Moffett attains Model of the Year status

[[email protected]]

Free Flight Duration Louis Joyner

Also included in this column:

• Other Models of the Year

• Clearphane covering

• Ink-jet tissue-graphics method

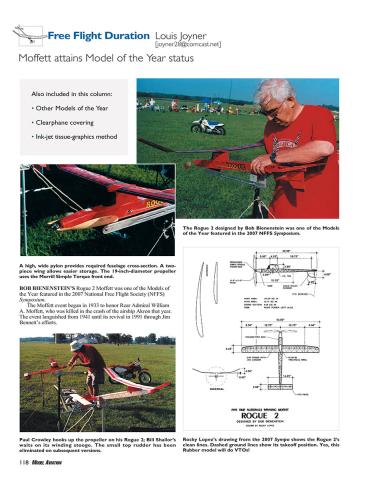

The Rogue 2 designed by Bob Bienenstein was one of the Models

of the Year featured in the 2007 NFFS Symposium.

A high, wide pylon provides required fuselage cross-section. A twopiece

wing allows easier storage. The 19-inch-diameter propeller

uses the Morrill Simple Torque front end.

Paul Crowley hooks up the propeller on his Rogue 2; Bill Shailor’s

waits on its winding stooge. The small top rudder has been

eliminated on subsequent versions.

Rocky Lopez’s drawing from the 2007 Sympo shows the Rogue 2’s

clean lines. Dashed ground lines show its takeoff position. Yes, this

Rubber model will do VTOs!

BOB BIENENSTEIN’S Rogue 2 Moffett was one of the Models of

the Year featured in the 2007 National Free Flight Society (NFFS)

Symposium.

The Moffett event began in 1933 to honor Rear Admiral William

A. Moffett, who was killed in the crash of the airship Akron that year.

The event languished from 1941 until its revival in 1991 through Jim

Bennett’s efforts.

118 MODEL AVIATION

11sig4.QXD 9/21/07 9:57 AM Page 118

The current Moffett rules limit the total projected

wing and stabilizer area to 13 square decimeters (202

square inches). The fuselage length cannot exceed

wingspan and a minimum cross-section of L2/150 is

required. Minimum airframe weight is 50 grams per

100 square inches of wing area.

There are no restrictions on the weight of the

rubber motor used. Models must rise off ground

(ROG).

Bob Bienenstein’s Rogue 2 evolved from his

earlier diamond-fuselage Bandit design. Along the

way Bob has tried a variety of things including

different wing airfoils, rudder configurations, and

wing constructions.

Several of Bob’s Detroit Balsa Bugs clubmates,

including Bill Shailor and Paul Crowley, also fly the

Rogue 2. At this year’s Nats the three were flying

side by side, so it was easy to see the subtle variations

among the permutations.

Having other modelers building and flying the model provides

feedback that helps improve the overall design.

“I’ve been learning all my life,” said Bob. (He seems to be learning

a lot. He has won the Mulvihill Trophy six times, beginning in 1947,

and won the Moffett Trophy four times.)

This year Bob flew his “wet” model that features Union Jack wing

and stabilizer construction and Mylar covering for damp conditions.

Power is 22 strands of 1/8-inch rubber that is 25 inches long. That’s

enough power to allow a VTO (vertical takeoff) launch, which is

actually safer than a conventional ROG launch. Motor run is 70

seconds.

2007 Models of the Year: Following is a list of the other models

honored by the NFFS.

• The Astrostar 404 is Terry Kerger’s update of Terry Thorkildsen’s

1988 design. Cody Secor used this model to win the Junior FF World

Championships last year.

• Jack Emery’s F1G Coupe uses composite carbon-fiber construction

and features a folding-wing DT.

• Graham Selick’s Accorte II CO2 model has accrued a total of eight

Nats wins in the F1K and Unlimited CO2 events. The 34-inch-span

design weighs roughly 60 grams.

