146 MODEL AVIATION

TIMING OF A Speed flight is the act that tells us how our model

performed. Today, many good digital stopwatches are available

that range from those built into a wristwatch to ones with special

functions. A few allow split timing so that a single lap can be

timed while the whole flight is being timed. When the flight is

completed, the time still needs to be converted to mph to

determine how well it went.

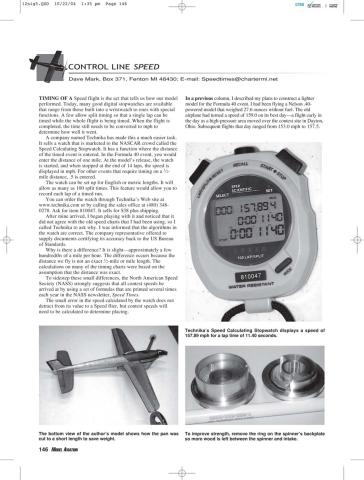

A company named Technika has made this a much easier task.

It sells a watch that is marketed to the NASCAR crowd called the

Speed Calculating Stopwatch. It has a function where the distance

of the timed event is entered. In the Formula 40 event, you would

enter the distance of one mile. At the model’s release, the watch

is started, and when stopped at the end of 14 laps, the speed is

displayed in mph. For other events that require timing on a 1⁄2-

mile distance, .5 is entered.

The watch can be set up for English or metric lengths. It will

allow as many as 100 split times. This feature would allow you to

record each lap of a timed run.

You can order the watch through Technika’s Web site at

www.technika.com or by calling the sales office at (480) 348-

0278. Ask for item 810047. It sells for $38 plus shipping.

After mine arrived, I began playing with it and noticed that it

did not agree with the old speed charts that I had been using, so I

called Technika to ask why. I was informed that the algorithms in

the watch are correct. The company representative offered to

supply documents certifying its accuracy back to the US Bureau

of Standards.

Why is there a difference? It is slight—approximately a few

hundredths of a mile per hour. The difference occurs because the

distance we fly is not an exact 1⁄2-mile or mile length. The

calculations on many of the timing charts were based on the

assumption that the distance was exact.

To sidestep these small differences, the North American Speed

Society (NASS) strongly suggests that all contest speeds be

arrived at by using a set of formulas that are printed several times

each year in the NASS newsletter, Speed Times.

The small error in the speed calculated by the watch does not

detract from its value to a Speed flier, but contest speeds will

need to be calculated to determine placing.

CONTROL LINE SPEED

Dave Mark, Box 371, Fenton MI 48430; E-mail: [email protected]

Technika’s Speed Calculating Stopwatch displays a speed of

157.89 mph for a lap time of 11.40 seconds.

The bottom view of the author’s model shows how the pan was

cut to a short length to save weight.

To improve strength, remove the ring on the spinner’s backplate

so more wood is left between the spinner and intake.

In a previous column, I described my plans to construct a lighter

model for the Formula 40 event. I had been flying a Nelson .40-

powered model that weighed 27.6 ounces without fuel. The old

airplane had turned a speed of 159.0 on its best day—a flight early in

the day as a high-pressure area moved over the contest site in Dayton,

Ohio. Subsequent flights that day ranged from 153.0 mph to 157.5.

12sig5.QXD 10/22/04 1:35 pm Page 146

My new model weighs 21.9 ounces

without fuel. It is constructed from

basswood and balsa wood. The only hightech

items used in its construction were

four strips of .015 x .25 x 12-inch carbon

fiber that I inserted into the LE and TE of

the wing to increase resistance to

handling dents.

During the 2004 contest season, the

model finished second at the Nats and

took three first places with a best speed of

161.1. The decrease in weight has been

good for roughly 3 mph. This is a great

return for the effort at weight reduction.

Holding the length of the magnesium

pan to 5.25 inches produced a large

weight savings. The pan is held in place

with four bolts. Two are located just

behind the spinner and two are at the very

rear of the pan. The area behind the pan

was replaced with a carved balsa block.

I tried to use 1⁄64 plywood that I

wrapped around a form. This was lighter,

but it did not have the strength to resist

my grip. I hold onto this section of the

model when starting the engine.

The crutch for the body was cut from

1⁄2 basswood. The sidewall area of the

crutch behind the wing was cut to 3⁄32 inch

in thickness. The area from the wing to

the rear of the model was covered with

1⁄64 plywood.

