03Swami.jt1.doc

SPECIFICATIONS

Manufacturer: BMJR Models

Model Type: Nostalgic Old Timer

Skill Level: Intermediate pilot; intermediate builder

Wingspan: 46 inches

Wing Area: 307 square inches

Airfoil: Flat bottom, undercambered

Length: 30 inches

Weight: 18.5 ounces

Power System: 150-300 watt outrunner motor

Radio: Three channel with two micro servos

Construction: Balsa and light ply

Price: $92.00

Test Model Details

Motor: Scorpion SII-2215-900kv outrunner

ESC: Scorpion Commander 25A ESC.

Battery: Thunder Power three-cell 1350 mAh 45C

Propeller: APC E 9X4.5 or 9 3.5 SF

Radio system: Spektrum DX7 transmitter, Spektrum AR600 receiver, two Hitec HS-65HB servos

Ready to fly weight: 18.5 ounces

Flight Duration: 15 minutes or more

Pluses

Nostalgic old time look.

Laser cut parts.

Excellent flying characteristics.

Great curb appeal.

Minuses

Manual too abbreviated.

Motor mount needs modification for outrunner motor.

Stab built into fuselage.

Wheel hub holes too large.

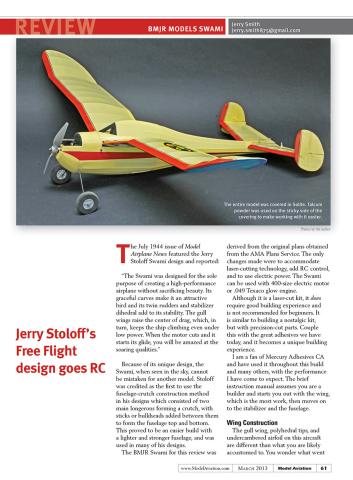

The July 1944 issue of Model Airplane News featured the Jerry Stoloff Swami design and reported “The Swami was designed for the sole purpose of creating a high performance airplane without sacrificing beauty. Its graceful curves make it an attractive bird and its twin rudders and stabilizer dihedral add to its stability. The gull wings raise the center of drag, which in turn keeps the ship climbing even under low power. When the motor cuts and it starts its glide, you will be amazed at the soaring qualities.”

Because of its unique design the Swami, when seen in the sky, cannot be recognized as something else. Stoloff was credited as the first to use the fuselage crutch construction method in his designs which consisted of two main longerons forming a crutch with sticks or bulkheads added between them to form the fuselage top and bottom. This provided an easier build, lighter and stronger fuselage, and was used in many of his designs.

The BMJR Swami, in this review, was derived from the original plan obtained from the AMA Plans Service. The only changes were to accommodate laser cutting technology, adding RC control, and for the use of electric power. The Swami can be used with 400-sized electric motor or .049 Texaco glow engine.

Although it is a laser cut kit it does require good building experience and is not recommended for the beginner. More like building one of the old time kits but with precision cut parts, which is a big help. Couple this with the great adhesives we have today and it becomes a different building experience from the past.

I am a great fan of Mercury Adhesives CA and have used it throughout this build and many others with the performance I have come to expect. The instruction manual, which is very abbreviated and assumes you are a builder, starts you out with the wing, which is the most construction, then the stab and finally the fuselage.

Wing Construction

The gull wing and polyhedral tips along with the under cambered airfoil on this bird are something different than you are used to looking at. You wonder what went through the designers mind when he thought of it and what he was after, but it is a thing of beauty with flowing lines and different shapes.

The wing is built in three panels, on each side, with each panel built separately. After cutting the wing spars to the proper angle from the front view on the plans, the spars are pinned down with the rear spar shimmed up 1/8 inch because of the under camber in the airfoil. The ribs are added followed by the LE and TE. After sanding the proper angle on the end of each panel, they are joined by a brace on each spar.

A jig is included to assure the proper angle of each panel during assembly. I added the diagonal 3/32 inch square bracing to stiffen it some, but that’s just me. The laser cut parts all fit very well. After assembly it requires careful sanding to ready it for covering.

Stab Construction

The stab is built much like the wing, a panel at a time. Pin down the spar, assemble the ribs and attach the LE and TE. However this one is different, it has dihedral and is a lifting stab. By that I mean it provides lift because of its flat bottom airfoil shape.

The two panels are joined with a brace giving the correct dihedral. Once joined, the center section is covered with 1/32 sheet balsa. The elevators are constructed by first laying down a one inch wide piece of 1/32 sheet balsa. A laser cut LE with notches, spacing the ribs, is glued down, and followed by the ribs.

A piece of 1/16 x ¼ balsa is glued to the TE to reinforce it. Plans are not required for this step because of the self-jigging laser cut parts.

The vertical stabs and rudders are solid sheet and are keyed to the ends of the stab to the main spar with a square hole in the fin. However, in order to keep the tail light, because of the short nose moment on the Swami, I removed some of the sheet from the center and lightened the fins up.