• Marvin Mace’s AMA Gas Super Marval is the bunt version of his

1993 Model of the Year Marvel. Wing construction uses a traditional

balsa D-box. A K&B 3.5 powers the 564-square-inch airplane.

In addition, Sergio Montes received a special award for his Free

Flight Quarterly. The international publication is now in its sixth year.

To order a copy of the 2007 Sympo or for other information about

the NFFS, visit the Web site.

Right: Neat model identification on John

Pratt’s F1B combines AMA number and

“if found” info. Characters are printed as

mirror image on back side of white tissue

then attached with thinner.

Below: For this small Rubber model

John printed color graphics on the dull

side of white tissue and then covered

the wing conventionally.

Hank Nystrom uses inexpensive Clearphane to cover smaller

models such as this Rex Hinson-designed E-36 Sparks from the

BMJR kit.

November 2007 119

11sig4.QXD 9/21/07 10:05 AM Page 119

Colorful Covering: Hank Nystrom has

found an inexpensive source of colored

transparent plastic film. The brand name is

Clearphane, and it is sold at craft stores for

wrapping gift baskets.

“Right after Easter is the best time to

buy,” said Hank. “It’s usually on discount.

It’s really cheap.”

As when using many plastic films, the

model structure must be coated with a heatactivated

adhesive beforehand. Then the

covering is attached using a trimming iron,

after which a 300° MonoKote iron is used to

tighten the covering.

“I’ve used it for years,” said Hank. “I’ve

used it on 1/2As no problem.”

However, as with most plastic-film

Jet Adhesives

PO Box 633, Deerfield, IL 60015

1-866-538-4583

www.jetglues.com

Often

Imitated.

Never

Equaled.

Chrono-stabilized for

extra-long shelf life.

Gasket-sealed

lids to prevent

leakage.

Unsurpassed

bond

strength.

Exclusive

formulations

developed to

withstand heat

and vibration

Specially treated,

clog-resistant tips

and attached caps.

Easy-to-squeeze

see-through

containers.

CA’s.

We set the standard.

covering materials, the thin plastic

contributes little to a wing’s structural

rigidity.

“I used it on an A/B Spacer,” said Hank.

“It was too much airplane for this covering.”

Tissue Graphics: I’ve been cutting

individual numbers from tissue for years. I

stack three or four small pieces of tissue and

then tape down a printed paper outline of the

letter. The straight lines are easy, but the

curves are difficult to do neatly.

Then I dope the numbers one at a time,

keeping them straight and properly spaced.

It’s not one of my favorite things to do. At

the Nats John Pratt showed a quicker and

easier method using an ink-jet printer.

He designs the numbers, selecting the

typeface and size he wants. For the model

number on his F1B airplane John adds the

“USA” prefix that is required by FAI rules.

He also includes a line of smaller type below

with contact information in case the model is

lost.

Then John flips the number in the

computer to create a mirror image. (The

command is “Flip Horizontal” in the

Photoshop software on my computer.)

John attaches an 8.5 x 11-inch sheet of

white tissue, glossy side down, to a sheet of

printer paper using repositionable spray

mount. He found that this works much better

than taping the tissue to the heavier backing

paper.

He runs the paper/tissue combination

through the printer with the dull side of the

tissue up. (Make sure to check how your

printer feeds; some pull the paper through a

180° “half loop” so the up face in the paper

tray becomes the back of the document. Just

remember that you want the printer to print

on the dull side of the tissue.)

After allowing the ink to dry, John

carefully peels it off the backing paper and

trims the excess tissue away with four

straight cuts. Then he attaches the block of

numbers, right side up, to the model using

thinner.

(John covers his model with Polyspan,

which requires a dope finish. If you are trying

this technique on a model that is covered with

plastic film, you’ll need to apply a coat of

clear dope in the area and allow it to dry

before attaching the tissue numbers.)

John has also tried printing directly on the

tissue used to cover the model. For a small

sport Rubber model he designed graphics for

each wing panel and for the fuselage sides.

