112 Model Aviation May 2012 www.ModelAviation.com

off, Gina placed

second behind

a flier with 30-

plus years of

experience—her

father, Andrew.

The Junior

Team Committee,

consisting of Jim

Parker, Charlie

Jones, Tom Vaccaro, and George Batiuk,

is raising funds to help defray some of

the team’s expenses. AMA covers travel,

lodging, and entry fees, but extra support

is needed.

In February, the Junior Committee

raffled off one of the late Bob White’s

Wakefields, model number 23, which

was the backup model when Bob won

the World Championship in 1987. Bob’s

winning model, number 22, is on display

in the National Model Aviation Museum

in Muncie, Indiana.

Also raffled off was a quilt depicting

all of the previous Junior World

Championships sites made by Charlie

Jones’ mother. Donations can be made

by check to AMA and should be

earmarked for the Junior Free Flight

Team. You can also send a check directly

ff DURATION

T he 2012 FAI Junior World Championships for Free Flight Model Aircraft

will be held July 27 through August 3 near Ljubljana, Slovenia. The United

States will be represented by Gina Barron, Logan Tetrick, and Michelle

Barron in F1A Towline Glider; Sevak Malkhasyan, Brian Pacelli, and Peyton

Tetrick in F1B Wakefield Rubber; and Taron Malkhasyan and Brian Pacelli in F1P

Power. As of early February, the third

slot in F1P had not been filled.

Once again, Brian Pacelli will do

double duty, flying Wakefield and

F1P Power. This year’s team includes

a set of brothers, Sevak and Taron

Malkhasyan; brother and sister, Logan

and Peyton Tetrick; and sisters, Gina

and Michelle Barron. George Batiuk

will be team manager.

Gina, who will turn 10 during the

Junior World Championships, will

be one of the youngest contestants

to represent the US in any World

Championships. Although her F1A

Towline gliders may span twice her

height, she handles them with skill.

At a contest last fall in Seguin, Texas,

Gina picked her own air for all seven

rounds and was one of two contestants

to max out; both fliers maxed the

first fly-off round. In the second fly-

FF Junior World Champs

by Louis Joyner

[email protected]

PLUS:

> America Cup

> National Cup

> Two-piece wings

> StarLink FliteTech

models

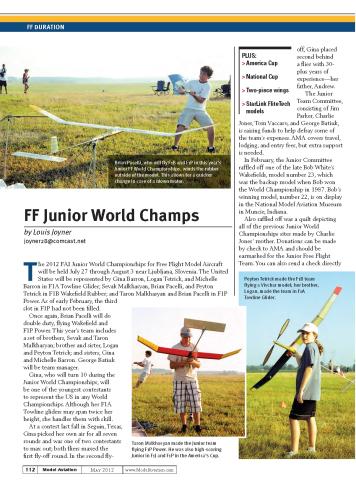

Brian Pacelli, who will fly F1B and F1P in this year’s

Junior FF World Championships, winds the rubber

outside of the model. This allows for a quicker

change in case of a blown motor.

Peyton Tetrick made the F1B team

flying a Vivchar model; her brother,

Logan, made the team in F1A

Towline Glider.

Taron Malkhasyan made the Junior team

flying F1P Power. He was also high-scoring

Junior in F1J and F1P in the America’s Cup.

114 Model Aviation May 2012 www.ModelAviation.com

ff duration

Below: Michelle Barron and her sister, Gina, comprise

two-thirds of the Junior F1A team attending the World

Championships in Slovenia.

Left: StarLink-FliteTech Models offers a variety

of models, kits, and accessories, including this

replacement shaft and three-part bobbin used

to update the front end of Burdov F1G Coupe

models.

Taron’s brother, Sevak Malkhasyan,

made the Junior team in F1B, earned

top points in the National Cup Junior

category, and was high Junior in F1B in

the America’s Cup.

to team manager George Batiuk, 576

Dana St., San Luis Obispo CA 93401.

America’s Cup

The annual multi-contest

competition for all of the FAI FF

events concluded this December. Here

are the results:

F1A Towline Glider: Brian Van Nest

(Gina Barron, high Junior)

F1B Wakefield Rubber: Blake Jensen

(Sevak Malkhasyan, high Junior)

F1C: Faust Parker

F1G Coupe Rubber: Blake Jensen

(Troy Davis, high Junior)

F1H Towline Glider: Mike McKeever

(Gina Barron, high Junior)

F1J Power: Faust Parker (Taron

Malkhasyan, high Junior and 4th place

overall)

F1P Power: Glen Schneider (Taron

Malkhasyan, high Junior and tied for

3rd place overall)

F1Q Electric: John Oldenkamp

F1E Slope Soaring: Peter Brocks

The America’s Cup, which was

created by the Southern California

Aero Team and is administered by Jim

Parker, offers a multi-contest format

that encourages modelers from the

United States, Canada, and Mexico,

to compete in FAI FF events. Points

are awarded at each contest, with a

first place receiving 25, second place

receiving 20, third place receiving 15,

fourth place receiving 10, and fifth

place receiving 5 points.

Additional points are awarded

depending on the number of

contestants flying in the event. Best

results from four contests are counted.

To encourage travel, only two contests

at any one site can be counted; the

other two results must be from two

other sites. In the case of a tie, results

from more contests are counted.

Detailed rules for the America’s Cup

can be found on the National Free

Flight Society (NFFS) website.

National Cup

The National Cup was created in

2003 to encourage participants to

travel and compete at FF contests

across the country. As is the America’s

Cup, the National Cup is a multicontest

competition. However, the

National Cup focuses on AMA FF

events.

Contestants in each of seven

categories accumulate points in the

individual events within that category

at contests across the country. To score

points, contestants must place in the

top five in an event. The highest six

scores in each event are counted.

To make it truly a nationwide cup,

no more than two scores are counted

from any single location. A seventh

score can be added by placing at one

of four exempt contests in each of the

four NFFS regions. The contests are the

Southwest Regionals in Eloy, Arizona;

the AMA Nats in Muncie, Indiana;

the Rocky Mountain Championships

in Denver, Colorado; and the King

Orange Internationals in Palm Bay,

Florida. A third score from one of the

exempt contests is to be counted.

In 2011, there were 81 contests with

615 contestants posting scores in 1,762

individual events. The categories and

the 2011 winners are:

AMA Power: Bob Hanford

Classic Power: Bob Hanford

Nostalgia Power (small): Bob Hanford

Nostalgia Power (large): Bob Hanford

AMA Rubber: Earl Griffith

Nostalgia Rubber: Don DeLoach

Glider: Tim Batiuk

Bob Hanford won all four of the

Power categories.

The National Cup includes a Junior

category, which combines scores from

selected Rubber, Power, and Glider

events. Sevak Malkhasyan topped this

category, with Tyler Moore in second,

only 14 points behind. Samuel Smetzer

was third, Taron Malkhasyan came in

fourth, and Elliot Plantner placed fifth.

Rules, detailed scores, and the 2012

National Cup contest schedule can be

found on the NFFS website.

Two-Piece Wings

Fifty years ago, one-piece wings were

the rule, even for large FF models.

In those days, before minivans and

SUVs, large wings were often strapped,

upside down, to the headliner of the

family sedan for transport to the flying

field. Today, many models use twopiece

wings that allow more compact

storage—often in a purpose-made

model box that safely stores several

complete models for a car trip or an

international flight.

Two-piece wings allow easy

adjustment of the relative incidence

between the two wing halves

as a trimming aid. This can be

accomplished by shimming underneath

the TE on a two-piece wing, rubber

banded to a traditional pylon or rail

system on the fuselage. The two wing

halves can also be connected by a

single wire running through the pylon

or fuselage; often one half is located by

a fixed rear pin and the other half with

an adjustable pin.

The adjustable pin can be linked to a

timer, either through a line or a servo,

to change the incidence of the wing

half at a predetermined time during

the flight. Known as a wing wiggler,

its use is nearly universal in the larger

FAI classes of F1A Towline Glider, F1B

Wakefield Rubber, and F1C Power,

usually coupled with auto rudder and

auto stabilizer.

For smaller models, such as an F1G

Coupe d’Hiver, a wing wiggler can even

be used as the only auto surface. On

my Coupes, I use a simple wing wiggler

made from wire and tubing to control

the left wing. At launch, the left panel

is set at several degrees negative relative

to the right wing half. This provides a

left rolling tendency during the initial

burst.

