle is attached with fine copper wrapping wire and solder.

The CustomCDR Baby Bullet (Cool Wind) brushless motor weighs

just 16 grams and has a thrust output of approximately 12 ounces.

The number of shaped or formed parts required to construct a

Stahlwerk Mark III is minimal.

Cutting the 11 balsa wing ribs is easy and

rapid if you first make a rib master

template from plywood, aluminum, or

plastic.

The landing-gear structure is fabricated from two pieces of .047

(3/64 inch) music wire. Guillow’s 2-inch lightweight plastic wheels

are used.

process. That way the model’s construction

seems to go more smoothly and

uninterrupted.

I did not prepare a list of required

materials because most modelers who possess

at least some building experience will have

most, if not all, of the various-size wood

pieces in their spare-wood supply box. Some

of the sizes indicated do not require a full

sheet, and the hardware needed is minimal.

Some modelers with built-up model

construction experience know that using a

balsa stripper greatly simplifies the

material-acquisition process. With this tool

all the stick stock can be cut easily from

sheet stock to any custom width needed. I

used a Jones balsa stripper, which is

considered to be the Rolls-Royce of balsa

strippers, but an inexpensive version such

as Master Airscrew’s will work fine.

01sig2.QXD 11/19/07 2:03 PM Page 33

34 MODEL AVIATION

Although it is optional, you can give your model a more

scalelike appearance by adding 1/16 x 3/16 balsa to the landinggear

assembly legs.

The author made the decals on his Stahlwerk using a homecomputer

ink-jet printer and water-transfer decal sheets.

The tail surfaces are constructed from balsa stick and sheet stock. The curved perimeter pieces are made from laminated 1/32 balsa sheet.

Scale Documentation Sources

• www.histaviation.com/Mark_R_III_colour_profile.jpg

• http://aircraftwalkaround.hobbyvista.com/rieseler/rieseler.htm

• www.histaviation.com/Stahlwerk_Mark_III.html MA

—Bob Wallace

The number of shaped or formed parts required to construct a

Stahlwerk Mark III is minimal. Since the wing is a constantchord

type, cutting the 11 balsa wing ribs is easy and fast if you

make a master template from a scrap piece of 1/32 plywood, thin

sheet aluminum, or plastic.

The motor-mount former is cut from 1/8 light plywood. Its

height and width may vary a bit depending on what type of motor

you use and where that former will be positioned within the nose

portion of the fuselage.

The only other shaped parts that need to be cut are the 1/16

plywood tail skid, two 1/16 plywood landing-gear mounting

crossbraces, three 3/32 sheet top fuselage formers, and the 1/16

plywood wing-spar brace.

The main components are constructed directly over the plans

sheet placed on a flat building surface. Fledgling builders are

reminded to place a sheet of clear vinyl plastic (backing from

many heat-shrinkable film-type covering materials works well for

this) or good, old kitchen-variety waxed paper over the plans

sheet to permit easy separation of the assembled part from the

sheet.

Wing: To construct each wing panel, pin the 1/8 x 1/4 main spar in

place along with the 1/8 x 3/8 TE. Use the wing ribs to achieve the

proper lateral spacing. Pin all the wing ribs in place. Be sure to

cant the 1/8 center-section rib using the wing-dihedral-angle

template as a guide. Glue these pieces together with thin

cyanoacrylate adhesive, and then pin and glue the 1/8 x 1/4 LE and

01sig2.QXD 11/19/07 2:35 PM Page 34

Any lightweight film-type covering, such as silkspan, or tissue-type materials can be used.

A Williams Brothers 1/12th scale racing pilot bust was cut down to fit and painted.

Three Williams Brothers plastic Gnome engine cylinders (item 206) were trimmed

and mounted to resemble the Anzani engine used on most Stahlwerk Mark III aircraft

that were produced.

Using Litespan

requires that a heatsensitive

adhesive

be applied to the

various components

before covering.

two 3/32 square top spars in place.

Pin and glue the 1/8 x 1/4 wingtip pieces

in place. The two 3/32 square top spars are

cut at the outer W2 rib and angled

downward to the 1/8 x 1/4 tip; see Section BB

on the plans sheet.

