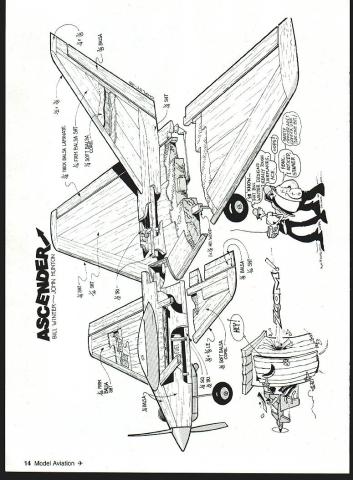

Good stall stability plenty lifting area ensures good takeoff successeven short bumpy fields 8 Model Aviation a canard has unusual look feel THE NAMESAKE Ascender World War II Curtiss canard experimental fighteran exciting design never made production Understanding tail-first design has come long way since unique Curtiss fighter XB-70 Valkyrie SAAB jet fighters Rutans work QED model design March 1996 Model Aviation proved canard configuration much offer stability giving up anything performance Bill Winters first delta canard Javelin September 1997 RC Modeler developed way like flyfast becoming familiar superb low-speed characteristics delta-wing-plus-canard configuration through Javelin Bill designed second delta canard way flies model has sport-type speed good solid handling characteristics Ascender surpassed goals has great look can zip other 40 models yet hang air breeze thermal idle higher aspect ratio Javelin squared-off tips Ascender may bend definition delta however maintains slotted effect between foreplane mainplane its 300 swept wing its extraordinary stability coordinated smooth response control inputs around three axes think delta-canard description may still applicable CONSTRUCTION Select light-grade balsa unless otherwise stated Sheet balsa wing must able curl easily along its length match airfoil eliminate tendency pull free blocks must light wood Wood sizes given plans generally mentioned text Wing Make 1As plywood patterns tip root ribs core will cut off flat behind inner leading edge front aileron spar used Evans Aircraft both cores double-stick lightweight tape skinning overall sequence building wing Attach inner leading edge aileron spars core panel Prepare skinning materials make servo landing gear cutouts drill cable access tunnels apply skin add root tip trailing edge pieces add tips join panels centerline last step preparing center leading edge cutout fuselage Begin tapering inner leading edge strip nearly required shape Make slightly oversize safety sand match airfoil after has pinned glued place use yellow [aliphatic resin] glue Use long straight pins holding alignment wrap short pieces masking tape Balsa selection has significant effect success performance model Industry rates balsa light six nine pounds per cubic foot medium nine 12 hard 12-16 method grading too coarse good scratch-building used cubic foot oftenpound-density medium balsa project wood alone could weigh desired gross weight completely finished appropriately built model five pounds eight ounces Ascender weighs 55 percent weight cubic foot block balsa Expert builders rate balsa light four six pounds per cubic foot medium-light six eight medium eight nine medium-hard 10-12 hard 13-15 extra-hard 15 Ascender used light medium-light medium balsa upper medium limit sufficiently hard foreplane aileron spars Fuselage sheeting cores vertical stabilizer foreplane six-pound-density maximum Foreplane wing sheeting six- eightpound density Leading edges medium-light Hobby shops large well-stocked wood supplies may enable make one-stop selection Some send away suppliers select open stock light medium hard specify Some will hand-select wood extra charge Some carry certain sizes light wood modest premium price consider medium-light sheet x 36 roughly 175 ounces seven-pound density light piece ounce four-pound density 125 ounces five-pound density Reasonably hard x 36 sheet weighs about 22 ounces about 85-pound density general six-pound-density beautiful wood Serious builders will order wood needed ensure wide range select above notes consider grainanother important factor balsa selection Grain selection addressed relevant Ascender construction notes Balsa weights larger powerful designs will require more-dense wood load-carrying members Bill Winter & John Hunton July1998 9 Designers Notes Os 40 FP fits nicely Note needle valve extension probably necessary newer rear-needle engines ensure firm joint Sight along wing cheek edges bowed Note outer leading edge attached later after skinning Attach aileron spar same way Make sanding board piece plywood sandpaper attached spray adhesive Sand edges repeated spanwise paths root tip Vacuum panel thoroughly following skinning method used Ascender may prefer preassembling four wing skins before starting allow least overlap along long edges tolerance minor layout errors double-stick tape convenient put down skin section time using appropriate width tape strips sheet pieces must precisely trimmed match using straightedge Begin skinning installing two four-inch-wide sheets overlapping inner leading edge other overlapping trailing edge spar grain parallel edge After servo mounting rails landing gear blocks have installed fill remaining open triangular shape prefitted triangular skin section Apply thin coat yellow glue along butt edge sheet being installed ensure good strong joint Make cardboard pattern servo landing gear block cutouts locate outlines cut through skins rule #11 knife blade Excavate cavities servo mounting rails landing gear blocks set flush foam skin overlaps wood servo mounts best strength permit triangular skin pieces hand-fitted removed Install tailored pieces after wood parts installed Use spade drills sharpened tubing cut servo wire access tunnels Note landing gear torque forces transferred top skin additional block set under skin front wing root cutout made after finished sanded panels have joined Note ailerons inboard outboard trailing edge chord extension pieces k laminated ner sheets After gluing extensions place block-sand tips square install tip blocks Trim overlapping skins true/flush edges attach slightly oversized outer leading edge piece Sand top Photos Bernie Stuecker Graphic Design Carla Kunz July1998 11 Triangular longerons notched 1/4 verticals cross members Sides shown completed ready former installation Install firewall plywood former side squared up add other side Cross-pieces added parallel area Empennage built 1/4 soft balsa cores firm 1/16 Servo mounting rails under skin protection against rocking sheeting overlay attached contact cement forces gear block cut sheet skin shear resistance STANDARD SERVO MOUNT BRACKET TO STOP DREET 1ARALSA OREET DOUBLER FOREPLANEREMOVABLE172 RALSA TRISTOCIT DRILL MOTOR irIISTRUT LIV RALSA DREET TOPII [ TRUE LENOTOI MOUNT OF SIDE____________________ 174 RULSA RAP WITHMETAL OFILE CASOPO72 BALSA 175 PINE B OCR FORLINE JOINTSPELT TOP THREAD RROD DEN NOSE WHEEL SERVOCUT FROM LARUERREMOVABLE TOP RLDCK ____________________CANOPT BOLD DOWN SEBEW HATCH ROLOW107 PROP LINE EPSON IN H4If.FRPS II~~-Z- OS AS -L - ---- ~2TRI K-101 SToCK-4 ENGINE \TAPIIASO L--II __-- r - 174 BALSA DREET1 172 TRI-STOCESIDES -PISE BLOCKWINS SEAT5716 DOWELONOERONSo~ IB OZ FUEL TUNET7L DOUBLERPOOBRUD ISO DIV MB2fl72 010 FOR BALANCELANSING GEARBALANCEISA BALSA SHEETHAPSUSODSPINNER WINO ATTACOISA BALSA BLOCKS BOLTEACH SIDE ISA BALSA SHEET TISS DIV MAIN ABEELS Ev&UFUSELAGE SIDE VIEW --WING SEAT DOUBLER2-152 DIA BOSE WHEEL ISA DIV LANDING GEARWREEL MAIL BRA BO010 ISO BALSASHOWN -7I DRII BALSA SOOBLEBE IHG/-\\BOTTOM SB PLOWOADNSTCHEU ISOISA BALSA FOBMEBTHI-STOCKSHEET HOLLOW ISO BALSANE BLOCK 02 BALSA BLOCK ISA PLOWOOD SB PLYWOOD j PETOR MOANT -ISO BALSA SHEET BAISO BALSA SEVER HERE FOBE PLANE MOUNTING ISP PLOWOOB PINE BLOCK AT CLEAR BLOCKSi -Vt REMOVE FORE PLANE MOUNTING PLATE ISO TRIANOL ISA SO <BEMOVE AT TYC AL VIEW OF CUTS INTERSECTION TOPICAL S MEMBER IN S TAL L AT ION THE TRIANGULOCK SYSTEM EN DO NOSE S DE DE WING SPAN50 75 AVERAGE WINO CHORD13 B75 REIGHTS H LBS WING LOADINGIS OZ PER TA PT AIRFOILNACA ANSI POWEROS 00 FP IOT PROPI FOREPLANE SPAN32 FOREPLANE AVG CHORDB 25 FOBEPLANE AREAOHA SO IN TOTAL LIFTING DORFACEISBN DV IN TOTAL SURFACE LOADING110 07 PER 55 FT COOTROLSENUINE ELKO AILERONS DODDER MODEL AVIATION 1 CD i C 3m CD TOP LONGERON ASCFNflFR 52 BALSA TRI- BlOCK TOPICAL SECTIONBOTTOMLONGERON AT INTERSECTION112 BALSA FRI-STOCK DESIGNED HO DROWN BT SOON BURTON LONUENONS RE ASSEMBLO IAPR INKED PLANS AT USE DEMARCO -L 0 0 CD 0 SLITS FOR H tih ri Vt [ II H H-] H CAT OUT ALL TRIWNOULAR DO-BRA LARGE HORN USE OUTER HOLE -3-142 AlA SHEET OR TWO LAMINATIONS OF I/HBALSA SHEET AGE LIGHT WOOS MR BALSA SHEET AILERON REAR SPAR m itYt LU WIDE MEOIUM GLASS CLOTHIH HO PASHAHO -AND CLEHICES WING PLAN RIGHT SIDE BOTTOM OF WING SHOWN -0* 50 SERHO MOUNTING HAILS NOTE THAT 141K SHEET IS OOER IEPORO IN PLACE ----144 BALSA SHEET PRIMARY LEADINO 14 HARDWOOD L S BLOCK lOB OIU S WISE IIFIN IS OUSOFT BALSA BALSA DAN HUT10KG DASBED 42 DUB HARD BALSA /-L 0 BALSA SHEETRUDDER-- LEASINA EDOF CM TYPICAL HINUEDOS BALSA SHEETRUDOER LOCATIONTAPER TS BEARHORN ---- END OF CORE WING-PARTIAL REAR VIEW LOADS I/O SO HARD WOOD TIP RI LATE PCORE I/K BALSASERVO WELLLG BLOCK WINO SKINDETAILDETAIL IA BALSA WING j OF DOWELSKIN 4 101K PLO AT ROOT CENTER SECTION ROOT BIB TEMPLATE FOR CUTTING WINO CORESEE WINO PLAN ~REAR HIEW OF WINO ING DIRE DR AL BLOCK OP AS SHOWN TO JOIN AT ROOK SO BALSA BLOCK ii LEV D4O 348 HDBALSA I/O DUB BALSA TIP tfl K I-SKIN SECTION ADOWEL JOINER T BALSA FORPLANE SECT IlOAN SOB BALSALE LUMINAT ELESA B WITH HO BALSA SHEET CORE K GRAIN. 