BELL AIRCRAFT Corporation’s P-63 Kingcobra has

always suffered from something of an identity crisis. Because

of its midengine design, car-door-style cockpit, and bullet

shape, it has been repeatedly misidentified as a P-39

Airacobra.

Carefully examining the two World War II aircraft reveals

that their resemblance is only skin-deep; the P-63 had few

parts in common with the smaller P-39. (Among the shared

components were the so-called “car doors.”) The Kingcobra

was quite a different aircraft, featuring a two-stage

supercharger, a laminar-flow wing, and flying surfaces of

totally new design compared with the Airacobra.

The P-63 never served in combat with the US military, but

the Soviet Air Force used lend-lease aircraft in defense of

Moscow and on the Eastern Front after the Soviet Union

declared war on Japan late in the conflict. Following World

War II, the fledgling French Air Force employed P-63s in,

among other places, French Indochina, later to be Vietnam.

The Kingcobra’s excellent moments and lightly tapered

wing make it an obvious subject for a flying Scale model, yet

few rubber-powered plans for this aircraft were ever

by Mark Fineman

Looking at the bottom of the P-63, you can see the simulated

retracted landing gear. This is legal for FAC competition.

30 MODEL AVIATION

Often overlooked warbird makes great

FAC WW II Mass Launch design

08sig1.QXD 5/24/04 10:46 am Page 30

Check out the P-63’s cockpit area; the long, sleek nose that fairs

into the spinner; and the simulated exhaust stacks!

This gives you a better look at the simulated retracted landing

gear. Mark drew the details with a fine-point Sharpie.

Mark Fineman looks proud of his new craft at the field. This is a

great first low-wing Free Flight Scale project.

The author’s original P-63 required few adjustments other than a

bit of downthrust and right thrust to propeller.

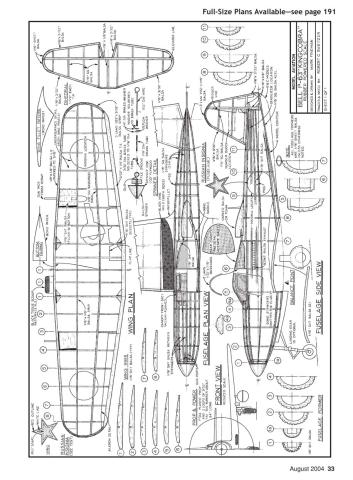

published. To the best of my knowledge, there were no P-63

kits either.

The 22-inch version featured here was intended primarily

for the Flying Aces Club (FAC) WW II Mass Launch event.

FAC mass-launch rules permit retractable gear to be modeled

in the “up” position, but fidelity to scale must be maintained.

The full-scale P-63 featured a hub-firing 37mm cannon and

four 50-caliber machine guns, two of which were mounted in

gondolas beneath the wings. Photos show that the latter were

sometimes removed from Soviet Kingcobras, and I carried out

that practice on my model. The wing guns are shown on the

plans for anyone who would like to include the gondolas on

his or her model.

CONSTRUCTION

The P-63 model’s design should be familiar to anyone who

has ever built a World War II model designed by Earl Stahl,

Comet, and many others.

Flying Surfaces: The curved wingtips and the rudder tip are

formed from three laminations of 1⁄32 x 1⁄16 balsa. A good way

to make the laminations is to glue copies of the curved areas

of the plans onto illustration board, cut them to their inside

dimensions, and apply wax to their edges (candle wax works

well). Pin the forms firmly to your building board.

Soak the lengths of balsa in extremely hot water for a few

minutes, and then carefully bend three laminations to the

outside of a form, applying slightly diluted white glue

between layers. Use straight pins to hold the balsa “sandwich”

to the building board while it dries—probably overnight.

Carefully remove the dried laminations from the forms, and

trim them for assembly into the flying surfaces.

The wing spars are on the top surface of the wing. Build

the wing halves separate, and then block up each wingtip 11⁄2

inches. Sand the ends of the spars, the LEs, and the TEs so

they will form a tight joint when the wing halves are

connected.