One problem area to watch out for in

the crutch is the small section between the

spinner and the front intake. This area

will get so thin that it is easily broken

during building. To strengthen this

section, epoxy a piece of 1⁄4 basswood

with the grain running across the crutch

or 90° to the crutch grain. This will

strengthen the nose tremendously.

The backplate of the Nelson spinner

should be modified as shown in the

December 2004 147

picture so that the clearance required for it

is reduced. The center-section of the wing

is cut in a diamond shape from 1⁄4

basswood. The center of the diamond

measures 1⁄8-inch wider than the 13⁄4-inch

Morris bellcrank. The basswood diamond

tapers to 1⁄4-inch wide at the wingtips. On

the inboard side of the diamond, 3⁄32-inch

grooves are cut in the front and back for

the control wires.

The LEs and TEs are made from

lightweight 1⁄4 balsa. These will dent easily

and possibly blow off at high speed. By

inserting the strips of carbon fiber

described earlier in the LE and TE on each

side of the wing, that can be stopped. It

will stiffen the balsa without a large weight

gain.

The stabilizer is 1⁄8 basswood. It is

important to cut a large radius on the tip of

the stabilizer and wing. If the tips remain

square, they will flutter and wipe off great

amounts of speed before they fail.

The model was finished with two coats

of epoxy resin. The first coat was applied,

and after five minutes, all of the resin that

had not soaked in was wiped off with paper

towel. I sanded the model, dusted it off,

and applied another coat of resin. I wiped

off the excess after five minutes, sanded it

again, then applied two coats of clear dope

thinned 50%.

Initially I used a 11⁄8-inch wheel on my

model in an effort to keep the weight

down. This resulted in an airplane that

rolled toward a stop and then gently

flipped over. A larger wheel changed this

inelegant finish into a good flight.

Many modelers think that to begin

flying Speed, they need the most high-tech

model. This information shows that it is

not the case. You don’t need a molded

carbon-fiber model to be competitive. A

clean model, constructed from standard

basswood and balsa, will get the beginner

started.

Anyone who has an interest in flying

Speed should consider joining NASS. The

group’s newsletter is published four times

a year. It is filled with information about

model design and engine work, contains

contest reports and a parts finder, and

features many other items relating to

Speed. The Web site is www.clspeed.com,

or write to Box 371, Fenton MI 48430. MA

www.modelaircraft.org

12sig5.QXD 10/22/04 1:35 pm Page 147

Edition: Model Aviation - 2004/12

Page Numbers: 146,147

Edition: Model Aviation - 2004/12

Page Numbers: 146,147

146 MODEL AVIATION

TIMING OF A Speed flight is the act that tells us how our model

performed. Today, many good digital stopwatches are available

that range from those built into a wristwatch to ones with special

functions. A few allow split timing so that a single lap can be

timed while the whole flight is being timed. When the flight is

completed, the time still needs to be converted to mph to

determine how well it went.

A company named Technika has made this a much easier task.

It sells a watch that is marketed to the NASCAR crowd called the

Speed Calculating Stopwatch. It has a function where the distance

of the timed event is entered. In the Formula 40 event, you would

enter the distance of one mile. At the model’s release, the watch

is started, and when stopped at the end of 14 laps, the speed is

displayed in mph. For other events that require timing on a 1⁄2-

mile distance, .5 is entered.

The watch can be set up for English or metric lengths. It will

allow as many as 100 split times. This feature would allow you to

record each lap of a timed run.

You can order the watch through Technika’s Web site at

www.technika.com or by calling the sales office at (480) 348-

0278. Ask for item 810047. It sells for $38 plus shipping.

After mine arrived, I began playing with it and noticed that it

did not agree with the old speed charts that I had been using, so I

called Technika to ask why. I was informed that the algorithms in

the watch are correct. The company representative offered to

supply documents certifying its accuracy back to the US Bureau

of Standards.

Why is there a difference? It is slight—approximately a few

hundredths of a mile per hour. The difference occurs because the

distance we fly is not an exact 1⁄2-mile or mile length. The

calculations on many of the timing charts were based on the

assumption that the distance was exact.

To sidestep these small differences, the North American Speed

Society (NASS) strongly suggests that all contest speeds be

arrived at by using a set of formulas that are printed several times

each year in the NASS newsletter, Speed Times.

The small error in the speed calculated by the watch does not

detract from its value to a Speed flier, but contest speeds will

need to be calculated to determine placing.