They were printed on the dull side of the

tissue and allowed to dry. The model was

covered conventionally, misted with water to

shrink the tissue, and then doped.

The limiting factor is the maximum size

of paper your printer can accommodate. (Be

sure to run a test sample using your printer

inks since different ink brands could react

differently to thinner.) MA

Sources:

National Free Flight Society

www.freeflight.org

Edition: Model Aviation - 2007/11

Page Numbers: 118,119,120

Edition: Model Aviation - 2007/11

Page Numbers: 118,119,120

Moffett attains Model of the Year status

[[email protected]]

Free Flight Duration Louis Joyner

Also included in this column:

• Other Models of the Year

• Clearphane covering

• Ink-jet tissue-graphics method

The Rogue 2 designed by Bob Bienenstein was one of the Models

of the Year featured in the 2007 NFFS Symposium.

A high, wide pylon provides required fuselage cross-section. A twopiece

wing allows easier storage. The 19-inch-diameter propeller

uses the Morrill Simple Torque front end.

Paul Crowley hooks up the propeller on his Rogue 2; Bill Shailor’s

waits on its winding stooge. The small top rudder has been

eliminated on subsequent versions.

Rocky Lopez’s drawing from the 2007 Sympo shows the Rogue 2’s

clean lines. Dashed ground lines show its takeoff position. Yes, this

Rubber model will do VTOs!

BOB BIENENSTEIN’S Rogue 2 Moffett was one of the Models of

the Year featured in the 2007 National Free Flight Society (NFFS)

Symposium.

The Moffett event began in 1933 to honor Rear Admiral William

A. Moffett, who was killed in the crash of the airship Akron that year.

The event languished from 1941 until its revival in 1991 through Jim

Bennett’s efforts.

118 MODEL AVIATION

11sig4.QXD 9/21/07 9:57 AM Page 118

The current Moffett rules limit the total projected

wing and stabilizer area to 13 square decimeters (202

square inches). The fuselage length cannot exceed

wingspan and a minimum cross-section of L2/150 is

required. Minimum airframe weight is 50 grams per

100 square inches of wing area.

There are no restrictions on the weight of the

rubber motor used. Models must rise off ground

(ROG).

Bob Bienenstein’s Rogue 2 evolved from his

earlier diamond-fuselage Bandit design. Along the

way Bob has tried a variety of things including

different wing airfoils, rudder configurations, and

wing constructions.

Several of Bob’s Detroit Balsa Bugs clubmates,

including Bill Shailor and Paul Crowley, also fly the

Rogue 2. At this year’s Nats the three were flying

side by side, so it was easy to see the subtle variations

among the permutations.

Having other modelers building and flying the model provides

feedback that helps improve the overall design.

“I’ve been learning all my life,” said Bob. (He seems to be learning

a lot. He has won the Mulvihill Trophy six times, beginning in 1947,

and won the Moffett Trophy four times.)

This year Bob flew his “wet” model that features Union Jack wing

and stabilizer construction and Mylar covering for damp conditions.

Power is 22 strands of 1/8-inch rubber that is 25 inches long. That’s

enough power to allow a VTO (vertical takeoff) launch, which is

actually safer than a conventional ROG launch. Motor run is 70

seconds.

2007 Models of the Year: Following is a list of the other models

honored by the NFFS.

• The Astrostar 404 is Terry Kerger’s update of Terry Thorkildsen’s

1988 design. Cody Secor used this model to win the Junior FF World

Championships last year.

• Jack Emery’s F1G Coupe uses composite carbon-fiber construction

and features a folding-wing DT.

• Graham Selick’s Accorte II CO2 model has accrued a total of eight

Nats wins in the F1K and Unlimited CO2 events. The 34-inch-span

design weighs roughly 60 grams.

• Marvin Mace’s AMA Gas Super Marval is the bunt version of his

1993 Model of the Year Marvel. Wing construction uses a traditional

balsa D-box. A K&B 3.5 powers the 564-square-inch airplane.

