ARF PATCHING

TECHNIQUES by

Steve Hunt

No matter what causes the damage, whether it's a rock or your

son's model car, a repair occasionally needs to be made!

These are the tools and materials that are required to make a

seamless repair in an ARF aircraft's wing.

SOMETIMES WE DON’T get quite the landing we had hoped

for or a pet rock takes a “shortcut” through our model’s wing.

Sometimes we just have to admit that we dropped something

onto—and on through—the wing.

This article is primarily for new pilots or those who have flown

only the ARF versions of airplanes. However, even seasoned

modelers might find a method here that is useful for repairing all

fixed-wing models incorporating boxed-in (ribbed and sheeted)

areas.

Please reacquaint yourself with the safety and

recommendations of the particular brand of modeling knife and

adhesives you will be using. The knife can cut you with very little

force, to the extent that you will need stitches. To make sure you

don’t need stitches for another reason, make sure you have a

proper cutting board under your work when you use the modeling

knife.

The cyanoacrylate glue can stick your fingers together or to

another object in seconds. When you are holding parts in place

while this glue is curing, use some plastic backing from your

covering; it was engineered so that adhesives will not stick to it.

Procedure: Cut back as much covering as necessary to examine

and repair without the remainder of the covering being in the way.

Remove the broken pieces of the model, and square off the

damaged area using the modeling knife.

Dealing with oddly shaped damaged areas is common, but try

to keep the replacement area as small as possible. Once the

harmed sheeting is cut away, inspect for hidden damage such as a

broken spar or crushed ribs.

Broken ribs are fairly easy to repair by manufacturing one of

like contour and gluing it onto the side of the original. If you

encounter a broken main spar, seek some advice from a more

Tools and Items Needed for Patching

• Sharp modeling-knife handle fitted with #11 blade.

• Pounce wheel.

• Holding tool made from music wire.

• Replacement balsa that is the same thickness as the

sheeting on the wing.

• Thin scrap balsa.

• Sanding block.

• T-pins.

• Cyanoacrylate glue.

• Yellow wood glue.

• Aluminum foil.

Photos courtesy the author

Remove as much of the surrounding covering material as

necessary to make the repair. It's better to remove a bit too much

than not enough.

Use the modeling knife to square off the opening as best you

can. Try to keep the edges of the opening straight.

Cut several cross-grain reinforcement strips to use under the lip

of the sheeting in the prepared area.

experienced builder. Spars are load-carrying members, and their

integrity must be maintained for safety’s sake.

Make reinforcement strips, which are cut cross-grain from

scrap balsa. Install these in place on the underside of the existing

sheeting in the damaged area using cyanoacrylate glue. Hold the

reinforcement strips in place using the custom-made holding tool,

which is shown, until the cyanoacrylate cures.

If the area to be repaired is too close to a rib, spar, or other

support, make a ledge using 1⁄4 balsa fit to contour and glue it in

place, leaving room for the replacement balsa to fit flush when

installed. Now the damaged area is prepared for new sheeting.

Place a piece of aluminum foil over the prepared hole. While

holding the foil so it does not move, trace the edges of the hole

with your finger and make a visible crease at all edges.

Carefully place and hold the aluminum foil over the replacement

balsa stock, being careful not to smooth out any of the creases.

(To hold it, you can press two fingers on the foil inside the traced

area or use tape on the outer edges and/or T-pins placed out of the

way of the pounce wheel.)

A pounce wheel is a small, spurlike tool that is used to transfer

patterns to wood. While holding the aluminum foil firmly in

place, run this tool along the edge of each traced mark. If you are

unable to locate a pounce wheel, you can make a series of pin

pricks along the creases. It produces the same effect but takes

longer.

Remove the foil from the balsa, and then cut along the dotted

lines left in the wood. Make the cross-grain cuts first. Use light

pressure on the knife blade for these cross-grain slices, and make

several passes with the knife until it cuts cleanly through the

balsa. If you try to make the cross-grain cuts with one knife pass,

the result might be a split part.

