GWS A-10 Warthog

18 MODEL AVIATION

Use of curved trim adjacent to straight lines on wing gives

illusion of elliptical planform. Phil looks justifiably proud!

by Phil Granderson

IN 1980 I was fortunate to compete in the Control Line World

Championships in Poland. As a member of the Combat team, I

captured the Bronze Medal for the USA.

The CL Precision Aerobatics (Stunt) contingent was the

“Dream Team” of Bob Hunt, Les McDonald, Bill Werwage, and

Wynn Paul. Bob was the defending World Champion, Les is a

three-time World Champion, and Bill is a three-time World

Champion and the first American to win a World Championships.

Those guys were there to win. And they did! Les, Bob, and Bill

took the Gold, Silver, and Bronze medals in that order.

There was a wealth of knowledge in just watching them and

learning. Today two of them are still fierce competitors and good

friends. Although Les McDonald is no longer competing, he left a

wealth of knowledge with his Stiletto series of aircraft.

I remember thinking, “As soon as I win a Combat World

Championships, I’ll switch hats and become a Stunt World

Champion.” How hard could it be? Now that you’re laughing,

let’s get to work.

Stylish, elegant CL

Stunter designed with

original thinking

@@Web Extra

February 2005 19

The entire model is covered with .2-ounce carbon mat, applied with modeling dope.

When fully cured, the carbon makes the airframe incredibly stiff.

The Diva in the foreground features a built-up Lost Foam wing, and the one in the

background was built using a foam-core wing. Both fly extremely well!

The Diva sits low and has great ground-handling qualities. An outstanding blend of

aesthetic features gives this aircraft an original flair.

Photos by Roger Grotheer

Many people are looking for simplicity in a

complex world. That was exactly my

thinking when I began the Diva odyssey six

years ago; just build a distinctive box

around a proven formula. After exploring

and observing a variety of proven formulas,

it became apparent that this approach simply

would not produce the airplane I envisioned.

So what is Diva? It is the culmination of

a few ideas and experiments that worked

well and the exclusion of many ideas and

experiments that either did not work at all or

worked poorly. It is an original work.

From the high cheek cowls, to the

canopy, to the rudder, it is different. Top,

front, and side views reveal that it is unique.

The thinking and application of power is

different. The airfoil is original.

You might ask the question, Why

reinvent the wheel? That was never my

intention, but if you look closely you will

see that the wheel was tweaked in some

unique ways.

Beginning in the late 1960s, there were

experiments with extremely long tail

moments, gapless hinge lines, variations on

rudder offset, engine side thrust and

downthrust, numerous airfoils, and far too

many ideas and experiments with engines.

Through all of that, somehow I still have old

sketches, templates, and garbled notes

tucked away in boxes and files that have

been moved countless times.

In November 1998 construction began

on the first Diva. Rather than wading into

the whole thing blindly, I applied a process

that had proved successful for me and

countless others. It was simply to formulate

a plan, make modifications when and where

required, but, most important, never lose

sight of the original goal. This had worked

quite nicely in my Combat endeavors and in

business. So here’s the plan.

First, set a goal. You’ve probably heard

the question, How will you get there if you

don’t know where you’re going? The goal

was to design and refine a world-class CL

Aerobatics airplane. The model would

someday win a World Championships—

preferably with me as the pilot. Today I’m

much closer and having so much fun that

the only slightly painful chore so far is

writing this article; I’d rather be building or

flying!

The first Diva was promptly renamed

“Ante” when my wife Kathleen made the

observation that the paint scheme I planned

did not look like a Diva. Ante was the first

airplane to emerge from my clean-slate

approach to design. Its maiden flight was

eight months after I cut the first piece of

wood.

This was the watershed project. I was

going for the whole package: distinctive

looks, front-row finish, piped engine, and

world-class performance. The results fell

somewhat short of the goal.

A summary of the results was that the

finishing system worked well and was

relatively easy to apply. Ante was a frontrow

airplane. The piped PA .65 engine

performed well. The wing with the unique

tra

20 MODEL AVIATION

A close-up shows the wraparound header that is available from Aero Products to fit the

Magnum .36. The company also handles the carbon pipe for that engine.

Phil has developed a method of using a computer to design his complete trim scheme.

This allows an infinite amount of adjusting and brainstorming.

airfoil that was developed and implemented

on the Triumph model built in 1969 worked

exactly as I remembered it, generating a great

deal of lift with no real side effects.

There were also some primary things that

didn’t work. I was completely baffled about

why the tried-and-true combination of long

tail moment and relatively small stabilizer/

elevator size suddenly didn’t work as it did

on so many of my previous designs. The

Ante had no problem turning, but it was

difficult once the turn started to get it

stopped. I also noticed that it required more

force on the handle to turn outside.

The design had an assortment of inherent

problems that could not be corrected by

adjusting, tweaking, and trimming. And

finally, the line tension was way beyond my

tolerance level.

I knew after roughly 20 flights with this

airplane that the next model would have

major modifications. Ante was left in its “best

flight condition” and would serve as a

measurement for changes and improvements

to subsequent airplanes. To this day, it is still

the control for all my experiments.

The second airplane—appropriately

painted and approved for the name Diva—

had four significant changes: equal-span

panels, less wing area, the elevator and

stabilizer were moved down closer to the

thrustline, and the stabilizer/elevator area was

increased to 26% of the wing area.

There were other changes too. The tail

moment was shortened 1⁄2 inch to compensate

for the larger stabilizer’s additional weight.

The wingtip shape was changed slightly. The

flap area was reduced by 5%, and the fueltank

compartment was expanded to allow the

tank to be moved backward and forward an

additional 2 inches. I also took much more

care in the alignment and setup of the entire

airplane.

Ultimately I installed the faithful PA .65.

It was apparent from the first flights that

these changes made significant

improvements in the overall performance.

The whole package seemed to come together.

Most noticeable was the marked

improvement in tracking. There was no more

hunting, and the overturning problem was

completely gone. Additionally, control

pressure for outside and inside maneuvers

was the same. Line tension was reduced

slightly.

The Diva’s finish was even slicker and

shinier than the one applied to the Ante. The

horizontally adjustable tank proved to be

golden for finding the perfect CG. I could

move the CG aft or forward by 1 inch

without adding weight.

Another bonus from the tank arrangement

was that the CG did not shift as much from

the beginning of the flight to the end. This

was indeed a marked improvement over

Ante. Flight scores immediately rose and

were continuing to improve. It even captured

my first Concours d’Elegance award.

I was just beginning to appreciate and

enjoy the fruits of my labor when disaster

struck. In what could only be called the

dumbest thing I’ve ever done, my brain died

and I hooked up the handle upside down and

never did a preflight check! It’s been said that

few people have ever saved an airplane from

crashing with the controls reversed. I was not

one of the few!

The Diva’s 36th flight is now

memorialized by its unique dent in the

blacktop at Whittier Narrows in Southern

California. I still chuckle when I visualize

Keith Trostle chasing it around the circle as

the nose was firmly planted and the PA .65

chewing up the carbon propeller just before

performing its brief fatal maneuver. No one

ever imagined Keith could move that fast!

Within minutes of the disaster, the

model’s remains were loaded into the van

and I started the six-hour drive home. I spent

the first three hours of the drive chewing

myself out and the next three planning my

recovery.

I arrived home at 4:24 p.m., unloaded the

van, got a sandwich, and began cutting balsa.

By 7 p.m., I had the fuselage sides cut and the

doublers clamped and laminated.

Construction of “Diva 2 Quick”

February 2005 21

Phil notches the wing LE to allow for more tank-compartment

room. This also puts the fuel’s weight closer to the model’s CG.

How is this for an inspirational photo? All components are built

and ready to assemble. Note the extremely clean workmanship.