0 41 BALSA SKIN-ORAl LE TO1WISE I100 ESLSA -DEAR JOINTI I- EPL E IOIKPO WOOD I I I - SLAb - 4I' /I-~ ft94'4 II1/ I- TOPICAL FOREPLA E CDNST UCTION 44 S OPT BALSA COK WITH /16 BALS NM SKIN TOP AND B TTOM DRERE WI SPRHO ADRESIHE 4 4 Ilo/ - 4 LIMITLINEPOR -j--LIGHTENING BOLES 1/NI I2 N OPTIONAL LIGHTENING - 1ROLESCUT WITH TUBE -H IOR FORDTNER BIT II j 11IINOTE USE 15 SHEET METAL ISCREWS TO ATTAEH FOREPLANE 1 N MODEL AVIATION -H K 2 ASCENDER DESIRNED MO BILL WINTER BRAWN 60 JORN HANTON 1O0 DURINKED PLANS MD DOE DEMARCO BALBA TIP SUlK BIRCH _ DOWEL I/B PLY FACE PLATE BLANKS lOB PEY.JfF~7iV2DRILL FOR BAKE 0k\y1H1T5016 BOWEL THEN *00 LE CAP D4BTEFOR ELCOON USE 102400 H RAE P ALERON DOW LE DETAILAILERON DETAILTHICK MAO 4 DRILLII lolA PLYWOOD CRACA AT JOINT-BOTTOM ACCESS HOLE CUT TUNNE WITH DR PLYWUSO FACE PLATED ISO B CUT ROOT AT THIS ARDLE SO IF CUT FROM TOP NO OCR TEXT Purchase 10 Thunderbolt R/C Long Glow Plugs $2490 Before Wednesday July j5th 1998 J Will Receive. Pick Up Deal Hobby Order TOLL FREE Today Add 535- postage & handling es dents add 775% sales tax UEbYIWL IDISCOUNT HOBBY STORES MIaSION VIEJO FOUN N VA EYSAND EGOENG NOE CAJONLAWNS ArAvery1S480SSS85w wryme544 S 2S33lMergverSe 405FFSOB55AS10806 wllrrrre56W50 714-354-333671964-6846696$ 9885-68844644 RIVERSIDEPASADENAORDER TOLLLAHARPASTORE HOURS 10125 Indiana Ave270 Norllr H Ave1401 S Seacs SledMon Fr 1000 8110 Tyler Village Center NOrIS 6 & LOCUSSOO85a8l7 1Seer lrnpenalSal 1000-600 809-785-6773626-568-0883 562-967-2574 -714-996-5721Sell 1000 500 aLw Offertng Ao#&&&M UY e..fle ereonsY aewee bottom faces match airfoil Mark precise leading edge forward point straightedge felt-tip pen guidance shaping final shape leading edge critical good flying stall characteristicsr shape accurately Gradually shape outer leading edge balsa plane roughing sanding board sculpting desired profile Work paths root tip removing material progressively Finish fine sandpaper pad Cut wing roots proper angles horizontal vertical planes using table saw just shaping sanding block over edge workbench jig up panel blocks Spotglue pin blocks wingtip sanding board held flush bench face used long-stroke milling action Check mating cores flush fit epoxy roots together blocking up panels required dihedral angle Use long straight pins and/or masking tape help hold position crevices remain joint after epoxy has cured fill mixture epoxy filler Outline cut out front wing recess install facing plywood pieces sides cutout sloped fit against fuselage sides spanwise plywood dowel plate glued first Trialfit wing fuselage checking two side cutout pieces fit snugly will butt against dowel plate Remove wing glue side plates place Cut rear protective bolt plate A6 plywood put vise force partial cracking along its centerline Set required dihedral angle glue bottom wing Apply two-inchwide fiberglass lightweight over top bottom center section joint Jnflsgnt UN/OFF -Switching Simple Plug Installation Sensors Internal & Unaffected External Conditions Consistent Operation Day Night Overcast Sunny KEEP FLYING THAT MODEL BTA AUTO PILOT FOR YEARS real Auto Pilot Designed back-up unit levels skill BTA Automatic Piloting Systems 192 Yorktown Lane Costa Mesa CA 92626 Phone 714-979-8948 Fax 714-979-8947 Send SASE Information Adjustable Zero & Gains Compatible RC Systems Endorsed Used Top Gun TOC Giant Scale Race Pilots & Experimental Full-Size also 16 Model Aviation i I1AU nergy Management Tools Introducing new generation 12-volt DC input delta peak field chargers Hitec RCD Delta Peak cut-off automatic trickle 11 Amp Glow charging 4-24 cells adjustable 05-5 Amps 24 cells charge 3 Amps LCD panel Amp voltage display Simultaneous 3-in-i charging capability Hitec RCD has tools make hobby fun full line radio systems servos receivers speed controls chargers offer high quality dependable equipment affordable price year factory warranty award-winning Hitec service department enough reason call hobby dealer today ask Hitec RCD products Now go out have fun information call 619 258-4940 write Hitec RCD Inc 10729 Wheatlands Ave Suite C Santee CA 92071 epoxy cyanoacrylate CyAbe sure use foam-friendly brand Trial-fit control horns ailerons dry fit hinges minimum gap between ailerons rear spar Slotting depends type hinge Nylon strip hinges simple light strong anything else properly installed insurance pinned hinges toothpick stay place Hinge slots can accurately cut #11 blade Mark positions exactly use something straight guide sure cut parallel surface Fuselage Construction Ascender fuselage somewhat unusual triangulock detailing use slotted triangle stock key uprights crossmembers easy accurate building Cut out triangular longerons notch accurately shown Make thin cardboard pattern mainplane wing cutout area accurately scribe sides pencil around outlines removed well doubler Cut fuselage sides outline shape Attach triangles side being very careful get accurate position sure make right side left side Install wing foreplane nose doublers Pin blanks together back-to-back true edges identical outlines Place sheet sandpaper workbench slide paired sides back forth milling action Part sides taper aft ends joining later Install vertical members side Cut firewall install blind nuts now both plywood formers Install firewall formers side using triangle true attach other side pull rear together yet Install crosspieces between former firewall along straight-sided portion fuselage pull tail after assembly dry temporary crosspieces can added foreplane area True top bottom sanding block install top bottom sheeting Add nose ring 18 Model Aviation 30 Features U CG-335 offers features CG-330 required doubling Basic shaping sanding fuselage should done now Corners should well-rounded leave square wing root leading edge foreplane mount area Prepare plywood foreplane seat sure install hardwood blocks underside plywood plate receive hold-down screws Check foreplane area level true mount plywood plate fiber-reinforced plastic engine mount used holes typical nosewheel strut because mount turned its side similar holes 132 must drilled sideways through stock mount Cover engine mount bolt holes masking tape tabs coat front face firewall epoxy allow set Trial-install engine nose gear Install fuel tank much plumbing can done stage Install servos note foreplane servo mounted directly through side fuselage end mounted square vertical other re hardwood block rudder/nosewheel servo can mounted stock bracket inside top sheeting canopy assembled after foreplane position Mark centerline top rear fuselage sheet cut holes fin attachment tabs Vertical Stabilizer Foreplane Build vertical stabilizer foreplane assembling light balsa core hard balsa fin foreplane main spars Make lightening holes outer areas cores indicated Use Forstner bit make hole-cutting tool large thinwalled tubing its cutting edges sharpened Use repetitive twisting motion Pretape entry side protection Sheet skins diagonal grain core Sand leading edge square add leading edge piece full thickness Install plywood foreplane reinforcements Sand surfaces shape sanding board smooth fine sandpaper Cut glue block wing holdJuly1998 