Carefully sand the edges of this replacement part until it fits

perfectly inside the prepared area. Sandpaper cuts quickly, so

check your progress after one or two passes to make sure that you

are not removing too much material.

If the damaged section is in a curved portion of the wing, such

as the LE area, you may need to bend the replacement panel

slightly to fit by lightly dampening the panel with water on the

outside before gluing. To do that, dip your fingers in water and

shake off the excess, and then lightly rub the outside surface of

the insert. Don’t saturate the wood; wet balsa warps and does not

glue well.

Install the replacement part using a yellow wood glue (such as

an aliphatic type) and remove any excess glue using a damp paper

towel. You can use small weights to hold the replacement part in

place on curved areas. Use plastic sheeting to keep the glue from

sticking to your weights while it sets.

You should allow the adhesive to dry for several hours before

sanding. You can use five-minute epoxy here, but it is more

difficult to sand smooth. The more time and care you take in

preparation, the better the fit will be.

After the glue has dried and the surface has been sanded to

your satisfaction, there may still be some small gaps in the seam

between the wing and the patch. You can fill these with a vinyl

spackling compound. When the spackling is dry, it is simple to

block-sand even with the surface.

At this point you can re-cover the repaired area with a heatshrink

film that closely matches the original finish.

Additional Thoughts: The custom holding tool shown was made

from some small-diameter music wire. It was bent in such a

manner that it allowed the tool to splice pieces in place under the

sheeting while the glue cured.

I have only been successful in locating pounce wheels at

Micro-Mark; they are $19.95 for a set of three (item 15200). Visit

the company online at www.micromark.com. MA

Steven Hunt

Box 1152

Evansville WY 82636

[email protected]

Repair any internal damage to ribs before proceeding. The hole

is shown ready for the patch.

Install the reinforcement strips using the custom wire tool and

cyanoacrylate glue. They form a sort of "shelf."

Place aluminum foil over the replacement balsa stock—being

careful not to smooth any of the creases—then run the pounce

wheel around the creased edge.

Place a piece of aluminum foil over the prepared hole. Trace

the edges of the hole with your finger, making a visible crease

at all edges.

With the aluminum foil removed, you can easily see the marked

area that will become the patch piece.

Carefully cut the patch along the outside of the marked lines

with the modeling knife. Leave some material to allow a perfect

fit with some sanding.

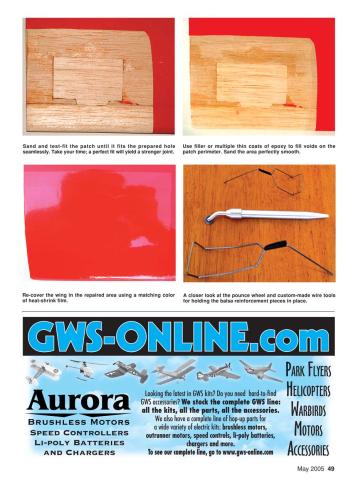

Sand and test-fit the patch until it fits the prepared hole

seamlessly. Take your time; a perfect fit will yield a stronger joint.

Re-cover the wing in the repaired area using a matching color

of heat-shrink film.

A closer look at the pounce wheel and custom-made wire tools

for holding the balsa reinforcement pieces in place.

Use filler or multiple thin coats of epoxy to fill voids on the

patch perimeter. Sand the area perfectly smooth.

Edition: Model Aviation - 2005/05

Page Numbers: 46,47,48,49

Edition: Model Aviation - 2005/05

Page Numbers: 46,47,48,49

ARF PATCHING

TECHNIQUES by

Steve Hunt

No matter what causes the damage, whether it's a rock or your

son's model car, a repair occasionally needs to be made!

These are the tools and materials that are required to make a

seamless repair in an ARF aircraft's wing.

SOMETIMES WE DON’T get quite the landing we had hoped

for or a pet rock takes a “shortcut” through our model’s wing.

Sometimes we just have to admit that we dropped something

onto—and on through—the wing.