When the halves are joined correctly, glue them together

with a few drops of cyanoacrylate. The instant glue is better

for this operation than ordinary model-airplane glue because

the cyanoacrylate will not pull on the joint as it dries, thereby

adding dihedral.

Fuselage: Build the fuselage using the time-tested half-shell

August 2004 31

08sig1.QXD 5/24/04 10:48 am Page 31

method. Construct each former in halves, separated along the

vertical midline. Lay the top and bottom longerons directly on the

plans. Glue the formers into place starting at the rear of the

fuselage.

You should use a small metal triangle or square with a true

right angle to make certain that each former is glued in at right

angles to the building board. Never trust this alignment to the

eye! If the former halves are properly aligned with the longerons,

everything else will fall into place.

Once the formers have dried, systematically add the remaining

stringers to create a complete fuselage half. When this assembly

is dry, remove the fuselage half from the building board and add

the complementary former halves and stringers on the other side

to complete the structure.

The canopy-area construction is unusual. For the sake of

appearance, the canopy brace is formed from two laminations of

basswood. Balsa should also work here. The clear canopy aft of

the canopy brace is a simple acetate sheet. (The pattern is

included on the plans.) You must vacuum-form or plunge-form

the more complex clear canopy to the front of the brace, which

requires that you fashion a mold.

The accompanying framework photos show that I filled

several stringer bays at the front of the fuselage with 1⁄16 balsa

scrap. This technique strengthens and smoothes the nose contours

and adds nose weight, which is usually needed anyway. It also

makes it easier to make the indentations for the two fuselagemounted

machine-gun muzzles.

Make sure you sand this sheeted area smooth and paint it with

two coats of sanding sealer before you apply the tissue.

Finishing: Carve the scoop behind the canopy from balsa or foam.

Refer to pictures of the full-scale aircraft to get an accurate idea of the

contours.

Most Kingcobras were painted standard-issue olive drab on the

upper surfaces and gray below—even the Soviet airplanes. Stateside

P-63s and postwar French versions were often left with a bare metal

finish.

For ease of construction, and because FAC rules permit it, I

covered my model with dark green and gray Japanese tissue. I

simulated the control surfaces and landing gear with a Sharpie

permanent fine-tip marker. I created the red star insignia on the

computer.

Flying: Power to the 7-inch plastic propeller is supplied by two loops

of 3⁄32-inch FAI Tan rubber that are approximately 24 inches in length.

My model required no nose weight and few adjustments which

included a bit of downthrust and right thrust to the propeller.

The model is extremely stable in the power and glide portions of

flight and will consistently put in times in excess of a minute; twominute

flights are common.

The elegant Kingcobra gives the enthusiast yet another choice of

subject—one that has perhaps been neglected for too long. MA

Mark Fineman

1244 Wolf Hill Rd.

Cheshire CT 06410

The fuselage is built using the time-tested half-shell method.

Is there anything more elegant than a well-built FF Scale

structure? All the pieces are ready to go together.

32 MODEL AVIATION

Type: FF Scale

Wingspan: 22 inches

Power: FAI Tan rubber

Flying weight: 11⁄8 ounces without

rubber

Construction: Built-up balsa

Covering/finish: Dark green and

gray Japanese tissue

08sig1.QXD 5/24/04 10:50 am Page 32

Edition: Model Aviation - 2004/08

Page Numbers: 30,31,32,33

Edition: Model Aviation - 2004/08

Page Numbers: 30,31,32,33

BELL AIRCRAFT Corporation’s P-63 Kingcobra has

always suffered from something of an identity crisis. Because

of its midengine design, car-door-style cockpit, and bullet

shape, it has been repeatedly misidentified as a P-39

Airacobra.

Carefully examining the two World War II aircraft reveals

that their resemblance is only skin-deep; the P-63 had few

parts in common with the smaller P-39. (Among the shared

components were the so-called “car doors.”) The Kingcobra

was quite a different aircraft, featuring a two-stage

supercharger, a laminar-flow wing, and flying surfaces of

totally new design compared with the Airacobra.