Glue the gussets and 1/16 x 1/8 wing-strut

attachment pieces in place. It is easier to

install the center-section cockpit-recess 1/16

sheet trim pieces after the two wing panels

have been joined.

After both wing panels have been

fabricated, lightly block-sand the faces of

the canted center-section W1 ribs and trialfit

them to ensure that the indicated dihedral

angle (3/4 inch under each tip) is produced.

Glue the two wing panels together, and then

install the 1/16 plywood DB1 brace.

Install the 1/16 sheet cockpit-recess pieces

in the aft center-section recess. The

completed wing assembly can be sanded

and contoured to the indicated airfoil and

planform.

Tail: The tail surfaces are constructed from

balsa stick and sheet stock. The curved

perimeter pieces are made from laminated

1/32 balsa sheet.

Three pieces of 1/32 balsa sheet are glued

together, with the center piece positioned

cross-grain to provide additional strength,

and then the curved perimeter tail-surface

pieces are cut from this laminated balsa

sheet stock.

Fuselage: The basic fuselage is a box-type

structure that is composed primarily of 1/8

square balsa to make its open framework.

The two fuselage sides are constructed

directly over the plans sheet side view, and

then the various 1/8 square crossbraces are

installed using the plans sheet top view as a

guide.

As I mentioned, the size and position of

the 1/8 light-plywood motor bulkhead may

vary depending on what type of motor,

propeller mounting adapter, and motor

mount you choose. I also mentioned that I

used a Baby Bullet brushless motor, but a

January 2008 35

01sig2.QXD 11/19/07 2:36 PM Page 35

variety of other motors can be employed.

Mine weighs 16 grams and has a thrust output

of roughly 12 ounces using a 2S Li-Poly

battery source and 7-inch propeller.

After installing the motor-mount

bulkhead, 1/16 nose-sheeting inlays, and 1/8

scrap bulkhead gussets, fit and secure the

fuselage F1 and F2 top formers, 1/16 square

stringer, and 1/16 top sheeting.

To ensure that the wing-mounting pylon

structure is constructed at the proper

incidence angle and aligned correctly, use the

incidence template shown on the plans sheet

as a guide.

Using a piece of string or thread, along

with a couple pins or a flexible straightedge,

determine the fuselage centerline and lightly

mark it along the top sheeting between the F2

fuselage top formers. Pin the 1/8 sheet

incidence template onto the fuselage top

sheeting along the marked fuselage centerline

between the F2 formers.

Once the 1/8 x 1/4 wing-support portion of

the pylon is pinned in place on top of the

template, the 1/8 and 1/16 square pylon support

pieces can be cut, fitted (notching the top

sheeting as required), and glued in place.

Since the full-scale Stahlwerk’s pylon support

pieces were made from welded steel tubing, it

is easier to sand the 1/8 and 1/16 square pieces

round before cutting them and fitting them in

place.

36 MODEL AVIATION

Full-Size Plans Available—See Page 199

After you have glued the wing pylon

structure in place, remove and discard the

incidence template.

The landing-gear structure is fabricated

from two pieces of .047 (3/64 inch) music

wire. One piece is the 4-inch-long axle that

will ultimately be trimmed to accommodate

whatever type of wheel you choose. I used

Guillow’s 2-inch lightweight plastic wheels

on my Stahlwerk.

The main landing-gear structure is bent

to shape using the detail shown on the plans

sheet. Then the landing-gear structure is

mounted on the two 1/16 plywood

crossbraces using button thread and

cyanoacrylate adhesive.

A 1/16 cap piece of balsa is applied over

the laced-on landing-gear/plywood

crosspieces to provide a finished appearance

after being installed on the fuselage. The

axle is attached to the main landing gear

with fine copper wrapping wire and solder.

Although optional, you can attain a more

scalelike appearance by adding 1/16 x 3/16

balsa to the landing-gear-assembly legs. I did

this by cutting a small channel along the

balsa strips and then gluing them in place

with cyanoacrylate. After sanding a radius

on the legs, I painted the landing-gear

assembly with satin-finish black paint.

The fuselage bottom access hatch is

fabricated using the hatch detail shown on

the plans sheet, and it is held in place with a

small magnet. Glue the 1/4 sheet nose block

in place and sand the fuselage assembly to

the indicated contours.