Type: CL Aerobatics

Wingspan: 58 inches

Engine: .36-.65

Flying weight: 50-62 ounces

Construction: Balsa and plywood

Covering/finish: .2-ounce carbon mat, light-grade silkspan

and modeling dope, clear automotive topcoat

progressed at breakneck speed. It was ready

for the maiden flight August 28—just seven

weeks after cutting the first piece of wood.

There were no big changes from its

predecessor. I did make the stabilizer slightly

bigger and added ribs to make it lighter. I

lengthened the tail back to the original 21

inches used on the Ante. I also used thinner

balsa for the rudder (3⁄16) and left it flat. It

flew virtually the same as its forerunner and

was easier to trim.

By all accounts and observations,

everything worked very well. The model

looked good, it flew really well, I looked

comfortable flying it, and flight scores were

on the rise again. It was fairly easy to

“practice myself” into this airplane, but I

wanted an airplane to practice with rather

than one to practice for.

Wow, the truth can hurt! I had invested

serious time, effort, wood, and money in

creating a great airplane, and I wasn’t happy.

What would I have rather been flying? How

about an airplane that was as positive as the

Diva and as refined and nimble as a finely

tuned Classic aircraft? As I sat in my shop,

the Classic models began talking to me.

“Hey Phil, over here. I’m your Vulcan;

I’ll be nice to you. You can relax; fly me!”

“Me too! I’m your Lark; ditto what the

Vulcan said.”

The task was clear: tame and refine the

60-size airplane’s edginess and brute force. I

would have to break the mold that I

painstakingly crafted in the first three

airplanes. I would have to redesign, reengineer,

and reinvent a major portion of an

excellent airplane.

Was there a smaller, lighter engine that

would make the right kind and amount of

power? What size should the new Diva be to

score well when big airplanes generally score

better? It was impractical to simply downsize

Diva by a specific percentage.

The toughest task would be to find a

readily available engine with the right kind

and amount of power. It would also have to

Wood Weights and Measures

Thickness Length (inches) Weight (grams) Length Weight (grams)

1/16 3 x 36 8-11 4 x 36 11-14

3/32 3 x 36 12-16 4 x 36 17-21

1/8 3 x 36 18-21 4 x 36 21-28

3/16 3 x 36 24-30 4 x 36 32-43

1/4 3 x 36 32-42 4 x 36 43-57

3/8 3 x 36 48-63 4 x 36 63-83

1/2 3 x 36 62-85 4 x 36 81-110

1/16 3 x 48 11-14 4 x 48 15-18

3/32 3 x 48 17-21 4 x 48 23-28

1/8 3 x 48 21-28 4 x 48 28-37

3/16 3 x 48 33-40 4 x 48 44-56

1/4 3 x 48 44-57 4 x 48 56-75

3/8 3 x 48 63-85 4 x 48 84-112

1/2 3 x 48 86-112 4 x 48 114-150

be light and manufactured to consistently high

standards. If such an engine could be found

and possessed good Stunt fundamentals, I was

confident in my ability to identify and make

modifications if necessary.

Believing that most modern 40-size

engines had plenty of power, the quest began

to find the best one for the refined Diva. I

started collecting every 25- to 40-size engine I

could find. Since I had conducted no tests, my

only requirement was that it could not weigh

more than 91⁄2 ounces.

In December 2001 I began testing and

evaluating eight engines. In the end, the

Magnum .36 was clearly the top contender. It

weighed only 81⁄4 ounces and easily turned an

11-inch propeller more than 11,000 rpm. The

next step was to install a pipe and put the

engine in a model to see if the power could be

controlled.

The only airplane I was willing to sacrifice

with all the modifications necessary was my

15-year-old Et al, which had a 21-inch tail

moment, 600 square inches of wing area, and

weighed 54 ounces with the engine and pipe

installed and ready to fly.

The first 20 flights were interesting in that

most were spent finding the right pipe and

length. I used a Bolly 12 x 4 narrow-blade

propeller cut to 11 inches.

My suspicions about usable power were

confirmed. There was definitely a great deal

of power, and it seemed quite usable. Most of

those flights were with the engine not running

“on the pipe” and revealed a flat power curve

and the smooth delivery of more power

exactly when and where it was necessary.

At this point the pipe was just a muffler.

The engine was happy being launched at a

soft two-cycle and would break into a

controlled faster speed the moment the nose

was pointed up and then back into its soft

phase as soon as the model returned to level.

There was also no tendency to wind up or

charge at any point. It seemed to “come on” in

all the right places.

The first flight with the pipe in the range

(on the pipe) produced a noticeably stronger

feel everywhere in the pattern, and lap times

went from 5.0 to 5.4. When the needle was

turned in slightly to get to 5.2 lap times, the

engine and airplane were ecstatic, and I

couldn’t keep myself from joining in the

celebration by pushing that old model to

previously unobtainable performance levels.

Since I felt comfortable with the engine, I

was able to turn my focus to the new aircraft.

It would have to be smaller and lighter but

still have that “big airplane” presence.

Deciding that it would probably be a series of

design modifications, I decided to build the

first version only slightly smaller than the

previous .65-powered Divas.

The Ante has 750 square inches of wing

area, and the two larger Divas have 710-

square-inch wings. The wing area presented

here is only 4% less; in fact, there is as much

as in most modern .60-powered models that

are flown today. The tail moment is 18.5

inches, which is slightly longer than most

other airplanes. The fuselage is massive. The

elevator/stabilizer area is medium to small

compared to many models’.

After the first flight, it was apparent that

Diva IV was something special. My good

friend Jim Aron remarked candidly, “I’ve

seen the first flights of your previous

airplanes, and this is the first time I’ve ever

seen you smile!”

To date, there are two smaller Divas, each

weighing 57 ounces. One has a foam-core

wing with balsa sheeting, and the other uses

the Lost Foam Wing Building System

construction shown on the plans.

As an experiment, I used stick-on weights

to increase the overall weight to 64 ounces,

just to see what would happen. The only

noticeable difference was more line tension.

There was still plenty of power, and the Diva

didn’t hesitate anywhere in the pattern.

In general, the two primary components of

any design are aerodynamics and power

dynamics. Aerodynamics is the science of

solid bodies moving through air. Diva was

designed for competition from the beginning.

It is an aerodynamic package that produces a

stable solution for a set of complex and

complicated variables.

Provisions have been made and tested that

allow for the variety of adjustments necessary

to bring the entire package into your personal

comfort zone without adversely affecting

visual presentation or limiting flight

performance.

In our world, power dynamics consists of

two primary components. For our purpose, the

engine is a simple pump that converts fuel to

energy and directs the energy to a specific

output. Integral to this pump is a simple

transmission system. It comprises the

propeller and an adjustable exhaust timing

device (tuned pipe).

The propeller acts as a gear and a final

power converter. The pipe regulates the

time, delivery, and consistency of power. It

is a static throttle of sorts. The whole system

is actually quite primitive because its

components are overtly static, but it is

elegant in its simplicity. When properly

installed and adjusted, it delivers consistent,

reliable, usable power.

So if that’s all there is, why is it so

difficult to get everything working the way

you want?

How you attack a problem is the key.

When you are on the flightline, how things

work is far more important than why they

work. These two factors should not be

interchangeable, although frequently they

are.

When you ask the question “How does it

work?” the answer should be “good” or

“bad.” These answers ultimately quantify

results because if you are honest, they

confirm or deny the need for change.

When you ask “Why does it work?” the

quest for an answer suddenly becomes

complex. Ask those questions and see for

yourself. An analogy would be that you

don’t have to know why a television works

to be satisfied with how it works. This

translates to our sport quite nicely. Ask how

and make progress; ask why and ponder.

The preceding is not intended to be a

brainteaser, but rather a systematic approach

to problem solving and a foundation for

performance building and enhancement.