The P-63 never served in combat with the US military, but

the Soviet Air Force used lend-lease aircraft in defense of

Moscow and on the Eastern Front after the Soviet Union

declared war on Japan late in the conflict. Following World

War II, the fledgling French Air Force employed P-63s in,

among other places, French Indochina, later to be Vietnam.

The Kingcobra’s excellent moments and lightly tapered

wing make it an obvious subject for a flying Scale model, yet

few rubber-powered plans for this aircraft were ever

by Mark Fineman

Looking at the bottom of the P-63, you can see the simulated

retracted landing gear. This is legal for FAC competition.

30 MODEL AVIATION

Often overlooked warbird makes great

FAC WW II Mass Launch design

08sig1.QXD 5/24/04 10:46 am Page 30

Check out the P-63’s cockpit area; the long, sleek nose that fairs

into the spinner; and the simulated exhaust stacks!

This gives you a better look at the simulated retracted landing

gear. Mark drew the details with a fine-point Sharpie.

Mark Fineman looks proud of his new craft at the field. This is a

great first low-wing Free Flight Scale project.

The author’s original P-63 required few adjustments other than a

bit of downthrust and right thrust to propeller.

published. To the best of my knowledge, there were no P-63

kits either.

The 22-inch version featured here was intended primarily

for the Flying Aces Club (FAC) WW II Mass Launch event.

FAC mass-launch rules permit retractable gear to be modeled

in the “up” position, but fidelity to scale must be maintained.

The full-scale P-63 featured a hub-firing 37mm cannon and

four 50-caliber machine guns, two of which were mounted in

gondolas beneath the wings. Photos show that the latter were

sometimes removed from Soviet Kingcobras, and I carried out

that practice on my model. The wing guns are shown on the

plans for anyone who would like to include the gondolas on

his or her model.

CONSTRUCTION

The P-63 model’s design should be familiar to anyone who

has ever built a World War II model designed by Earl Stahl,

Comet, and many others.

Flying Surfaces: The curved wingtips and the rudder tip are

formed from three laminations of 1⁄32 x 1⁄16 balsa. A good way

to make the laminations is to glue copies of the curved areas

of the plans onto illustration board, cut them to their inside

dimensions, and apply wax to their edges (candle wax works

well). Pin the forms firmly to your building board.

Soak the lengths of balsa in extremely hot water for a few

minutes, and then carefully bend three laminations to the

outside of a form, applying slightly diluted white glue

between layers. Use straight pins to hold the balsa “sandwich”

to the building board while it dries—probably overnight.

Carefully remove the dried laminations from the forms, and

trim them for assembly into the flying surfaces.

The wing spars are on the top surface of the wing. Build

the wing halves separate, and then block up each wingtip 11⁄2

inches. Sand the ends of the spars, the LEs, and the TEs so

they will form a tight joint when the wing halves are

connected.

When the halves are joined correctly, glue them together

with a few drops of cyanoacrylate. The instant glue is better

for this operation than ordinary model-airplane glue because

the cyanoacrylate will not pull on the joint as it dries, thereby

adding dihedral.

Fuselage: Build the fuselage using the time-tested half-shell

August 2004 31

08sig1.QXD 5/24/04 10:48 am Page 31

method. Construct each former in halves, separated along the

vertical midline. Lay the top and bottom longerons directly on the

plans. Glue the formers into place starting at the rear of the

fuselage.

You should use a small metal triangle or square with a true

right angle to make certain that each former is glued in at right

angles to the building board. Never trust this alignment to the

eye! If the former halves are properly aligned with the longerons,

everything else will fall into place.

Once the formers have dried, systematically add the remaining

stringers to create a complete fuselage half. When this assembly

is dry, remove the fuselage half from the building board and add

the complementary former halves and stringers on the other side

to complete the structure.