In addition, Sergio Montes received a special award for his Free

Flight Quarterly. The international publication is now in its sixth year.

To order a copy of the 2007 Sympo or for other information about

the NFFS, visit the Web site.

Right: Neat model identification on John

Pratt’s F1B combines AMA number and

“if found” info. Characters are printed as

mirror image on back side of white tissue

then attached with thinner.

Below: For this small Rubber model

John printed color graphics on the dull

side of white tissue and then covered

the wing conventionally.

Hank Nystrom uses inexpensive Clearphane to cover smaller

models such as this Rex Hinson-designed E-36 Sparks from the

BMJR kit.

November 2007 119

11sig4.QXD 9/21/07 10:05 AM Page 119

Colorful Covering: Hank Nystrom has

found an inexpensive source of colored

transparent plastic film. The brand name is

Clearphane, and it is sold at craft stores for

wrapping gift baskets.

“Right after Easter is the best time to

buy,” said Hank. “It’s usually on discount.

It’s really cheap.”

As when using many plastic films, the

model structure must be coated with a heatactivated

adhesive beforehand. Then the

covering is attached using a trimming iron,

after which a 300° MonoKote iron is used to

tighten the covering.

“I’ve used it for years,” said Hank. “I’ve

used it on 1/2As no problem.”

However, as with most plastic-film

Jet Adhesives

PO Box 633, Deerfield, IL 60015

1-866-538-4583

www.jetglues.com

Often

Imitated.

Never

Equaled.

Chrono-stabilized for

extra-long shelf life.

Gasket-sealed

lids to prevent

leakage.

Unsurpassed

bond

strength.

Exclusive

formulations

developed to

withstand heat

and vibration

Specially treated,

clog-resistant tips

and attached caps.

Easy-to-squeeze

see-through

containers.

CA’s.

We set the standard.

covering materials, the thin plastic

contributes little to a wing’s structural

rigidity.

“I used it on an A/B Spacer,” said Hank.

“It was too much airplane for this covering.”

Tissue Graphics: I’ve been cutting

individual numbers from tissue for years. I

stack three or four small pieces of tissue and

then tape down a printed paper outline of the

letter. The straight lines are easy, but the

curves are difficult to do neatly.

Then I dope the numbers one at a time,

keeping them straight and properly spaced.

It’s not one of my favorite things to do. At

the Nats John Pratt showed a quicker and

easier method using an ink-jet printer.

He designs the numbers, selecting the

typeface and size he wants. For the model

number on his F1B airplane John adds the

“USA” prefix that is required by FAI rules.

He also includes a line of smaller type below

with contact information in case the model is

lost.

Then John flips the number in the

computer to create a mirror image. (The

command is “Flip Horizontal” in the

Photoshop software on my computer.)

John attaches an 8.5 x 11-inch sheet of

white tissue, glossy side down, to a sheet of

printer paper using repositionable spray

mount. He found that this works much better

than taping the tissue to the heavier backing

paper.

He runs the paper/tissue combination

through the printer with the dull side of the

tissue up. (Make sure to check how your

printer feeds; some pull the paper through a

180° “half loop” so the up face in the paper

tray becomes the back of the document. Just

remember that you want the printer to print

on the dull side of the tissue.)

After allowing the ink to dry, John

carefully peels it off the backing paper and

trims the excess tissue away with four

straight cuts. Then he attaches the block of

numbers, right side up, to the model using

thinner.

(John covers his model with Polyspan,

which requires a dope finish. If you are trying

this technique on a model that is covered with

plastic film, you’ll need to apply a coat of

clear dope in the area and allow it to dry

before attaching the tissue numbers.)

John has also tried printing directly on the

tissue used to cover the model. For a small

sport Rubber model he designed graphics for

each wing panel and for the fuselage sides.

They were printed on the dull side of the

tissue and allowed to dry. The model was

covered conventionally, misted with water to

shrink the tissue, and then doped.

