130 MODEL AVIATION

CONTROL LINE SCALE

Bill Boss, 77-06 269th St., New Hyde Park NY 11040

THE F-4 PHANTOM featured in this

month’s column was built by Dennis Slater

of Chicago, Illinois, from a Westcoast Radio

Control (RC) kit he found at a swap meet; he

had never seen one before and hasn’t seen

one since. The very yellow newspaper found

stuffed between the parts in the box was

dated 1972.

Dennis noted that the kit was in excellent

condition and easy to build, and it is a great

size for a Control Line model. It has a

wingspan of 44 inches, a length of 48 inches,

500-plus square inches of wing area, and

was designed as a tractor propeller. The

power is an Enya .60 III, and the model has a

standard three-line bellcrank system for

throttle control.

The fuselage is all fiberglass, the

horizontal stabilizer is solid balsa, and the

wing is sheeted foam covered with fiberglass

cloth and Z-Poxy. The dual-shock nose gear

comes with the kit. The model is painted

with Formula-U airbrushed in a vintage

Vietnam color scheme and markings. All is

topcoated with Minwax Poly-U satin spray.

The scale details were also easy. Bombs

and rockets are Great Planes kit accessories

for the Tomcat and the Eagle. The belly drop

tank was made from two Estes rocket nose

cones butt-joined at the bases. Cockpit

interiors were scratch-built, and the pilots are

modified action figures from a dollar store.

Added scale operations are the drop tank

and drag chute. Both are operated via

electric servos, controlled by sending power

up insulated lines. The servos are regular RC

with the electronics removed. The battery

power sent up the lines is supplied by four

nine-volt batteries in series to provide 36

volts. The voltage is required to overcome

the resistance of the lines and provide

efficient operation of the servos.

The finished Phantom weighs 5 pounds

and is a great-flying model. Dennis says that

it never fails to stop traffic on the final

landing when it taxis to a stop with the drag

chute deployed. What makes the drag chute

work is a small hardware/variety-store item:

a spring-loaded key reel. Not a heavy-duty

type for a pound of keys, but the smalldiameter

reel with a nylon or .021-inch

coated cable cord.

The reel is mounted forward near the

servo or wherever it’s easy to access. Dennis

extended the length of the cord with the

same nylon used for the chute shroud lines.

The cord is then run through an eyelet at the

tail of the fuselage, and a 1⁄2A line clip is

used to connect it to the chute.

The chute compartment is built with a

hinged door that is controlled by a control

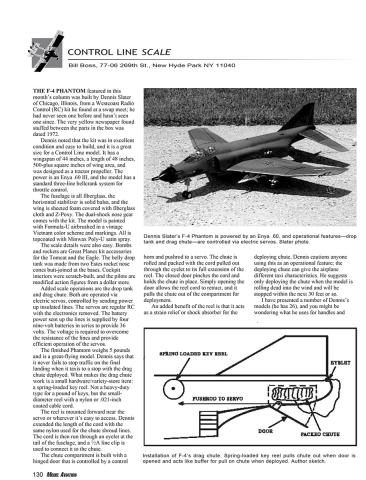

Dennis Slater’s F-4 Phantom is powered by an Enya .60, and operational features—drop

tank and drag chute—are controlled via electric servos. Slater photo.

Installation of F-4’s drag chute. Spring-loaded key reel pulls chute out when door is

opened and acts like buffer for pull on chute when deployed. Author sketch.

horn and pushrod to a servo. The chute is

rolled and packed with the cord pulled out

through the eyelet to its full extension of the

reel. The closed door pinches the cord and

holds the chute in place. Simply opening the

door allows the reel cord to retract, and it

pulls the chute out of the compartment for

deployment.

An added benefit of the reel is that it acts

as a strain relief or shock absorber for the

deploying chute. Dennis cautions anyone

using this as an operational feature; the

deploying chute can give the airplane

different taxi characteristics. He suggests

only deploying the chute when the model is

rolling dead into the wind and will be

stopped within the next 30 feet or so.