The canopy-area construction is unusual. For the sake of

appearance, the canopy brace is formed from two laminations of

basswood. Balsa should also work here. The clear canopy aft of

the canopy brace is a simple acetate sheet. (The pattern is

included on the plans.) You must vacuum-form or plunge-form

the more complex clear canopy to the front of the brace, which

requires that you fashion a mold.

The accompanying framework photos show that I filled

several stringer bays at the front of the fuselage with 1⁄16 balsa

scrap. This technique strengthens and smoothes the nose contours

and adds nose weight, which is usually needed anyway. It also

makes it easier to make the indentations for the two fuselagemounted

machine-gun muzzles.

Make sure you sand this sheeted area smooth and paint it with

two coats of sanding sealer before you apply the tissue.

Finishing: Carve the scoop behind the canopy from balsa or foam.

Refer to pictures of the full-scale aircraft to get an accurate idea of the

contours.

Most Kingcobras were painted standard-issue olive drab on the

upper surfaces and gray below—even the Soviet airplanes. Stateside

P-63s and postwar French versions were often left with a bare metal

finish.

For ease of construction, and because FAC rules permit it, I

covered my model with dark green and gray Japanese tissue. I

simulated the control surfaces and landing gear with a Sharpie

permanent fine-tip marker. I created the red star insignia on the

computer.

Flying: Power to the 7-inch plastic propeller is supplied by two loops

of 3⁄32-inch FAI Tan rubber that are approximately 24 inches in length.

My model required no nose weight and few adjustments which

included a bit of downthrust and right thrust to the propeller.

The model is extremely stable in the power and glide portions of

flight and will consistently put in times in excess of a minute; twominute

flights are common.

The elegant Kingcobra gives the enthusiast yet another choice of

subject—one that has perhaps been neglected for too long. MA

Mark Fineman

1244 Wolf Hill Rd.

Cheshire CT 06410

The fuselage is built using the time-tested half-shell method.

Is there anything more elegant than a well-built FF Scale

structure? All the pieces are ready to go together.

32 MODEL AVIATION

Type: FF Scale

Wingspan: 22 inches

Power: FAI Tan rubber

Flying weight: 11⁄8 ounces without

rubber

Construction: Built-up balsa

Covering/finish: Dark green and

gray Japanese tissue

08sig1.QXD 5/24/04 10:50 am Page 32

Edition: Model Aviation - 2004/08

Page Numbers: 30,31,32,33

BELL AIRCRAFT Corporation’s P-63 Kingcobra has

always suffered from something of an identity crisis. Because

of its midengine design, car-door-style cockpit, and bullet

shape, it has been repeatedly misidentified as a P-39

Airacobra.

Carefully examining the two World War II aircraft reveals

that their resemblance is only skin-deep; the P-63 had few

parts in common with the smaller P-39. (Among the shared

components were the so-called “car doors.”) The Kingcobra

was quite a different aircraft, featuring a two-stage

supercharger, a laminar-flow wing, and flying surfaces of

totally new design compared with the Airacobra.

The P-63 never served in combat with the US military, but

the Soviet Air Force used lend-lease aircraft in defense of

Moscow and on the Eastern Front after the Soviet Union

declared war on Japan late in the conflict. Following World

War II, the fledgling French Air Force employed P-63s in,

among other places, French Indochina, later to be Vietnam.

The Kingcobra’s excellent moments and lightly tapered

wing make it an obvious subject for a flying Scale model, yet

few rubber-powered plans for this aircraft were ever

by Mark Fineman

Looking at the bottom of the P-63, you can see the simulated

retracted landing gear. This is legal for FAC competition.

30 MODEL AVIATION

Often overlooked warbird makes great

FAC WW II Mass Launch design

08sig1.QXD 5/24/04 10:46 am Page 30

Check out the P-63’s cockpit area; the long, sleek nose that fairs

into the spinner; and the simulated exhaust stacks!

This gives you a better look at the simulated retracted landing

gear. Mark drew the details with a fine-point Sharpie.