Because the stab is built into the fuselage it would make it more difficult to cover. So I integrated the part of the fuselage that goes over the stab, gluing it to the stab ending up with a joint. This allowed me to cover the stab, and glue it to the fuselage afterwards while not having to build it in the fuselage.

Fuselage Construction

The fuselage begins by laying down a crutch over the plans, typical of Soloff designs. The bottom half is constructed first and stringers are inserted in the notched bulkheads. When complete the bottom half is lifted from the plans and the top half bulkheads are installed, and then stringers added.

The parts fit here was good and the fuselage takes shape in a hurry. I assembled the cabin/wing hold down on the fuselage with the wing in place to ensure a good fit. Since I was using a different motor than recommended, I modified the front end and made the cowl removable so I could install or remove the motor easily. I used dowel pins to locate it and magnets to hold it in place. This took a little extra time but worked out great.

The motor I chose to power the Swami is a Scorpion SII-2215-900Kv along with their Commander 25A ESC. I have had good luck with these motors and why change when things are working good? Their motors are excellent quality and what I like about the ESC is that you can program it with their IR receiver and programmer key pad. No more listening to how many beeps you heard. All this included with the Commander 25A ESC package.

The most pain staking job on this build is hooking up the pull-pull linkage to the rudders. BMJR did a great job here of keeping it light with no heavy bell cranks and solid wire linkage. Instead small plastic tubing is threaded through the stab from the rudders and then down the fuselage to the servos.

The Spiderwire, 10 pound fishing line, is threaded through the tubes to provide the linkage connection. This is where it takes a lot of patience, but it’s not impossible as long as you don’t kink the line and can see it! I must say, the rudders work quite well.

Covering the Swami

Once I carefully sanded the airframe parts with 220 paper, I went on with the covering. I used Solite, the light version of Solarfilm, to keep the weight down. If you have never covered with Solite, you’ll find it takes some understanding on how to apply it.

The first problem encountered is taking off the backing. Take a square corner and place tape on both sides, then pull the tape apart. If that doesn’t work, place the corner between thumb and forefinger and use and X-Acto knife to start the separation, and then use the tape method.

Next, pull off the backing but be careful of static electricity which will cause it to curl and stick together. While pulling off the backing, lay it flat on the surface and dust it with talcum powder. This will cut the tackiness of the adhesive and allow you to pull it apart in case it sticks together.

Once you get it to the part to be covered and arranged, it is wonderful and becomes the best covering you have ever used. I covered the Swami with cream Solite and the underside of the wings with transparent Solite blue. The red trim is Solarfilm trim sheet.

Time to Fly

The manual does give you a starting CG location, but no information on control throws. Curious where the CG would fall I installed a three-cell 1350 mAh battery and strapped on the wings. It balanced perfect for the first flight at 40% (2.8 inches) of the wing chord. The lifting stab allows you a further aft CG. The two-inch from the leading edge, mentioned in the manual, will make the Swami too nose heavy. I then adjusted the control travel at a reasonable amount, with some expo, and she was ready to fly.

It was a perfect day for the maiden with very little wind. Setting it down on the grass runway, into the wind, I slowly advanced the throttle. The large size wheels worked great in the grass and the Swami was airborne. After gaining some altitude and flying at half throttle, I took my fingers off the sticks and it flew right on, straight and level. I didn’t touch a trim. Unbelievable!

Flying around and getting comfortable with the aircraft I finally set up for the landing. Pulling off the power it lost very little altitude in a very stable glide and with a little round off, in ground effect, settled in for a perfect landing. After that I flew it again wanting to yet again experience that wonderful flight performance and then let my flying buddy, Terry Ferentino, fly it while I took the flight pictures. What a great flying airplane.

Summary

The BMJR Swami is not for everyone, but if you have some building skills you should be able to put it together successfully. The wood in my review kit was decent and the plans were adequate although the instruction manual left you hanging at times.

I found the rudders to be very effective in flight and the glide was excellent. It is not a difficult model to build but again, it does require building experience. The finished model, if built straight, does have excellent flying characteristics. Because the model is so unusual you can expect plenty of remarks when you take it to the flying field. Models from back in that day are completely different than we see today. This is one old timer I am proud to have in my hanger and fly for a while, that is on good calm days.

Jerry Smith

[email protected]

MANUFACTURER/DISTRIBUTOR

BMJR Models

P.O. Box 1210

Sharpes FL 32959-1210

(321) 537-1159

www.bmjrmodels.com

Sources:

Spektrum RC

(800) 338-4639

www.spektrumrc.com

Solite

www.solarfilm.co.uk

Hitec RCD

(858) 748-8440

www.hitecrcd.com

Thunder Power

(702) 228-8883

www.thunderpowerrc.com

Landing Products/APC Propeller

(530) 661-0399

www.apcprop.com

Mercury Adhesives

(678) 513-4450

www.atlantahobby.com