21 down bolt drill bolt hole until wing has finished fitted Assemble two elevator blanks connecting dowel piece snugly against rear main surface strip waxed paper between foreplane Pin parts down accurately Use epoxy dowel joint After epoxy has cured pick up work taper/sand elevator assembly sanding board feather trailing edge elevators rudder see plan Shape elevator hinge line shown Canopy/Foreplane Hatch Cut canopy base 1/8 sheet match canopy shape required Trial-fit canopy base gently sanding wood match canopy slope around perimeter mount will glued later top built-up fairing block cross-sectioned fit top foreplane Preassembly Mark locations foreplane hold-down screws Pin foreplane assembly over plywood foreplane mount Drill guide holes #10 self-tapping sheet-metal screws three such screws hold down removable foreplane tank access two smaller screws canopy assembly After installing screws remove strengthen holes CyA Temporarily install hinges elevator horn remove until covering complete Fit wing fuselage before installing hold-down dowel rib profile fuselage will fairly accurate inside doublers will have tapered shaped fit wing Run masking tape along top wing will meet fuselage coat tape lipstick Seat wing remove trim away material marked lipstick Repeat process until wing seated level foreplane wing accurately mated fuselage drill /16 hold-down hole through wing rear plywood EeRIRIC SERVICE AT ITS BEST Sales Service Anything Radio Controlled KMI 7420 Seven Mile Rd Northville Michigan 48167 Ph 248-486-4800 Fax 248-486-1603 Repairs Updates Custom Modifications Frequency Changes 6 Send Legal sized SAE 1997 Meter conversions ACE Airtronics Aristo-craft Cirrus EK Catalog containing lists RIC maintenance hints Futaba Hitec Heathkit Hobby Shack JR Kraft KGL KSE Kline Discover MCard VISA COD KoPropo Pro-Line RCD Tower Hobbies World Engines & others UPS USMAIL FEDEX etc Calibrated Equipment Quick Turnaround Walk-in daily service 800 am-S 00 pm Send E-Mail PTWaters@junocom 22 Model Aviation 1 8 1/10 Scale Single $595 mounting plate Remove wing drill wing alone clearance bit Tap hole plywood mounting piece -20 nylon hold-down screw Realign wing fuselage attach mounting bolt Put dab modeling clay wingmount faceplate push wing place Remove wing drill dowel indicated Epoxy dowel peg faceplate ensure accuracy put epoxy hole plate rub bit dowel reposition wing making sure accurate alignment Drill landing gear wire holes hardwood blocks main landing gear shaped /s music wire cut long allow bending Make bends using vise hammer etc Hint File small notch vise jaws provide small radius prevent breaking wire bends Trial-mount landing gear temporarily install mounting screwplates Check alignment symmetry landing gear wire Remove before covering wing Covering/Painting On prototype used 21st Century films Coverite Prepare surfaces sanding block true Touch-up curves folded sandpaper Wipe off vacuum balsa dust Follow film covering instructions accurately generally try pull film tight enough during adhesion minimize amount shrunk Final Assembly Install landing gear RC gear linkage engine engine mount Hook up fuel tank plumbing Install antenna full length critical make model balance indicated Use ballast necessary Also check side-to-side balance correct tip weight necessary Check free control movements indicated amounts Flying There two areas delta canard model presents differences flight characteristics normally configured models looks air Keep model close least mistake high until familiar looks helps greatly color top light bottom dark white fin also helps Landing its excellent stall characteristics very easy get Ascender too slow landing therefore have enough airspeed left flare admonition may seem strange keep speed up until its time flare will bounce touchdown normal flight areas Ascender responds gracefully controls provides good feedback Rudder needed coordinated turns yet will turn rudder alone can seem hover breeze like kestrel waiting pounce prey controls remain effective very low velocities rudder very useful Stalls must forced feared prototype flown foreplane elevator control mixed elevon RC system capable mixing controls might try responsiveness mixed flap elevon additional up-control no down gave us additional up slower landings may want experiment moving Center Gravity CC back incrementally Y4 inch time shifting battery adding ballast gain sensitive control response expect Ascender snap spin will invert rolls well little down helps inverted loops just fine Ascender flies similar other sport model does class Hun ton 9154 Rixeyville Rd Rixeyville VA 22737 Bill Winter 12811 Melville Ln Fairfax VA 22033 Scales Sport Flyer Pro Pylon Racer top performance N just tun hasic secret fop engine performance N ht ealance ltd easy halance engine precision scales Baancing instruchono ecery scale An Investment Enjoyment" lighter illsInvestments longer itll stay up$ggg5--S&H Now can weigh parts hot ore glue toget airhrushing really I9 lighter9 Tissue g9 No govosiogi Now youh hnow hefo 0 ts 15 hhed t3 digitni models Model V-600Model GS-200Accuracy tam weigh Ouz 10105 1/2535th stan ounce CHAMPION 1924 E Edinger Ave a Ana CA 92705 -259-1 142 Fax 714-259-1025 Dept-131 Some gay shipping Payment US tongs AOO $5 5511 lO 01150 sates Canada & Mexico atarI $12 oh omers add StrI CA add h25% tax 24 Model Aviation

Edition: Model Aviation - 1998/07

Page Numbers: 8, 9, 11, 12, 13, 14, 16, 18, 21, 22, 24

Good stall stability plenty lifting area ensures good takeoff successeven short bumpy fields 8 Model Aviation a canard has unusual look feel THE NAMESAKE Ascender World War II Curtiss canard experimental fighteran exciting design never made production Understanding tail-first design has come long way since unique Curtiss fighter XB-70 Valkyrie SAAB jet fighters Rutans work QED model design March 1996 Model Aviation proved canard configuration much offer stability giving up anything performance Bill Winters first delta canard Javelin September 1997 RC Modeler developed way like flyfast becoming familiar superb low-speed characteristics delta-wing-plus-canard configuration through Javelin Bill designed second delta canard way flies model has sport-type speed good solid handling characteristics Ascender surpassed goals has great look can zip other 40 models yet hang air breeze thermal idle higher aspect ratio Javelin squared-off tips Ascender may bend definition delta however maintains slotted effect between foreplane mainplane its 300 swept wing its extraordinary stability coordinated smooth response control inputs around three axes think delta-canard description may still applicable CONSTRUCTION Select light-grade balsa unless otherwise stated Sheet balsa wing must able curl easily along its length match airfoil eliminate tendency pull free blocks must light wood Wood sizes given plans generally mentioned text Wing Make 1As plywood patterns tip root ribs core will cut off flat behind inner leading edge front aileron spar used Evans Aircraft both cores double-stick lightweight tape skinning overall sequence building wing Attach inner leading edge aileron spars core panel Prepare skinning materials make servo landing gear cutouts drill cable access tunnels apply skin add root tip trailing edge pieces add tips join panels centerline last step preparing center leading edge cutout fuselage Begin tapering inner leading edge strip nearly required shape Make slightly oversize safety sand match airfoil after has pinned glued place use yellow [aliphatic resin] glue Use long straight pins holding alignment wrap short pieces masking tape Balsa selection has significant effect success performance model Industry rates balsa light six nine pounds per cubic foot medium nine 12 hard 12-16 method grading too coarse good scratch-building used cubic foot oftenpound-density medium balsa project wood alone could weigh desired gross weight completely finished appropriately built model five pounds eight ounces Ascender weighs 55 percent weight cubic foot block balsa Expert builders rate balsa light four six pounds per cubic foot medium-light six eight medium eight nine