Mark Fineman looks proud of his new craft at the field. This is a

great first low-wing Free Flight Scale project.

The author’s original P-63 required few adjustments other than a

bit of downthrust and right thrust to propeller.

published. To the best of my knowledge, there were no P-63

kits either.

The 22-inch version featured here was intended primarily

for the Flying Aces Club (FAC) WW II Mass Launch event.

FAC mass-launch rules permit retractable gear to be modeled

in the “up” position, but fidelity to scale must be maintained.

The full-scale P-63 featured a hub-firing 37mm cannon and

four 50-caliber machine guns, two of which were mounted in

gondolas beneath the wings. Photos show that the latter were

sometimes removed from Soviet Kingcobras, and I carried out

that practice on my model. The wing guns are shown on the

plans for anyone who would like to include the gondolas on

his or her model.

CONSTRUCTION

The P-63 model’s design should be familiar to anyone who

has ever built a World War II model designed by Earl Stahl,

Comet, and many others.

Flying Surfaces: The curved wingtips and the rudder tip are

formed from three laminations of 1⁄32 x 1⁄16 balsa. A good way

to make the laminations is to glue copies of the curved areas

of the plans onto illustration board, cut them to their inside

dimensions, and apply wax to their edges (candle wax works

well). Pin the forms firmly to your building board.

Soak the lengths of balsa in extremely hot water for a few

minutes, and then carefully bend three laminations to the

outside of a form, applying slightly diluted white glue

between layers. Use straight pins to hold the balsa “sandwich”

to the building board while it dries—probably overnight.

Carefully remove the dried laminations from the forms, and

trim them for assembly into the flying surfaces.

The wing spars are on the top surface of the wing. Build

the wing halves separate, and then block up each wingtip 11⁄2

inches. Sand the ends of the spars, the LEs, and the TEs so

they will form a tight joint when the wing halves are

connected.

When the halves are joined correctly, glue them together

with a few drops of cyanoacrylate. The instant glue is better

for this operation than ordinary model-airplane glue because

the cyanoacrylate will not pull on the joint as it dries, thereby

adding dihedral.

Fuselage: Build the fuselage using the time-tested half-shell

August 2004 31

08sig1.QXD 5/24/04 10:48 am Page 31

method. Construct each former in halves, separated along the

vertical midline. Lay the top and bottom longerons directly on the

plans. Glue the formers into place starting at the rear of the

fuselage.

You should use a small metal triangle or square with a true

right angle to make certain that each former is glued in at right

angles to the building board. Never trust this alignment to the

eye! If the former halves are properly aligned with the longerons,

everything else will fall into place.

Once the formers have dried, systematically add the remaining

stringers to create a complete fuselage half. When this assembly

is dry, remove the fuselage half from the building board and add

the complementary former halves and stringers on the other side

to complete the structure.

The canopy-area construction is unusual. For the sake of

appearance, the canopy brace is formed from two laminations of

basswood. Balsa should also work here. The clear canopy aft of

the canopy brace is a simple acetate sheet. (The pattern is

included on the plans.) You must vacuum-form or plunge-form

the more complex clear canopy to the front of the brace, which

requires that you fashion a mold.

The accompanying framework photos show that I filled

several stringer bays at the front of the fuselage with 1⁄16 balsa

scrap. This technique strengthens and smoothes the nose contours

and adds nose weight, which is usually needed anyway. It also

makes it easier to make the indentations for the two fuselagemounted

machine-gun muzzles.

Make sure you sand this sheeted area smooth and paint it with

two coats of sanding sealer before you apply the tissue.

Finishing: Carve the scoop behind the canopy from balsa or foam.

Refer to pictures of the full-scale aircraft to get an accurate idea of the

contours.

Most Kingcobras were painted standard-issue olive drab on the

upper surfaces and gray below—even the Soviet airplanes. Stateside

P-63s and postwar French versions were often left with a bare metal

finish.