CONTROL LINE SPEED

Dave Mark, Box 371, Fenton MI 48430; E-mail: [email protected]

Technika’s Speed Calculating Stopwatch displays a speed of

157.89 mph for a lap time of 11.40 seconds.

The bottom view of the author’s model shows how the pan was

cut to a short length to save weight.

To improve strength, remove the ring on the spinner’s backplate

so more wood is left between the spinner and intake.

In a previous column, I described my plans to construct a lighter

model for the Formula 40 event. I had been flying a Nelson .40-

powered model that weighed 27.6 ounces without fuel. The old

airplane had turned a speed of 159.0 on its best day—a flight early in

the day as a high-pressure area moved over the contest site in Dayton,

Ohio. Subsequent flights that day ranged from 153.0 mph to 157.5.

12sig5.QXD 10/22/04 1:35 pm Page 146

My new model weighs 21.9 ounces

without fuel. It is constructed from

basswood and balsa wood. The only hightech

items used in its construction were

four strips of .015 x .25 x 12-inch carbon

fiber that I inserted into the LE and TE of

the wing to increase resistance to

handling dents.

During the 2004 contest season, the

model finished second at the Nats and

took three first places with a best speed of

161.1. The decrease in weight has been

good for roughly 3 mph. This is a great

return for the effort at weight reduction.

Holding the length of the magnesium

pan to 5.25 inches produced a large

weight savings. The pan is held in place

with four bolts. Two are located just

behind the spinner and two are at the very

rear of the pan. The area behind the pan

was replaced with a carved balsa block.

I tried to use 1⁄64 plywood that I

wrapped around a form. This was lighter,

but it did not have the strength to resist

my grip. I hold onto this section of the

model when starting the engine.

The crutch for the body was cut from

1⁄2 basswood. The sidewall area of the

crutch behind the wing was cut to 3⁄32 inch

in thickness. The area from the wing to

the rear of the model was covered with

1⁄64 plywood.

One problem area to watch out for in

the crutch is the small section between the

spinner and the front intake. This area

will get so thin that it is easily broken

during building. To strengthen this

section, epoxy a piece of 1⁄4 basswood

with the grain running across the crutch

or 90° to the crutch grain. This will

strengthen the nose tremendously.

The backplate of the Nelson spinner

should be modified as shown in the

December 2004 147

picture so that the clearance required for it

is reduced. The center-section of the wing

is cut in a diamond shape from 1⁄4

basswood. The center of the diamond

measures 1⁄8-inch wider than the 13⁄4-inch

Morris bellcrank. The basswood diamond

tapers to 1⁄4-inch wide at the wingtips. On

the inboard side of the diamond, 3⁄32-inch

grooves are cut in the front and back for

the control wires.

The LEs and TEs are made from

lightweight 1⁄4 balsa. These will dent easily

and possibly blow off at high speed. By

inserting the strips of carbon fiber

described earlier in the LE and TE on each

side of the wing, that can be stopped. It

will stiffen the balsa without a large weight

gain.

The stabilizer is 1⁄8 basswood. It is

important to cut a large radius on the tip of

the stabilizer and wing. If the tips remain

square, they will flutter and wipe off great

amounts of speed before they fail.

The model was finished with two coats

of epoxy resin. The first coat was applied,

and after five minutes, all of the resin that

had not soaked in was wiped off with paper

towel. I sanded the model, dusted it off,

and applied another coat of resin. I wiped

off the excess after five minutes, sanded it

again, then applied two coats of clear dope

thinned 50%.

Initially I used a 11⁄8-inch wheel on my

model in an effort to keep the weight

down. This resulted in an airplane that

rolled toward a stop and then gently

flipped over. A larger wheel changed this

inelegant finish into a good flight.

Many modelers think that to begin

flying Speed, they need the most high-tech

model. This information shows that it is

not the case. You don’t need a molded

carbon-fiber model to be competitive. A

clean model, constructed from standard

basswood and balsa, will get the beginner

started.

Anyone who has an interest in flying

Speed should consider joining NASS. The

group’s newsletter is published four times

a year. It is filled with information about

model design and engine work, contains

contest reports and a parts finder, and

features many other items relating to

Speed. The Web site is www.clspeed.com,

or write to Box 371, Fenton MI 48430. MA

www.modelaircraft.org

12sig5.QXD 10/22/04 1:35 pm Page 147