medium-hard 10-12 hard 13-15 extra-hard 15 Ascender used light medium-light medium balsa upper medium limit sufficiently hard foreplane aileron spars Fuselage sheeting cores vertical stabilizer foreplane six-pound-density maximum Foreplane wing sheeting six- eightpound density Leading edges medium-light Hobby shops large well-stocked wood supplies may enable make one-stop selection Some send away suppliers select open stock light medium hard specify Some will hand-select wood extra charge Some carry certain sizes light wood modest premium price consider medium-light sheet x 36 roughly 175 ounces seven-pound density light piece ounce four-pound density 125 ounces five-pound density Reasonably hard x 36 sheet weighs about 22 ounces about 85-pound density general six-pound-density beautiful wood Serious builders will order wood needed ensure wide range select above notes consider grainanother important factor balsa selection Grain selection addressed relevant Ascender construction notes Balsa weights larger powerful designs will require more-dense wood load-carrying members Bill Winter & John Hunton July1998 9 Designers Notes Os 40 FP fits nicely Note needle valve extension probably necessary newer rear-needle engines ensure firm joint Sight along wing cheek edges bowed Note outer leading edge attached later after skinning Attach aileron spar same way Make sanding board piece plywood sandpaper attached spray adhesive Sand edges repeated spanwise paths root tip Vacuum panel thoroughly following skinning method used Ascender may prefer preassembling four wing skins before starting allow least overlap along long edges tolerance minor layout errors double-stick tape convenient put down skin section time using appropriate width tape strips sheet pieces must precisely trimmed match using straightedge Begin skinning installing two four-inch-wide sheets overlapping inner leading edge other overlapping trailing edge spar grain parallel edge After servo mounting rails landing gear blocks have installed fill remaining open triangular shape prefitted triangular skin section Apply thin coat yellow glue along butt edge sheet being installed ensure good strong joint Make cardboard pattern servo landing gear block cutouts locate outlines cut through skins rule #11 knife blade Excavate cavities servo mounting rails landing gear blocks set flush foam skin overlaps wood servo mounts best strength permit triangular skin pieces hand-fitted removed Install tailored pieces after wood parts installed Use spade drills sharpened tubing cut servo wire access tunnels Note landing gear torque forces transferred top skin additional block set under skin front wing root cutout made after finished sanded panels have joined Note ailerons inboard outboard trailing edge chord extension pieces k laminated ner sheets After gluing extensions place block-sand tips square install tip blocks Trim overlapping skins true/flush edges attach slightly oversized outer leading edge piece Sand top Photos Bernie Stuecker Graphic Design Carla Kunz July1998 11 Triangular longerons notched 1/4 verticals cross members Sides shown completed ready former installation Install firewall plywood former side squared up add other side Cross-pieces added parallel area Empennage built 1/4 soft balsa cores firm 1/16 Servo mounting rails under skin protection against rocking sheeting overlay attached contact cement forces gear block cut sheet skin shear resistance STANDARD SERVO MOUNT BRACKET TO STOP DREET 1ARALSA OREET DOUBLER FOREPLANEREMOVABLE172 RALSA TRISTOCIT DRILL MOTOR irIISTRUT LIV RALSA DREET TOPII [ TRUE LENOTOI MOUNT OF SIDE____________________ 174 RULSA RAP WITHMETAL OFILE CASOPO72 BALSA 175 PINE B OCR FORLINE JOINTSPELT TOP THREAD RROD DEN NOSE WHEEL SERVOCUT FROM LARUERREMOVABLE TOP RLDCK ____________________CANOPT BOLD DOWN SEBEW HATCH ROLOW107 PROP LINE EPSON IN H4If.FRPS II~~-Z- OS AS -L - ---- ~2TRI K-101 SToCK-4 ENGINE \TAPIIASO L--II __-- r - 174 BALSA DREET1 172 TRI-STOCESIDES -PISE BLOCKWINS SEAT5716 DOWELONOERONSo~ IB OZ FUEL TUNET7L DOUBLERPOOBRUD ISO DIV MB2fl72 010 FOR BALANCELANSING GEARBALANCEISA BALSA SHEETHAPSUSODSPINNER WINO ATTACOISA BALSA BLOCKS BOLTEACH SIDE ISA BALSA SHEET TISS DIV MAIN ABEELS Ev&UFUSELAGE SIDE VIEW --WING SEAT DOUBLER2-152 DIA BOSE WHEEL ISA DIV LANDING GEARWREEL MAIL BRA BO010 ISO BALSASHOWN -7I DRII BALSA SOOBLEBE IHG/-\\BOTTOM SB PLOWOADNSTCHEU ISOISA BALSA FOBMEBTHI-STOCKSHEET HOLLOW ISO BALSANE BLOCK 02 BALSA BLOCK ISA PLOWOOD SB PLYWOOD j PETOR MOANT -ISO BALSA SHEET BAISO BALSA SEVER HERE FOBE PLANE MOUNTING ISP PLOWOOB PINE BLOCK AT CLEAR BLOCKSi -Vt REMOVE FORE PLANE MOUNTING PLATE ISO TRIANOL ISA SO <BEMOVE AT TYC AL VIEW OF CUTS INTERSECTION TOPICAL S MEMBER IN S TAL L AT ION THE TRIANGULOCK SYSTEM EN DO NOSE S DE DE WING SPAN50 75 AVERAGE WINO CHORD13 B75 REIGHTS H LBS WING LOADINGIS OZ PER TA PT AIRFOILNACA ANSI POWEROS 00 FP IOT PROPI FOREPLANE SPAN32 FOREPLANE AVG CHORDB 25 FOBEPLANE AREAOHA SO IN TOTAL LIFTING DORFACEISBN DV IN TOTAL SURFACE LOADING110 07 PER 55 FT COOTROLSENUINE ELKO AILERONS DODDER MODEL AVIATION 1 CD i C 3m CD TOP LONGERON ASCFNflFR 52 BALSA TRI- BlOCK TOPICAL SECTIONBOTTOMLONGERON AT INTERSECTION112 BALSA FRI-STOCK DESIGNED HO DROWN BT SOON BURTON LONUENONS RE ASSEMBLO IAPR INKED PLANS AT USE DEMARCO -L 0 0 CD 0 SLITS FOR H tih ri Vt [ II H H-] H CAT OUT ALL TRIWNOULAR DO-BRA LARGE HORN USE OUTER HOLE -3-142 AlA SHEET OR TWO LAMINATIONS OF I/HBALSA SHEET AGE LIGHT WOOS MR BALSA SHEET AILERON REAR SPAR m itYt LU WIDE MEOIUM GLASS CLOTHIH HO PASHAHO -AND CLEHICES WING PLAN RIGHT SIDE BOTTOM OF WING SHOWN -0* 50 SERHO MOUNTING HAILS NOTE THAT 141K SHEET IS OOER IEPORO IN PLACE ----144 BALSA SHEET PRIMARY LEADINO 14 HARDWOOD L S BLOCK lOB OIU S WISE IIFIN IS OUSOFT BALSA BALSA DAN HUT10KG DASBED 42 DUB HARD BALSA /-L 0 BALSA SHEETRUDDER-- LEASINA EDOF CM TYPICAL HINUEDOS BALSA SHEETRUDOER LOCATIONTAPER TS BEARHORN ---- END OF CORE WING-PARTIAL REAR VIEW LOADS I/O SO HARD WOOD TIP RI LATE PCORE I/K BALSASERVO WELLLG BLOCK WINO SKINDETAILDETAIL IA BALSA WING j OF DOWELSKIN 4 101K PLO AT ROOT CENTER SECTION ROOT BIB TEMPLATE FOR CUTTING WINO CORESEE WINO PLAN ~REAR HIEW OF WINO ING DIRE DR AL BLOCK OP AS SHOWN TO JOIN AT ROOK SO BALSA BLOCK ii LEV D4O 348 HDBALSA I/O DUB BALSA TIP tfl K I-SKIN SECTION ADOWEL JOINER T BALSA FORPLANE SECT IlOAN SOB BALSALE LUMINAT ELESA B WITH HO BALSA SHEET CORE K GRAIN. 0 41 BALSA SKIN-ORAl LE TO1WISE I100 ESLSA -DEAR JOINTI I- EPL E IOIKPO WOOD I I I - SLAb - 4I' /I-~ ft94'4 II1/ I- TOPICAL FOREPLA E CDNST UCTION 44 S OPT BALSA COK WITH /16 BALS NM SKIN TOP AND B TTOM DRERE WI SPRHO ADRESIHE 4 4 Ilo/ - 4 LIMITLINEPOR -j--LIGHTENING BOLES 1/NI I2 N OPTIONAL LIGHTENING - 1ROLESCUT WITH TUBE -H IOR FORDTNER BIT II j 11IINOTE USE 15 SHEET METAL ISCREWS TO ATTAEH FOREPLANE 1 N MODEL AVIATION -H K 2 ASCENDER DESIRNED MO BILL WINTER BRAWN 60 JORN HANTON 1O0 DURINKED PLANS MD DOE DEMARCO BALBA TIP SUlK BIRCH _ DOWEL I/B PLY FACE PLATE BLANKS lOB PEY.JfF~7iV2DRILL FOR BAKE 0k\y1H1T5016 BOWEL THEN *00 LE CAP D4BTEFOR ELCOON USE 102400 H RAE P ALERON DOW LE DETAILAILERON DETAILTHICK MAO 4 DRILLII lolA PLYWOOD CRACA AT JOINT-BOTTOM ACCESS HOLE CUT TUNNE WITH DR PLYWUSO FACE PLATED ISO B CUT ROOT AT THIS ARDLE SO IF CUT FROM TOP NO OCR TEXT Purchase 10 Thunderbolt R/C Long Glow Plugs $2490 Before Wednesday July j5th 1998 J Will Receive. Pick Up Deal Hobby Order TOLL FREE Today Add 535- postage & handling es dents add 775% sales tax UEbYIWL IDISCOUNT HOBBY STORES MIaSION VIEJO FOUN N VA EYSAND EGOENG NOE CAJONLAWNS ArAvery1S480SSS85w wryme544 S 2S33lMergverSe 405FFSOB55AS10806 wllrrrre56W50 714-354-333671964-6846696$ 9885-68844644 RIVERSIDEPASADENAORDER TOLLLAHARPASTORE HOURS 10125 Indiana Ave270 Norllr H Ave1401 S Seacs SledMon Fr 1000 8110 Tyler Village Center NOrIS 6 & LOCUSSOO85a8l7 1Seer lrnpenalSal 1000-600 809-785-6773626-568-0883 562-967-2574 -714-996-5721Sell 1000 500 aLw Offertng Ao#&&&M UY e..fle ereonsY aewee bottom faces match airfoil Mark precise leading edge forward point straightedge felt-tip pen guidance shaping final shape leading edge critical good flying