Before beginning construction, let’s look at

the whole package. In the past six years of

concentrated building and developing the

Diva, I have come to understand and

separate much fact from fiction. This

process is not too different from my

experiences in competitive Combat flying

and business. Following are some facts I

have learned.

• A good contest-caliber finish adds 7-10

ounces from bare wood.

• A light finish cannot save a heavy airplane.

• Good wood is 4-6 pounds per cubic foot. It

is rare to find good wood that weighs less

than 4.5 pounds, and, for our purposes, it

should never exceed 6 pounds stock.

• In an aerodynamically well-designed

airplane, weight distribution is far more

important than weight conservation.

• The three most significant trim

adjustments are CG, propeller, and control

system. You can only use as much power as

you need. Excess power will probably find a

way to work against you.

Look closely at the plans and you will

see some things that are out of the norm.

These differences are what make the whole

package work. Everything on the plans is

there for a reason.

The majority of details relate to function.

If you build the airplane per the plans—at a

finished weight of 62 ounces or less—and

build it accurately and straight, you will be

pleased. Actually, the only frill is the little

faux air scoop on the bottom of the cowl.

Following are details of note.

• The fuselage gets wider at the midpoint

and remains fairly wide where the stabilizer

is mounted.

• The tank compartment is slightly wider

than most, at 23⁄32 inches.

• The wing LE at the root inside the fuselage

has a recessed cavity for tank adjustment.

• Cheek cowls terminate on the wing top at

the high point of the root airfoil.

• The fuselage is deep at the dorsal fin. The

rudder is 1⁄8 balsa.

• There is 3° of permanent rudder offset.

• There is no engine offset.

• The airfoil is completely different at the

root than at the tip.

• The wing panels have equal spans.

• The outboard flap is 1⁄4 inch longer than

the inboard flap.

• The control system is completely adjustable.

• There is a large air inlet in the cowl.

• The air outlet in the fuselage around the pipe

is roughly three times that of the cowl inlet.

• Control horns are made from 3⁄32-inchdiameter

wire.

Construction is probably not for a

beginner, but an accomplished Advanced

competitor or builder should have no

problems. Diva makes extensive use of

molded-balsa components. The cheek cowls,

aft fuselage top block, bottom fuselage block,

most of the cowl, and LE sheeting are molded

balsa.

Having built several wings using the Lost

Foam Wing Building System, I do not hesitate

to recommend it. The Diva IV has a

traditional foam-core, balsa-sheeted wing that

performs equal to the built-up wing.

The entire model is covered with .02-

ounce carbon veil before finishing. In a builtup

wing, cover the entire structure—including

open bays and rib capstrips—with the veil and

cut the openings before final covering. See the

photo. Final wing covering of open bays is

done with silkspan.

Wood selection is crucial for strength and

weight. Today, grain type is less critical with

the use of carbon veil before the final finish.

The accompanying wood-weight chart refers

to common balsa lengths and thicknesses, but

the plans call for extensive use of .077-inchthick

wood. The weights for 1⁄16 wood in the

chart should be close to those for the .077

wood.

Most of the custom-cut, contest-gradewood

suppliers will cut the thicker wood

when requested. As a general rule, it is

preferable for thicker pieces to bias to the

lighter side of the chart. You will also find

exceptional wood that is actually lighter and

obviously usable. The chart is only a gauge.

My favorite method of building is to

complete entire components. I finish the wing

with controls installed and tips and flaps

shaped and fitted. Hinge slots and hinges are

fitted.

I complete the fuselage with the cowl and

front hold downs installed and all top blocks

and 1⁄32-inch cross-grain sheeting on the

bottom permanently glued, leaving only the

opening for the wing. This is critical for final

assembly because the fuselage can twist if

it’s not stabilized by permanent installation

of major components.

The landing-gear mount and rear cowl

hold down are integrated and can only be

installed after the wing is permanently glued

in. The elevator/stabilizer assembly is

completely built, with all hinges aligned and

test fitted. The control horn is permanently

attached to the stabilizer. The rudder is

completed with the dorsal fin. See the photos

for final-assembly clarification.

Volumes have been written about

construction methods. If you want to know

more about two-stroke engines, Larry

Scarinzi’s “Blitz” article from the mid-1960s

is a must read. Bob Gaildini’s “Olympic”

article from 1963 is the definitive work for

CL Stunt aircraft-design considerations.

Robin’s View Productions, Windy

Urtnowski, and a host of other sources have

produced videotapes chronicling everything

from wood selection to finishing to installing

tail wheels. Get your hands on as much

information as you can and digest it. Your

building will improve measurably and

quickly as you gain knowledge.

As with any successful venture, countless

people have made contributions. My

grandmother helped me with words as I

struggled to read model-airplane magazines

when I was 7 years old. My mother was my

lone defender when the house was filled with

modeling-dope fumes and the rest of the

family voted to disown me.

Mrs. Norton, who owned the local hobby

shop, extended credit to me at the age of 16

and introduced me to Ed Southwick and

Dick McCoy. This publication’s

aeromodeling editor has been a great friend

for the past 30 years, and with him I have

debated and shared thoughts on almost

everything.

I must mention Brett Buck; in my humble

opinion, he is the ultimate guru when it

comes to trimming and adjusting just about

anything on a Stunt model. There is also Jim

Aron—one of very few who could ask for

and actually get a piece of my best wood.

And I can’t leave out Ted Fancher and Dave

Fitzgerald, who are my protagonists.

I hope you’ve enjoyed the preceding and

found it informative. As you persist in your

quest for the perfect Stunt pattern, I leave

you with one simple thought: rely on the fact

that something is working to validate the

fact that it does work. MA

Phil Granderson

13250 Campus Dr.

Oakland CA 94619

(Editor’s note: We have chosen a

portion of Phil’s “Diva” article to be the

subject of our new online feature that we

call MA “Web Extra.”

As he explained, Phil designed his Diva

with a specific engine size and type in mind.

Moreover, he used a carbon-fiber tuned pipe

to augment the engine’s power and to contour

its power output to a specific rpm band. This

is an interesting subject, and not much is

written about how it works or the practical

specifics of how to properly set up and adjust

a piped system.

Whether you intend to build the Diva or

not, this online material is interesting and

educational. Give it a look; go to

www.modelaircraft.org and then to the

MA Web Extra section.)

Sources:

Lost Foam Wing Building Systems, fully

assembled Lost Foam wings, Lost Foam

video sets, building videos, foam wing cores,

covered foam wings:

Robin’s View Productions

Box 68

Stockertown PA 18083

(610) 746-0106

Building videos:

Windy Urtnowski

93 Elliott Pl.

Rutherford NJ 07070

(201) 896-8740

Magnum .36 engines, side-to-rear exhaust

manifolds, carbon-fiber AeroPipes—tuned

pipes:

Aero Products

980 Winnbrook Dr.

Dacula GA 30019

(678) 407-9376

Edition: Model Aviation - 2005/02

Page Numbers: 18,19,20,21,22,23,24,25,26,28

Edition: Model Aviation - 2005/02

Page Numbers: 18,19,20,21,22,23,24,25,26,28

GWS A-10 Warthog

18 MODEL AVIATION

Use of curved trim adjacent to straight lines on wing gives

illusion of elliptical planform. Phil looks justifiably proud!

by Phil Granderson

IN 1980 I was fortunate to compete in the Control Line World

Championships in Poland. As a member of the Combat team, I

captured the Bronze Medal for the USA.

The CL Precision Aerobatics (Stunt) contingent was the

“Dream Team” of Bob Hunt, Les McDonald, Bill Werwage, and

Wynn Paul. Bob was the defending World Champion, Les is a

three-time World Champion, and Bill is a three-time World

Champion and the first American to win a World Championships.