After 5 to 7 seconds, a timer releases

a line, allowing the left TE to move

down to the glide position. The result

is a straight, near-vertical initial climb,

transitioning into a right cruise and

right glide. No other auto surfaces

are used. (Photographs and a detailed

description of this wing wiggler can

be found in MA’s November 2010 “FF

Duration” column.)

A two-piece wing requires slightly

more effort during construction, but

the convenience of adjusting the wing

halves independently, as well as the

compactness, make it worth the effort.

Two-piece wings are often heavier

than a one-piece wing. The wing wire,

sockets in the two wing halves, and the

socket and additional reinforcing in the

pylon or fuselage, all add weight; this

is partially offset by eliminating the

center section reinforcements needed

with a one-piece wing.

The wing wire is often the main

offender concerning weight. In the past,

steel wire has been the most popular

choice. Typical diameters range from

3.0mm (slightly less than 1/8 inch) for

F1B, to 5.5mm to 6.0mm (less than 1/4

inch) for F1A and F1C. Steel wire can

also bend during a hard towline launch

or on DT.

Carbon fiber has been tried as a

lighter-weight alternative. The weight

saving can be significant. On his

F1B models, Paul Crowley has tried

substituting 1/8-inch diameter carbonfiber

rod for 1/8-inch steel wing wires.

“The weight saving was nice; 1 gram

for carbon versus 4 grams for steel,” he

said.

But there were problems. “I found

that the carbon-fiber rods would break

after repeated use, usually on launch,”

said Paul. “But the break was actually

promoted by hard DT landings. I

believe that the shear load at the pylon

was the cause; rounding the corners of

the holes didn’t help. The carbon-fiber

rod is a bundle of strands and you start

breaking them one at a time until the

strands that are left can’t take the stress

of a hard launch or DT.”

A solution is to protect the carbon

fiber with steel. One method is to

use thin-wall stainless steel tubing of

the desired diameter and fill it with

carbon-fiber tow wetted out with

epoxy. This can be done by inserting a

loop of Kevlar thread through a length

of steel tubing, then using the Kevlar

thread to pull a bundle of doubled

lengths of epoxy-soaked carbon-fiber

tow back through the tube.

For lighter models, such as F1G

Coupe and other Rubber models,

carbon-fiber rods or tubes still offer the

best weight-to-strength option for wing

wires. The popular Burdov Candy G

Coupe uses a purpose-made 4.5mmdiameter

carbon tube; carbon-tube

pultrusions, available from A2Z Corp

and CST, are offered in 3mm, 4mm,

and 5mm, which would be suitable for

many smaller, lightly-loaded models. (I

have had no problems using the 4.0mm

pultrusion for the wing wire on my

Coupes.) To avoid problems, frequently

inspect and replace carbon wing rods

or tubes.

Whatever you use for the wing wire,

it must fit properly into sockets in the

wings. Standard piano wire and the

next larger size aluminum tubing fits

too loosely. Aluminum tubing from

K&S has a wall thickness of 0.014 inch.

If you use 5/32-inch OD aluminum

tubing, the ID will be 0.12825; that’s

0.00325 inch bigger than 1/8-inch

piano wire. Not quite sloppy, but

loose enough to potentially cause trim

problems.

How do you get a perfect fit? One

solution is to make your own wing

sockets using a carbon-fiber sock. The

sock (available from CST) is slipped

over a length of wing-wire material

or drill rod of the same size that is

coated with release agent. (I’ve used

a double wrap of 1/4 mil Mylar.) The

sock is pulled tight and coated with

epoxy laminating resin. Excess epoxy is

blotted off.

After the epoxy hardens, the wire is

removed, leaving a rigid carbon-fiber

tube socket that’s a perfect fit for the

wing wire. For larger models, a second

sock can be added over the first for

extra strength. You can cut the socket

to length for each wing half or, better

yet, cut it to double length and build

it into both right- and left-wing inner

panels at the same time, ensuring

accurate alignment.

Don’t do as I did and glue the wing

socket permanently to the wing wire

I was using to align two main spar

halves while installing the sockets.

The carbon-fiber sock tubing I had

made was porous enough to let some

CA soak through to the wing wire.

(I intended to tack the sockets in

place with CA so the wing wire could

be removed and the socket-to-spar

joint filled in with epoxy and micro

balloons.)

Paul Crowley offers another option

to ensure a perfect fit: “I run a pipe

cleaner with epoxy on it to coat the

inside of the aluminum tube, then I

bore it out to size with a new, sharp

drill bit when it’s set,” he said. (I’ve

done it the other way around by

brushing slow epoxy glue onto a long

section of too-small carbon-fiber tube

and hanging the rod up to dry.)

The wing sockets must be tied into

the main spar structure. Ideally, the

wing socket is sandwiched between

upper and lower carbon-fiber caps in a

full-depth spar.

For the pylon or fuselage socket,

you can use a section of the carbonfiber

socket or make a custom-fit

aluminum tube. K&S, supplier of the

brass and aluminum tubing available

at most hobby shops, produces a line

of thick-wall aluminum tubing in a

variety of ODs with a wall thickness

of either 0.035 inch or 0.049 inch;

the aluminum used (6061 T-6) is

slightly harder than that used for the

thin-wall tubing.

The thick-walled tubing can be

bored out using the correct size drill

bit, preferably on a lathe. Few hobby

shops carry thick-wall tubing; an

online source is Hobbylinc. Its website

includes thick-wall aluminum tubing

in a few metric sizes, as well as brass

tubing in metric sizes.

The brass tubing has a 0.45mm wall

thickness, so it doesn’t give a close

fit on metric-size wire. For example,

the clearance between 3.0mm OD

brass tubing and 2mm diameter wire

is 0.10mm (0.004 inch)—too loose

to use as a shaft bearing or wingwire

socket.

StarLink FliteTech Models

Michael Pykelny is the new owner

of StarLink FliteTech. He took over

from previous owner Larry Bagalini,

who ran the mail-order operation for

a number of years after founder Al

Brush passed away. The new contact

information is at the end of the column.

StarLink offers a variety of models

and kits, ranging from Russian flier

Andrey Burdov’s F1B Wakefield and

F1G Coupe models to innovative

P-30 kits. StarLink carries an updated

version of Bob White’s Beau Coupe

design and several Nostalgia and Old-

Timer Rubber kits.

Items for the shop and flying field,

including a machined aluminum

winding stooge and clear plastic storage

tubes for tracking transmitters, are also

available. Components such as motor

tubes, front ends, propeller blades, and

even wings for F1B and F1G aircraft

can be purchased.

Parts are stocked to allow upgrading

of older Burdov Coupe front ends.

These include adjustable blade fittings

and a replacement shaft that allows

you to use a bobbin to connect

the rubber motor to the front end,

permitting winding without the

propeller attached.

Sources :

NFFS

www.freeflight.org

CST-The Composites Store

(800) 338-1278

www.cstsales.com

A2Z Corp

(877) 754-7465

www.A2ZCorp.us/store

Hobbylinc

(888) 327-9673

www.hobbylinc.com

StarLink-FliteTech Models

(858) 231-4994

www.starlink-flitetech.com

Edition: Model Aviation - 2012/05

Page Numbers: 112,114,115,116,117

Edition: Model Aviation - 2012/05

Page Numbers: 112,114,115,116,117

112 Model Aviation May 2012 www.ModelAviation.com

off, Gina placed

second behind

a flier with 30-

plus years of

experience—her

father, Andrew.

The Junior

Team Committee,

consisting of Jim

Parker, Charlie

Jones, Tom Vaccaro, and George Batiuk,

is raising funds to help defray some of

the team’s expenses. AMA covers travel,

lodging, and entry fees, but extra support

is needed.

In February, the Junior Committee

raffled off one of the late Bob White’s

Wakefields, model number 23, which

was the backup model when Bob won

the World Championship in 1987. Bob’s

winning model, number 22, is on display

in the National Model Aviation Museum

in Muncie, Indiana.