Notch the fuselage to accept the 1/16

plywood tail skid, but do not permanently

install the tail skid until after you cover the

model. Also, it is easier to install the rudder

and elevator servos and control rods now

rather than after the model has been covered.

The wing struts are made from 3/32 x 3/16

balsa and have their edges rounded. The

wing, tail surfaces, and fuselage assembly

can be fine-sanded in preparation for

covering. Any minor surface imperfections

can be filled with lightweight filler.

Covering: Any lightweight film-type

covering, such as silkspan or tissue-type

materials, can be used to cover this model. I

used buff-colored Litespan, which is a

lightweight, heat-shrinkable polyester tissuetype

covering that closely resembles the

natural linen-type material used on many

aircraft during the 1920s, including the

Stahlwerk.

Using Litespan requires that a heatsensitive

adhesive be applied to the various

components before covering. I used Coverite

Balsarite. The adhesive is brushed onto the

various subassemblies wherever the

covering material needs to be heat-fastened.

Once the Balsarite has dried, the Litespan

can be applied in the same manner as any

other heat-shrinkable covering material. In

areas where covering material overlaps, the

joint needs to be coated with Balsarite.

The decals shown on my Stahlwerk were

made using a home-computer ink-jet printer

01sig2.QXD 11/19/07 2:04 PM Page 36

38 MODEL AVIATION

and water-transfer decal sheets. These decal

sheets are readily available at graphic-arts

supply outlets or from a variety of Internet

sources. The sheets I used were purchased on

eBay and cost roughly one dollar each.

I trimmed three Williams Brothers plastic

Gnome engine cylinders and mounted them

on my model to resemble the Anzani engine

that was used in most of the Stahlwerk Mark

IIIs. Although they are not true scale, the

World War I-era Gnome cylinders resemble

those on the Anzani; I do believe they

enhance the model’s overall scale

appearance.

To complete the power package I

equipped the Baby Bullet brushless motor

with a GWS 6 x 3 propeller (item

GW/EP6030), a Castle Creations

Thunderbird-9 ESC, and an Apache 7.4-volt,

300 mAh 20C Li-Poly battery pack. I used

an Airtronics RD6000 transmitter, and the

airborne radio system consisted of a Corona

RS410 single-conversion microreceiver and

two Blue Bird BMS-303 microservos.

I achieved the indicated CG on my model

by positioning the operating components as

shown on the plans sheet. My Stahlwerk,

ready to fly, weighed 116 grams (4.1

ounces).

Flying: A beautiful, mild spring day with

sunny skies and only a wisp of a breeze

proved to be ideal conditions for my

Stahlwerk’s test flights. Since our club flying

field is all grass, and the Stahlwerk is

equipped with relatively small-diameter

wheels, I decided to hand launch for the

maiden flight.

After a usual radio range check and final

inspection, it was flip-and-fly time. Standing

stationary with approximately two-thirds

throttle introduced, a light, straight-out toss

was all that was necessary for the Stahlwerk

to climb out nicely.

After gaining roughly 75 feet of altitude,

a few blips of right rudder and down-elevator

trim correction made the Stahlwerk fly hands

off. I spent the next several minutes flying

about, performing mild maneuvers at various

throttle settings to assess the model’s inflight

capabilities. It became apparent that a

bit more rudder and slightly less elevator

control-surface movement were needed.

The first landing was easy and

uneventful. With the motor throttled back to

approximately one-quarter power, I made a

shallow, gentle approach until the Stahlwerk

was a few feet above the grass surface. The

landing stall occurred predictably after

easing back the throttle to idle, which

resulted in a soft landing.

Since the Stahlwerk is a small,

lightweight aircraft with a low wing loading,

landing on grass could best be described as a

three-point plop rather than a conventional

landing. There is no rollout once the wheels

make contact with the grass!