stall characteristicsr shape accurately Gradually shape outer leading edge balsa plane roughing sanding board sculpting desired profile Work paths root tip removing material progressively Finish fine sandpaper pad Cut wing roots proper angles horizontal vertical planes using table saw just shaping sanding block over edge workbench jig up panel blocks Spotglue pin blocks wingtip sanding board held flush bench face used long-stroke milling action Check mating cores flush fit epoxy roots together blocking up panels required dihedral angle Use long straight pins and/or masking tape help hold position crevices remain joint after epoxy has cured fill mixture epoxy filler Outline cut out front wing recess install facing plywood pieces sides cutout sloped fit against fuselage sides spanwise plywood dowel plate glued first Trialfit wing fuselage checking two side cutout pieces fit snugly will butt against dowel plate Remove wing glue side plates place Cut rear protective bolt plate A6 plywood put vise force partial cracking along its centerline Set required dihedral angle glue bottom wing Apply two-inchwide fiberglass lightweight over top bottom center section joint Jnflsgnt UN/OFF -Switching Simple Plug Installation Sensors Internal & Unaffected External Conditions Consistent Operation Day Night Overcast Sunny KEEP FLYING THAT MODEL BTA AUTO PILOT FOR YEARS real Auto Pilot Designed back-up unit levels skill BTA Automatic Piloting Systems 192 Yorktown Lane Costa Mesa CA 92626 Phone 714-979-8948 Fax 714-979-8947 Send SASE Information Adjustable Zero & Gains Compatible RC Systems Endorsed Used Top Gun TOC Giant Scale Race Pilots & Experimental Full-Size also 16 Model Aviation i I1AU nergy Management Tools Introducing new generation 12-volt DC input delta peak field chargers Hitec RCD Delta Peak cut-off automatic trickle 11 Amp Glow charging 4-24 cells adjustable 05-5 Amps 24 cells charge 3 Amps LCD panel Amp voltage display Simultaneous 3-in-i charging capability Hitec RCD has tools make hobby fun full line radio systems servos receivers speed controls chargers offer high quality dependable equipment affordable price year factory warranty award-winning Hitec service department enough reason call hobby dealer today ask Hitec RCD products Now go out have fun information call 619 258-4940 write Hitec RCD Inc 10729 Wheatlands Ave Suite C Santee CA 92071 epoxy cyanoacrylate CyAbe sure use foam-friendly brand Trial-fit control horns ailerons dry fit hinges minimum gap between ailerons rear spar Slotting depends type hinge Nylon strip hinges simple light strong anything else properly installed insurance pinned hinges toothpick stay place Hinge slots can accurately cut #11 blade Mark positions exactly use something straight guide sure cut parallel surface Fuselage Construction Ascender fuselage somewhat unusual triangulock detailing use slotted triangle stock key uprights crossmembers easy accurate building Cut out triangular longerons notch accurately shown Make thin cardboard pattern mainplane wing cutout area accurately scribe sides pencil around outlines removed well doubler Cut fuselage sides outline shape Attach triangles side being very careful get accurate position sure make right side left side Install wing foreplane nose doublers Pin blanks together back-to-back true edges identical outlines Place sheet sandpaper workbench slide paired sides back forth milling action Part sides taper aft ends joining later Install vertical members side Cut firewall install blind nuts now both plywood formers Install firewall formers side using triangle true attach other side pull rear together yet Install crosspieces between former firewall along straight-sided portion fuselage pull tail after assembly dry temporary crosspieces can added foreplane area True top bottom sanding block install top bottom sheeting Add nose ring 18 Model Aviation 30 Features U CG-335 offers features CG-330 required doubling Basic shaping sanding fuselage should done now Corners should well-rounded leave square wing root leading edge foreplane mount area Prepare plywood foreplane seat sure install hardwood blocks underside plywood plate receive hold-down screws Check foreplane area level true mount plywood plate fiber-reinforced plastic engine mount used holes typical nosewheel strut because mount turned its side similar holes 132 must drilled sideways through stock mount Cover engine mount bolt holes masking tape tabs coat front face firewall epoxy allow set Trial-install engine nose gear Install fuel tank much plumbing can done stage Install servos note foreplane servo mounted directly through side fuselage end mounted square vertical other re hardwood block rudder/nosewheel servo can mounted stock bracket inside top sheeting canopy assembled after foreplane position Mark centerline top rear fuselage sheet cut holes fin attachment tabs Vertical Stabilizer Foreplane Build vertical stabilizer foreplane assembling light balsa core hard balsa fin foreplane main spars Make lightening holes outer areas cores indicated Use Forstner bit make hole-cutting tool large thinwalled tubing its cutting edges sharpened Use repetitive twisting motion Pretape entry side protection Sheet skins diagonal grain core Sand leading edge square add leading edge piece full thickness Install plywood foreplane reinforcements Sand surfaces shape sanding board smooth fine sandpaper Cut glue block wing holdJuly1998 21 down bolt drill bolt hole until wing has finished fitted Assemble two elevator blanks connecting dowel piece snugly against rear main surface strip waxed paper between foreplane Pin parts down accurately Use epoxy dowel joint After epoxy has cured pick up work taper/sand elevator assembly sanding board feather trailing edge elevators rudder see plan Shape elevator hinge line shown Canopy/Foreplane Hatch Cut canopy base 1/8 sheet match canopy shape required Trial-fit canopy base gently sanding wood match canopy slope around perimeter mount will glued later top built-up fairing block cross-sectioned fit top foreplane Preassembly Mark locations foreplane hold-down screws Pin foreplane assembly over plywood foreplane mount Drill guide holes #10 self-tapping sheet-metal screws three such screws hold down removable foreplane tank access two smaller screws canopy assembly After installing screws remove strengthen holes CyA Temporarily install hinges elevator horn remove until covering complete Fit wing fuselage before installing hold-down dowel rib profile fuselage will fairly accurate inside doublers will have tapered shaped fit wing Run masking tape along top wing will meet fuselage coat tape lipstick Seat wing remove trim away material marked lipstick Repeat process until wing seated level foreplane wing accurately mated fuselage drill /16 hold-down hole through wing rear plywood EeRIRIC SERVICE AT ITS BEST Sales Service Anything Radio Controlled KMI 7420 Seven Mile Rd Northville Michigan 48167 Ph 248-486-4800 Fax 248-486-1603 Repairs Updates Custom Modifications Frequency Changes 6 Send Legal sized SAE 1997 Meter conversions ACE Airtronics Aristo-craft Cirrus EK Catalog containing lists RIC maintenance hints Futaba Hitec Heathkit Hobby Shack JR Kraft KGL KSE Kline Discover MCard VISA COD KoPropo Pro-Line RCD Tower Hobbies World Engines & others UPS USMAIL FEDEX etc Calibrated Equipment Quick Turnaround Walk-in daily service 800 am-S 00 pm Send E-Mail PTWaters@junocom 22 Model Aviation 1 8 1/10 Scale Single $595 mounting plate Remove wing drill wing alone clearance bit Tap hole plywood mounting piece -20 nylon hold-down screw Realign wing fuselage attach mounting bolt Put dab modeling clay wingmount faceplate push wing place Remove wing drill dowel indicated Epoxy dowel peg faceplate ensure accuracy put epoxy hole plate rub bit dowel reposition wing making sure accurate alignment Drill landing gear wire holes hardwood blocks main landing gear shaped /s music wire cut long allow bending Make bends using vise hammer etc Hint File small notch vise jaws provide small radius prevent breaking wire bends Trial-mount landing gear temporarily install mounting screwplates Check alignment symmetry