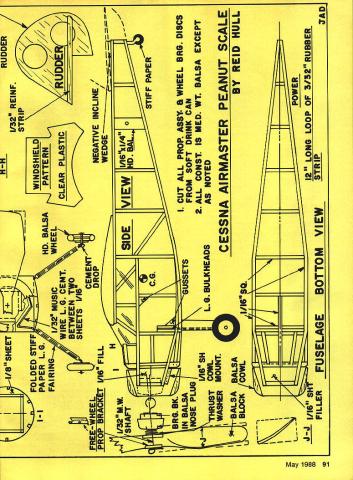

DESIGNED Clyde Cessna early 1940s Cessna Airmaster fourplace plane air-minded public time considered superbly effi cient machine boasted maximum cruis ing speed 145 mph 165 mph powered respectively 145-hp 165-hp Warner Scarab radial engine airplane could equipped either achieve 1 mph hp somewhat remarkable performance time Though plane exceptionally effi cient todays standards two drawbacks pilots view restricted big radial engine Airmaster somewhat prone ground looping probably because vertical tail too small Maybe will intrigued grand old machine Cessna want build Peanut-size version per plans presented article Modifi cations required make model stable flier have made based upon flight experiences really work As might expect enlarging pro peller detracts considerably glide However rubber motor wind-down time considerable pack 700 turns Construction Start out basic fuse lage structure first step build sides directly over plan form usual rectangular cross-sectioned basic box Add curved pieces fuse lage becomes nearly circular After cement ing sheet balsa fillers near front make very hard balsa nose plug fit snug ly front between filler pieces cowl worked shape block balsa grain running parallel centerline fuselage Locate cir cular objects make templates trace around front rear cowl block After shaping apply coat clear dope will resist splitting next step 72 Model Aviation Top It would hard tell wasnt full-size plane overhead non-scale prop wasnt giving away simple lines great Peanut Scale Photo Dwight G McSmith Above Noted its efficiency Cessna shares elegance other airframes its time roughly drill out cowl block carve sand nearly feathered edge rear shown plan finished cowl goes A6 sheet cowl mount cement forward up per corners basic fuselage structure plan will somewhat clarify Carve propeller hard balsa block Glue metal fittings youre See plan details Bend prop shaft %2 music wire sure include brass teflon thrust washers tween prop nose plug assem bling pieces prop shaft Wing tail Construction tail sur faces pretty obvious studying plan curved balsa laminates two strips cemented together bent around sheet balsa cardboard templates Set laminates aside until cement hardens basic structure horizon tal tail faired /32 sheet trailing edge surface will have no irregu larities covered tail structures should allowed warp will cause erratic flight wing similarly straightforward Laminated tips formed same way tail short spar added until after dihedral joint center wing panels cemented Covering simplest way cover model Japanese tissue doping tail very lightly minimize warping ever found covering model -mil chrome Mylar adhered contact