This article is primarily for new pilots or those who have flown

only the ARF versions of airplanes. However, even seasoned

modelers might find a method here that is useful for repairing all

fixed-wing models incorporating boxed-in (ribbed and sheeted)

areas.

Please reacquaint yourself with the safety and

recommendations of the particular brand of modeling knife and

adhesives you will be using. The knife can cut you with very little

force, to the extent that you will need stitches. To make sure you

don’t need stitches for another reason, make sure you have a

proper cutting board under your work when you use the modeling

knife.

The cyanoacrylate glue can stick your fingers together or to

another object in seconds. When you are holding parts in place

while this glue is curing, use some plastic backing from your

covering; it was engineered so that adhesives will not stick to it.

Procedure: Cut back as much covering as necessary to examine

and repair without the remainder of the covering being in the way.

Remove the broken pieces of the model, and square off the

damaged area using the modeling knife.

Dealing with oddly shaped damaged areas is common, but try

to keep the replacement area as small as possible. Once the

harmed sheeting is cut away, inspect for hidden damage such as a

broken spar or crushed ribs.

Broken ribs are fairly easy to repair by manufacturing one of

like contour and gluing it onto the side of the original. If you

encounter a broken main spar, seek some advice from a more

Tools and Items Needed for Patching

• Sharp modeling-knife handle fitted with #11 blade.

• Pounce wheel.

• Holding tool made from music wire.

• Replacement balsa that is the same thickness as the

sheeting on the wing.

• Thin scrap balsa.

• Sanding block.

• T-pins.

• Cyanoacrylate glue.

• Yellow wood glue.

• Aluminum foil.

Photos courtesy the author

Remove as much of the surrounding covering material as

necessary to make the repair. It's better to remove a bit too much

than not enough.

Use the modeling knife to square off the opening as best you

can. Try to keep the edges of the opening straight.

Cut several cross-grain reinforcement strips to use under the lip

of the sheeting in the prepared area.

experienced builder. Spars are load-carrying members, and their

integrity must be maintained for safety’s sake.

Make reinforcement strips, which are cut cross-grain from

scrap balsa. Install these in place on the underside of the existing

sheeting in the damaged area using cyanoacrylate glue. Hold the

reinforcement strips in place using the custom-made holding tool,

which is shown, until the cyanoacrylate cures.

If the area to be repaired is too close to a rib, spar, or other

support, make a ledge using 1⁄4 balsa fit to contour and glue it in

place, leaving room for the replacement balsa to fit flush when

installed. Now the damaged area is prepared for new sheeting.

Place a piece of aluminum foil over the prepared hole. While

holding the foil so it does not move, trace the edges of the hole

with your finger and make a visible crease at all edges.

Carefully place and hold the aluminum foil over the replacement

balsa stock, being careful not to smooth out any of the creases.

(To hold it, you can press two fingers on the foil inside the traced

area or use tape on the outer edges and/or T-pins placed out of the

way of the pounce wheel.)

A pounce wheel is a small, spurlike tool that is used to transfer

patterns to wood. While holding the aluminum foil firmly in

place, run this tool along the edge of each traced mark. If you are

unable to locate a pounce wheel, you can make a series of pin

pricks along the creases. It produces the same effect but takes

longer.

Remove the foil from the balsa, and then cut along the dotted

lines left in the wood. Make the cross-grain cuts first. Use light

pressure on the knife blade for these cross-grain slices, and make

several passes with the knife until it cuts cleanly through the

balsa. If you try to make the cross-grain cuts with one knife pass,

the result might be a split part.

Carefully sand the edges of this replacement part until it fits

perfectly inside the prepared area. Sandpaper cuts quickly, so

check your progress after one or two passes to make sure that you

are not removing too much material.

If the damaged section is in a curved portion of the wing, such

as the LE area, you may need to bend the replacement panel

slightly to fit by lightly dampening the panel with water on the

outside before gluing. To do that, dip your fingers in water and

shake off the excess, and then lightly rub the outside surface of

the insert. Don’t saturate the wood; wet balsa warps and does not

glue well.