Also raffled off was a quilt depicting

all of the previous Junior World

Championships sites made by Charlie

Jones’ mother. Donations can be made

by check to AMA and should be

earmarked for the Junior Free Flight

Team. You can also send a check directly

ff DURATION

T he 2012 FAI Junior World Championships for Free Flight Model Aircraft

will be held July 27 through August 3 near Ljubljana, Slovenia. The United

States will be represented by Gina Barron, Logan Tetrick, and Michelle

Barron in F1A Towline Glider; Sevak Malkhasyan, Brian Pacelli, and Peyton

Tetrick in F1B Wakefield Rubber; and Taron Malkhasyan and Brian Pacelli in F1P

Power. As of early February, the third

slot in F1P had not been filled.

Once again, Brian Pacelli will do

double duty, flying Wakefield and

F1P Power. This year’s team includes

a set of brothers, Sevak and Taron

Malkhasyan; brother and sister, Logan

and Peyton Tetrick; and sisters, Gina

and Michelle Barron. George Batiuk

will be team manager.

Gina, who will turn 10 during the

Junior World Championships, will

be one of the youngest contestants

to represent the US in any World

Championships. Although her F1A

Towline gliders may span twice her

height, she handles them with skill.

At a contest last fall in Seguin, Texas,

Gina picked her own air for all seven

rounds and was one of two contestants

to max out; both fliers maxed the

first fly-off round. In the second fly-

FF Junior World Champs

by Louis Joyner

[email protected]

PLUS:

> America Cup

> National Cup

> Two-piece wings

> StarLink FliteTech

models

Brian Pacelli, who will fly F1B and F1P in this year’s

Junior FF World Championships, winds the rubber

outside of the model. This allows for a quicker

change in case of a blown motor.

Peyton Tetrick made the F1B team

flying a Vivchar model; her brother,

Logan, made the team in F1A

Towline Glider.

Taron Malkhasyan made the Junior team

flying F1P Power. He was also high-scoring

Junior in F1J and F1P in the America’s Cup.

114 Model Aviation May 2012 www.ModelAviation.com

ff duration

Below: Michelle Barron and her sister, Gina, comprise

two-thirds of the Junior F1A team attending the World

Championships in Slovenia.

Left: StarLink-FliteTech Models offers a variety

of models, kits, and accessories, including this

replacement shaft and three-part bobbin used

to update the front end of Burdov F1G Coupe

models.

Taron’s brother, Sevak Malkhasyan,

made the Junior team in F1B, earned

top points in the National Cup Junior

category, and was high Junior in F1B in

the America’s Cup.

to team manager George Batiuk, 576

Dana St., San Luis Obispo CA 93401.

America’s Cup

The annual multi-contest

competition for all of the FAI FF

events concluded this December. Here

are the results:

F1A Towline Glider: Brian Van Nest

(Gina Barron, high Junior)

F1B Wakefield Rubber: Blake Jensen

(Sevak Malkhasyan, high Junior)

F1C: Faust Parker

F1G Coupe Rubber: Blake Jensen

(Troy Davis, high Junior)

F1H Towline Glider: Mike McKeever

(Gina Barron, high Junior)

F1J Power: Faust Parker (Taron

Malkhasyan, high Junior and 4th place

overall)

F1P Power: Glen Schneider (Taron

Malkhasyan, high Junior and tied for

3rd place overall)

F1Q Electric: John Oldenkamp

F1E Slope Soaring: Peter Brocks

The America’s Cup, which was

created by the Southern California

Aero Team and is administered by Jim

Parker, offers a multi-contest format

that encourages modelers from the

United States, Canada, and Mexico,

to compete in FAI FF events. Points

are awarded at each contest, with a

first place receiving 25, second place

receiving 20, third place receiving 15,

fourth place receiving 10, and fifth

place receiving 5 points.

Additional points are awarded

depending on the number of

contestants flying in the event. Best

results from four contests are counted.

To encourage travel, only two contests

at any one site can be counted; the

other two results must be from two

other sites. In the case of a tie, results

from more contests are counted.

Detailed rules for the America’s Cup

can be found on the National Free

Flight Society (NFFS) website.

National Cup

The National Cup was created in

2003 to encourage participants to

travel and compete at FF contests

across the country. As is the America’s

Cup, the National Cup is a multicontest

competition. However, the

National Cup focuses on AMA FF

events.

Contestants in each of seven

categories accumulate points in the

individual events within that category

at contests across the country. To score

points, contestants must place in the

top five in an event. The highest six

scores in each event are counted.

To make it truly a nationwide cup,

no more than two scores are counted

from any single location. A seventh

score can be added by placing at one

of four exempt contests in each of the

four NFFS regions. The contests are the

Southwest Regionals in Eloy, Arizona;

the AMA Nats in Muncie, Indiana;

the Rocky Mountain Championships

in Denver, Colorado; and the King

Orange Internationals in Palm Bay,

Florida. A third score from one of the

exempt contests is to be counted.

In 2011, there were 81 contests with

615 contestants posting scores in 1,762

individual events. The categories and

the 2011 winners are:

AMA Power: Bob Hanford

Classic Power: Bob Hanford

Nostalgia Power (small): Bob Hanford

Nostalgia Power (large): Bob Hanford

AMA Rubber: Earl Griffith

Nostalgia Rubber: Don DeLoach

Glider: Tim Batiuk

Bob Hanford won all four of the

Power categories.

The National Cup includes a Junior

category, which combines scores from

selected Rubber, Power, and Glider

events. Sevak Malkhasyan topped this

category, with Tyler Moore in second,

only 14 points behind. Samuel Smetzer

was third, Taron Malkhasyan came in

fourth, and Elliot Plantner placed fifth.

Rules, detailed scores, and the 2012

National Cup contest schedule can be

found on the NFFS website.

Two-Piece Wings

Fifty years ago, one-piece wings were

the rule, even for large FF models.

In those days, before minivans and

SUVs, large wings were often strapped,

upside down, to the headliner of the

family sedan for transport to the flying

field. Today, many models use twopiece

wings that allow more compact

storage—often in a purpose-made

model box that safely stores several

complete models for a car trip or an

international flight.

Two-piece wings allow easy

adjustment of the relative incidence

between the two wing halves

as a trimming aid. This can be

accomplished by shimming underneath

the TE on a two-piece wing, rubber

banded to a traditional pylon or rail

system on the fuselage. The two wing

halves can also be connected by a

single wire running through the pylon

or fuselage; often one half is located by

a fixed rear pin and the other half with

an adjustable pin.

The adjustable pin can be linked to a

timer, either through a line or a servo,

to change the incidence of the wing

half at a predetermined time during

the flight. Known as a wing wiggler,

its use is nearly universal in the larger

FAI classes of F1A Towline Glider, F1B

Wakefield Rubber, and F1C Power,

usually coupled with auto rudder and

auto stabilizer.

For smaller models, such as an F1G

Coupe d’Hiver, a wing wiggler can even

be used as the only auto surface. On

my Coupes, I use a simple wing wiggler

made from wire and tubing to control

the left wing. At launch, the left panel

is set at several degrees negative relative

to the right wing half. This provides a

left rolling tendency during the initial

burst.

After 5 to 7 seconds, a timer releases

a line, allowing the left TE to move

down to the glide position. The result

is a straight, near-vertical initial climb,

transitioning into a right cruise and

right glide. No other auto surfaces

are used. (Photographs and a detailed

description of this wing wiggler can

be found in MA’s November 2010 “FF

Duration” column.)

A two-piece wing requires slightly

more effort during construction, but

the convenience of adjusting the wing

halves independently, as well as the

compactness, make it worth the effort.

Two-piece wings are often heavier

than a one-piece wing. The wing wire,

sockets in the two wing halves, and the

socket and additional reinforcing in the

pylon or fuselage, all add weight; this

is partially offset by eliminating the

center section reinforcements needed

with a one-piece wing.

The wing wire is often the main

offender concerning weight. In the past,

steel wire has been the most popular

choice. Typical diameters range from

3.0mm (slightly less than 1/8 inch) for

F1B, to 5.5mm to 6.0mm (less than 1/4

inch) for F1A and F1C. Steel wire can

also bend during a hard towline launch

or on DT.

Carbon fiber has been tried as a

lighter-weight alternative. The weight

saving can be significant. On his

F1B models, Paul Crowley has tried

substituting 1/8-inch diameter carbonfiber

rod for 1/8-inch steel wing wires.

