July 2007 35

A simple-to-build

RC foam flying

wing that’s easy

to personalize

BY BENNY LANTERMAN

Left: The AXI 2208-34-

powered Foamy 5 is made

from five foam trays: two

black, one yellow, two small

white. The yellow tray is the

thickest; the vertical tails are

the thinnest.

Below: Foamy 4 is the

smallest and one of the

fastest in the series when

powered by a custom CD

outrunner motor.

ONE OF THE joys of living in today’s world is that the difference

between wonders caused by science and wonders caused by magic

is getting harder to differentiate. This applies to our radio-control

hobby.

The small receivers, servos, and motors have given us the ability

to put controls on almost anything we want to fly, from airplanes

weighing less than an ounce (surely magic) to turbo jet-powered,

flame-shooting monsters (definitely magic and science).

Much of the available magic is found in our trash! The modern

foam tray used in supermarkets (and other stores) is brought into our

houses while performing its prime purpose and then

unceremoniously dumped into the wastebasket. The tray is an

airplane waiting to happen; you just have to cut away everything

that isn’t an airplane and let the magic out.

Another source of foam trays is a company such as Leftovers,

etc. here in Saint Charles, Missouri. Most larger cities have a similar

facility.

It is a recycling center that supplies free and affordable materials

to teachers and crafters, and among the many items available are

foam trays. You can find these trays in many different sizes and

thicknesses, and it might be worth eating some broccoli to get a

piece of foam with the right dimensions.

For those who are unfortunate enough to live far away from a

recycling center and who never go to a supermarket, foam sheets are

available with the product name Depron. This material is available

in several thicknesses and is a lot of fun with which to work.

07sig2.QXD 5/23/07 10:33 AM Page 35

36 MODEL AVIATION

pieces of foam: one wing, one vertical, and

two elevons. (I don’t count the motor

mount.)

I experimented with single and multiple

vertical tails, rectangular- and ovalplanform

wings, more delta-looking wings,

and many different profile fuselage shapes.

The model’s configuration is your choice.

Even a fully contoured fuselage could be

made from the foam with no problems.

Let your imagination be your limit. I’ll

include a simple process to determine

whether or not your design will work before

you commit any radio gear and money to

the project.

CONSTRUCTION

The first and only step is to gather the

foam and see what you can make with it.

Well, it is almost that easy; I encourage

experimentation and variation with this

material.

As simple as the Foamy is, I don’t

recommend it as a first airplane. It is fully

aerobatic and responsive in pitch and roll.

Except for Foamy 6 (which is large, light,

and slow), this design is fairly fast.

I was fortunate enough to find a large

tray that was suitable to use as the main

wing on some of the Foamy configurations

and some small trays for the fuselages and

vertical tails. Another model was

constructed from several colors and

thicknesses of foam trays.

The foam is easy to cut with a sharp

blade, and it can be glued with any foamsafe

adhesive. I use foam-friendly

cyanoacrylate and find that I can build an

airplane in just a few minutes. When in

doubt, try a few test pieces of foam and

verify that your glue and foam are

compatible.

Butt joints seem to be strong, but if you

put a large motor on the Foamy you should

reinforce any questionable area with a small

strip of thin foam or balsa on either side. I

haven’t had any joint problems with the

airplanes that are shown.

Well, I did have one problem. I was

holding Foamy 4 fairly low by one vertical

tail (while I was busy talking and walking)

and stepped on the antenna wire. I was left

with a surprised look, a tail in my hand, and

an airplane on the ground. However, that

was the only damage and it was simple to

fix.

I have presented plans for a typical

model. Foamy 1 started out as a rectangle

and flew fine, but the angular wingtip sweep

looks nice and helps determine which way

the airplane is going at any given time. It is

unnecessary to adhere blindly to any of the

dimensions I give you; just get close.

You can use the following information to

determine whether or not your changes will

allow the airplane to fly. It is my quick and

easy method of determining your design’s

aerodynamic worth and the CG for the first

flight.

Cut and glue together only the foam and

balsa reinforcement parts of your airplane,

adding the elevons with pieces of tape. With

Foamy 1’s bottom shows red balsa stiffeners. Benny initially planned to use markers to

color the whole bottom red, but test areas on foam showed that permanent markers

would dissolve it slightly.