Those guys were there to win. And they did! Les, Bob, and Bill

took the Gold, Silver, and Bronze medals in that order.

There was a wealth of knowledge in just watching them and

learning. Today two of them are still fierce competitors and good

friends. Although Les McDonald is no longer competing, he left a

wealth of knowledge with his Stiletto series of aircraft.

I remember thinking, “As soon as I win a Combat World

Championships, I’ll switch hats and become a Stunt World

Champion.” How hard could it be? Now that you’re laughing,

let’s get to work.

Stylish, elegant CL

Stunter designed with

original thinking

@@Web Extra

February 2005 19

The entire model is covered with .2-ounce carbon mat, applied with modeling dope.

When fully cured, the carbon makes the airframe incredibly stiff.

The Diva in the foreground features a built-up Lost Foam wing, and the one in the

background was built using a foam-core wing. Both fly extremely well!

The Diva sits low and has great ground-handling qualities. An outstanding blend of

aesthetic features gives this aircraft an original flair.

Photos by Roger Grotheer

Many people are looking for simplicity in a

complex world. That was exactly my

thinking when I began the Diva odyssey six

years ago; just build a distinctive box

around a proven formula. After exploring

and observing a variety of proven formulas,

it became apparent that this approach simply

would not produce the airplane I envisioned.

So what is Diva? It is the culmination of

a few ideas and experiments that worked

well and the exclusion of many ideas and

experiments that either did not work at all or

worked poorly. It is an original work.

From the high cheek cowls, to the

canopy, to the rudder, it is different. Top,

front, and side views reveal that it is unique.

The thinking and application of power is

different. The airfoil is original.

You might ask the question, Why

reinvent the wheel? That was never my

intention, but if you look closely you will

see that the wheel was tweaked in some

unique ways.

Beginning in the late 1960s, there were

experiments with extremely long tail

moments, gapless hinge lines, variations on

rudder offset, engine side thrust and

downthrust, numerous airfoils, and far too

many ideas and experiments with engines.

Through all of that, somehow I still have old

sketches, templates, and garbled notes

tucked away in boxes and files that have

been moved countless times.

In November 1998 construction began

on the first Diva. Rather than wading into

the whole thing blindly, I applied a process

that had proved successful for me and

countless others. It was simply to formulate

a plan, make modifications when and where

required, but, most important, never lose

sight of the original goal. This had worked

quite nicely in my Combat endeavors and in

business. So here’s the plan.

First, set a goal. You’ve probably heard

the question, How will you get there if you

don’t know where you’re going? The goal

was to design and refine a world-class CL

Aerobatics airplane. The model would

someday win a World Championships—

preferably with me as the pilot. Today I’m

much closer and having so much fun that

the only slightly painful chore so far is

writing this article; I’d rather be building or

flying!

The first Diva was promptly renamed

“Ante” when my wife Kathleen made the

observation that the paint scheme I planned

did not look like a Diva. Ante was the first

airplane to emerge from my clean-slate

approach to design. Its maiden flight was

eight months after I cut the first piece of

wood.

This was the watershed project. I was

going for the whole package: distinctive

looks, front-row finish, piped engine, and

world-class performance. The results fell

somewhat short of the goal.

A summary of the results was that the

finishing system worked well and was

relatively easy to apply. Ante was a frontrow

airplane. The piped PA .65 engine

performed well. The wing with the unique

tra

20 MODEL AVIATION

A close-up shows the wraparound header that is available from Aero Products to fit the

Magnum .36. The company also handles the carbon pipe for that engine.

Phil has developed a method of using a computer to design his complete trim scheme.

This allows an infinite amount of adjusting and brainstorming.

airfoil that was developed and implemented

on the Triumph model built in 1969 worked

exactly as I remembered it, generating a great

deal of lift with no real side effects.

There were also some primary things that

didn’t work. I was completely baffled about

why the tried-and-true combination of long

tail moment and relatively small stabilizer/

elevator size suddenly didn’t work as it did

on so many of my previous designs. The

Ante had no problem turning, but it was

difficult once the turn started to get it

stopped. I also noticed that it required more

force on the handle to turn outside.

The design had an assortment of inherent

problems that could not be corrected by

adjusting, tweaking, and trimming. And

finally, the line tension was way beyond my

tolerance level.

I knew after roughly 20 flights with this

airplane that the next model would have

major modifications. Ante was left in its “best

flight condition” and would serve as a

measurement for changes and improvements

to subsequent airplanes. To this day, it is still

the control for all my experiments.

The second airplane—appropriately

painted and approved for the name Diva—

had four significant changes: equal-span

panels, less wing area, the elevator and

stabilizer were moved down closer to the

thrustline, and the stabilizer/elevator area was

increased to 26% of the wing area.

There were other changes too. The tail

moment was shortened 1⁄2 inch to compensate

for the larger stabilizer’s additional weight.

The wingtip shape was changed slightly. The

flap area was reduced by 5%, and the fueltank

compartment was expanded to allow the

tank to be moved backward and forward an

additional 2 inches. I also took much more

care in the alignment and setup of the entire

airplane.

Ultimately I installed the faithful PA .65.

It was apparent from the first flights that

these changes made significant

improvements in the overall performance.

The whole package seemed to come together.

Most noticeable was the marked

improvement in tracking. There was no more

hunting, and the overturning problem was

completely gone. Additionally, control

pressure for outside and inside maneuvers

was the same. Line tension was reduced

slightly.

The Diva’s finish was even slicker and

shinier than the one applied to the Ante. The

horizontally adjustable tank proved to be

golden for finding the perfect CG. I could

move the CG aft or forward by 1 inch

without adding weight.

Another bonus from the tank arrangement

was that the CG did not shift as much from

the beginning of the flight to the end. This

was indeed a marked improvement over

Ante. Flight scores immediately rose and

were continuing to improve. It even captured

my first Concours d’Elegance award.

I was just beginning to appreciate and

enjoy the fruits of my labor when disaster

struck. In what could only be called the

dumbest thing I’ve ever done, my brain died

and I hooked up the handle upside down and

never did a preflight check! It’s been said that

few people have ever saved an airplane from

crashing with the controls reversed. I was not

one of the few!

The Diva’s 36th flight is now

memorialized by its unique dent in the

blacktop at Whittier Narrows in Southern

California. I still chuckle when I visualize

Keith Trostle chasing it around the circle as

the nose was firmly planted and the PA .65

chewing up the carbon propeller just before

performing its brief fatal maneuver. No one

ever imagined Keith could move that fast!

Within minutes of the disaster, the

model’s remains were loaded into the van

and I started the six-hour drive home. I spent

the first three hours of the drive chewing

myself out and the next three planning my

recovery.

I arrived home at 4:24 p.m., unloaded the

van, got a sandwich, and began cutting balsa.

By 7 p.m., I had the fuselage sides cut and the

doublers clamped and laminated.

Construction of “Diva 2 Quick”

February 2005 21

Phil notches the wing LE to allow for more tank-compartment

room. This also puts the fuel’s weight closer to the model’s CG.

How is this for an inspirational photo? All components are built

and ready to assemble. Note the extremely clean workmanship.

Type: CL Aerobatics

Wingspan: 58 inches

Engine: .36-.65

Flying weight: 50-62 ounces

Construction: Balsa and plywood

Covering/finish: .2-ounce carbon mat, light-grade silkspan

and modeling dope, clear automotive topcoat

progressed at breakneck speed. It was ready

for the maiden flight August 28—just seven

weeks after cutting the first piece of wood.

There were no big changes from its

predecessor. I did make the stabilizer slightly

bigger and added ribs to make it lighter. I

lengthened the tail back to the original 21

inches used on the Ante. I also used thinner

balsa for the rudder (3⁄16) and left it flat. It

flew virtually the same as its forerunner and

was easier to trim.