“The weight saving was nice; 1 gram

for carbon versus 4 grams for steel,” he

said.

But there were problems. “I found

that the carbon-fiber rods would break

after repeated use, usually on launch,”

said Paul. “But the break was actually

promoted by hard DT landings. I

believe that the shear load at the pylon

was the cause; rounding the corners of

the holes didn’t help. The carbon-fiber

rod is a bundle of strands and you start

breaking them one at a time until the

strands that are left can’t take the stress

of a hard launch or DT.”

A solution is to protect the carbon

fiber with steel. One method is to

use thin-wall stainless steel tubing of

the desired diameter and fill it with

carbon-fiber tow wetted out with

epoxy. This can be done by inserting a

loop of Kevlar thread through a length

of steel tubing, then using the Kevlar

thread to pull a bundle of doubled

lengths of epoxy-soaked carbon-fiber

tow back through the tube.

For lighter models, such as F1G

Coupe and other Rubber models,

carbon-fiber rods or tubes still offer the

best weight-to-strength option for wing

wires. The popular Burdov Candy G

Coupe uses a purpose-made 4.5mmdiameter

carbon tube; carbon-tube

pultrusions, available from A2Z Corp

and CST, are offered in 3mm, 4mm,

and 5mm, which would be suitable for

many smaller, lightly-loaded models. (I

have had no problems using the 4.0mm

pultrusion for the wing wire on my

Coupes.) To avoid problems, frequently

inspect and replace carbon wing rods

or tubes.

Whatever you use for the wing wire,

it must fit properly into sockets in the

wings. Standard piano wire and the

next larger size aluminum tubing fits

too loosely. Aluminum tubing from

K&S has a wall thickness of 0.014 inch.

If you use 5/32-inch OD aluminum

tubing, the ID will be 0.12825; that’s

0.00325 inch bigger than 1/8-inch

piano wire. Not quite sloppy, but

loose enough to potentially cause trim

problems.

How do you get a perfect fit? One

solution is to make your own wing

sockets using a carbon-fiber sock. The

sock (available from CST) is slipped

over a length of wing-wire material

or drill rod of the same size that is

coated with release agent. (I’ve used

a double wrap of 1/4 mil Mylar.) The

sock is pulled tight and coated with

epoxy laminating resin. Excess epoxy is

blotted off.

After the epoxy hardens, the wire is

removed, leaving a rigid carbon-fiber

tube socket that’s a perfect fit for the

wing wire. For larger models, a second

sock can be added over the first for

extra strength. You can cut the socket

to length for each wing half or, better

yet, cut it to double length and build

it into both right- and left-wing inner

panels at the same time, ensuring

accurate alignment.

Don’t do as I did and glue the wing

socket permanently to the wing wire

I was using to align two main spar

halves while installing the sockets.

The carbon-fiber sock tubing I had

made was porous enough to let some

CA soak through to the wing wire.

(I intended to tack the sockets in

place with CA so the wing wire could

be removed and the socket-to-spar

joint filled in with epoxy and micro

balloons.)

Paul Crowley offers another option

to ensure a perfect fit: “I run a pipe

cleaner with epoxy on it to coat the

inside of the aluminum tube, then I

bore it out to size with a new, sharp

drill bit when it’s set,” he said. (I’ve

done it the other way around by

brushing slow epoxy glue onto a long

section of too-small carbon-fiber tube

and hanging the rod up to dry.)

The wing sockets must be tied into

the main spar structure. Ideally, the

wing socket is sandwiched between

upper and lower carbon-fiber caps in a

full-depth spar.

For the pylon or fuselage socket,

you can use a section of the carbonfiber

socket or make a custom-fit

aluminum tube. K&S, supplier of the

brass and aluminum tubing available

at most hobby shops, produces a line

of thick-wall aluminum tubing in a

variety of ODs with a wall thickness

of either 0.035 inch or 0.049 inch;

the aluminum used (6061 T-6) is

slightly harder than that used for the

thin-wall tubing.

The thick-walled tubing can be

bored out using the correct size drill

bit, preferably on a lathe. Few hobby

shops carry thick-wall tubing; an

online source is Hobbylinc. Its website

includes thick-wall aluminum tubing

in a few metric sizes, as well as brass

tubing in metric sizes.

The brass tubing has a 0.45mm wall

thickness, so it doesn’t give a close

fit on metric-size wire. For example,

the clearance between 3.0mm OD

brass tubing and 2mm diameter wire

is 0.10mm (0.004 inch)—too loose

to use as a shaft bearing or wingwire

socket.

StarLink FliteTech Models

Michael Pykelny is the new owner

of StarLink FliteTech. He took over

from previous owner Larry Bagalini,

who ran the mail-order operation for

a number of years after founder Al

Brush passed away. The new contact

information is at the end of the column.

StarLink offers a variety of models

and kits, ranging from Russian flier

Andrey Burdov’s F1B Wakefield and

F1G Coupe models to innovative

P-30 kits. StarLink carries an updated

version of Bob White’s Beau Coupe

design and several Nostalgia and Old-

Timer Rubber kits.

Items for the shop and flying field,

including a machined aluminum

winding stooge and clear plastic storage

tubes for tracking transmitters, are also

available. Components such as motor

tubes, front ends, propeller blades, and

even wings for F1B and F1G aircraft

can be purchased.

Parts are stocked to allow upgrading

of older Burdov Coupe front ends.

These include adjustable blade fittings

and a replacement shaft that allows

you to use a bobbin to connect

the rubber motor to the front end,

permitting winding without the

propeller attached.

Sources :

NFFS

www.freeflight.org

CST-The Composites Store

(800) 338-1278

www.cstsales.com

A2Z Corp

(877) 754-7465

www.A2ZCorp.us/store

Hobbylinc

(888) 327-9673

www.hobbylinc.com

StarLink-FliteTech Models

(858) 231-4994

www.starlink-flitetech.com

Edition: Model Aviation - 2012/05

Page Numbers: 112,114,115,116,117

112 Model Aviation May 2012 www.ModelAviation.com

off, Gina placed

second behind

a flier with 30-

plus years of

experience—her

father, Andrew.

The Junior

Team Committee,

consisting of Jim

Parker, Charlie

Jones, Tom Vaccaro, and George Batiuk,

is raising funds to help defray some of

the team’s expenses. AMA covers travel,

lodging, and entry fees, but extra support

is needed.

In February, the Junior Committee

raffled off one of the late Bob White’s

Wakefields, model number 23, which

was the backup model when Bob won

the World Championship in 1987. Bob’s

winning model, number 22, is on display

in the National Model Aviation Museum

in Muncie, Indiana.

Also raffled off was a quilt depicting

all of the previous Junior World

Championships sites made by Charlie

Jones’ mother. Donations can be made

by check to AMA and should be

earmarked for the Junior Free Flight

Team. You can also send a check directly

ff DURATION

T he 2012 FAI Junior World Championships for Free Flight Model Aircraft

will be held July 27 through August 3 near Ljubljana, Slovenia. The United

States will be represented by Gina Barron, Logan Tetrick, and Michelle

Barron in F1A Towline Glider; Sevak Malkhasyan, Brian Pacelli, and Peyton

Tetrick in F1B Wakefield Rubber; and Taron Malkhasyan and Brian Pacelli in F1P

Power. As of early February, the third

slot in F1P had not been filled.

Once again, Brian Pacelli will do

double duty, flying Wakefield and

F1P Power. This year’s team includes

a set of brothers, Sevak and Taron

Malkhasyan; brother and sister, Logan

and Peyton Tetrick; and sisters, Gina

and Michelle Barron. George Batiuk

will be team manager.

Gina, who will turn 10 during the

Junior World Championships, will

be one of the youngest contestants

to represent the US in any World

Championships. Although her F1A

Towline gliders may span twice her

height, she handles them with skill.

At a contest last fall in Seguin, Texas,

Gina picked her own air for all seven

rounds and was one of two contestants

to max out; both fliers maxed the

first fly-off round. In the second fly-

FF Junior World Champs

by Louis Joyner

[email protected]

PLUS:

> America Cup

> National Cup

> Two-piece wings

> StarLink FliteTech

models

Brian Pacelli, who will fly F1B and F1P in this year’s

Junior FF World Championships, winds the rubber

outside of the model. This allows for a quicker

change in case of a blown motor.