After making the required controlsurface-

movement adjustments, I installed a

fresh battery pack and the Stahlwerk was

airborne again and flying quite nicely. It is

easy to fly and forgiving, with no bad in-

FLIGHT GLOW

■ Fully Automatic

■ No set-up, no servo reversal

■ Progressive heating

■ Full off at 1/4 throttle

■ Turn off with engine kill

■ Red LED when driver on

$39.95 plus shipping & handling

C-TRONICS,Inc. P.O. Box 192, Ramsey, NJ 07446 201 818-4289 www.c-tronicsinc.com

C-TRONICS ON BOARD GLOW DRIVERS

FLIGHT GLOW II

All of the features of

FLIGHT GLOW PLUS:

Tri-Color LED

Green–good driver battery

Orange–low driver battery

Red–driver on

Flashing Red–very low battery or

disconnected plug wire

Specify connector (Futaba, JR-Hitec-Airtronics) $49.95 plus shipping & handling

All units complete with plug connector and 1900 MA/HR battery

Work with single or twin engines* and twin cylinder*

(*requires additional battery and plug connector)

Dealer inquiries invited. Simple,Safe,Secure.

Visit our website

for full details

and to see our

other RC products!

01sig2.QXD 11/19/07 2:04 PM Page 38

flight characteristics. Its mild aerobatic

capability proved to be suitable for this type of

model. The well-built Baby Bullet proved to

be an ideal choice, with outstanding power.

Subsequent flights were in the 10- to 12-

minute range using an Apache two-cell, 300

mAh Li-Poly battery pack. The recommended

control-surface travel limits, in each direction,

are three-eights rudder and one-quarter

elevator. Those are suggested starting points,

and those who decide to build a Stahlwerk

may ultimately decide to alter them a bit to

suit their flying preferences.

Although I have not had the opportunity to

fly my Stahlwerk indoors, I am sure I will

when what is referred to as the “building

season” (winter) arrives in New England.

Since it is slow-flying, docile, and easy to fly,

it should be well suited for indoor flying.

The Stahlwerk is an easy-to-build sport-scale

model that is a bit different. It is well suited to

those who would like to try a traditional stickand-

tissue-type built-up model. Experienced

modelers who are looking for a project that

will renew pleasant memories of a time that

may well become known as the golden age of

model aviation should also find this to be a

worthy subject.

If I can be of help in answering any

questions relative to how I built my

Stahlwerk, I will be most willing to do so. My

address is 91 Sylvan St., Avon CT 06001. MA

Bob Wallace

[email protected]

Sources:

Baby Bullet Double Cool Wind motor:

CustomCDR

1215 Diamondback Dr. NE

Albuquerque NM 87113

www.customcdr.com

Castle Creations Thunderbird-9 ESC:

(913) 390-6939

www.castlecreations.com

Battery pack, servos, receiver, covering

material:

BP Hobbies

(732) 287-3933

www.bphobbies.com

Master Airscrew Balsa Stripper:

(916) 631-8385

www.masterairscrew.com

Jim Jones Design Balsa Stripper:

A2Z CNC

(877) 754-7465

www.a2zcnc.com/airplane.asp

Still Paying

a dollar for 4 screws?

Here’s a sensible

alternative from

Master Builder Assortment #5000

Retail price: $360.00

RTL price $129.95!

The Master Assortment is the most complete

model building hardware kit available anywhere

in the country. It contains the most often used

hardware for the average modeler.

• Socket Head Cap Screws

• Cowl and canopy Button Heads

• Socket Head Servo Screws

• Screws for landing gear

• Miscellaneous general purpose screws

• Nylon insert lock nuts

• Blind (T) nuts

• Hex nuts

• Lock washers

• Flat washers

• Organizers

• 1 telescoping magnetic screw grabber.

A total of 2,124 pieces!

RTL offers 10 other assortments and 500

individual hardware packs in small and large

quantities. Every fastener you need for model

building!

Join thousands of your fellow modelers. Visit

RTL Fasteners online. You’ll be glad you did!

RTL Fasteners

www.rtlfasteners.com

or call 800-239-6010

800 Battlefi eld Blvd. South, Suite 109

Chesapeake, VA 23322

40 MODEL AVIATION

01sig2.QXD 11/19/07 2:04 PM Page 40

Edition: Model Aviation - 2008/01

Page Numbers: 31,32,33,34,35,36,38,40

January 2008 31

ALTHOUGH IT’S virtually unknown in

the US, other than by historical-aviation

enthusiasts, the Stahlwerk Mark III was a

popular and successful sport aviation design

in Europe during the 1920s and 1930s.

Walter Rieseler designed the airplane in

1922, and it is sometimes referred to as the

Rieseler R III.