By all accounts and observations,

everything worked very well. The model

looked good, it flew really well, I looked

comfortable flying it, and flight scores were

on the rise again. It was fairly easy to

“practice myself” into this airplane, but I

wanted an airplane to practice with rather

than one to practice for.

Wow, the truth can hurt! I had invested

serious time, effort, wood, and money in

creating a great airplane, and I wasn’t happy.

What would I have rather been flying? How

about an airplane that was as positive as the

Diva and as refined and nimble as a finely

tuned Classic aircraft? As I sat in my shop,

the Classic models began talking to me.

“Hey Phil, over here. I’m your Vulcan;

I’ll be nice to you. You can relax; fly me!”

“Me too! I’m your Lark; ditto what the

Vulcan said.”

The task was clear: tame and refine the

60-size airplane’s edginess and brute force. I

would have to break the mold that I

painstakingly crafted in the first three

airplanes. I would have to redesign, reengineer,

and reinvent a major portion of an

excellent airplane.

Was there a smaller, lighter engine that

would make the right kind and amount of

power? What size should the new Diva be to

score well when big airplanes generally score

better? It was impractical to simply downsize

Diva by a specific percentage.

The toughest task would be to find a

readily available engine with the right kind

and amount of power. It would also have to

Wood Weights and Measures

Thickness Length (inches) Weight (grams) Length Weight (grams)

1/16 3 x 36 8-11 4 x 36 11-14

3/32 3 x 36 12-16 4 x 36 17-21

1/8 3 x 36 18-21 4 x 36 21-28

3/16 3 x 36 24-30 4 x 36 32-43

1/4 3 x 36 32-42 4 x 36 43-57

3/8 3 x 36 48-63 4 x 36 63-83

1/2 3 x 36 62-85 4 x 36 81-110

1/16 3 x 48 11-14 4 x 48 15-18

3/32 3 x 48 17-21 4 x 48 23-28

1/8 3 x 48 21-28 4 x 48 28-37

3/16 3 x 48 33-40 4 x 48 44-56

1/4 3 x 48 44-57 4 x 48 56-75

3/8 3 x 48 63-85 4 x 48 84-112

1/2 3 x 48 86-112 4 x 48 114-150

be light and manufactured to consistently high

standards. If such an engine could be found

and possessed good Stunt fundamentals, I was

confident in my ability to identify and make

modifications if necessary.

Believing that most modern 40-size

engines had plenty of power, the quest began

to find the best one for the refined Diva. I

started collecting every 25- to 40-size engine I

could find. Since I had conducted no tests, my

only requirement was that it could not weigh

more than 91⁄2 ounces.

In December 2001 I began testing and

evaluating eight engines. In the end, the

Magnum .36 was clearly the top contender. It

weighed only 81⁄4 ounces and easily turned an

11-inch propeller more than 11,000 rpm. The

next step was to install a pipe and put the

engine in a model to see if the power could be

controlled.

The only airplane I was willing to sacrifice

with all the modifications necessary was my

15-year-old Et al, which had a 21-inch tail

moment, 600 square inches of wing area, and

weighed 54 ounces with the engine and pipe

installed and ready to fly.

The first 20 flights were interesting in that

most were spent finding the right pipe and

length. I used a Bolly 12 x 4 narrow-blade

propeller cut to 11 inches.

My suspicions about usable power were

confirmed. There was definitely a great deal

of power, and it seemed quite usable. Most of

those flights were with the engine not running

“on the pipe” and revealed a flat power curve

and the smooth delivery of more power

exactly when and where it was necessary.

At this point the pipe was just a muffler.

The engine was happy being launched at a

soft two-cycle and would break into a

controlled faster speed the moment the nose

was pointed up and then back into its soft

phase as soon as the model returned to level.

There was also no tendency to wind up or

charge at any point. It seemed to “come on” in

all the right places.

The first flight with the pipe in the range

(on the pipe) produced a noticeably stronger

feel everywhere in the pattern, and lap times

went from 5.0 to 5.4. When the needle was

turned in slightly to get to 5.2 lap times, the

engine and airplane were ecstatic, and I

couldn’t keep myself from joining in the

celebration by pushing that old model to

previously unobtainable performance levels.

Since I felt comfortable with the engine, I

was able to turn my focus to the new aircraft.

It would have to be smaller and lighter but

still have that “big airplane” presence.

Deciding that it would probably be a series of

design modifications, I decided to build the

first version only slightly smaller than the

previous .65-powered Divas.

The Ante has 750 square inches of wing

area, and the two larger Divas have 710-

square-inch wings. The wing area presented

here is only 4% less; in fact, there is as much

as in most modern .60-powered models that

are flown today. The tail moment is 18.5

inches, which is slightly longer than most

other airplanes. The fuselage is massive. The

elevator/stabilizer area is medium to small

compared to many models’.

After the first flight, it was apparent that

Diva IV was something special. My good

friend Jim Aron remarked candidly, “I’ve

seen the first flights of your previous

airplanes, and this is the first time I’ve ever

seen you smile!”

To date, there are two smaller Divas, each

weighing 57 ounces. One has a foam-core

wing with balsa sheeting, and the other uses

the Lost Foam Wing Building System

construction shown on the plans.

As an experiment, I used stick-on weights

to increase the overall weight to 64 ounces,

just to see what would happen. The only

noticeable difference was more line tension.

There was still plenty of power, and the Diva

didn’t hesitate anywhere in the pattern.

In general, the two primary components of

any design are aerodynamics and power

dynamics. Aerodynamics is the science of

solid bodies moving through air. Diva was

designed for competition from the beginning.

It is an aerodynamic package that produces a

stable solution for a set of complex and

complicated variables.

Provisions have been made and tested that

allow for the variety of adjustments necessary

to bring the entire package into your personal

comfort zone without adversely affecting

visual presentation or limiting flight

performance.

In our world, power dynamics consists of

two primary components. For our purpose, the

engine is a simple pump that converts fuel to

energy and directs the energy to a specific

output. Integral to this pump is a simple

transmission system. It comprises the

propeller and an adjustable exhaust timing

device (tuned pipe).

The propeller acts as a gear and a final

power converter. The pipe regulates the

time, delivery, and consistency of power. It

is a static throttle of sorts. The whole system

is actually quite primitive because its

components are overtly static, but it is

elegant in its simplicity. When properly

installed and adjusted, it delivers consistent,

reliable, usable power.

So if that’s all there is, why is it so

difficult to get everything working the way

you want?

How you attack a problem is the key.

When you are on the flightline, how things

work is far more important than why they

work. These two factors should not be

interchangeable, although frequently they

are.

When you ask the question “How does it

work?” the answer should be “good” or

“bad.” These answers ultimately quantify

results because if you are honest, they

confirm or deny the need for change.

When you ask “Why does it work?” the

quest for an answer suddenly becomes

complex. Ask those questions and see for

yourself. An analogy would be that you

don’t have to know why a television works

to be satisfied with how it works. This

translates to our sport quite nicely. Ask how

and make progress; ask why and ponder.

The preceding is not intended to be a

brainteaser, but rather a systematic approach

to problem solving and a foundation for

performance building and enhancement.

Before beginning construction, let’s look at

the whole package. In the past six years of

concentrated building and developing the

Diva, I have come to understand and

separate much fact from fiction. This

process is not too different from my

experiences in competitive Combat flying

and business. Following are some facts I

have learned.

• A good contest-caliber finish adds 7-10

ounces from bare wood.

• A light finish cannot save a heavy airplane.

• Good wood is 4-6 pounds per cubic foot. It

is rare to find good wood that weighs less

than 4.5 pounds, and, for our purposes, it

should never exceed 6 pounds stock.