The limiting factor is the maximum size

of paper your printer can accommodate. (Be

sure to run a test sample using your printer

inks since different ink brands could react

differently to thinner.) MA

Sources:

National Free Flight Society

www.freeflight.org

Edition: Model Aviation - 2007/11

Page Numbers: 118,119,120

Moffett attains Model of the Year status

[[email protected]]

Free Flight Duration Louis Joyner

Also included in this column:

• Other Models of the Year

• Clearphane covering

• Ink-jet tissue-graphics method

The Rogue 2 designed by Bob Bienenstein was one of the Models

of the Year featured in the 2007 NFFS Symposium.

A high, wide pylon provides required fuselage cross-section. A twopiece

wing allows easier storage. The 19-inch-diameter propeller

uses the Morrill Simple Torque front end.

Paul Crowley hooks up the propeller on his Rogue 2; Bill Shailor’s

waits on its winding stooge. The small top rudder has been

eliminated on subsequent versions.

Rocky Lopez’s drawing from the 2007 Sympo shows the Rogue 2’s

clean lines. Dashed ground lines show its takeoff position. Yes, this

Rubber model will do VTOs!

BOB BIENENSTEIN’S Rogue 2 Moffett was one of the Models of

the Year featured in the 2007 National Free Flight Society (NFFS)

Symposium.

The Moffett event began in 1933 to honor Rear Admiral William

A. Moffett, who was killed in the crash of the airship Akron that year.

The event languished from 1941 until its revival in 1991 through Jim

Bennett’s efforts.

118 MODEL AVIATION

11sig4.QXD 9/21/07 9:57 AM Page 118

The current Moffett rules limit the total projected

wing and stabilizer area to 13 square decimeters (202

square inches). The fuselage length cannot exceed

wingspan and a minimum cross-section of L2/150 is

required. Minimum airframe weight is 50 grams per

100 square inches of wing area.

There are no restrictions on the weight of the

rubber motor used. Models must rise off ground

(ROG).

Bob Bienenstein’s Rogue 2 evolved from his

earlier diamond-fuselage Bandit design. Along the

way Bob has tried a variety of things including

different wing airfoils, rudder configurations, and

wing constructions.

Several of Bob’s Detroit Balsa Bugs clubmates,

including Bill Shailor and Paul Crowley, also fly the

Rogue 2. At this year’s Nats the three were flying

side by side, so it was easy to see the subtle variations

among the permutations.

Having other modelers building and flying the model provides

feedback that helps improve the overall design.

“I’ve been learning all my life,” said Bob. (He seems to be learning

a lot. He has won the Mulvihill Trophy six times, beginning in 1947,

and won the Moffett Trophy four times.)

This year Bob flew his “wet” model that features Union Jack wing

and stabilizer construction and Mylar covering for damp conditions.

Power is 22 strands of 1/8-inch rubber that is 25 inches long. That’s

enough power to allow a VTO (vertical takeoff) launch, which is

actually safer than a conventional ROG launch. Motor run is 70

seconds.

2007 Models of the Year: Following is a list of the other models

honored by the NFFS.

• The Astrostar 404 is Terry Kerger’s update of Terry Thorkildsen’s

1988 design. Cody Secor used this model to win the Junior FF World

Championships last year.

• Jack Emery’s F1G Coupe uses composite carbon-fiber construction

and features a folding-wing DT.

• Graham Selick’s Accorte II CO2 model has accrued a total of eight

Nats wins in the F1K and Unlimited CO2 events. The 34-inch-span

design weighs roughly 60 grams.

• Marvin Mace’s AMA Gas Super Marval is the bunt version of his

1993 Model of the Year Marvel. Wing construction uses a traditional

balsa D-box. A K&B 3.5 powers the 564-square-inch airplane.

In addition, Sergio Montes received a special award for his Free

Flight Quarterly. The international publication is now in its sixth year.

To order a copy of the 2007 Sympo or for other information about

the NFFS, visit the Web site.