For ease of construction, and because FAC rules permit it, I

covered my model with dark green and gray Japanese tissue. I

simulated the control surfaces and landing gear with a Sharpie

permanent fine-tip marker. I created the red star insignia on the

computer.

Flying: Power to the 7-inch plastic propeller is supplied by two loops

of 3⁄32-inch FAI Tan rubber that are approximately 24 inches in length.

My model required no nose weight and few adjustments which

included a bit of downthrust and right thrust to the propeller.

The model is extremely stable in the power and glide portions of

flight and will consistently put in times in excess of a minute; twominute

flights are common.

The elegant Kingcobra gives the enthusiast yet another choice of

subject—one that has perhaps been neglected for too long. MA

Mark Fineman

1244 Wolf Hill Rd.

Cheshire CT 06410

The fuselage is built using the time-tested half-shell method.

Is there anything more elegant than a well-built FF Scale

structure? All the pieces are ready to go together.

32 MODEL AVIATION

Type: FF Scale

Wingspan: 22 inches

Power: FAI Tan rubber

Flying weight: 11⁄8 ounces without

rubber

Construction: Built-up balsa

Covering/finish: Dark green and

gray Japanese tissue

08sig1.QXD 5/24/04 10:50 am Page 32

Edition: Model Aviation - 2004/08

Page Numbers: 30,31,32,33

BELL AIRCRAFT Corporation’s P-63 Kingcobra has

always suffered from something of an identity crisis. Because

of its midengine design, car-door-style cockpit, and bullet

shape, it has been repeatedly misidentified as a P-39

Airacobra.

Carefully examining the two World War II aircraft reveals

that their resemblance is only skin-deep; the P-63 had few

parts in common with the smaller P-39. (Among the shared

components were the so-called “car doors.”) The Kingcobra

was quite a different aircraft, featuring a two-stage

supercharger, a laminar-flow wing, and flying surfaces of

totally new design compared with the Airacobra.

The P-63 never served in combat with the US military, but

the Soviet Air Force used lend-lease aircraft in defense of

Moscow and on the Eastern Front after the Soviet Union

declared war on Japan late in the conflict. Following World

War II, the fledgling French Air Force employed P-63s in,

among other places, French Indochina, later to be Vietnam.

The Kingcobra’s excellent moments and lightly tapered

wing make it an obvious subject for a flying Scale model, yet

few rubber-powered plans for this aircraft were ever

by Mark Fineman

Looking at the bottom of the P-63, you can see the simulated

retracted landing gear. This is legal for FAC competition.

30 MODEL AVIATION

Often overlooked warbird makes great

FAC WW II Mass Launch design

08sig1.QXD 5/24/04 10:46 am Page 30

Check out the P-63’s cockpit area; the long, sleek nose that fairs

into the spinner; and the simulated exhaust stacks!

This gives you a better look at the simulated retracted landing

gear. Mark drew the details with a fine-point Sharpie.

Mark Fineman looks proud of his new craft at the field. This is a

great first low-wing Free Flight Scale project.

The author’s original P-63 required few adjustments other than a

bit of downthrust and right thrust to propeller.

published. To the best of my knowledge, there were no P-63

kits either.

The 22-inch version featured here was intended primarily

for the Flying Aces Club (FAC) WW II Mass Launch event.

FAC mass-launch rules permit retractable gear to be modeled

in the “up” position, but fidelity to scale must be maintained.

The full-scale P-63 featured a hub-firing 37mm cannon and

four 50-caliber machine guns, two of which were mounted in

gondolas beneath the wings. Photos show that the latter were

sometimes removed from Soviet Kingcobras, and I carried out

that practice on my model. The wing guns are shown on the

plans for anyone who would like to include the gondolas on

his or her model.

CONSTRUCTION

The P-63 model’s design should be familiar to anyone who

has ever built a World War II model designed by Earl Stahl,

Comet, and many others.

Flying Surfaces: The curved wingtips and the rudder tip are

formed from three laminations of 1⁄32 x 1⁄16 balsa. A good way

to make the laminations is to glue copies of the curved areas

of the plans onto illustration board, cut them to their inside

dimensions, and apply wax to their edges (candle wax works

well). Pin the forms firmly to your building board.