Peyton Tetrick made the F1B team

flying a Vivchar model; her brother,

Logan, made the team in F1A

Towline Glider.

Taron Malkhasyan made the Junior team

flying F1P Power. He was also high-scoring

Junior in F1J and F1P in the America’s Cup.

114 Model Aviation May 2012 www.ModelAviation.com

ff duration

Below: Michelle Barron and her sister, Gina, comprise

two-thirds of the Junior F1A team attending the World

Championships in Slovenia.

Left: StarLink-FliteTech Models offers a variety

of models, kits, and accessories, including this

replacement shaft and three-part bobbin used

to update the front end of Burdov F1G Coupe

models.

Taron’s brother, Sevak Malkhasyan,

made the Junior team in F1B, earned

top points in the National Cup Junior

category, and was high Junior in F1B in

the America’s Cup.

to team manager George Batiuk, 576

Dana St., San Luis Obispo CA 93401.

America’s Cup

The annual multi-contest

competition for all of the FAI FF

events concluded this December. Here

are the results:

F1A Towline Glider: Brian Van Nest

(Gina Barron, high Junior)

F1B Wakefield Rubber: Blake Jensen

(Sevak Malkhasyan, high Junior)

F1C: Faust Parker

F1G Coupe Rubber: Blake Jensen

(Troy Davis, high Junior)

F1H Towline Glider: Mike McKeever

(Gina Barron, high Junior)

F1J Power: Faust Parker (Taron

Malkhasyan, high Junior and 4th place

overall)

F1P Power: Glen Schneider (Taron

Malkhasyan, high Junior and tied for

3rd place overall)

F1Q Electric: John Oldenkamp

F1E Slope Soaring: Peter Brocks

The America’s Cup, which was

created by the Southern California

Aero Team and is administered by Jim

Parker, offers a multi-contest format

that encourages modelers from the

United States, Canada, and Mexico,

to compete in FAI FF events. Points

are awarded at each contest, with a

first place receiving 25, second place

receiving 20, third place receiving 15,

fourth place receiving 10, and fifth

place receiving 5 points.

Additional points are awarded

depending on the number of

contestants flying in the event. Best

results from four contests are counted.

To encourage travel, only two contests

at any one site can be counted; the

other two results must be from two

other sites. In the case of a tie, results

from more contests are counted.

Detailed rules for the America’s Cup

can be found on the National Free

Flight Society (NFFS) website.

National Cup

The National Cup was created in

2003 to encourage participants to

travel and compete at FF contests

across the country. As is the America’s

Cup, the National Cup is a multicontest

competition. However, the

National Cup focuses on AMA FF

events.

Contestants in each of seven

categories accumulate points in the

individual events within that category

at contests across the country. To score

points, contestants must place in the

top five in an event. The highest six

scores in each event are counted.

To make it truly a nationwide cup,

no more than two scores are counted

from any single location. A seventh

score can be added by placing at one

of four exempt contests in each of the

four NFFS regions. The contests are the

Southwest Regionals in Eloy, Arizona;

the AMA Nats in Muncie, Indiana;

the Rocky Mountain Championships

in Denver, Colorado; and the King

Orange Internationals in Palm Bay,

Florida. A third score from one of the

exempt contests is to be counted.

In 2011, there were 81 contests with

615 contestants posting scores in 1,762

individual events. The categories and

the 2011 winners are:

AMA Power: Bob Hanford

Classic Power: Bob Hanford

Nostalgia Power (small): Bob Hanford

Nostalgia Power (large): Bob Hanford

AMA Rubber: Earl Griffith

Nostalgia Rubber: Don DeLoach

Glider: Tim Batiuk

Bob Hanford won all four of the

Power categories.

The National Cup includes a Junior

category, which combines scores from

selected Rubber, Power, and Glider

events. Sevak Malkhasyan topped this

category, with Tyler Moore in second,

only 14 points behind. Samuel Smetzer

was third, Taron Malkhasyan came in

fourth, and Elliot Plantner placed fifth.

Rules, detailed scores, and the 2012

National Cup contest schedule can be

found on the NFFS website.

Two-Piece Wings

Fifty years ago, one-piece wings were

the rule, even for large FF models.

In those days, before minivans and

SUVs, large wings were often strapped,

upside down, to the headliner of the

family sedan for transport to the flying

field. Today, many models use twopiece

wings that allow more compact

storage—often in a purpose-made

model box that safely stores several

complete models for a car trip or an

international flight.

Two-piece wings allow easy

adjustment of the relative incidence

between the two wing halves

as a trimming aid. This can be

accomplished by shimming underneath

the TE on a two-piece wing, rubber

banded to a traditional pylon or rail

system on the fuselage. The two wing

halves can also be connected by a

single wire running through the pylon

or fuselage; often one half is located by

a fixed rear pin and the other half with

an adjustable pin.

The adjustable pin can be linked to a

timer, either through a line or a servo,

to change the incidence of the wing

half at a predetermined time during

the flight. Known as a wing wiggler,

its use is nearly universal in the larger

FAI classes of F1A Towline Glider, F1B

Wakefield Rubber, and F1C Power,

usually coupled with auto rudder and

auto stabilizer.

For smaller models, such as an F1G

Coupe d’Hiver, a wing wiggler can even

be used as the only auto surface. On

my Coupes, I use a simple wing wiggler

made from wire and tubing to control

the left wing. At launch, the left panel

is set at several degrees negative relative

to the right wing half. This provides a

left rolling tendency during the initial

burst.

After 5 to 7 seconds, a timer releases

a line, allowing the left TE to move

down to the glide position. The result

is a straight, near-vertical initial climb,

transitioning into a right cruise and

right glide. No other auto surfaces

are used. (Photographs and a detailed

description of this wing wiggler can

be found in MA’s November 2010 “FF

Duration” column.)

A two-piece wing requires slightly

more effort during construction, but

the convenience of adjusting the wing

halves independently, as well as the

compactness, make it worth the effort.

Two-piece wings are often heavier

than a one-piece wing. The wing wire,

sockets in the two wing halves, and the

socket and additional reinforcing in the

pylon or fuselage, all add weight; this

is partially offset by eliminating the

center section reinforcements needed

with a one-piece wing.

The wing wire is often the main

offender concerning weight. In the past,

steel wire has been the most popular

choice. Typical diameters range from

3.0mm (slightly less than 1/8 inch) for

F1B, to 5.5mm to 6.0mm (less than 1/4

inch) for F1A and F1C. Steel wire can

also bend during a hard towline launch

or on DT.

Carbon fiber has been tried as a

lighter-weight alternative. The weight

saving can be significant. On his

F1B models, Paul Crowley has tried

substituting 1/8-inch diameter carbonfiber

rod for 1/8-inch steel wing wires.

“The weight saving was nice; 1 gram

for carbon versus 4 grams for steel,” he

said.

But there were problems. “I found

that the carbon-fiber rods would break

after repeated use, usually on launch,”

said Paul. “But the break was actually

promoted by hard DT landings. I

believe that the shear load at the pylon

was the cause; rounding the corners of

the holes didn’t help. The carbon-fiber

rod is a bundle of strands and you start

breaking them one at a time until the

strands that are left can’t take the stress

of a hard launch or DT.”

A solution is to protect the carbon

fiber with steel. One method is to

use thin-wall stainless steel tubing of

the desired diameter and fill it with

carbon-fiber tow wetted out with

epoxy. This can be done by inserting a

loop of Kevlar thread through a length

of steel tubing, then using the Kevlar

thread to pull a bundle of doubled

lengths of epoxy-soaked carbon-fiber

tow back through the tube.

For lighter models, such as F1G

Coupe and other Rubber models,

carbon-fiber rods or tubes still offer the

best weight-to-strength option for wing

wires. The popular Burdov Candy G

Coupe uses a purpose-made 4.5mmdiameter

carbon tube; carbon-tube

pultrusions, available from A2Z Corp

and CST, are offered in 3mm, 4mm,

and 5mm, which would be suitable for

many smaller, lightly-loaded models. (I

have had no problems using the 4.0mm

pultrusion for the wing wire on my

Coupes.) To avoid problems, frequently

inspect and replace carbon wing rods

or tubes.