• In an aerodynamically well-designed

airplane, weight distribution is far more

important than weight conservation.

• The three most significant trim

adjustments are CG, propeller, and control

system. You can only use as much power as

you need. Excess power will probably find a

way to work against you.

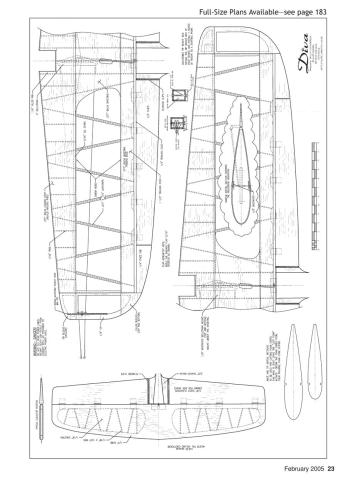

Look closely at the plans and you will

see some things that are out of the norm.

These differences are what make the whole

package work. Everything on the plans is

there for a reason.

The majority of details relate to function.

If you build the airplane per the plans—at a

finished weight of 62 ounces or less—and

build it accurately and straight, you will be

pleased. Actually, the only frill is the little

faux air scoop on the bottom of the cowl.

Following are details of note.

• The fuselage gets wider at the midpoint

and remains fairly wide where the stabilizer

is mounted.

• The tank compartment is slightly wider

than most, at 23⁄32 inches.

• The wing LE at the root inside the fuselage

has a recessed cavity for tank adjustment.

• Cheek cowls terminate on the wing top at

the high point of the root airfoil.

• The fuselage is deep at the dorsal fin. The

rudder is 1⁄8 balsa.

• There is 3° of permanent rudder offset.

• There is no engine offset.

• The airfoil is completely different at the

root than at the tip.

• The wing panels have equal spans.

• The outboard flap is 1⁄4 inch longer than

the inboard flap.

• The control system is completely adjustable.

• There is a large air inlet in the cowl.

• The air outlet in the fuselage around the pipe

is roughly three times that of the cowl inlet.

• Control horns are made from 3⁄32-inchdiameter

wire.

Construction is probably not for a

beginner, but an accomplished Advanced

competitor or builder should have no

problems. Diva makes extensive use of

molded-balsa components. The cheek cowls,

aft fuselage top block, bottom fuselage block,

most of the cowl, and LE sheeting are molded

balsa.

Having built several wings using the Lost

Foam Wing Building System, I do not hesitate

to recommend it. The Diva IV has a

traditional foam-core, balsa-sheeted wing that

performs equal to the built-up wing.

The entire model is covered with .02-

ounce carbon veil before finishing. In a builtup

wing, cover the entire structure—including

open bays and rib capstrips—with the veil and

cut the openings before final covering. See the

photo. Final wing covering of open bays is

done with silkspan.

Wood selection is crucial for strength and

weight. Today, grain type is less critical with

the use of carbon veil before the final finish.

The accompanying wood-weight chart refers

to common balsa lengths and thicknesses, but

the plans call for extensive use of .077-inchthick

wood. The weights for 1⁄16 wood in the

chart should be close to those for the .077

wood.

Most of the custom-cut, contest-gradewood

suppliers will cut the thicker wood

when requested. As a general rule, it is

preferable for thicker pieces to bias to the

lighter side of the chart. You will also find

exceptional wood that is actually lighter and

obviously usable. The chart is only a gauge.

My favorite method of building is to

complete entire components. I finish the wing

with controls installed and tips and flaps

shaped and fitted. Hinge slots and hinges are

fitted.

I complete the fuselage with the cowl and

front hold downs installed and all top blocks

and 1⁄32-inch cross-grain sheeting on the

bottom permanently glued, leaving only the

opening for the wing. This is critical for final

assembly because the fuselage can twist if

it’s not stabilized by permanent installation

of major components.

The landing-gear mount and rear cowl

hold down are integrated and can only be

installed after the wing is permanently glued

in. The elevator/stabilizer assembly is

completely built, with all hinges aligned and

test fitted. The control horn is permanently

attached to the stabilizer. The rudder is

completed with the dorsal fin. See the photos

for final-assembly clarification.

Volumes have been written about

construction methods. If you want to know

more about two-stroke engines, Larry

Scarinzi’s “Blitz” article from the mid-1960s

is a must read. Bob Gaildini’s “Olympic”

article from 1963 is the definitive work for

CL Stunt aircraft-design considerations.

Robin’s View Productions, Windy

Urtnowski, and a host of other sources have

produced videotapes chronicling everything

from wood selection to finishing to installing

tail wheels. Get your hands on as much

information as you can and digest it. Your

building will improve measurably and

quickly as you gain knowledge.

As with any successful venture, countless

people have made contributions. My

grandmother helped me with words as I

struggled to read model-airplane magazines

when I was 7 years old. My mother was my

lone defender when the house was filled with

modeling-dope fumes and the rest of the

family voted to disown me.

Mrs. Norton, who owned the local hobby

shop, extended credit to me at the age of 16

and introduced me to Ed Southwick and

Dick McCoy. This publication’s

aeromodeling editor has been a great friend

for the past 30 years, and with him I have

debated and shared thoughts on almost

everything.

I must mention Brett Buck; in my humble

opinion, he is the ultimate guru when it

comes to trimming and adjusting just about

anything on a Stunt model. There is also Jim

Aron—one of very few who could ask for

and actually get a piece of my best wood.

And I can’t leave out Ted Fancher and Dave

Fitzgerald, who are my protagonists.

I hope you’ve enjoyed the preceding and

found it informative. As you persist in your

quest for the perfect Stunt pattern, I leave

you with one simple thought: rely on the fact

that something is working to validate the

fact that it does work. MA

Phil Granderson

13250 Campus Dr.

Oakland CA 94619

(Editor’s note: We have chosen a

portion of Phil’s “Diva” article to be the

subject of our new online feature that we

call MA “Web Extra.”

As he explained, Phil designed his Diva

with a specific engine size and type in mind.

Moreover, he used a carbon-fiber tuned pipe

to augment the engine’s power and to contour

its power output to a specific rpm band. This

is an interesting subject, and not much is

written about how it works or the practical

specifics of how to properly set up and adjust

a piped system.

Whether you intend to build the Diva or

not, this online material is interesting and

educational. Give it a look; go to

www.modelaircraft.org and then to the

MA Web Extra section.)

Sources:

Lost Foam Wing Building Systems, fully

assembled Lost Foam wings, Lost Foam

video sets, building videos, foam wing cores,

covered foam wings:

Robin’s View Productions

Box 68

Stockertown PA 18083

(610) 746-0106

Building videos:

Windy Urtnowski

93 Elliott Pl.

Rutherford NJ 07070

(201) 896-8740

Magnum .36 engines, side-to-rear exhaust

manifolds, carbon-fiber AeroPipes—tuned

pipes:

Aero Products

980 Winnbrook Dr.

Dacula GA 30019

(678) 407-9376

Edition: Model Aviation - 2005/02

Page Numbers: 18,19,20,21,22,23,24,25,26,28

GWS A-10 Warthog

18 MODEL AVIATION

Use of curved trim adjacent to straight lines on wing gives

illusion of elliptical planform. Phil looks justifiably proud!

by Phil Granderson

IN 1980 I was fortunate to compete in the Control Line World

Championships in Poland. As a member of the Combat team, I

captured the Bronze Medal for the USA.

The CL Precision Aerobatics (Stunt) contingent was the

“Dream Team” of Bob Hunt, Les McDonald, Bill Werwage, and

Wynn Paul. Bob was the defending World Champion, Les is a

three-time World Champion, and Bill is a three-time World

Champion and the first American to win a World Championships.

Those guys were there to win. And they did! Les, Bob, and Bill

took the Gold, Silver, and Bronze medals in that order.