Soak the lengths of balsa in extremely hot water for a few

minutes, and then carefully bend three laminations to the

outside of a form, applying slightly diluted white glue

between layers. Use straight pins to hold the balsa “sandwich”

to the building board while it dries—probably overnight.

Carefully remove the dried laminations from the forms, and

trim them for assembly into the flying surfaces.

The wing spars are on the top surface of the wing. Build

the wing halves separate, and then block up each wingtip 11⁄2

inches. Sand the ends of the spars, the LEs, and the TEs so

they will form a tight joint when the wing halves are

connected.

When the halves are joined correctly, glue them together

with a few drops of cyanoacrylate. The instant glue is better

for this operation than ordinary model-airplane glue because

the cyanoacrylate will not pull on the joint as it dries, thereby

adding dihedral.

Fuselage: Build the fuselage using the time-tested half-shell

August 2004 31

08sig1.QXD 5/24/04 10:48 am Page 31

method. Construct each former in halves, separated along the

vertical midline. Lay the top and bottom longerons directly on the

plans. Glue the formers into place starting at the rear of the

fuselage.

You should use a small metal triangle or square with a true

right angle to make certain that each former is glued in at right

angles to the building board. Never trust this alignment to the

eye! If the former halves are properly aligned with the longerons,

everything else will fall into place.

Once the formers have dried, systematically add the remaining

stringers to create a complete fuselage half. When this assembly

is dry, remove the fuselage half from the building board and add

the complementary former halves and stringers on the other side

to complete the structure.

The canopy-area construction is unusual. For the sake of

appearance, the canopy brace is formed from two laminations of

basswood. Balsa should also work here. The clear canopy aft of

the canopy brace is a simple acetate sheet. (The pattern is

included on the plans.) You must vacuum-form or plunge-form

the more complex clear canopy to the front of the brace, which

requires that you fashion a mold.

The accompanying framework photos show that I filled

several stringer bays at the front of the fuselage with 1⁄16 balsa

scrap. This technique strengthens and smoothes the nose contours

and adds nose weight, which is usually needed anyway. It also

makes it easier to make the indentations for the two fuselagemounted

machine-gun muzzles.

Make sure you sand this sheeted area smooth and paint it with

two coats of sanding sealer before you apply the tissue.

Finishing: Carve the scoop behind the canopy from balsa or foam.

Refer to pictures of the full-scale aircraft to get an accurate idea of the

contours.

Most Kingcobras were painted standard-issue olive drab on the

upper surfaces and gray below—even the Soviet airplanes. Stateside

P-63s and postwar French versions were often left with a bare metal

finish.

For ease of construction, and because FAC rules permit it, I

covered my model with dark green and gray Japanese tissue. I

simulated the control surfaces and landing gear with a Sharpie

permanent fine-tip marker. I created the red star insignia on the

computer.

Flying: Power to the 7-inch plastic propeller is supplied by two loops

of 3⁄32-inch FAI Tan rubber that are approximately 24 inches in length.

My model required no nose weight and few adjustments which

included a bit of downthrust and right thrust to the propeller.

The model is extremely stable in the power and glide portions of

flight and will consistently put in times in excess of a minute; twominute

flights are common.

The elegant Kingcobra gives the enthusiast yet another choice of

subject—one that has perhaps been neglected for too long. MA

Mark Fineman

1244 Wolf Hill Rd.

Cheshire CT 06410

The fuselage is built using the time-tested half-shell method.

Is there anything more elegant than a well-built FF Scale

structure? All the pieces are ready to go together.

32 MODEL AVIATION

Type: FF Scale

Wingspan: 22 inches

Power: FAI Tan rubber

Flying weight: 11⁄8 ounces without

rubber

Construction: Built-up balsa

Covering/finish: Dark green and

gray Japanese tissue

08sig1.QXD 5/24/04 10:50 am Page 32