cement satisfactory Heatshrink Mylar other modeling iron-on coverings being sure first heatcure cemented edges model shown pictures has fuselage covering chrome-backed Kapton yielding pretty gold color however material very difficult install covering put before stabi lizer rudder wing cowl cemented position However cement lightly enough units can cut loose retrimming found necessaryand possible repairs may need later Flying Install loop %2 lubed rubber 12 long add bits metal inside cowl until model balances center gravity CG location shown plan Wait calm day make first test flights Take model nearby schoolyardor use extra large lawn available Start out 150 winds rubber motor gently hand launch model directly oncoming breeze Through trial error may find downthrust needed prevent stall simply may launching model too hard After slight-stall no-stall flights achieved wind propeller 300 turns hand launch model will striving non-stalling flight gen tle right turn turn will help prevent stalls time may have noticed quickly stall can occur followed snap-over loop some other maneuver subsequent plunge ground bit right thrust may added achieve desired right turn may just what needed prevent stalling case secret graceful flight model seems Don t let stall Rise-off-ground ROG flights Airmaster easy have smooth sur face roll Consistent house-toplevel flights occur rubber motor stretch-wound 700 turns winder Have ball creation can exciting times always seems sur vive Its tough little bird May 1988 73 huge propeller pulls model lots authority 100 flights already logged its very tough model Petite ships highly reflective covering chrome-backed Kapton SAFE FLYING IS NO ACCIDENT nitty winding stooge shown made thick paper tube roll wrapping paper held place foot Dont try full power until trim correct author concentration set go 700 turns pecked rubber flights over house uncommon model Trimming particularly difficult I/tO SQ SPAR IIB IIII HEET XE II II I/32 SHEET I/8xI/16 T E RIBS ____________ WING ______________ LEFT II II V 1/16 SQ SOAK 8 AROUND 3 OUT THIS TIP EDOE V16x I/B LEADING 1/32 SHEET FAIRED 1/32 SHEET ______RIGHT WING PANEL1/tB SQ LAMINATE WASHOUT THIS TIP STIFF PAPER EXTES AFT TO INSTALL PAN II II' FRONT VIEW ATh2HFFTI Id 2 II nI ET FOLDED STIFF I-IPAPER LG 1/32 MUSIC WHEEL WIRE LG CEMT CEMENT PROP BRACItE I/IS FILLDROP -Ag FREE-WHEEL WINDSHIELD PATlE RN CLEAR PLASTIC RUDUU V32 REINF STRIP7 1 7/ RUDDE NEGATIVE INCLINE WEDGE L6 BULKHEADS VIEW I CUT ALL PROP ASSY S WHEEL BRO DISCS FROM SOFT DRINK CAN 2 ALL CONST IS MED WT BALSA EXCEPT AS NOTED CESSNA AIRMASTER PEANUT yI6 Q BY REID HULL /1 / I/IS SHT FILLER FUSELAGE 12 LONG LOOP OF 3/32 RUBBER STRIP BOTTOM VIEWJAD BALSA COWL SCALE