Foamy 1 launches nice and stable. Servos sticking through the wing’s bottom give a good

holding point for launching. They are inadequate for holding higher-power Foamys.

Whether it is tray or Depron, you should

look for foam that is 1/16-1/8 inch thick

(3mm-4mm) with a smooth surface skin.

Use the thicker size for the inner wing and

fuselages and thinner material for the outer

wing and vertical tails.

If all you can find are several smaller

pieces of foam, you can glue them together

in a pleasing geometric pattern and cut your

parts out of it. I did that with the black,

yellow, and white Foamy 5 model.

The Airplane: Foamy is an airplane—or

series of airplanes—that is based on the

low-aspect-ratio flying wing. Many vertical

tail and fuselage configurations can be

added to the basic design to get many

different looks.

The flying wings presented here are only

some of what can be made from foam trays

and are examples of how little material is

required to produce a flyable airplane. The

simplest model is made from only four

07sig2.QXD 5/23/07 10:41 AM Page 36

July 2007 37

Foamy 5 in the test-glide phase. Weight is added to the nose and

elevons are adjusted until it glides well. Mark the location on the

wing bottom and use it as a safe starting point for the first flight.

Foamy 6 is the slowest, lightest version tried. Its stock GWS

motor was previously used on a Pico Stick. Note the large tip

dihedral that stabilizes the Foamy in roll, still allowing full pitch

control to be maintained.

Twin Foamy was an experiment in using twin motors. Although it

uses Jeti brushless outrunners, it would fly well with small GWS

IPS geared motors.

Foamy 2 is leaving major sonic booms in its wake. (Some imagination

is needed.) The oversized Jeti Advance ESC for Li-Poly cells was

employed to make use of what was available in the model shop.

Foamy 6 on a low pass. Its slow speed makes it a good intermediate airplane. Even though it is the slowest Foamy to date, it is still

fast compared to a Pico Stick.

Photos by the author

07sig2.QXD 5/23/07 10:51 AM Page 37

38 MODEL AVIATION

Sheets of 3mm Depron (12 x 24 inches) are used to make Foamy

6. This is simplicity itself. All that is needed to finish the model is

a motor mount and radio gear.

The foam trays used to construct Foamy 4. A fairly large one was

used to make the main wing. The dashed lines are where the

vertical tails are located.

no radio, motor, or batteries, it becomes a light, simple glider.

Adjust the elevons slightly up (use tape to hold them in place)

and add weight to the model’s nose to balance the airplane at

roughly 20% of the wing chord. Make adjustments to the nose

weight and elevons until the aircraft glides nicely. If you are really

off in your CG guess, the foam glider will gently flop to the floor.

Once you get an okay glide, mark that CG location on the foam

wing. Add the radio gear, motors, and batteries in the proper

fashion, per the manufacturers’ recommendations.

I won’t get too detailed with installation notes since the Foamy

shouldn’t be considered as a first model. A design such as the GWS

Pico Stick would be a better choice. (Mine still works fine after

many years, motors, and flights.)

Move the various pieces of equipment around to keep the CG in

the same location as on the nonpowered glider, and use sticky-back

Velcro to fasten the receiver and ESC. Use the photos as a general

guide for equipment locations. You can temporarily tape the

receiver, servos, etc. in place to see if the CG is going to work.

Cut holes in the wing and push the servos through with a bit of

glue to hold them in place. Set the initial elevon deflections (you can

use tape or your favorite hinges on the elevons) to be the same as

used by the glider. The model (if not the pilot) will be in fine shape

for the first flight.

I have used motors ranging from the little workhorse GWS IPS

geared units and hand-wound CD-drive conversions to the elegant

brushless golden anodized AXI 2208-34. With any lightweight

equipment the airplane will weigh less than 4.5 ounces without

batteries.

I have used a small seven-cell, 280 mAh NiMH pack with the

GWS motor system and two- or three-cell, 700 mAh Li-Poly packs

for the brushless motors. I selected propellers per the motor

manufacturer’s suggestions.

I have been using the small, single-conversion receivers that

GWS and Hitec make. I have used a large variety of ESC brands,

but I have used the Jeti the most. In each case the unit has been

appropriate for the motor and battery pack. Use string to tie down

any loose wires so it looks fairly neat.

The motor is attached to a hardwood stick with balsa fill added

as necessary to fit the power plant that is used. Although we never

crash, remember that the stick should be the weakest link—weak

enough to break instead of the motor on those rare nose-down

arrivals.