Whatever you use for the wing wire,

it must fit properly into sockets in the

wings. Standard piano wire and the

next larger size aluminum tubing fits

too loosely. Aluminum tubing from

K&S has a wall thickness of 0.014 inch.

If you use 5/32-inch OD aluminum

tubing, the ID will be 0.12825; that’s

0.00325 inch bigger than 1/8-inch

piano wire. Not quite sloppy, but

loose enough to potentially cause trim

problems.

How do you get a perfect fit? One

solution is to make your own wing

sockets using a carbon-fiber sock. The

sock (available from CST) is slipped

over a length of wing-wire material

or drill rod of the same size that is

coated with release agent. (I’ve used

a double wrap of 1/4 mil Mylar.) The

sock is pulled tight and coated with

epoxy laminating resin. Excess epoxy is

blotted off.

After the epoxy hardens, the wire is

removed, leaving a rigid carbon-fiber

tube socket that’s a perfect fit for the

wing wire. For larger models, a second

sock can be added over the first for

extra strength. You can cut the socket

to length for each wing half or, better

yet, cut it to double length and build

it into both right- and left-wing inner

panels at the same time, ensuring

accurate alignment.

Don’t do as I did and glue the wing

socket permanently to the wing wire

I was using to align two main spar

halves while installing the sockets.

The carbon-fiber sock tubing I had

made was porous enough to let some

CA soak through to the wing wire.

(I intended to tack the sockets in

place with CA so the wing wire could

be removed and the socket-to-spar

joint filled in with epoxy and micro

balloons.)

Paul Crowley offers another option

to ensure a perfect fit: “I run a pipe

cleaner with epoxy on it to coat the

inside of the aluminum tube, then I

bore it out to size with a new, sharp

drill bit when it’s set,” he said. (I’ve

done it the other way around by

brushing slow epoxy glue onto a long

section of too-small carbon-fiber tube

and hanging the rod up to dry.)

The wing sockets must be tied into

the main spar structure. Ideally, the

wing socket is sandwiched between

upper and lower carbon-fiber caps in a

full-depth spar.

For the pylon or fuselage socket,

you can use a section of the carbonfiber

socket or make a custom-fit

aluminum tube. K&S, supplier of the

brass and aluminum tubing available

at most hobby shops, produces a line

of thick-wall aluminum tubing in a

variety of ODs with a wall thickness

of either 0.035 inch or 0.049 inch;

the aluminum used (6061 T-6) is

slightly harder than that used for the

thin-wall tubing.

The thick-walled tubing can be

bored out using the correct size drill

bit, preferably on a lathe. Few hobby

shops carry thick-wall tubing; an

online source is Hobbylinc. Its website

includes thick-wall aluminum tubing

in a few metric sizes, as well as brass

tubing in metric sizes.

The brass tubing has a 0.45mm wall

thickness, so it doesn’t give a close

fit on metric-size wire. For example,

the clearance between 3.0mm OD

brass tubing and 2mm diameter wire

is 0.10mm (0.004 inch)—too loose

to use as a shaft bearing or wingwire

socket.

StarLink FliteTech Models

Michael Pykelny is the new owner

of StarLink FliteTech. He took over

from previous owner Larry Bagalini,

who ran the mail-order operation for

a number of years after founder Al

Brush passed away. The new contact

information is at the end of the column.

StarLink offers a variety of models

and kits, ranging from Russian flier

Andrey Burdov’s F1B Wakefield and

F1G Coupe models to innovative

P-30 kits. StarLink carries an updated

version of Bob White’s Beau Coupe

design and several Nostalgia and Old-

Timer Rubber kits.

Items for the shop and flying field,

including a machined aluminum

winding stooge and clear plastic storage

tubes for tracking transmitters, are also

available. Components such as motor

tubes, front ends, propeller blades, and

even wings for F1B and F1G aircraft

can be purchased.

Parts are stocked to allow upgrading

of older Burdov Coupe front ends.

These include adjustable blade fittings

and a replacement shaft that allows

you to use a bobbin to connect

the rubber motor to the front end,

permitting winding without the

propeller attached.

Sources :

NFFS

www.freeflight.org

CST-The Composites Store

(800) 338-1278

www.cstsales.com

A2Z Corp

(877) 754-7465

www.A2ZCorp.us/store

Hobbylinc

(888) 327-9673

www.hobbylinc.com

StarLink-FliteTech Models

(858) 231-4994

www.starlink-flitetech.com

Edition: Model Aviation - 2012/05

Page Numbers: 112,114,115,116,117

112 Model Aviation May 2012 www.ModelAviation.com

off, Gina placed

second behind

a flier with 30-

plus years of

experience—her

father, Andrew.

The Junior

Team Committee,

consisting of Jim

Parker, Charlie

Jones, Tom Vaccaro, and George Batiuk,

is raising funds to help defray some of

the team’s expenses. AMA covers travel,

lodging, and entry fees, but extra support

is needed.

In February, the Junior Committee

raffled off one of the late Bob White’s

Wakefields, model number 23, which

was the backup model when Bob won

the World Championship in 1987. Bob’s

winning model, number 22, is on display

in the National Model Aviation Museum

in Muncie, Indiana.

Also raffled off was a quilt depicting

all of the previous Junior World

Championships sites made by Charlie

Jones’ mother. Donations can be made

by check to AMA and should be

earmarked for the Junior Free Flight

Team. You can also send a check directly

ff DURATION

T he 2012 FAI Junior World Championships for Free Flight Model Aircraft

will be held July 27 through August 3 near Ljubljana, Slovenia. The United

States will be represented by Gina Barron, Logan Tetrick, and Michelle

Barron in F1A Towline Glider; Sevak Malkhasyan, Brian Pacelli, and Peyton

Tetrick in F1B Wakefield Rubber; and Taron Malkhasyan and Brian Pacelli in F1P

Power. As of early February, the third

slot in F1P had not been filled.

Once again, Brian Pacelli will do

double duty, flying Wakefield and

F1P Power. This year’s team includes

a set of brothers, Sevak and Taron

Malkhasyan; brother and sister, Logan

and Peyton Tetrick; and sisters, Gina

and Michelle Barron. George Batiuk

will be team manager.

Gina, who will turn 10 during the

Junior World Championships, will

be one of the youngest contestants

to represent the US in any World

Championships. Although her F1A

Towline gliders may span twice her

height, she handles them with skill.

At a contest last fall in Seguin, Texas,

Gina picked her own air for all seven

rounds and was one of two contestants

to max out; both fliers maxed the

first fly-off round. In the second fly-

FF Junior World Champs

by Louis Joyner

[email protected]

PLUS:

> America Cup

> National Cup

> Two-piece wings

> StarLink FliteTech

models

Brian Pacelli, who will fly F1B and F1P in this year’s

Junior FF World Championships, winds the rubber

outside of the model. This allows for a quicker

change in case of a blown motor.

Peyton Tetrick made the F1B team

flying a Vivchar model; her brother,

Logan, made the team in F1A

Towline Glider.

Taron Malkhasyan made the Junior team

flying F1P Power. He was also high-scoring

Junior in F1J and F1P in the America’s Cup.

114 Model Aviation May 2012 www.ModelAviation.com

ff duration

Below: Michelle Barron and her sister, Gina, comprise

two-thirds of the Junior F1A team attending the World

Championships in Slovenia.

Left: StarLink-FliteTech Models offers a variety

of models, kits, and accessories, including this

replacement shaft and three-part bobbin used

to update the front end of Burdov F1G Coupe

models.

Taron’s brother, Sevak Malkhasyan,

made the Junior team in F1B, earned

top points in the National Cup Junior

category, and was high Junior in F1B in

the America’s Cup.

to team manager George Batiuk, 576

Dana St., San Luis Obispo CA 93401.