landing gear wire Remove before covering wing Covering/Painting On prototype used 21st Century films Coverite Prepare surfaces sanding block true Touch-up curves folded sandpaper Wipe off vacuum balsa dust Follow film covering instructions accurately generally try pull film tight enough during adhesion minimize amount shrunk Final Assembly Install landing gear RC gear linkage engine engine mount Hook up fuel tank plumbing Install antenna full length critical make model balance indicated Use ballast necessary Also check side-to-side balance correct tip weight necessary Check free control movements indicated amounts Flying There two areas delta canard model presents differences flight characteristics normally configured models looks air Keep model close least mistake high until familiar looks helps greatly color top light bottom dark white fin also helps Landing its excellent stall characteristics very easy get Ascender too slow landing therefore have enough airspeed left flare admonition may seem strange keep speed up until its time flare will bounce touchdown normal flight areas Ascender responds gracefully controls provides good feedback Rudder needed coordinated turns yet will turn rudder alone can seem hover breeze like kestrel waiting pounce prey controls remain effective very low velocities rudder very useful Stalls must forced feared prototype flown foreplane elevator control mixed elevon RC system capable mixing controls might try responsiveness mixed flap elevon additional up-control no down gave us additional up slower landings may want experiment moving Center Gravity CC back incrementally Y4 inch time shifting battery adding ballast gain sensitive control response expect Ascender snap spin will invert rolls well little down helps inverted loops just fine Ascender flies similar other sport model does class Hun ton 9154 Rixeyville Rd Rixeyville VA 22737 Bill Winter 12811 Melville Ln Fairfax VA 22033 Scales Sport Flyer Pro Pylon Racer top performance N just tun hasic secret fop engine performance N ht ealance ltd easy halance engine precision scales Baancing instruchono ecery scale An Investment Enjoyment" lighter illsInvestments longer itll stay up$ggg5--S&H Now can weigh parts hot ore glue toget airhrushing really I9 lighter9 Tissue g9 No govosiogi Now youh hnow hefo 0 ts 15 hhed t3 digitni models Model V-600Model GS-200Accuracy tam weigh Ouz 10105 1/2535th stan ounce CHAMPION 1924 E Edinger Ave a Ana CA 92705 -259-1 142 Fax 714-259-1025 Dept-131 Some gay shipping Payment US tongs AOO $5 5511 lO 01150 sates Canada & Mexico atarI $12 oh omers add StrI CA add h25% tax 24 Model Aviation

Edition: Model Aviation - 1998/07

Page Numbers: 8, 9, 11, 12, 13, 14, 16, 18, 21, 22, 24

Good stall stability plenty lifting area ensures good takeoff successeven short bumpy fields 8 Model Aviation a canard has unusual look feel THE NAMESAKE Ascender World War II Curtiss canard experimental fighteran exciting design never made production Understanding tail-first design has come long way since unique Curtiss fighter XB-70 Valkyrie SAAB jet fighters Rutans work QED model design March 1996 Model Aviation proved canard configuration much offer stability giving up anything performance Bill Winters first delta canard Javelin September 1997 RC Modeler developed way like flyfast becoming familiar superb low-speed characteristics delta-wing-plus-canard configuration through Javelin Bill designed second delta canard way flies model has sport-type speed good solid handling characteristics Ascender surpassed goals has great look can zip other 40 models yet hang air breeze thermal idle higher aspect ratio Javelin squared-off tips Ascender may bend definition delta however maintains slotted effect between foreplane mainplane its 300 swept wing its extraordinary stability coordinated smooth response control inputs around three axes think delta-canard description may still applicable CONSTRUCTION Select light-grade balsa unless otherwise stated Sheet balsa wing must able curl easily along its length match airfoil eliminate tendency pull free blocks must light wood Wood sizes given plans generally mentioned text Wing Make 1As plywood patterns tip root ribs core will cut off flat behind inner leading edge front aileron spar used Evans Aircraft both cores double-stick lightweight tape skinning overall sequence building wing Attach inner leading edge aileron spars core panel Prepare skinning materials make servo landing gear cutouts drill cable access tunnels apply skin add root tip trailing edge pieces add tips join panels centerline last step preparing center leading edge cutout fuselage Begin tapering inner leading edge strip nearly required shape Make slightly oversize safety sand match airfoil after has pinned glued place use yellow [aliphatic resin] glue Use long straight pins holding alignment wrap short pieces masking tape Balsa selection has significant effect success performance model Industry rates balsa light six nine pounds per cubic foot medium nine 12 hard 12-16 method grading too coarse good scratch-building used cubic foot oftenpound-density medium balsa project wood alone could weigh desired gross weight completely finished appropriately built model five pounds eight ounces Ascender weighs 55 percent weight cubic foot block balsa Expert builders rate balsa light four six pounds per cubic foot medium-light six eight medium eight nine medium-hard 10-12 hard 13-15 extra-hard 15 Ascender used light medium-light medium balsa upper medium limit sufficiently hard foreplane aileron spars Fuselage sheeting cores vertical stabilizer foreplane six-pound-density maximum Foreplane wing sheeting six- eightpound density Leading edges medium-light Hobby shops large well-stocked wood supplies may enable make one-stop selection Some send away suppliers select open stock light medium hard specify Some will hand-select wood extra charge Some carry certain sizes light wood modest premium price consider medium-light sheet x 36 roughly 175 ounces seven-pound density light piece ounce four-pound density 125 ounces five-pound density Reasonably hard x 36 sheet weighs about 22 ounces about 85-pound density general six-pound-density beautiful wood Serious builders will order wood needed ensure wide range select above notes consider grainanother important factor balsa selection Grain selection addressed relevant Ascender construction notes Balsa weights larger powerful designs will require more-dense wood load-carrying members Bill Winter & John Hunton July1998 9 Designers Notes Os 40 FP fits nicely Note needle valve extension probably necessary newer rear-needle engines ensure firm joint Sight along wing cheek edges bowed Note outer leading edge attached later after skinning Attach aileron spar same way Make sanding board piece plywood sandpaper attached spray adhesive Sand edges repeated spanwise paths root tip Vacuum panel thoroughly following skinning method used Ascender may prefer preassembling four wing skins before starting allow least overlap along long edges tolerance minor layout errors double-stick tape convenient put down skin section time using appropriate width tape strips sheet pieces must precisely trimmed match using straightedge Begin skinning installing two four-inch-wide sheets overlapping inner leading edge other overlapping trailing edge spar grain parallel edge After servo mounting rails landing gear blocks have installed fill remaining open triangular shape prefitted triangular skin section Apply thin coat yellow glue along butt edge sheet being installed ensure good strong joint Make cardboard pattern servo landing gear block cutouts locate outlines cut through skins rule #11 knife blade Excavate cavities servo mounting rails landing gear blocks set flush foam skin overlaps wood servo mounts best strength permit triangular skin pieces hand-fitted removed Install tailored pieces after wood parts installed Use spade drills sharpened tubing cut servo wire access tunnels Note landing gear torque forces transferred top skin additional block set under skin front wing root cutout made after finished sanded panels have joined