Install the replacement part using a yellow wood glue (such as

an aliphatic type) and remove any excess glue using a damp paper

towel. You can use small weights to hold the replacement part in

place on curved areas. Use plastic sheeting to keep the glue from

sticking to your weights while it sets.

You should allow the adhesive to dry for several hours before

sanding. You can use five-minute epoxy here, but it is more

difficult to sand smooth. The more time and care you take in

preparation, the better the fit will be.

After the glue has dried and the surface has been sanded to

your satisfaction, there may still be some small gaps in the seam

between the wing and the patch. You can fill these with a vinyl

spackling compound. When the spackling is dry, it is simple to

block-sand even with the surface.

At this point you can re-cover the repaired area with a heatshrink

film that closely matches the original finish.

Additional Thoughts: The custom holding tool shown was made

from some small-diameter music wire. It was bent in such a

manner that it allowed the tool to splice pieces in place under the

sheeting while the glue cured.

I have only been successful in locating pounce wheels at

Micro-Mark; they are $19.95 for a set of three (item 15200). Visit

the company online at www.micromark.com. MA

Steven Hunt

Box 1152

Evansville WY 82636

[email protected]

Repair any internal damage to ribs before proceeding. The hole

is shown ready for the patch.

Install the reinforcement strips using the custom wire tool and

cyanoacrylate glue. They form a sort of "shelf."

Place aluminum foil over the replacement balsa stock—being

careful not to smooth any of the creases—then run the pounce

wheel around the creased edge.

Place a piece of aluminum foil over the prepared hole. Trace

the edges of the hole with your finger, making a visible crease

at all edges.

With the aluminum foil removed, you can easily see the marked

area that will become the patch piece.

Carefully cut the patch along the outside of the marked lines

with the modeling knife. Leave some material to allow a perfect

fit with some sanding.

Sand and test-fit the patch until it fits the prepared hole

seamlessly. Take your time; a perfect fit will yield a stronger joint.

Re-cover the wing in the repaired area using a matching color

of heat-shrink film.

A closer look at the pounce wheel and custom-made wire tools

for holding the balsa reinforcement pieces in place.

Use filler or multiple thin coats of epoxy to fill voids on the

patch perimeter. Sand the area perfectly smooth.

Edition: Model Aviation - 2005/05

Page Numbers: 46,47,48,49

ARF PATCHING

TECHNIQUES by

Steve Hunt

No matter what causes the damage, whether it's a rock or your

son's model car, a repair occasionally needs to be made!

These are the tools and materials that are required to make a

seamless repair in an ARF aircraft's wing.

SOMETIMES WE DON’T get quite the landing we had hoped

for or a pet rock takes a “shortcut” through our model’s wing.

Sometimes we just have to admit that we dropped something

onto—and on through—the wing.

This article is primarily for new pilots or those who have flown

only the ARF versions of airplanes. However, even seasoned

modelers might find a method here that is useful for repairing all

fixed-wing models incorporating boxed-in (ribbed and sheeted)

areas.

Please reacquaint yourself with the safety and

recommendations of the particular brand of modeling knife and

adhesives you will be using. The knife can cut you with very little

force, to the extent that you will need stitches. To make sure you

don’t need stitches for another reason, make sure you have a

proper cutting board under your work when you use the modeling

knife.

The cyanoacrylate glue can stick your fingers together or to

another object in seconds. When you are holding parts in place

while this glue is curing, use some plastic backing from your

covering; it was engineered so that adhesives will not stick to it.

Procedure: Cut back as much covering as necessary to examine

and repair without the remainder of the covering being in the way.

Remove the broken pieces of the model, and square off the

damaged area using the modeling knife.

Dealing with oddly shaped damaged areas is common, but try

to keep the replacement area as small as possible. Once the

harmed sheeting is cut away, inspect for hidden damage such as a

broken spar or crushed ribs.