I have presented a number of Dennis’s

models (he has 26), and you might be

wondering what he uses for handles and

lines. He has equipped his airplanes in such

a fashion that he is able to control all of his

models with three handle and line

arrangements.

1) He uses an electric handle with voltage

up the lines (four nine-volt batteries in series

for operation of servos with the electronics

removed) for his B-29, C-130, B-25, and F-4

Phantom.

2) The electronic encoder/decoder system

“signals up the lines” for his B-17 and P-61

Black Widow.

3) He uses a standard three-line throttle

only and maybe a “full down” nose-wheel

brake on multiengine tricycle-gear models.

Care taken during building and setting up

the control installations in his models allows

him to use handle type 1, 2, or 3 from model

to model without any adjustments. No matter

how many airplanes he brings out to a flying

field, he only needs the three handles and

line systems.

Documentation for the Phantom is

readily available. Warbird Tech Series

Volume 8—McDonnell Douglas F-4 Gun

Nosed Phantoms—has several pages of

Vietnam-era color photos, information about

the F4-E gunfighter version, tech-manual

excerpts, exploded views and cutaways, and

some fine detail and arrangement of the front

and rear cockpit panels and instrumentation.

The book is a product of Specialty Press,

11481 Kost Dam Rd., North Branch MN

55056; Tel.: (612) 583-3239.

A good selection of three-views for the

Phantom, and hundreds of other airplanes, is

available from Bob’s Aircraft

Documentation, 3114 Yukon Ave., Costa

Mesa CA 92626; Tel.: (714) 979-8058.

Good News: Stan Alexander, president of

the National Association of Scale

Aeromodelers (NASA), reports that the 2003

National Scale Championships will be held

at the AMA Headquarters site in Muncie,

Indiana, the weekend of June 27-29 and that

the 2004 Scale events will also be held the

last weekend in June.

Stan noted that this information should

help all competitors who work in planning

their vacation time and days off for attending

the national competition. The weekend

May 2003 131

schedule might also help get more Scale

competitors to the Nationals by cutting down

on the number of days off work that were

required with the former middle-of-the-week

dates.

It was also reported that the AMA

Executive Council has approved a plan for

the construction of a 200 x 400-foot paved

area to the north of the L-pad, where Control

Line (CL) Scale events will be flown in 2003

and thereafter. This will be a great

improvement with respect to the “overfly

problem.”

NASA is working on becoming a

nonprofit organization. However, it is quite

costly in legal fees, so NASA has set up a

special account for the project and is asking

all members and friends to make a donation

to the cause. Nonprofit status will help the

organization with mailing costs, keep the

dues as low as possible, and put NASA in a

better position to receive donations of

money, merchandise, etc. from sponsors. All

donations should be sent to NASA

Secretary/Treasurer Bonnie Rediske, 128

Darnley Dr., Moon Township PA 15108.

Field Tips: Bob Furr of the Orbiting Eagles

of Omaha in Nebraska says that if you’re

having the problem of a propeller nut coming

loose inside a spinner, one thing you can use

that works well is a jam nut. This is nothing

more than another propeller nut up against

the first one you put on. It locks the first nut

in place and keeps your propeller from

working loose.

Keep in mind that a wood propeller will

compress in time, and both nuts will need to

be retightened. Do this one nut at a time; get

the nut closest to the propeller tight first, then

tighten the other nut while holding the first

one in place. If a rounded propeller nut is

required for safety reasons, it can serve as

the jam nut.

With the spring and summer months

coming, Bob also has a tip for controlling

bees and wasps around the flying site during

those hot summer days. Bob said that this is

an item for the flying field, but it also works

well in the back yard at home.

You can make a simple flying-insect trap

by cutting off the upper one-third of a twoliter

plastic soda bottle with a hobby or

utility knife. Pour a few ounces of regular

soda—not diet—into the lower part, then

invert the top one-third and nest it in the

bottom. Leave a space between the neck of

the bottle and the pool of soda. The bees and

wasps are attracted to the sweet smell; they

find their way through the bottle neck but

cannot find their way out. Eventually they

get exhausted, fall into the liquid, and

drown.