Note ailerons inboard outboard trailing edge chord extension pieces k laminated ner sheets After gluing extensions place block-sand tips square install tip blocks Trim overlapping skins true/flush edges attach slightly oversized outer leading edge piece Sand top Photos Bernie Stuecker Graphic Design Carla Kunz July1998 11 Triangular longerons notched 1/4 verticals cross members Sides shown completed ready former installation Install firewall plywood former side squared up add other side Cross-pieces added parallel area Empennage built 1/4 soft balsa cores firm 1/16 Servo mounting rails under skin protection against rocking sheeting overlay attached contact cement forces gear block cut sheet skin shear resistance STANDARD SERVO MOUNT BRACKET TO STOP DREET 1ARALSA OREET DOUBLER FOREPLANEREMOVABLE172 RALSA TRISTOCIT DRILL MOTOR irIISTRUT LIV RALSA DREET TOPII [ TRUE LENOTOI MOUNT OF SIDE____________________ 174 RULSA RAP WITHMETAL OFILE CASOPO72 BALSA 175 PINE B OCR FORLINE JOINTSPELT TOP THREAD RROD DEN NOSE WHEEL SERVOCUT FROM LARUERREMOVABLE TOP RLDCK ____________________CANOPT BOLD DOWN SEBEW HATCH ROLOW107 PROP LINE EPSON IN H4If.FRPS II~~-Z- OS AS -L - ---- ~2TRI K-101 SToCK-4 ENGINE \TAPIIASO L--II __-- r - 174 BALSA DREET1 172 TRI-STOCESIDES -PISE BLOCKWINS SEAT5716 DOWELONOERONSo~ IB OZ FUEL TUNET7L DOUBLERPOOBRUD ISO DIV MB2fl72 010 FOR BALANCELANSING GEARBALANCEISA BALSA SHEETHAPSUSODSPINNER WINO ATTACOISA BALSA BLOCKS BOLTEACH SIDE ISA BALSA SHEET TISS DIV MAIN ABEELS Ev&UFUSELAGE SIDE VIEW --WING SEAT DOUBLER2-152 DIA BOSE WHEEL ISA DIV LANDING GEARWREEL MAIL BRA BO010 ISO BALSASHOWN -7I DRII BALSA SOOBLEBE IHG/-\\BOTTOM SB PLOWOADNSTCHEU ISOISA BALSA FOBMEBTHI-STOCKSHEET HOLLOW ISO BALSANE BLOCK 02 BALSA BLOCK ISA PLOWOOD SB PLYWOOD j PETOR MOANT -ISO BALSA SHEET BAISO BALSA SEVER HERE FOBE PLANE MOUNTING ISP PLOWOOB PINE BLOCK AT CLEAR BLOCKSi -Vt REMOVE FORE PLANE MOUNTING PLATE ISO TRIANOL ISA SO <BEMOVE AT TYC AL VIEW OF CUTS INTERSECTION TOPICAL S MEMBER IN S TAL L AT ION THE TRIANGULOCK SYSTEM EN DO NOSE S DE DE WING SPAN50 75 AVERAGE WINO CHORD13 B75 REIGHTS H LBS WING LOADINGIS OZ PER TA PT AIRFOILNACA ANSI POWEROS 00 FP IOT PROPI FOREPLANE SPAN32 FOREPLANE AVG CHORDB 25 FOBEPLANE AREAOHA SO IN TOTAL LIFTING DORFACEISBN DV IN TOTAL SURFACE LOADING110 07 PER 55 FT COOTROLSENUINE ELKO AILERONS DODDER MODEL AVIATION 1 CD i C 3m CD TOP LONGERON ASCFNflFR 52 BALSA TRI- BlOCK TOPICAL SECTIONBOTTOMLONGERON AT INTERSECTION112 BALSA FRI-STOCK DESIGNED HO DROWN BT SOON BURTON LONUENONS RE ASSEMBLO IAPR INKED PLANS AT USE DEMARCO -L 0 0 CD 0 SLITS FOR H tih ri Vt [ II H H-] H CAT OUT ALL TRIWNOULAR DO-BRA LARGE HORN USE OUTER HOLE -3-142 AlA SHEET OR TWO LAMINATIONS OF I/HBALSA SHEET AGE LIGHT WOOS MR BALSA SHEET AILERON REAR SPAR m itYt LU WIDE MEOIUM GLASS CLOTHIH HO PASHAHO -AND CLEHICES WING PLAN RIGHT SIDE BOTTOM OF WING SHOWN -0* 50 SERHO MOUNTING HAILS NOTE THAT 141K SHEET IS OOER IEPORO IN PLACE ----144 BALSA SHEET PRIMARY LEADINO 14 HARDWOOD L S BLOCK lOB OIU S WISE IIFIN IS OUSOFT BALSA BALSA DAN HUT10KG DASBED 42 DUB HARD BALSA /-L 0 BALSA SHEETRUDDER-- LEASINA EDOF CM TYPICAL HINUEDOS BALSA SHEETRUDOER LOCATIONTAPER TS BEARHORN ---- END OF CORE WING-PARTIAL REAR VIEW LOADS I/O SO HARD WOOD TIP RI LATE PCORE I/K BALSASERVO WELLLG BLOCK WINO SKINDETAILDETAIL IA BALSA WING j OF DOWELSKIN 4 101K PLO AT ROOT CENTER SECTION ROOT BIB TEMPLATE FOR CUTTING WINO CORESEE WINO PLAN ~REAR HIEW OF WINO ING DIRE DR AL BLOCK OP AS SHOWN TO JOIN AT ROOK SO BALSA BLOCK ii LEV D4O 348 HDBALSA I/O DUB BALSA TIP tfl K I-SKIN SECTION ADOWEL JOINER T BALSA FORPLANE SECT IlOAN SOB BALSALE LUMINAT ELESA B WITH HO BALSA SHEET CORE K GRAIN. 0 41 BALSA SKIN-ORAl LE TO1WISE I100 ESLSA -DEAR JOINTI I- EPL E IOIKPO WOOD I I I - SLAb - 4I' /I-~ ft94'4 II1/ I- TOPICAL FOREPLA E CDNST UCTION 44 S OPT BALSA COK WITH /16 BALS NM SKIN TOP AND B TTOM DRERE WI SPRHO ADRESIHE 4 4 Ilo/ - 4 LIMITLINEPOR -j--LIGHTENING BOLES 1/NI I2 N OPTIONAL LIGHTENING - 1ROLESCUT WITH TUBE -H IOR FORDTNER BIT II j 11IINOTE USE 15 SHEET METAL ISCREWS TO ATTAEH FOREPLANE 1 N MODEL AVIATION -H K 2 ASCENDER DESIRNED MO BILL WINTER BRAWN 60 JORN HANTON 1O0 DURINKED PLANS MD DOE DEMARCO BALBA TIP SUlK BIRCH _ DOWEL I/B PLY FACE PLATE BLANKS lOB PEY.JfF~7iV2DRILL FOR BAKE 0k\y1H1T5016 BOWEL THEN *00 LE CAP D4BTEFOR ELCOON USE 102400 H RAE P ALERON DOW LE DETAILAILERON DETAILTHICK MAO 4 DRILLII lolA PLYWOOD CRACA AT JOINT-BOTTOM ACCESS HOLE CUT TUNNE WITH DR PLYWUSO FACE PLATED ISO B CUT ROOT AT THIS ARDLE SO IF CUT FROM TOP NO OCR TEXT Purchase 10 Thunderbolt R/C Long Glow Plugs $2490 Before Wednesday July j5th 1998 J Will Receive. Pick Up Deal Hobby Order TOLL FREE Today Add 535- postage & handling es dents add 775% sales tax UEbYIWL IDISCOUNT HOBBY STORES MIaSION VIEJO FOUN N VA EYSAND EGOENG NOE CAJONLAWNS ArAvery1S480SSS85w wryme544 S 2S33lMergverSe 405FFSOB55AS10806 wllrrrre56W50 714-354-333671964-6846696$ 9885-68844644 RIVERSIDEPASADENAORDER TOLLLAHARPASTORE HOURS 10125 Indiana Ave270 Norllr H Ave1401 S Seacs SledMon Fr 1000 8110 Tyler Village Center NOrIS 6 & LOCUSSOO85a8l7 1Seer lrnpenalSal 1000-600 809-785-6773626-568-0883 562-967-2574 -714-996-5721Sell 1000 500 aLw Offertng Ao#&&&M UY e..fle ereonsY aewee bottom faces match airfoil Mark precise leading edge forward point straightedge felt-tip pen guidance shaping final shape leading edge critical good flying stall characteristicsr shape accurately Gradually shape outer leading edge balsa plane roughing sanding board sculpting desired profile Work paths root tip removing material progressively Finish fine sandpaper pad Cut wing roots proper angles horizontal vertical planes using table saw just shaping sanding block over edge workbench jig up panel blocks Spotglue pin blocks wingtip sanding board held flush bench face used long-stroke milling action Check mating cores flush fit epoxy roots together blocking up panels required dihedral angle Use long straight pins and/or masking tape help hold position crevices remain joint after epoxy has cured fill mixture epoxy filler Outline cut out front wing recess install facing plywood pieces sides cutout sloped fit against fuselage sides spanwise plywood dowel plate glued first Trialfit wing fuselage checking two side cutout pieces fit snugly will butt against dowel plate Remove wing glue side plates place Cut rear protective bolt plate A6 plywood put vise force partial cracking along its centerline Set required dihedral angle glue bottom wing Apply two-inchwide fiberglass lightweight over top bottom center section joint Jnflsgnt UN/OFF -Switching Simple Plug Installation Sensors Internal & Unaffected External Conditions Consistent Operation Day Night Overcast Sunny KEEP FLYING THAT MODEL BTA AUTO PILOT FOR YEARS real Auto Pilot Designed back-up unit levels skill BTA Automatic Piloting Systems 192 Yorktown Lane Costa Mesa CA 92626 Phone 714-979-8948 Fax 714-979-8947 Send SASE Information Adjustable Zero & Gains Compatible RC Systems Endorsed Used Top Gun TOC Giant Scale Race Pilots & Experimental Full-Size also 16 Model Aviation i I1AU nergy Management Tools Introducing new generation 12-volt DC input delta peak field chargers Hitec RCD Delta Peak cut-off automatic trickle 11 Amp Glow charging 4-24 cells adjustable 05-5 Amps 24 cells charge 3 Amps LCD panel Amp voltage display Simultaneous 3-in-i charging capability Hitec RCD has tools make hobby fun full line radio systems servos receivers speed controls chargers offer high quality dependable equipment affordable price year factory warranty award-winning Hitec service department enough reason call hobby dealer today ask Hitec RCD products Now go out have fun information call 619 258-4940 write Hitec RCD Inc 10729 Wheatlands Ave Suite C Santee CA 92071 epoxy cyanoacrylate CyAbe sure use foam-friendly brand Trial-fit control horns ailerons dry fit hinges minimum gap between ailerons rear spar Slotting depends type hinge Nylon strip hinges simple light strong anything else properly installed insurance pinned hinges toothpick stay place Hinge slots can accurately cut #11 blade Mark positions exactly use