Broken ribs are fairly easy to repair by manufacturing one of

like contour and gluing it onto the side of the original. If you

encounter a broken main spar, seek some advice from a more

Tools and Items Needed for Patching

• Sharp modeling-knife handle fitted with #11 blade.

• Pounce wheel.

• Holding tool made from music wire.

• Replacement balsa that is the same thickness as the

sheeting on the wing.

• Thin scrap balsa.

• Sanding block.

• T-pins.

• Cyanoacrylate glue.

• Yellow wood glue.

• Aluminum foil.

Photos courtesy the author

Remove as much of the surrounding covering material as

necessary to make the repair. It's better to remove a bit too much

than not enough.

Use the modeling knife to square off the opening as best you

can. Try to keep the edges of the opening straight.

Cut several cross-grain reinforcement strips to use under the lip

of the sheeting in the prepared area.

experienced builder. Spars are load-carrying members, and their

integrity must be maintained for safety’s sake.

Make reinforcement strips, which are cut cross-grain from

scrap balsa. Install these in place on the underside of the existing

sheeting in the damaged area using cyanoacrylate glue. Hold the

reinforcement strips in place using the custom-made holding tool,

which is shown, until the cyanoacrylate cures.

If the area to be repaired is too close to a rib, spar, or other

support, make a ledge using 1⁄4 balsa fit to contour and glue it in

place, leaving room for the replacement balsa to fit flush when

installed. Now the damaged area is prepared for new sheeting.

Place a piece of aluminum foil over the prepared hole. While

holding the foil so it does not move, trace the edges of the hole

with your finger and make a visible crease at all edges.

Carefully place and hold the aluminum foil over the replacement

balsa stock, being careful not to smooth out any of the creases.

(To hold it, you can press two fingers on the foil inside the traced

area or use tape on the outer edges and/or T-pins placed out of the

way of the pounce wheel.)

A pounce wheel is a small, spurlike tool that is used to transfer

patterns to wood. While holding the aluminum foil firmly in

place, run this tool along the edge of each traced mark. If you are

unable to locate a pounce wheel, you can make a series of pin

pricks along the creases. It produces the same effect but takes

longer.

Remove the foil from the balsa, and then cut along the dotted

lines left in the wood. Make the cross-grain cuts first. Use light

pressure on the knife blade for these cross-grain slices, and make

several passes with the knife until it cuts cleanly through the

balsa. If you try to make the cross-grain cuts with one knife pass,

the result might be a split part.

Carefully sand the edges of this replacement part until it fits

perfectly inside the prepared area. Sandpaper cuts quickly, so

check your progress after one or two passes to make sure that you

are not removing too much material.

If the damaged section is in a curved portion of the wing, such

as the LE area, you may need to bend the replacement panel

slightly to fit by lightly dampening the panel with water on the

outside before gluing. To do that, dip your fingers in water and

shake off the excess, and then lightly rub the outside surface of

the insert. Don’t saturate the wood; wet balsa warps and does not

glue well.

Install the replacement part using a yellow wood glue (such as

an aliphatic type) and remove any excess glue using a damp paper

towel. You can use small weights to hold the replacement part in

place on curved areas. Use plastic sheeting to keep the glue from

sticking to your weights while it sets.

You should allow the adhesive to dry for several hours before

sanding. You can use five-minute epoxy here, but it is more

difficult to sand smooth. The more time and care you take in

preparation, the better the fit will be.

After the glue has dried and the surface has been sanded to

your satisfaction, there may still be some small gaps in the seam

between the wing and the patch. You can fill these with a vinyl

spackling compound. When the spackling is dry, it is simple to

block-sand even with the surface.

At this point you can re-cover the repaired area with a heatshrink

film that closely matches the original finish.

Additional Thoughts: The custom holding tool shown was made

from some small-diameter music wire. It was bent in such a

manner that it allowed the tool to splice pieces in place under the

sheeting while the glue cured.