Edition: Model Aviation - 1988/05

Page Numbers: 72, 73, 90, 91

DESIGNED Clyde Cessna early 1940s Cessna Airmaster fourplace plane air-minded public time considered superbly effi cient machine boasted maximum cruis ing speed 145 mph 165 mph powered respectively 145-hp 165-hp Warner Scarab radial engine airplane could equipped either achieve 1 mph hp somewhat remarkable performance time Though plane exceptionally effi cient todays standards two drawbacks pilots view restricted big radial engine Airmaster somewhat prone ground looping probably because vertical tail too small Maybe will intrigued grand old machine Cessna want build Peanut-size version per plans presented article Modifi cations required make model stable flier have made based upon flight experiences really work As might expect enlarging pro peller detracts considerably glide However rubber motor wind-down time considerable pack 700 turns Construction Start out basic fuse lage structure first step build sides directly over plan form usual rectangular cross-sectioned basic box Add curved pieces fuse lage becomes nearly circular After cement ing sheet balsa fillers near front make very hard balsa nose plug fit snug ly front between filler pieces cowl worked shape block balsa grain running parallel centerline fuselage Locate cir cular objects make templates trace around front rear cowl block After shaping apply coat clear dope will resist splitting next step 72 Model Aviation Top It would hard tell wasnt full-size plane overhead non-scale prop wasnt giving away simple lines great Peanut Scale Photo Dwight G McSmith Above Noted its efficiency Cessna shares elegance other airframes its time roughly drill out cowl block carve sand nearly feathered edge rear shown plan finished cowl goes A6 sheet cowl mount cement forward up per corners basic fuselage structure plan will somewhat clarify Carve propeller hard balsa block Glue metal fittings youre See plan details Bend prop shaft %2 music wire sure include brass teflon thrust washers tween prop nose plug assem bling pieces prop shaft Wing tail Construction tail sur faces pretty obvious studying plan curved balsa laminates two strips cemented together bent around sheet balsa cardboard templates Set laminates aside until cement hardens basic structure horizon tal tail faired /32 sheet trailing edge surface will have no irregu larities covered tail structures should allowed warp will cause erratic flight wing similarly straightforward Laminated tips formed same way tail short spar added until after dihedral joint center wing panels cemented Covering simplest way cover model Japanese tissue doping tail very lightly minimize warping ever found covering model -mil chrome Mylar adhered contact cement satisfactory Heatshrink Mylar other modeling iron-on coverings being sure first heatcure cemented edges model shown pictures has fuselage covering chrome-backed Kapton yielding pretty gold color however material very difficult install covering put before stabi lizer rudder wing cowl cemented position However cement lightly enough units can cut loose retrimming found necessaryand possible repairs may need later Flying Install loop %2 lubed rubber 12 long add bits metal inside cowl until model balances center gravity CG location shown plan Wait calm day make first test flights Take model nearby schoolyardor use extra large lawn available Start out 150 winds rubber motor gently hand launch model directly oncoming breeze Through trial error may find downthrust needed prevent stall simply may launching model too hard After slight-stall no-stall flights achieved wind propeller 300 turns hand launch model will striving non-stalling flight gen tle right turn turn will help prevent stalls time may have noticed quickly stall can occur followed snap-over loop some other maneuver subsequent plunge ground bit right thrust may added achieve desired right turn may just what needed prevent stalling case secret graceful flight model seems Don t let stall Rise-off-ground ROG flights Airmaster easy have smooth sur face roll Consistent house-toplevel flights occur rubber motor stretch-wound 700 turns winder Have ball creation can exciting times always seems sur vive Its tough little bird May 1988 73 huge propeller pulls model lots authority 100 flights already logged its very tough model Petite ships highly reflective covering chrome-backed Kapton SAFE FLYING IS NO ACCIDENT nitty winding stooge shown made thick paper tube roll wrapping paper held place foot Dont try full power until trim correct author concentration set go 700 turns pecked rubber flights over house uncommon model Trimming particularly difficult I/tO SQ SPAR IIB IIII HEET XE II II I/32 SHEET I/8xI/16 T E RIBS ____________ WING ______________ LEFT II II V 1/16 SQ SOAK 8 AROUND 3 OUT THIS TIP EDOE V16x I/B LEADING 1/32 SHEET FAIRED 1/32 SHEET ______RIGHT WING PANEL1/tB SQ LAMINATE WASHOUT THIS TIP STIFF PAPER EXTES AFT TO INSTALL PAN II II' FRONT VIEW ATh2HFFTI Id 2 II nI ET FOLDED STIFF I-IPAPER LG 1/32 MUSIC WHEEL WIRE LG CEMT CEMENT PROP BRACItE I/IS FILLDROP -Ag FREE-WHEEL WINDSHIELD PATlE RN CLEAR PLASTIC RUDUU V32 REINF STRIP7 1 7/ RUDDE NEGATIVE INCLINE WEDGE L6 BULKHEADS VIEW I CUT ALL PROP ASSY S WHEEL BRO DISCS FROM SOFT DRINK CAN 2 ALL CONST IS MED WT BALSA EXCEPT AS NOTED CESSNA AIRMASTER PEANUT yI6 Q BY REID HULL /1 / I/IS SHT FILLER FUSELAGE 12 LONG LOOP OF 3/32 RUBBER STRIP BOTTOM VIEWJAD BALSA COWL SCALE