Flying: The magic takes wing at the flying field. A gentle toss will

set the airplane flying straight and level. Trim as needed and be

prepared to have a great deal of relaxed fun. With almost zero cost

in materials for the airplane, the scary part of flying disappears.

Take along foam-friendly cyanoacrylate and kicker to do field

Type: RC sport electric

Wingspan: 24 inches

Weight: 4.5 ounces (without batteries)

Wing area: 268 square inches

Length: 12 inches (without motor)

Power: AXI 2208-34 motor with 30- to 50-watt output, 8-

to 10-amp ESC, two- to three-cell, 800 mAh Li-Poly

battery

Radio: Three channels minimum with two microservos

Construction: 3mm-6mm foam

Covering/finish: Magic Marker, foam-safe paint

07sig2.QXD 5/23/07 11:32 AM Page 38

July 2007 39

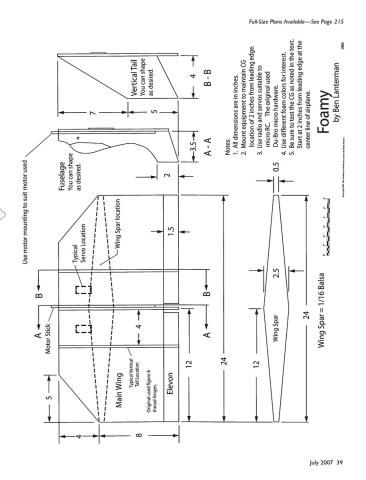

Full-Size Plans Available—See Page 215

07sig2.QXD 5/23/07 10:55 AM Page 39

repairs, and fly all day! The large, flat

piece of foam is a great-flying airplane

with flight characteristics dependent on

weight, size, and power.

There is one thing to watch out for (and

the embarrassing reason why I almost

called the model the “Whacker”). Make

sure you have a good grip on the Foamy

when checking the motor.

I was holding the airplane too loosely,

and it pivoted in my hand enough to allow

the propeller to hit the heel of my hand

several fierce whacks. A half dozen oozing

cuts put home the lesson: the little motors

should be treated with care and respect.

A large, light Foamy 1 or Foamy 6 with

the small GWS motor flies gently. It might

loop if you hold the dive long enough and

are lucky. It will roll more easily, but not

all that well. It is a bit like a butterfly, but I

have flown one in nearly 15 mph winds.

Using the tip dihedral makes the airplane

roll stable and helps the more

inexperienced pilot.

The same airplane with an AXI

brushless motor is a different machine.

Straight flight under full power is

surprisingly fast, yet slow flight is still very

nice. You can do continuous loops and

rolls, and go straight up for a long time.

Foamy 1 has made many flights and, as

the resident test bed, received my first

small brushless motor. While doing a

series of fast, small loops on its first flight,

I noticed it was developing more and more

dihedral until the wing folded in the center.

I throttled back and the Foamy slowly

fluttered down and settled on the runway

(another good thing about the light foam

wings). I put glue in the break and added

a 1/16-inch-thick, 2-inch-wide balsa wing

spar at the 25% chord position. In the

photos it is seen as the red-markered area

under the wing. No problems have

resurfaced since that addition.

Foamy 4 with the Custom CD or small

AXI brushless outrunner motor is a true

speed demon with amazing looping and

rolling performance. For this variation I

recommend the thicker foam.

Performance in the wind is great, and it

will be flying when other types of models

are grounded.

The other Foamys have varying

components and characteristics. They

have been a lot of fun to fly. Each one is

different and leads me to try something

else. No boring airplanes here!

I am presently wondering how

rounded surfaces would look and thinking

about the benefits of a full fuselage. A

single tail would be okay too, if you like

that kind of configuration. A recent

addition has been the twin Foamy that is

shown. It flies nicely and has a great twin

sound.

Something fun and educational is to

take one of the models, scissors, extra

pieces of foam, tape, foam-friendly

cyanoacrylate, and cyanoacrylate kicker

to the flying field. There you can

experiment with wing extensions, wing

strakes, vertical tail sizes, control-surface

sizes, and anything else you can think of.

What you can do is limited only by how

much magic you are willing to let out of

the foam. MA

Benny Lanterman

[email protected]