I have only been successful in locating pounce wheels at

Micro-Mark; they are $19.95 for a set of three (item 15200). Visit

the company online at www.micromark.com. MA

Steven Hunt

Box 1152

Evansville WY 82636

[email protected]

Repair any internal damage to ribs before proceeding. The hole

is shown ready for the patch.

Install the reinforcement strips using the custom wire tool and

cyanoacrylate glue. They form a sort of "shelf."

Place aluminum foil over the replacement balsa stock—being

careful not to smooth any of the creases—then run the pounce

wheel around the creased edge.

Place a piece of aluminum foil over the prepared hole. Trace

the edges of the hole with your finger, making a visible crease

at all edges.

With the aluminum foil removed, you can easily see the marked

area that will become the patch piece.

Carefully cut the patch along the outside of the marked lines

with the modeling knife. Leave some material to allow a perfect

fit with some sanding.

Sand and test-fit the patch until it fits the prepared hole

seamlessly. Take your time; a perfect fit will yield a stronger joint.

Re-cover the wing in the repaired area using a matching color

of heat-shrink film.

A closer look at the pounce wheel and custom-made wire tools

for holding the balsa reinforcement pieces in place.

Use filler or multiple thin coats of epoxy to fill voids on the

patch perimeter. Sand the area perfectly smooth.

Edition: Model Aviation - 2005/05

Page Numbers: 46,47,48,49

ARF PATCHING

TECHNIQUES by

Steve Hunt

No matter what causes the damage, whether it's a rock or your

son's model car, a repair occasionally needs to be made!

These are the tools and materials that are required to make a

seamless repair in an ARF aircraft's wing.

SOMETIMES WE DON’T get quite the landing we had hoped

for or a pet rock takes a “shortcut” through our model’s wing.

Sometimes we just have to admit that we dropped something

onto—and on through—the wing.

This article is primarily for new pilots or those who have flown

only the ARF versions of airplanes. However, even seasoned

modelers might find a method here that is useful for repairing all

fixed-wing models incorporating boxed-in (ribbed and sheeted)

areas.

Please reacquaint yourself with the safety and

recommendations of the particular brand of modeling knife and

adhesives you will be using. The knife can cut you with very little

force, to the extent that you will need stitches. To make sure you

don’t need stitches for another reason, make sure you have a

proper cutting board under your work when you use the modeling

knife.

The cyanoacrylate glue can stick your fingers together or to

another object in seconds. When you are holding parts in place

while this glue is curing, use some plastic backing from your

covering; it was engineered so that adhesives will not stick to it.

Procedure: Cut back as much covering as necessary to examine

and repair without the remainder of the covering being in the way.

Remove the broken pieces of the model, and square off the

damaged area using the modeling knife.

Dealing with oddly shaped damaged areas is common, but try

to keep the replacement area as small as possible. Once the

harmed sheeting is cut away, inspect for hidden damage such as a

broken spar or crushed ribs.

Broken ribs are fairly easy to repair by manufacturing one of

like contour and gluing it onto the side of the original. If you

encounter a broken main spar, seek some advice from a more

Tools and Items Needed for Patching

• Sharp modeling-knife handle fitted with #11 blade.

• Pounce wheel.

• Holding tool made from music wire.

• Replacement balsa that is the same thickness as the

sheeting on the wing.

• Thin scrap balsa.

• Sanding block.

• T-pins.

• Cyanoacrylate glue.

• Yellow wood glue.

• Aluminum foil.

Photos courtesy the author

Remove as much of the surrounding covering material as

necessary to make the repair. It's better to remove a bit too much

than not enough.

Use the modeling knife to square off the opening as best you

can. Try to keep the edges of the opening straight.

Cut several cross-grain reinforcement strips to use under the lip

of the sheeting in the prepared area.

experienced builder. Spars are load-carrying members, and their

integrity must be maintained for safety’s sake.

Make reinforcement strips, which are cut cross-grain from

scrap balsa. Install these in place on the underside of the existing

sheeting in the damaged area using cyanoacrylate glue. Hold the

reinforcement strips in place using the custom-made holding tool,

which is shown, until the cyanoacrylate cures.