America’s Cup

The annual multi-contest

competition for all of the FAI FF

events concluded this December. Here

are the results:

F1A Towline Glider: Brian Van Nest

(Gina Barron, high Junior)

F1B Wakefield Rubber: Blake Jensen

(Sevak Malkhasyan, high Junior)

F1C: Faust Parker

F1G Coupe Rubber: Blake Jensen

(Troy Davis, high Junior)

F1H Towline Glider: Mike McKeever

(Gina Barron, high Junior)

F1J Power: Faust Parker (Taron

Malkhasyan, high Junior and 4th place

overall)

F1P Power: Glen Schneider (Taron

Malkhasyan, high Junior and tied for

3rd place overall)

F1Q Electric: John Oldenkamp

F1E Slope Soaring: Peter Brocks

The America’s Cup, which was

created by the Southern California

Aero Team and is administered by Jim

Parker, offers a multi-contest format

that encourages modelers from the

United States, Canada, and Mexico,

to compete in FAI FF events. Points

are awarded at each contest, with a

first place receiving 25, second place

receiving 20, third place receiving 15,

fourth place receiving 10, and fifth

place receiving 5 points.

Additional points are awarded

depending on the number of

contestants flying in the event. Best

results from four contests are counted.

To encourage travel, only two contests

at any one site can be counted; the

other two results must be from two

other sites. In the case of a tie, results

from more contests are counted.

Detailed rules for the America’s Cup

can be found on the National Free

Flight Society (NFFS) website.

National Cup

The National Cup was created in

2003 to encourage participants to

travel and compete at FF contests

across the country. As is the America’s

Cup, the National Cup is a multicontest

competition. However, the

National Cup focuses on AMA FF

events.

Contestants in each of seven

categories accumulate points in the

individual events within that category

at contests across the country. To score

points, contestants must place in the

top five in an event. The highest six

scores in each event are counted.

To make it truly a nationwide cup,

no more than two scores are counted

from any single location. A seventh

score can be added by placing at one

of four exempt contests in each of the

four NFFS regions. The contests are the

Southwest Regionals in Eloy, Arizona;

the AMA Nats in Muncie, Indiana;

the Rocky Mountain Championships

in Denver, Colorado; and the King

Orange Internationals in Palm Bay,

Florida. A third score from one of the

exempt contests is to be counted.

In 2011, there were 81 contests with

615 contestants posting scores in 1,762

individual events. The categories and

the 2011 winners are:

AMA Power: Bob Hanford

Classic Power: Bob Hanford

Nostalgia Power (small): Bob Hanford

Nostalgia Power (large): Bob Hanford

AMA Rubber: Earl Griffith

Nostalgia Rubber: Don DeLoach

Glider: Tim Batiuk

Bob Hanford won all four of the

Power categories.

The National Cup includes a Junior

category, which combines scores from

selected Rubber, Power, and Glider

events. Sevak Malkhasyan topped this

category, with Tyler Moore in second,

only 14 points behind. Samuel Smetzer

was third, Taron Malkhasyan came in

fourth, and Elliot Plantner placed fifth.

Rules, detailed scores, and the 2012

National Cup contest schedule can be

found on the NFFS website.

Two-Piece Wings

Fifty years ago, one-piece wings were

the rule, even for large FF models.

In those days, before minivans and

SUVs, large wings were often strapped,

upside down, to the headliner of the

family sedan for transport to the flying

field. Today, many models use twopiece

wings that allow more compact

storage—often in a purpose-made

model box that safely stores several

complete models for a car trip or an

international flight.

Two-piece wings allow easy

adjustment of the relative incidence

between the two wing halves

as a trimming aid. This can be

accomplished by shimming underneath

the TE on a two-piece wing, rubber

banded to a traditional pylon or rail

system on the fuselage. The two wing

halves can also be connected by a

single wire running through the pylon

or fuselage; often one half is located by

a fixed rear pin and the other half with

an adjustable pin.

The adjustable pin can be linked to a

timer, either through a line or a servo,

to change the incidence of the wing

half at a predetermined time during

the flight. Known as a wing wiggler,

its use is nearly universal in the larger

FAI classes of F1A Towline Glider, F1B

Wakefield Rubber, and F1C Power,

usually coupled with auto rudder and

auto stabilizer.

For smaller models, such as an F1G

Coupe d’Hiver, a wing wiggler can even

be used as the only auto surface. On

my Coupes, I use a simple wing wiggler

made from wire and tubing to control

the left wing. At launch, the left panel

is set at several degrees negative relative

to the right wing half. This provides a

left rolling tendency during the initial

burst.

After 5 to 7 seconds, a timer releases

a line, allowing the left TE to move

down to the glide position. The result

is a straight, near-vertical initial climb,

transitioning into a right cruise and

right glide. No other auto surfaces

are used. (Photographs and a detailed

description of this wing wiggler can

be found in MA’s November 2010 “FF

Duration” column.)

A two-piece wing requires slightly

more effort during construction, but

the convenience of adjusting the wing

halves independently, as well as the

compactness, make it worth the effort.

Two-piece wings are often heavier

than a one-piece wing. The wing wire,

sockets in the two wing halves, and the

socket and additional reinforcing in the

pylon or fuselage, all add weight; this

is partially offset by eliminating the

center section reinforcements needed

with a one-piece wing.

The wing wire is often the main

offender concerning weight. In the past,

steel wire has been the most popular

choice. Typical diameters range from

3.0mm (slightly less than 1/8 inch) for

F1B, to 5.5mm to 6.0mm (less than 1/4

inch) for F1A and F1C. Steel wire can

also bend during a hard towline launch

or on DT.

Carbon fiber has been tried as a

lighter-weight alternative. The weight

saving can be significant. On his

F1B models, Paul Crowley has tried

substituting 1/8-inch diameter carbonfiber

rod for 1/8-inch steel wing wires.

“The weight saving was nice; 1 gram

for carbon versus 4 grams for steel,” he

said.

But there were problems. “I found

that the carbon-fiber rods would break

after repeated use, usually on launch,”

said Paul. “But the break was actually

promoted by hard DT landings. I

believe that the shear load at the pylon

was the cause; rounding the corners of

the holes didn’t help. The carbon-fiber

rod is a bundle of strands and you start

breaking them one at a time until the

strands that are left can’t take the stress

of a hard launch or DT.”

A solution is to protect the carbon

fiber with steel. One method is to

use thin-wall stainless steel tubing of

the desired diameter and fill it with

carbon-fiber tow wetted out with

epoxy. This can be done by inserting a

loop of Kevlar thread through a length

of steel tubing, then using the Kevlar

thread to pull a bundle of doubled

lengths of epoxy-soaked carbon-fiber

tow back through the tube.

For lighter models, such as F1G

Coupe and other Rubber models,

carbon-fiber rods or tubes still offer the

best weight-to-strength option for wing

wires. The popular Burdov Candy G

Coupe uses a purpose-made 4.5mmdiameter

carbon tube; carbon-tube

pultrusions, available from A2Z Corp

and CST, are offered in 3mm, 4mm,

and 5mm, which would be suitable for

many smaller, lightly-loaded models. (I

have had no problems using the 4.0mm

pultrusion for the wing wire on my

Coupes.) To avoid problems, frequently

inspect and replace carbon wing rods

or tubes.

Whatever you use for the wing wire,

it must fit properly into sockets in the

wings. Standard piano wire and the

next larger size aluminum tubing fits

too loosely. Aluminum tubing from

K&S has a wall thickness of 0.014 inch.

If you use 5/32-inch OD aluminum

tubing, the ID will be 0.12825; that’s

0.00325 inch bigger than 1/8-inch

piano wire. Not quite sloppy, but

loose enough to potentially cause trim

problems.

How do you get a perfect fit? One

solution is to make your own wing

sockets using a carbon-fiber sock. The

sock (available from CST) is slipped

over a length of wing-wire material

or drill rod of the same size that is

coated with release agent. (I’ve used

a double wrap of 1/4 mil Mylar.) The

sock is pulled tight and coated with

epoxy laminating resin. Excess epoxy is

blotted off.

After the epoxy hardens, the wire is

removed, leaving a rigid carbon-fiber

tube socket that’s a perfect fit for the

wing wire. For larger models, a second

sock can be added over the first for

extra strength. You can cut the socket

to length for each wing half or, better

yet, cut it to double length and build

it into both right- and left-wing inner

panels at the same time, ensuring

accurate alignment.

Don’t do as I did and glue the wing

socket permanently to the wing wire

I was using to align two main spar

halves while installing the sockets.

The carbon-fiber sock tubing I had

made was porous enough to let some

CA soak through to the wing wire.