Edition: Model Aviation - 1988/05

Page Numbers: 72, 73, 90, 91

DESIGNED Clyde Cessna early 1940s Cessna Airmaster fourplace plane air-minded public time considered superbly effi cient machine boasted maximum cruis ing speed 145 mph 165 mph powered respectively 145-hp 165-hp Warner Scarab radial engine airplane could equipped either achieve 1 mph hp somewhat remarkable performance time Though plane exceptionally effi cient todays standards two drawbacks pilots view restricted big radial engine Airmaster somewhat prone ground looping probably because vertical tail too small Maybe will intrigued grand old machine Cessna want build Peanut-size version per plans presented article Modifi cations required make model stable flier have made based upon flight experiences really work As might expect enlarging pro peller detracts considerably glide However rubber motor wind-down time considerable pack 700 turns Construction Start out basic fuse lage structure first step build sides directly over plan form usual rectangular cross-sectioned basic box Add curved pieces fuse lage becomes nearly circular After cement ing sheet balsa fillers near front make very hard balsa nose plug fit snug ly front between filler pieces cowl worked shape block balsa grain running parallel centerline fuselage Locate cir cular objects make templates trace around front rear cowl block After shaping apply coat clear dope will resist splitting next step 72 Model Aviation Top It would hard tell wasnt full-size plane overhead non-scale prop wasnt giving away simple lines great Peanut Scale Photo Dwight G McSmith Above Noted its efficiency Cessna shares elegance other airframes its time roughly drill out cowl block carve sand nearly feathered edge rear shown plan finished cowl goes A6 sheet cowl mount cement forward up per corners basic fuselage structure plan will somewhat clarify Carve propeller hard balsa block Glue metal fittings youre See plan details Bend prop shaft %2 music wire sure include brass teflon thrust washers tween prop nose plug assem bling pieces prop shaft Wing tail Construction tail sur faces pretty obvious studying plan curved balsa laminates two strips cemented together bent around sheet balsa cardboard templates Set laminates aside until cement hardens basic structure horizon tal tail faired /32 sheet trailing edge surface will have no irregu larities covered tail structures should allowed warp will cause erratic flight wing similarly straightforward Laminated tips formed same way tail short spar added until after dihedral joint center wing panels cemented Covering simplest way cover model Japanese tissue doping tail very lightly minimize warping ever found covering model -mil chrome Mylar adhered contact cement satisfactory Heatshrink Mylar other modeling iron-on coverings being sure first heatcure cemented edges model shown pictures has fuselage covering chrome-backed Kapton yielding pretty gold color however material very difficult install covering put before stabi lizer rudder wing cowl cemented position However cement lightly enough units can cut loose retrimming found necessaryand possible repairs may need later Flying Install loop %2 lubed rubber 12 long add bits metal inside cowl until model balances center gravity CG location shown plan Wait calm day make first test flights Take model nearby schoolyardor use extra large lawn available Start out 150 winds rubber motor gently hand launch model directly oncoming breeze Through trial error may find downthrust needed prevent stall simply may launching model too hard After slight-stall no-stall flights achieved wind propeller 300 turns hand launch model will striving non-stalling flight gen tle right turn turn will help prevent stalls time may have noticed quickly stall can occur followed snap-over loop some other maneuver subsequent plunge ground bit right thrust may added achieve desired right turn may just what needed prevent stalling case secret graceful flight model seems Don t let stall Rise-off-ground ROG flights Airmaster easy have smooth sur face roll Consistent house-toplevel flights occur rubber motor stretch-wound 700 turns winder Have ball creation can exciting times always seems sur vive Its tough little bird May 1988 73 huge propeller pulls model lots authority 100 flights already logged its very tough model Petite ships highly reflective covering chrome-backed Kapton SAFE FLYING IS NO ACCIDENT nitty winding stooge shown made thick paper tube roll wrapping paper held place foot Dont try full power until trim correct author concentration set go 700 turns pecked rubber flights over house uncommon model Trimming particularly difficult I/tO SQ SPAR IIB IIII HEET XE II II I/32 SHEET I/8xI/16 T E RIBS ____________ WING ______________ LEFT II II V 1/16 SQ SOAK 8 AROUND 3 OUT THIS TIP EDOE V16x I/B LEADING 1/32 SHEET FAIRED 1/32 SHEET ______RIGHT WING PANEL1/tB SQ LAMINATE WASHOUT THIS TIP STIFF PAPER EXTES AFT TO INSTALL PAN II II' FRONT VIEW ATh2HFFTI Id 2 II nI ET FOLDED STIFF I-IPAPER LG 1/32 MUSIC WHEEL WIRE LG CEMT CEMENT PROP BRACItE I/IS FILLDROP -Ag FREE-WHEEL WINDSHIELD PATlE RN CLEAR PLASTIC RUDUU V32 REINF STRIP7 1 7/ RUDDE NEGATIVE INCLINE WEDGE L6 BULKHEADS VIEW I CUT ALL PROP ASSY S WHEEL BRO DISCS FROM SOFT DRINK CAN 2 ALL CONST IS MED WT BALSA EXCEPT AS NOTED CESSNA AIRMASTER PEANUT yI6 Q BY REID HULL /1 / I/IS SHT FILLER FUSELAGE 12 LONG LOOP OF 3/32 RUBBER STRIP BOTTOM VIEWJAD BALSA COWL SCALE