Right: Neat model identification on John

Pratt’s F1B combines AMA number and

“if found” info. Characters are printed as

mirror image on back side of white tissue

then attached with thinner.

Below: For this small Rubber model

John printed color graphics on the dull

side of white tissue and then covered

the wing conventionally.

Hank Nystrom uses inexpensive Clearphane to cover smaller

models such as this Rex Hinson-designed E-36 Sparks from the

BMJR kit.

November 2007 119

11sig4.QXD 9/21/07 10:05 AM Page 119

Colorful Covering: Hank Nystrom has

found an inexpensive source of colored

transparent plastic film. The brand name is

Clearphane, and it is sold at craft stores for

wrapping gift baskets.

“Right after Easter is the best time to

buy,” said Hank. “It’s usually on discount.

It’s really cheap.”

As when using many plastic films, the

model structure must be coated with a heatactivated

adhesive beforehand. Then the

covering is attached using a trimming iron,

after which a 300° MonoKote iron is used to

tighten the covering.

“I’ve used it for years,” said Hank. “I’ve

used it on 1/2As no problem.”

However, as with most plastic-film

Jet Adhesives

PO Box 633, Deerfield, IL 60015

1-866-538-4583

www.jetglues.com

Often

Imitated.

Never

Equaled.

Chrono-stabilized for

extra-long shelf life.

Gasket-sealed

lids to prevent

leakage.

Unsurpassed

bond

strength.

Exclusive

formulations

developed to

withstand heat

and vibration

Specially treated,

clog-resistant tips

and attached caps.

Easy-to-squeeze

see-through

containers.

CA’s.

We set the standard.

covering materials, the thin plastic

contributes little to a wing’s structural

rigidity.

“I used it on an A/B Spacer,” said Hank.

“It was too much airplane for this covering.”

Tissue Graphics: I’ve been cutting

individual numbers from tissue for years. I

stack three or four small pieces of tissue and

then tape down a printed paper outline of the

letter. The straight lines are easy, but the

curves are difficult to do neatly.

Then I dope the numbers one at a time,

keeping them straight and properly spaced.

It’s not one of my favorite things to do. At

the Nats John Pratt showed a quicker and

easier method using an ink-jet printer.

He designs the numbers, selecting the

typeface and size he wants. For the model

number on his F1B airplane John adds the

“USA” prefix that is required by FAI rules.

He also includes a line of smaller type below

with contact information in case the model is

lost.

Then John flips the number in the

computer to create a mirror image. (The

command is “Flip Horizontal” in the

Photoshop software on my computer.)

John attaches an 8.5 x 11-inch sheet of

white tissue, glossy side down, to a sheet of

printer paper using repositionable spray

mount. He found that this works much better

than taping the tissue to the heavier backing

paper.

He runs the paper/tissue combination

through the printer with the dull side of the

tissue up. (Make sure to check how your

printer feeds; some pull the paper through a

180° “half loop” so the up face in the paper

tray becomes the back of the document. Just

remember that you want the printer to print

on the dull side of the tissue.)

After allowing the ink to dry, John

carefully peels it off the backing paper and

trims the excess tissue away with four

straight cuts. Then he attaches the block of

numbers, right side up, to the model using

thinner.

(John covers his model with Polyspan,

which requires a dope finish. If you are trying

this technique on a model that is covered with

plastic film, you’ll need to apply a coat of

clear dope in the area and allow it to dry

before attaching the tissue numbers.)

John has also tried printing directly on the

tissue used to cover the model. For a small

sport Rubber model he designed graphics for

each wing panel and for the fuselage sides.

They were printed on the dull side of the

tissue and allowed to dry. The model was

covered conventionally, misted with water to

shrink the tissue, and then doped.

The limiting factor is the maximum size

of paper your printer can accommodate. (Be

sure to run a test sample using your printer

inks since different ink brands could react

differently to thinner.) MA

Sources:

National Free Flight Society

www.freeflight.org