Please send ideas, notice of upcoming CL

Scale events, contest reports, and especially

photos of CL Scale activity to me at the

address at the top of this column. MA

Our Full-Size

Plans List

has hundreds

of models

to choose from.

See page 175

for details.

Edition: Model Aviation - 2003/05

Page Numbers: 130,131

Edition: Model Aviation - 2003/05

Page Numbers: 130,131

130 MODEL AVIATION

CONTROL LINE SCALE

Bill Boss, 77-06 269th St., New Hyde Park NY 11040

THE F-4 PHANTOM featured in this

month’s column was built by Dennis Slater

of Chicago, Illinois, from a Westcoast Radio

Control (RC) kit he found at a swap meet; he

had never seen one before and hasn’t seen

one since. The very yellow newspaper found

stuffed between the parts in the box was

dated 1972.

Dennis noted that the kit was in excellent

condition and easy to build, and it is a great

size for a Control Line model. It has a

wingspan of 44 inches, a length of 48 inches,

500-plus square inches of wing area, and

was designed as a tractor propeller. The

power is an Enya .60 III, and the model has a

standard three-line bellcrank system for

throttle control.

The fuselage is all fiberglass, the

horizontal stabilizer is solid balsa, and the

wing is sheeted foam covered with fiberglass

cloth and Z-Poxy. The dual-shock nose gear

comes with the kit. The model is painted

with Formula-U airbrushed in a vintage

Vietnam color scheme and markings. All is

topcoated with Minwax Poly-U satin spray.

The scale details were also easy. Bombs

and rockets are Great Planes kit accessories

for the Tomcat and the Eagle. The belly drop

tank was made from two Estes rocket nose

cones butt-joined at the bases. Cockpit

interiors were scratch-built, and the pilots are

modified action figures from a dollar store.

Added scale operations are the drop tank

and drag chute. Both are operated via

electric servos, controlled by sending power

up insulated lines. The servos are regular RC

with the electronics removed. The battery

power sent up the lines is supplied by four

nine-volt batteries in series to provide 36

volts. The voltage is required to overcome

the resistance of the lines and provide

efficient operation of the servos.

The finished Phantom weighs 5 pounds

and is a great-flying model. Dennis says that

it never fails to stop traffic on the final

landing when it taxis to a stop with the drag

chute deployed. What makes the drag chute

work is a small hardware/variety-store item:

a spring-loaded key reel. Not a heavy-duty

type for a pound of keys, but the smalldiameter

reel with a nylon or .021-inch

coated cable cord.

The reel is mounted forward near the

servo or wherever it’s easy to access. Dennis

extended the length of the cord with the

same nylon used for the chute shroud lines.

The cord is then run through an eyelet at the

tail of the fuselage, and a 1⁄2A line clip is

used to connect it to the chute.

The chute compartment is built with a

hinged door that is controlled by a control

Dennis Slater’s F-4 Phantom is powered by an Enya .60, and operational features—drop

tank and drag chute—are controlled via electric servos. Slater photo.

Installation of F-4’s drag chute. Spring-loaded key reel pulls chute out when door is

opened and acts like buffer for pull on chute when deployed. Author sketch.

horn and pushrod to a servo. The chute is

rolled and packed with the cord pulled out

through the eyelet to its full extension of the

reel. The closed door pinches the cord and

holds the chute in place. Simply opening the

door allows the reel cord to retract, and it

pulls the chute out of the compartment for

deployment.

An added benefit of the reel is that it acts

as a strain relief or shock absorber for the

deploying chute. Dennis cautions anyone

using this as an operational feature; the

deploying chute can give the airplane

different taxi characteristics. He suggests

only deploying the chute when the model is

rolling dead into the wind and will be

stopped within the next 30 feet or so.

I have presented a number of Dennis’s

models (he has 26), and you might be

wondering what he uses for handles and

lines. He has equipped his airplanes in such

a fashion that he is able to control all of his

models with three handle and line

arrangements.

1) He uses an electric handle with voltage

up the lines (four nine-volt batteries in series

for operation of servos with the electronics

removed) for his B-29, C-130, B-25, and F-4

Phantom.