Edition: Model Aviation - 1988/05

Page Numbers: 72, 73, 90, 91

DESIGNED Clyde Cessna early 1940s Cessna Airmaster fourplace plane air-minded public time considered superbly effi cient machine boasted maximum cruis ing speed 145 mph 165 mph powered respectively 145-hp 165-hp Warner Scarab radial engine airplane could equipped either achieve 1 mph hp somewhat remarkable performance time Though plane exceptionally effi cient todays standards two drawbacks pilots view restricted big radial engine Airmaster somewhat prone ground looping probably because vertical tail too small Maybe will intrigued grand old machine Cessna want build Peanut-size version per plans presented article Modifi cations required make model stable flier have made based upon flight experiences really work As might expect enlarging pro peller detracts considerably glide However rubber motor wind-down time considerable pack 700 turns Construction Start out basic fuse lage structure first step build sides directly over plan form usual rectangular cross-sectioned basic box Add curved pieces fuse lage becomes nearly circular After cement ing sheet balsa fillers near front make very hard balsa nose plug fit snug ly front between filler pieces cowl worked shape block balsa grain running parallel centerline fuselage Locate cir cular objects make templates trace around front rear cowl block After shaping apply coat clear dope will resist splitting next step 72 Model Aviation Top It would hard tell wasnt full-size plane overhead non-scale prop wasnt giving away simple lines great Peanut Scale Photo Dwight G McSmith Above Noted its efficiency Cessna shares elegance other airframes its time roughly drill out cowl block carve sand nearly feathered edge rear shown plan finished cowl goes A6 sheet cowl mount cement forward up per corners basic fuselage structure plan will somewhat clarify Carve propeller hard balsa block Glue metal fittings youre See plan details Bend prop shaft %2 music wire sure include brass teflon thrust washers tween prop nose plug assem bling pieces prop shaft Wing tail Construction tail sur faces pretty obvious studying plan curved balsa laminates two strips cemented together bent around sheet balsa cardboard templates Set laminates aside until cement hardens basic structure horizon tal tail faired /32 sheet trailing edge surface will have no irregu larities covered tail structures should allowed warp will cause erratic flight wing similarly straightforward Laminated tips formed same way tail short spar added until after dihedral joint center wing panels cemented Covering simplest way cover model Japanese tissue doping tail very lightly minimize warping ever found covering model -mil chrome Mylar adhered contact cement satisfactory Heatshrink Mylar other modeling iron-on coverings being sure first heatcure cemented edges model shown pictures has fuselage covering chrome-backed Kapton yielding pretty gold color however material very difficult install covering put before stabi lizer rudder wing cowl cemented position However cement lightly enough units can cut loose retrimming found necessaryand possible repairs may need later Flying Install loop %2 lubed rubber 12 long add bits metal inside cowl until model balances center gravity CG location shown plan Wait calm day make first test flights Take model nearby schoolyardor use extra large lawn available Start out 150 winds rubber motor gently hand launch model directly oncoming breeze Through trial error may find downthrust needed prevent stall simply may launching model too hard After slight-stall no-stall flights achieved wind propeller 300 turns hand launch model will striving non-stalling flight gen tle right turn turn will help prevent stalls time may have noticed quickly stall can occur followed snap-over loop some other maneuver subsequent plunge ground bit right thrust may added achieve desired right turn may just what needed prevent stalling case secret graceful flight model seems Don t let stall Rise-off-ground ROG flights Airmaster easy have smooth sur face roll Consistent house-toplevel flights occur rubber motor stretch-wound 700 turns winder Have ball creation can exciting times always seems sur vive Its tough little bird May 1988 73 huge propeller pulls model lots authority 100 flights already logged its very tough model Petite ships highly reflective covering chrome-backed Kapton SAFE FLYING IS NO ACCIDENT nitty winding stooge shown made thick paper tube roll wrapping paper held place foot Dont try full power until trim correct author concentration set go 700 turns pecked rubber flights over house uncommon model Trimming particularly difficult I/tO SQ SPAR IIB IIII HEET XE II II I/32 SHEET I/8xI/16 T E RIBS ____________ WING ______________ LEFT II II V 1/16 SQ SOAK 8 AROUND 3 OUT THIS TIP EDOE V16x I/B LEADING 1/32 SHEET FAIRED 1/32 SHEET ______RIGHT WING PANEL1/tB SQ LAMINATE WASHOUT THIS TIP STIFF PAPER EXTES AFT TO INSTALL PAN II II' FRONT VIEW ATh2HFFTI Id 2 II nI ET FOLDED STIFF I-IPAPER LG 1/32 MUSIC WHEEL WIRE LG CEMT CEMENT PROP BRACItE I/IS FILLDROP -Ag FREE-WHEEL WINDSHIELD PATlE RN CLEAR PLASTIC RUDUU V32 REINF STRIP7 1 7/ RUDDE NEGATIVE INCLINE WEDGE L6 BULKHEADS VIEW I CUT ALL PROP ASSY S WHEEL BRO DISCS FROM SOFT DRINK CAN 2 ALL CONST IS MED WT BALSA EXCEPT AS NOTED CESSNA AIRMASTER PEANUT yI6 Q BY REID HULL /1 / I/IS SHT FILLER FUSELAGE 12 LONG LOOP OF 3/32 RUBBER STRIP BOTTOM VIEWJAD BALSA COWL SCALE