There was a wealth of knowledge in just watching them and

learning. Today two of them are still fierce competitors and good

friends. Although Les McDonald is no longer competing, he left a

wealth of knowledge with his Stiletto series of aircraft.

I remember thinking, “As soon as I win a Combat World

Championships, I’ll switch hats and become a Stunt World

Champion.” How hard could it be? Now that you’re laughing,

let’s get to work.

Stylish, elegant CL

Stunter designed with

original thinking

@@Web Extra

February 2005 19

The entire model is covered with .2-ounce carbon mat, applied with modeling dope.

When fully cured, the carbon makes the airframe incredibly stiff.

The Diva in the foreground features a built-up Lost Foam wing, and the one in the

background was built using a foam-core wing. Both fly extremely well!

The Diva sits low and has great ground-handling qualities. An outstanding blend of

aesthetic features gives this aircraft an original flair.

Photos by Roger Grotheer

Many people are looking for simplicity in a

complex world. That was exactly my

thinking when I began the Diva odyssey six

years ago; just build a distinctive box

around a proven formula. After exploring

and observing a variety of proven formulas,

it became apparent that this approach simply

would not produce the airplane I envisioned.

So what is Diva? It is the culmination of

a few ideas and experiments that worked

well and the exclusion of many ideas and

experiments that either did not work at all or

worked poorly. It is an original work.

From the high cheek cowls, to the

canopy, to the rudder, it is different. Top,

front, and side views reveal that it is unique.

The thinking and application of power is

different. The airfoil is original.

You might ask the question, Why

reinvent the wheel? That was never my

intention, but if you look closely you will

see that the wheel was tweaked in some

unique ways.

Beginning in the late 1960s, there were

experiments with extremely long tail

moments, gapless hinge lines, variations on

rudder offset, engine side thrust and

downthrust, numerous airfoils, and far too

many ideas and experiments with engines.

Through all of that, somehow I still have old

sketches, templates, and garbled notes

tucked away in boxes and files that have

been moved countless times.

In November 1998 construction began

on the first Diva. Rather than wading into

the whole thing blindly, I applied a process

that had proved successful for me and

countless others. It was simply to formulate

a plan, make modifications when and where

required, but, most important, never lose

sight of the original goal. This had worked

quite nicely in my Combat endeavors and in

business. So here’s the plan.

First, set a goal. You’ve probably heard

the question, How will you get there if you

don’t know where you’re going? The goal

was to design and refine a world-class CL

Aerobatics airplane. The model would

someday win a World Championships—

preferably with me as the pilot. Today I’m

much closer and having so much fun that

the only slightly painful chore so far is

writing this article; I’d rather be building or

flying!

The first Diva was promptly renamed

“Ante” when my wife Kathleen made the

observation that the paint scheme I planned

did not look like a Diva. Ante was the first

airplane to emerge from my clean-slate

approach to design. Its maiden flight was

eight months after I cut the first piece of

wood.

This was the watershed project. I was

going for the whole package: distinctive

looks, front-row finish, piped engine, and

world-class performance. The results fell

somewhat short of the goal.

A summary of the results was that the

finishing system worked well and was

relatively easy to apply. Ante was a frontrow

airplane. The piped PA .65 engine

performed well. The wing with the unique

tra

20 MODEL AVIATION

A close-up shows the wraparound header that is available from Aero Products to fit the

Magnum .36. The company also handles the carbon pipe for that engine.

Phil has developed a method of using a computer to design his complete trim scheme.

This allows an infinite amount of adjusting and brainstorming.

airfoil that was developed and implemented

on the Triumph model built in 1969 worked

exactly as I remembered it, generating a great

deal of lift with no real side effects.

There were also some primary things that

didn’t work. I was completely baffled about

why the tried-and-true combination of long

tail moment and relatively small stabilizer/

elevator size suddenly didn’t work as it did

on so many of my previous designs. The

Ante had no problem turning, but it was

difficult once the turn started to get it

stopped. I also noticed that it required more

force on the handle to turn outside.

The design had an assortment of inherent

problems that could not be corrected by

adjusting, tweaking, and trimming. And

finally, the line tension was way beyond my

tolerance level.

I knew after roughly 20 flights with this

airplane that the next model would have

major modifications. Ante was left in its “best

flight condition” and would serve as a

measurement for changes and improvements

to subsequent airplanes. To this day, it is still

the control for all my experiments.

The second airplane—appropriately

painted and approved for the name Diva—

had four significant changes: equal-span

panels, less wing area, the elevator and

stabilizer were moved down closer to the

thrustline, and the stabilizer/elevator area was

increased to 26% of the wing area.

There were other changes too. The tail

moment was shortened 1⁄2 inch to compensate

for the larger stabilizer’s additional weight.

The wingtip shape was changed slightly. The

flap area was reduced by 5%, and the fueltank

compartment was expanded to allow the

tank to be moved backward and forward an

additional 2 inches. I also took much more

care in the alignment and setup of the entire

airplane.

Ultimately I installed the faithful PA .65.

It was apparent from the first flights that

these changes made significant

improvements in the overall performance.

The whole package seemed to come together.

Most noticeable was the marked

improvement in tracking. There was no more

hunting, and the overturning problem was

completely gone. Additionally, control

pressure for outside and inside maneuvers

was the same. Line tension was reduced

slightly.

The Diva’s finish was even slicker and

shinier than the one applied to the Ante. The

horizontally adjustable tank proved to be

golden for finding the perfect CG. I could

move the CG aft or forward by 1 inch

without adding weight.

Another bonus from the tank arrangement

was that the CG did not shift as much from

the beginning of the flight to the end. This

was indeed a marked improvement over

Ante. Flight scores immediately rose and

were continuing to improve. It even captured

my first Concours d’Elegance award.

I was just beginning to appreciate and

enjoy the fruits of my labor when disaster

struck. In what could only be called the

dumbest thing I’ve ever done, my brain died

and I hooked up the handle upside down and

never did a preflight check! It’s been said that

few people have ever saved an airplane from

crashing with the controls reversed. I was not

one of the few!

The Diva’s 36th flight is now

memorialized by its unique dent in the

blacktop at Whittier Narrows in Southern

California. I still chuckle when I visualize

Keith Trostle chasing it around the circle as

the nose was firmly planted and the PA .65

chewing up the carbon propeller just before

performing its brief fatal maneuver. No one

ever imagined Keith could move that fast!

Within minutes of the disaster, the

model’s remains were loaded into the van

and I started the six-hour drive home. I spent

the first three hours of the drive chewing

myself out and the next three planning my

recovery.

I arrived home at 4:24 p.m., unloaded the

van, got a sandwich, and began cutting balsa.

By 7 p.m., I had the fuselage sides cut and the

doublers clamped and laminated.

Construction of “Diva 2 Quick”

February 2005 21

Phil notches the wing LE to allow for more tank-compartment

room. This also puts the fuel’s weight closer to the model’s CG.

How is this for an inspirational photo? All components are built

and ready to assemble. Note the extremely clean workmanship.

Type: CL Aerobatics

Wingspan: 58 inches

Engine: .36-.65

Flying weight: 50-62 ounces

Construction: Balsa and plywood

Covering/finish: .2-ounce carbon mat, light-grade silkspan

and modeling dope, clear automotive topcoat

progressed at breakneck speed. It was ready

for the maiden flight August 28—just seven

weeks after cutting the first piece of wood.

There were no big changes from its

predecessor. I did make the stabilizer slightly

bigger and added ribs to make it lighter. I

lengthened the tail back to the original 21

inches used on the Ante. I also used thinner

balsa for the rudder (3⁄16) and left it flat. It

flew virtually the same as its forerunner and

was easier to trim.