something straight guide sure cut parallel surface Fuselage Construction Ascender fuselage somewhat unusual triangulock detailing use slotted triangle stock key uprights crossmembers easy accurate building Cut out triangular longerons notch accurately shown Make thin cardboard pattern mainplane wing cutout area accurately scribe sides pencil around outlines removed well doubler Cut fuselage sides outline shape Attach triangles side being very careful get accurate position sure make right side left side Install wing foreplane nose doublers Pin blanks together back-to-back true edges identical outlines Place sheet sandpaper workbench slide paired sides back forth milling action Part sides taper aft ends joining later Install vertical members side Cut firewall install blind nuts now both plywood formers Install firewall formers side using triangle true attach other side pull rear together yet Install crosspieces between former firewall along straight-sided portion fuselage pull tail after assembly dry temporary crosspieces can added foreplane area True top bottom sanding block install top bottom sheeting Add nose ring 18 Model Aviation 30 Features U CG-335 offers features CG-330 required doubling Basic shaping sanding fuselage should done now Corners should well-rounded leave square wing root leading edge foreplane mount area Prepare plywood foreplane seat sure install hardwood blocks underside plywood plate receive hold-down screws Check foreplane area level true mount plywood plate fiber-reinforced plastic engine mount used holes typical nosewheel strut because mount turned its side similar holes 132 must drilled sideways through stock mount Cover engine mount bolt holes masking tape tabs coat front face firewall epoxy allow set Trial-install engine nose gear Install fuel tank much plumbing can done stage Install servos note foreplane servo mounted directly through side fuselage end mounted square vertical other re hardwood block rudder/nosewheel servo can mounted stock bracket inside top sheeting canopy assembled after foreplane position Mark centerline top rear fuselage sheet cut holes fin attachment tabs Vertical Stabilizer Foreplane Build vertical stabilizer foreplane assembling light balsa core hard balsa fin foreplane main spars Make lightening holes outer areas cores indicated Use Forstner bit make hole-cutting tool large thinwalled tubing its cutting edges sharpened Use repetitive twisting motion Pretape entry side protection Sheet skins diagonal grain core Sand leading edge square add leading edge piece full thickness Install plywood foreplane reinforcements Sand surfaces shape sanding board smooth fine sandpaper Cut glue block wing holdJuly1998 21 down bolt drill bolt hole until wing has finished fitted Assemble two elevator blanks connecting dowel piece snugly against rear main surface strip waxed paper between foreplane Pin parts down accurately Use epoxy dowel joint After epoxy has cured pick up work taper/sand elevator assembly sanding board feather trailing edge elevators rudder see plan Shape elevator hinge line shown Canopy/Foreplane Hatch Cut canopy base 1/8 sheet match canopy shape required Trial-fit canopy base gently sanding wood match canopy slope around perimeter mount will glued later top built-up fairing block cross-sectioned fit top foreplane Preassembly Mark locations foreplane hold-down screws Pin foreplane assembly over plywood foreplane mount Drill guide holes #10 self-tapping sheet-metal screws three such screws hold down removable foreplane tank access two smaller screws canopy assembly After installing screws remove strengthen holes CyA Temporarily install hinges elevator horn remove until covering complete Fit wing fuselage before installing hold-down dowel rib profile fuselage will fairly accurate inside doublers will have tapered shaped fit wing Run masking tape along top wing will meet fuselage coat tape lipstick Seat wing remove trim away material marked lipstick Repeat process until wing seated level foreplane wing accurately mated fuselage drill /16 hold-down hole through wing rear plywood EeRIRIC SERVICE AT ITS BEST Sales Service Anything Radio Controlled KMI 7420 Seven Mile Rd Northville Michigan 48167 Ph 248-486-4800 Fax 248-486-1603 Repairs Updates Custom Modifications Frequency Changes 6 Send Legal sized SAE 1997 Meter conversions ACE Airtronics Aristo-craft Cirrus EK Catalog containing lists RIC maintenance hints Futaba Hitec Heathkit Hobby Shack JR Kraft KGL KSE Kline Discover MCard VISA COD KoPropo Pro-Line RCD Tower Hobbies World Engines & others UPS USMAIL FEDEX etc Calibrated Equipment Quick Turnaround Walk-in daily service 800 am-S 00 pm Send E-Mail PTWaters@junocom 22 Model Aviation 1 8 1/10 Scale Single $595 mounting plate Remove wing drill wing alone clearance bit Tap hole plywood mounting piece -20 nylon hold-down screw Realign wing fuselage attach mounting bolt Put dab modeling clay wingmount faceplate push wing place Remove wing drill dowel indicated Epoxy dowel peg faceplate ensure accuracy put epoxy hole plate rub bit dowel reposition wing making sure accurate alignment Drill landing gear wire holes hardwood blocks main landing gear shaped /s music wire cut long allow bending Make bends using vise hammer etc Hint File small notch vise jaws provide small radius prevent breaking wire bends Trial-mount landing gear temporarily install mounting screwplates Check alignment symmetry landing gear wire Remove before covering wing Covering/Painting On prototype used 21st Century films Coverite Prepare surfaces sanding block true Touch-up curves folded sandpaper Wipe off vacuum balsa dust Follow film covering instructions accurately generally try pull film tight enough during adhesion minimize amount shrunk Final Assembly Install landing gear RC gear linkage engine engine mount Hook up fuel tank plumbing Install antenna full length critical make model balance indicated Use ballast necessary Also check side-to-side balance correct tip weight necessary Check free control movements indicated amounts Flying There two areas delta canard model presents differences flight characteristics normally configured models looks air Keep model close least mistake high until familiar looks helps greatly color top light bottom dark white fin also helps Landing its excellent stall characteristics very easy get Ascender too slow landing therefore have enough airspeed left flare admonition may seem strange keep speed up until its time flare will bounce touchdown normal flight areas Ascender responds gracefully controls provides good feedback Rudder needed coordinated turns yet will turn rudder alone can seem hover breeze like kestrel waiting pounce prey controls remain effective very low velocities rudder very useful Stalls must forced feared prototype flown foreplane elevator control mixed elevon RC system capable mixing controls might try responsiveness mixed flap elevon additional up-control no down gave us additional up slower landings may want experiment moving Center Gravity CC back incrementally Y4 inch time shifting battery adding ballast gain sensitive control response expect Ascender snap spin will invert rolls well little down helps inverted loops just fine Ascender flies similar other sport model does class Hun ton 9154 Rixeyville Rd Rixeyville VA 22737 Bill Winter 12811 Melville Ln Fairfax VA 22033 Scales Sport Flyer Pro Pylon Racer top performance N just tun hasic secret fop engine performance N ht ealance ltd easy halance engine precision scales Baancing instruchono ecery scale An Investment Enjoyment" lighter illsInvestments longer itll stay up$ggg5--S&H Now can weigh parts hot ore glue toget airhrushing really I9 lighter9 Tissue g9 No govosiogi Now youh hnow hefo 0 ts 15 hhed t3 digitni models Model V-600Model GS-200Accuracy tam weigh Ouz 10105 1/2535th stan ounce CHAMPION 1924 E Edinger Ave a Ana CA 92705 -259-1 142 Fax 714-259-1025 Dept-131 Some gay shipping Payment US tongs AOO $5 5511 lO 01150 sates Canada & Mexico atarI $12 oh omers add StrI CA add h25% tax 24 Model Aviation

Edition: Model Aviation - 1998/07

Page Numbers: 8, 9, 11, 12, 13, 14, 16, 18, 21, 22, 24