2) The electronic encoder/decoder system

“signals up the lines” for his B-17 and P-61

Black Widow.

3) He uses a standard three-line throttle

only and maybe a “full down” nose-wheel

brake on multiengine tricycle-gear models.

Care taken during building and setting up

the control installations in his models allows

him to use handle type 1, 2, or 3 from model

to model without any adjustments. No matter

how many airplanes he brings out to a flying

field, he only needs the three handles and

line systems.

Documentation for the Phantom is

readily available. Warbird Tech Series

Volume 8—McDonnell Douglas F-4 Gun

Nosed Phantoms—has several pages of

Vietnam-era color photos, information about

the F4-E gunfighter version, tech-manual

excerpts, exploded views and cutaways, and

some fine detail and arrangement of the front

and rear cockpit panels and instrumentation.

The book is a product of Specialty Press,

11481 Kost Dam Rd., North Branch MN

55056; Tel.: (612) 583-3239.

A good selection of three-views for the

Phantom, and hundreds of other airplanes, is

available from Bob’s Aircraft

Documentation, 3114 Yukon Ave., Costa

Mesa CA 92626; Tel.: (714) 979-8058.

Good News: Stan Alexander, president of

the National Association of Scale

Aeromodelers (NASA), reports that the 2003

National Scale Championships will be held

at the AMA Headquarters site in Muncie,

Indiana, the weekend of June 27-29 and that

the 2004 Scale events will also be held the

last weekend in June.

Stan noted that this information should

help all competitors who work in planning

their vacation time and days off for attending

the national competition. The weekend

May 2003 131

schedule might also help get more Scale

competitors to the Nationals by cutting down

on the number of days off work that were

required with the former middle-of-the-week

dates.

It was also reported that the AMA

Executive Council has approved a plan for

the construction of a 200 x 400-foot paved

area to the north of the L-pad, where Control

Line (CL) Scale events will be flown in 2003

and thereafter. This will be a great

improvement with respect to the “overfly

problem.”

NASA is working on becoming a

nonprofit organization. However, it is quite

costly in legal fees, so NASA has set up a

special account for the project and is asking

all members and friends to make a donation

to the cause. Nonprofit status will help the

organization with mailing costs, keep the

dues as low as possible, and put NASA in a

better position to receive donations of

money, merchandise, etc. from sponsors. All

donations should be sent to NASA

Secretary/Treasurer Bonnie Rediske, 128

Darnley Dr., Moon Township PA 15108.

Field Tips: Bob Furr of the Orbiting Eagles

of Omaha in Nebraska says that if you’re

having the problem of a propeller nut coming

loose inside a spinner, one thing you can use

that works well is a jam nut. This is nothing

more than another propeller nut up against

the first one you put on. It locks the first nut

in place and keeps your propeller from

working loose.

Keep in mind that a wood propeller will

compress in time, and both nuts will need to

be retightened. Do this one nut at a time; get

the nut closest to the propeller tight first, then

tighten the other nut while holding the first

one in place. If a rounded propeller nut is

required for safety reasons, it can serve as

the jam nut.

With the spring and summer months

coming, Bob also has a tip for controlling

bees and wasps around the flying site during

those hot summer days. Bob said that this is

an item for the flying field, but it also works

well in the back yard at home.

You can make a simple flying-insect trap

by cutting off the upper one-third of a twoliter

plastic soda bottle with a hobby or

utility knife. Pour a few ounces of regular

soda—not diet—into the lower part, then

invert the top one-third and nest it in the

bottom. Leave a space between the neck of

the bottle and the pool of soda. The bees and

wasps are attracted to the sweet smell; they

find their way through the bottle neck but

cannot find their way out. Eventually they

get exhausted, fall into the liquid, and

drown.

Please send ideas, notice of upcoming CL

Scale events, contest reports, and especially

photos of CL Scale activity to me at the

address at the top of this column. MA

Our Full-Size

Plans List

has hundreds

of models

to choose from.

See page 175

for details.