By all accounts and observations,

everything worked very well. The model

looked good, it flew really well, I looked

comfortable flying it, and flight scores were

on the rise again. It was fairly easy to

“practice myself” into this airplane, but I

wanted an airplane to practice with rather

than one to practice for.

Wow, the truth can hurt! I had invested

serious time, effort, wood, and money in

creating a great airplane, and I wasn’t happy.

What would I have rather been flying? How

about an airplane that was as positive as the

Diva and as refined and nimble as a finely

tuned Classic aircraft? As I sat in my shop,

the Classic models began talking to me.

“Hey Phil, over here. I’m your Vulcan;

I’ll be nice to you. You can relax; fly me!”

“Me too! I’m your Lark; ditto what the

Vulcan said.”

The task was clear: tame and refine the

60-size airplane’s edginess and brute force. I

would have to break the mold that I

painstakingly crafted in the first three

airplanes. I would have to redesign, reengineer,

and reinvent a major portion of an

excellent airplane.

Was there a smaller, lighter engine that

would make the right kind and amount of

power? What size should the new Diva be to

score well when big airplanes generally score

better? It was impractical to simply downsize

Diva by a specific percentage.

The toughest task would be to find a

readily available engine with the right kind

and amount of power. It would also have to

Wood Weights and Measures

Thickness Length (inches) Weight (grams) Length Weight (grams)

1/16 3 x 36 8-11 4 x 36 11-14

3/32 3 x 36 12-16 4 x 36 17-21

1/8 3 x 36 18-21 4 x 36 21-28

3/16 3 x 36 24-30 4 x 36 32-43

1/4 3 x 36 32-42 4 x 36 43-57

3/8 3 x 36 48-63 4 x 36 63-83

1/2 3 x 36 62-85 4 x 36 81-110

1/16 3 x 48 11-14 4 x 48 15-18

3/32 3 x 48 17-21 4 x 48 23-28

1/8 3 x 48 21-28 4 x 48 28-37

3/16 3 x 48 33-40 4 x 48 44-56

1/4 3 x 48 44-57 4 x 48 56-75

3/8 3 x 48 63-85 4 x 48 84-112

1/2 3 x 48 86-112 4 x 48 114-150

be light and manufactured to consistently high

standards. If such an engine could be found

and possessed good Stunt fundamentals, I was

confident in my ability to identify and make

modifications if necessary.

Believing that most modern 40-size

engines had plenty of power, the quest began

to find the best one for the refined Diva. I

started collecting every 25- to 40-size engine I

could find. Since I had conducted no tests, my

only requirement was that it could not weigh

more than 91⁄2 ounces.

In December 2001 I began testing and

evaluating eight engines. In the end, the

Magnum .36 was clearly the top contender. It

weighed only 81⁄4 ounces and easily turned an

11-inch propeller more than 11,000 rpm. The

next step was to install a pipe and put the

engine in a model to see if the power could be

controlled.

The only airplane I was willing to sacrifice

with all the modifications necessary was my

15-year-old Et al, which had a 21-inch tail

moment, 600 square inches of wing area, and

weighed 54 ounces with the engine and pipe

installed and ready to fly.

The first 20 flights were interesting in that

most were spent finding the right pipe and

length. I used a Bolly 12 x 4 narrow-blade

propeller cut to 11 inches.

My suspicions about usable power were

confirmed. There was definitely a great deal

of power, and it seemed quite usable. Most of

those flights were with the engine not running

“on the pipe” and revealed a flat power curve

and the smooth delivery of more power

exactly when and where it was necessary.

At this point the pipe was just a muffler.

The engine was happy being launched at a

soft two-cycle and would break into a

controlled faster speed the moment the nose

was pointed up and then back into its soft

phase as soon as the model returned to level.

There was also no tendency to wind up or

charge at any point. It seemed to “come on” in

all the right places.

The first flight with the pipe in the range

(on the pipe) produced a noticeably stronger

feel everywhere in the pattern, and lap times

went from 5.0 to 5.4. When the needle was

turned in slightly to get to 5.2 lap times, the

engine and airplane were ecstatic, and I

couldn’t keep myself from joining in the

celebration by pushing that old model to

previously unobtainable performance levels.

Since I felt comfortable with the engine, I

was able to turn my focus to the new aircraft.

It would have to be smaller and lighter but

still have that “big airplane” presence.

Deciding that it would probably be a series of

design modifications, I decided to build the

first version only slightly smaller than the

previous .65-powered Divas.

The Ante has 750 square inches of wing

area, and the two larger Divas have 710-

square-inch wings. The wing area presented

here is only 4% less; in fact, there is as much

as in most modern .60-powered models that

are flown today. The tail moment is 18.5

inches, which is slightly longer than most

other airplanes. The fuselage is massive. The

elevator/stabilizer area is medium to small

compared to many models’.

After the first flight, it was apparent that

Diva IV was something special. My good

friend Jim Aron remarked candidly, “I’ve

seen the first flights of your previous

airplanes, and this is the first time I’ve ever

seen you smile!”

To date, there are two smaller Divas, each

weighing 57 ounces. One has a foam-core

wing with balsa sheeting, and the other uses

the Lost Foam Wing Building System

construction shown on the plans.

As an experiment, I used stick-on weights

to increase the overall weight to 64 ounces,

just to see what would happen. The only

noticeable difference was more line tension.

There was still plenty of power, and the Diva

didn’t hesitate anywhere in the pattern.

In general, the two primary components of

any design are aerodynamics and power

dynamics. Aerodynamics is the science of

solid bodies moving through air. Diva was

designed for competition from the beginning.

It is an aerodynamic package that produces a

stable solution for a set of complex and

complicated variables.

Provisions have been made and tested that

allow for the variety of adjustments necessary

to bring the entire package into your personal

comfort zone without adversely affecting

visual presentation or limiting flight

performance.

In our world, power dynamics consists of

two primary components. For our purpose, the

engine is a simple pump that converts fuel to

energy and directs the energy to a specific

output. Integral to this pump is a simple

transmission system. It comprises the

propeller and an adjustable exhaust timing

device (tuned pipe).

The propeller acts as a gear and a final

power converter. The pipe regulates the

time, delivery, and consistency of power. It

is a static throttle of sorts. The whole system

is actually quite primitive because its

components are overtly static, but it is

elegant in its simplicity. When properly

installed and adjusted, it delivers consistent,

reliable, usable power.

So if that’s all there is, why is it so

difficult to get everything working the way

you want?

How you attack a problem is the key.

When you are on the flightline, how things

work is far more important than why they

work. These two factors should not be

interchangeable, although frequently they

are.

When you ask the question “How does it

work?” the answer should be “good” or

“bad.” These answers ultimately quantify

results because if you are honest, they

confirm or deny the need for change.

When you ask “Why does it work?” the

quest for an answer suddenly becomes

complex. Ask those questions and see for

yourself. An analogy would be that you

don’t have to know why a television works

to be satisfied with how it works. This

translates to our sport quite nicely. Ask how

and make progress; ask why and ponder.

The preceding is not intended to be a

brainteaser, but rather a systematic approach

to problem solving and a foundation for

performance building and enhancement.

Before beginning construction, let’s look at

the whole package. In the past six years of

concentrated building and developing the

Diva, I have come to understand and

separate much fact from fiction. This

process is not too different from my

experiences in competitive Combat flying

and business. Following are some facts I

have learned.

• A good contest-caliber finish adds 7-10

ounces from bare wood.

• A light finish cannot save a heavy airplane.

• Good wood is 4-6 pounds per cubic foot. It

is rare to find good wood that weighs less

than 4.5 pounds, and, for our purposes, it

should never exceed 6 pounds stock.

• In an aerodynamically well-designed

airplane, weight distribution is far more

important than weight conservation.

• The three most significant trim