If the area to be repaired is too close to a rib, spar, or other

support, make a ledge using 1⁄4 balsa fit to contour and glue it in

place, leaving room for the replacement balsa to fit flush when

installed. Now the damaged area is prepared for new sheeting.

Place a piece of aluminum foil over the prepared hole. While

holding the foil so it does not move, trace the edges of the hole

with your finger and make a visible crease at all edges.

Carefully place and hold the aluminum foil over the replacement

balsa stock, being careful not to smooth out any of the creases.

(To hold it, you can press two fingers on the foil inside the traced

area or use tape on the outer edges and/or T-pins placed out of the

way of the pounce wheel.)

A pounce wheel is a small, spurlike tool that is used to transfer

patterns to wood. While holding the aluminum foil firmly in

place, run this tool along the edge of each traced mark. If you are

unable to locate a pounce wheel, you can make a series of pin

pricks along the creases. It produces the same effect but takes

longer.

Remove the foil from the balsa, and then cut along the dotted

lines left in the wood. Make the cross-grain cuts first. Use light

pressure on the knife blade for these cross-grain slices, and make

several passes with the knife until it cuts cleanly through the

balsa. If you try to make the cross-grain cuts with one knife pass,

the result might be a split part.

Carefully sand the edges of this replacement part until it fits

perfectly inside the prepared area. Sandpaper cuts quickly, so

check your progress after one or two passes to make sure that you

are not removing too much material.

If the damaged section is in a curved portion of the wing, such

as the LE area, you may need to bend the replacement panel

slightly to fit by lightly dampening the panel with water on the

outside before gluing. To do that, dip your fingers in water and

shake off the excess, and then lightly rub the outside surface of

the insert. Don’t saturate the wood; wet balsa warps and does not

glue well.

Install the replacement part using a yellow wood glue (such as

an aliphatic type) and remove any excess glue using a damp paper

towel. You can use small weights to hold the replacement part in

place on curved areas. Use plastic sheeting to keep the glue from

sticking to your weights while it sets.

You should allow the adhesive to dry for several hours before

sanding. You can use five-minute epoxy here, but it is more

difficult to sand smooth. The more time and care you take in

preparation, the better the fit will be.

After the glue has dried and the surface has been sanded to

your satisfaction, there may still be some small gaps in the seam

between the wing and the patch. You can fill these with a vinyl

spackling compound. When the spackling is dry, it is simple to

block-sand even with the surface.

At this point you can re-cover the repaired area with a heatshrink

film that closely matches the original finish.

Additional Thoughts: The custom holding tool shown was made

from some small-diameter music wire. It was bent in such a

manner that it allowed the tool to splice pieces in place under the

sheeting while the glue cured.

I have only been successful in locating pounce wheels at

Micro-Mark; they are $19.95 for a set of three (item 15200). Visit

the company online at www.micromark.com. MA

Steven Hunt

Box 1152

Evansville WY 82636

[email protected]

Repair any internal damage to ribs before proceeding. The hole

is shown ready for the patch.

Install the reinforcement strips using the custom wire tool and

cyanoacrylate glue. They form a sort of "shelf."

Place aluminum foil over the replacement balsa stock—being

careful not to smooth any of the creases—then run the pounce

wheel around the creased edge.

Place a piece of aluminum foil over the prepared hole. Trace

the edges of the hole with your finger, making a visible crease

at all edges.

With the aluminum foil removed, you can easily see the marked

area that will become the patch piece.

Carefully cut the patch along the outside of the marked lines

with the modeling knife. Leave some material to allow a perfect

fit with some sanding.

Sand and test-fit the patch until it fits the prepared hole

seamlessly. Take your time; a perfect fit will yield a stronger joint.

Re-cover the wing in the repaired area using a matching color

of heat-shrink film.

A closer look at the pounce wheel and custom-made wire tools

for holding the balsa reinforcement pieces in place.

Use filler or multiple thin coats of epoxy to fill voids on the

patch perimeter. Sand the area perfectly smooth.