(I intended to tack the sockets in

place with CA so the wing wire could

be removed and the socket-to-spar

joint filled in with epoxy and micro

balloons.)

Paul Crowley offers another option

to ensure a perfect fit: “I run a pipe

cleaner with epoxy on it to coat the

inside of the aluminum tube, then I

bore it out to size with a new, sharp

drill bit when it’s set,” he said. (I’ve

done it the other way around by

brushing slow epoxy glue onto a long

section of too-small carbon-fiber tube

and hanging the rod up to dry.)

The wing sockets must be tied into

the main spar structure. Ideally, the

wing socket is sandwiched between

upper and lower carbon-fiber caps in a

full-depth spar.

For the pylon or fuselage socket,

you can use a section of the carbonfiber

socket or make a custom-fit

aluminum tube. K&S, supplier of the

brass and aluminum tubing available

at most hobby shops, produces a line

of thick-wall aluminum tubing in a

variety of ODs with a wall thickness

of either 0.035 inch or 0.049 inch;

the aluminum used (6061 T-6) is

slightly harder than that used for the

thin-wall tubing.

The thick-walled tubing can be

bored out using the correct size drill

bit, preferably on a lathe. Few hobby

shops carry thick-wall tubing; an

online source is Hobbylinc. Its website

includes thick-wall aluminum tubing

in a few metric sizes, as well as brass

tubing in metric sizes.

The brass tubing has a 0.45mm wall

thickness, so it doesn’t give a close

fit on metric-size wire. For example,

the clearance between 3.0mm OD

brass tubing and 2mm diameter wire

is 0.10mm (0.004 inch)—too loose

to use as a shaft bearing or wingwire

socket.

StarLink FliteTech Models

Michael Pykelny is the new owner

of StarLink FliteTech. He took over

from previous owner Larry Bagalini,

who ran the mail-order operation for

a number of years after founder Al

Brush passed away. The new contact

information is at the end of the column.

StarLink offers a variety of models

and kits, ranging from Russian flier

Andrey Burdov’s F1B Wakefield and

F1G Coupe models to innovative

P-30 kits. StarLink carries an updated

version of Bob White’s Beau Coupe

design and several Nostalgia and Old-

Timer Rubber kits.

Items for the shop and flying field,

including a machined aluminum

winding stooge and clear plastic storage

tubes for tracking transmitters, are also

available. Components such as motor

tubes, front ends, propeller blades, and

even wings for F1B and F1G aircraft

can be purchased.

Parts are stocked to allow upgrading

of older Burdov Coupe front ends.

These include adjustable blade fittings

and a replacement shaft that allows

you to use a bobbin to connect

the rubber motor to the front end,

permitting winding without the

propeller attached.

Sources :

NFFS

www.freeflight.org

CST-The Composites Store

(800) 338-1278

www.cstsales.com

A2Z Corp

(877) 754-7465

www.A2ZCorp.us/store

Hobbylinc

(888) 327-9673

www.hobbylinc.com

StarLink-FliteTech Models

(858) 231-4994

www.starlink-flitetech.com

Edition: Model Aviation - 2012/05

Page Numbers: 112,114,115,116,117

112 Model Aviation May 2012 www.ModelAviation.com

off, Gina placed

second behind

a flier with 30-

plus years of

experience—her

father, Andrew.

The Junior

Team Committee,

consisting of Jim

Parker, Charlie

Jones, Tom Vaccaro, and George Batiuk,

is raising funds to help defray some of

the team’s expenses. AMA covers travel,

lodging, and entry fees, but extra support

is needed.

In February, the Junior Committee

raffled off one of the late Bob White’s

Wakefields, model number 23, which

was the backup model when Bob won

the World Championship in 1987. Bob’s

winning model, number 22, is on display

in the National Model Aviation Museum

in Muncie, Indiana.

Also raffled off was a quilt depicting

all of the previous Junior World

Championships sites made by Charlie

Jones’ mother. Donations can be made

by check to AMA and should be

earmarked for the Junior Free Flight

Team. You can also send a check directly

ff DURATION

T he 2012 FAI Junior World Championships for Free Flight Model Aircraft

will be held July 27 through August 3 near Ljubljana, Slovenia. The United

States will be represented by Gina Barron, Logan Tetrick, and Michelle

Barron in F1A Towline Glider; Sevak Malkhasyan, Brian Pacelli, and Peyton

Tetrick in F1B Wakefield Rubber; and Taron Malkhasyan and Brian Pacelli in F1P

Power. As of early February, the third

slot in F1P had not been filled.

Once again, Brian Pacelli will do

double duty, flying Wakefield and

F1P Power. This year’s team includes

a set of brothers, Sevak and Taron

Malkhasyan; brother and sister, Logan

and Peyton Tetrick; and sisters, Gina

and Michelle Barron. George Batiuk

will be team manager.

Gina, who will turn 10 during the

Junior World Championships, will

be one of the youngest contestants

to represent the US in any World

Championships. Although her F1A

Towline gliders may span twice her

height, she handles them with skill.

At a contest last fall in Seguin, Texas,

Gina picked her own air for all seven

rounds and was one of two contestants

to max out; both fliers maxed the

first fly-off round. In the second fly-

FF Junior World Champs

by Louis Joyner

[email protected]

PLUS:

> America Cup

> National Cup

> Two-piece wings

> StarLink FliteTech

models

Brian Pacelli, who will fly F1B and F1P in this year’s

Junior FF World Championships, winds the rubber

outside of the model. This allows for a quicker

change in case of a blown motor.

Peyton Tetrick made the F1B team

flying a Vivchar model; her brother,

Logan, made the team in F1A

Towline Glider.

Taron Malkhasyan made the Junior team

flying F1P Power. He was also high-scoring

Junior in F1J and F1P in the America’s Cup.

114 Model Aviation May 2012 www.ModelAviation.com

ff duration

Below: Michelle Barron and her sister, Gina, comprise

two-thirds of the Junior F1A team attending the World

Championships in Slovenia.

Left: StarLink-FliteTech Models offers a variety

of models, kits, and accessories, including this

replacement shaft and three-part bobbin used

to update the front end of Burdov F1G Coupe

models.

Taron’s brother, Sevak Malkhasyan,

made the Junior team in F1B, earned

top points in the National Cup Junior

category, and was high Junior in F1B in

the America’s Cup.

to team manager George Batiuk, 576

Dana St., San Luis Obispo CA 93401.

America’s Cup

The annual multi-contest

competition for all of the FAI FF

events concluded this December. Here

are the results:

F1A Towline Glider: Brian Van Nest

(Gina Barron, high Junior)

F1B Wakefield Rubber: Blake Jensen

(Sevak Malkhasyan, high Junior)

F1C: Faust Parker

F1G Coupe Rubber: Blake Jensen

(Troy Davis, high Junior)

F1H Towline Glider: Mike McKeever

(Gina Barron, high Junior)

F1J Power: Faust Parker (Taron

Malkhasyan, high Junior and 4th place

overall)

F1P Power: Glen Schneider (Taron

Malkhasyan, high Junior and tied for

3rd place overall)

F1Q Electric: John Oldenkamp

F1E Slope Soaring: Peter Brocks

The America’s Cup, which was

created by the Southern California

Aero Team and is administered by Jim

Parker, offers a multi-contest format

that encourages modelers from the

United States, Canada, and Mexico,

to compete in FAI FF events. Points

are awarded at each contest, with a

first place receiving 25, second place

receiving 20, third place receiving 15,

fourth place receiving 10, and fifth

place receiving 5 points.

Additional points are awarded

depending on the number of

contestants flying in the event. Best

results from four contests are counted.

To encourage travel, only two contests

at any one site can be counted; the

other two results must be from two

other sites. In the case of a tie, results

from more contests are counted.

Detailed rules for the America’s Cup

can be found on the National Free

Flight Society (NFFS) website.

National Cup

The National Cup was created in

2003 to encourage participants to

travel and compete at FF contests

across the country. As is the America’s

Cup, the National Cup is a multicontest

competition. However, the

National Cup focuses on AMA FF

events.

Contestants in each of seven

categories accumulate points in the

individual events within that category

at contests across the country. To score

points, contestants must place in the

top five in an event. The highest six

scores in each event are counted.

To make it truly a nationwide cup,

no more than two scores are counted