Rieseler, a gifted German airplane

pioneer and designer, has been all but

forgotten in aviation history in spite of his

numerous accomplishments. The Stahlwerk

Mark III was one of his earliest aircraft. He

became better known for his innovative

autogiros and was credited in 1935 with

designing and producing the world’s first

helicopter that featured twin counterrotating

blades.

In 1920 Rieseler, in partnership with his

brother, formed a small aircraft

manufacturing company in Breslau,

Germany, called Stahlwerk. The Mark III,

which was preceded by the Mark II and

Mark I, was offered for sale in 1922, and it

rapidly became popular among the sportaviation

community in Germany.

The Mark III was a small, single-place

design with a fuselage length of 17 feet

and a wingspan of 25 feet. It was

powered with several different air-cooled

engines, the most popular of which were

the Haacke HFM two-cylinder flat

opposed type that produced 26

horsepower and the Anzani three-cylinder

Fly the Stahlwerk indoors or out. The outrunner motor system is quiet and provides

enough power for a five-minute flight on a two-cell Li-Poly battery pack.

1922 Stahlwerk Mark III

BY BOB WALLACE

A semiscale

park flyer of

the golden-age

German sport

aircraft

radial that produced 30 horsepower.

The airplane’s maximum speed near sea

level was 66 mph, and it had a 62 mph

cruise speed. With its low wing loading the

Mark III had great short-field takeoff-andlanding

capabilities. It could be airborne in

slightly more than 100 feet, and it could be

put back on the ground in an even shorter

distance since its landing speed was just less

than 30 mph. Its large-diameter landing-gear

wheels were well suited to grass fields.

In 1923 a publicity seeker named

Antonius Raab made one of the Mark III’s

most publicized flights. He landed his

01sig1.QXD 11/19/07 1:14 PM Page 31

32 MODEL AVIATION

The constant-chord wing uses the same rib shape at each station. The flat-bottom

airfoil can be built on a flat surface with no fixturing required. Notice how the top

spars meet the wingtip.

It’s easier to install the rudder and elevator servos and control rods before the model

is covered. A 6-gram submicroservo with roughly 10 inch-ounce of torque is all that is

required.

Before sheeting the top of the fuselage, temporarily glue an incidence template in place

to build the wing support. Round all balsa parts before assembling the structure.

aircraft on the Unter den Linden, which is a

main thoroughfare in Berlin, Germany. The

police promptly arrested him.

At least one Mark III still exists. It is on

display at the Arlanda Aerospace Museum

in Stockholm, Sweden.

I selected the Stahlwerk Mark III as an

RC modeling project because it’s unique.

More importantly, it produced dimensions

and a planform that I hoped would result in

a model that would be easy to build and fly

and offer good flight characteristics.

Perhaps RC modelers who have never

built a stick-and-tissue-type model will find

this construction project to be one of interest

and give it a try. It uses simple, proven

building methods that require no unique

tools or building skills. Older modelers who

grew up eagerly constructing Comet and

Megow kits and chewing Lepage’s or

Ambroid glue off their fingers may find the

Mark III to be a trip down memory lane.

The intent in designing this model was to

keep it simple using inexpensive and readily

available construction materials most hobby

shops should have in stock. My Stahlwerk

Mark III is powered by a Baby Bullet

Double Cool Wind brushless outrunner

motor from CustomCDR.

CONSTRUCTION

As with any plans- or scratch-building

project, it helps to fabricate all the shaped or

formed parts before starting the assembly

Info

box

1922

Stahlwerk Mark III

Static shots by the author; flight shots by Lloyd Burnham

Type: Small vintage sport scale

Wingspan: 24 inches

Flying weight: 116 grams (4.1 ounces)

Wing area: 105 square inches

Length: 16.5 inches

Motor: Small microsize brushless

outrunner

Propeller: GWS 6 x 3

Battery: Two-cell, 300 mAh Li-Poly

Construction: Balsa and plywood

Covering/finish: Polyester tissue

(Litespan)

01sig1.QXD 11/19/07 1:18 PM Page 32

January 2008 33

The landing gear is stitched to the airframe with button thread.

The axle is attached with fine copper wrapping wire and solder.

The CustomCDR Baby Bullet (Cool Wind) brushless motor weighs

just 16 grams and has a thrust output of approximately 12 ounces.