PLEASE WRITE in with your questions;

that is the only way we can keep this

column format going. When referring to

questions and answers that have been

published (for follow-ups), provide the

number as a reference.

References to addresses and Web sites

are placed in a group, separate from the text,

at the end of this column under “Sources.”

Q432: “I’ve noted quite often in your

various construction articles that you

recommend a hinge tape. This just doesn’t

seem practical for every model aircraft

application. What are the limits when it

comes to using a tape material as a hinge?”

A432: It’s true; I have used tape as a

control-surface hinge for a long time. There

are certain limitations, as you’ve pointed

out, and there are different types of tape for

different applications.

Very few tapes you select will be

fuelproof. So a limitation is that hinge tape

is restricted to nonfueled models, such as

those that use electric power and sailplanes.

Another limitation is the size and weight

February 2010 91

cement gets into the metal pins and binds the hinge, creating more

problems. You also have to consider whether or not, depending on the

control-surface spacing, air can pass through the slot that the two

surfaces create.

So what about the use of hinge tape? With this method, there is no

gap between the surfaces. The hinge material is applied as one piece

and covers the entire hinge surface.

I have found two types of hinge tape that work well, and one of

those is more for park flyer-size aircraft up to my 3-pound limit. It is

Gapless Hinge Tape, supplied by Larry Sribnick of SR Batteries Inc.

It is a 3M product and is a clear material that is reasonably soft and

flexible. That is important, because I have found some tapes that

looked similar but were more rigid and placed a much greater load on

the servo when moving the control surface. I generally use SR

Batteries’ product for models in the 8- to 48-ounce weight class.

For those that weigh less than 8 ounces, down to some of the

smallest micro/indoor aircraft, I’ve had good luck with another 3M

product that I believe is intended for the medical-supply industry as a

bandage/adhesive tape. It’s Blenderm, and it comes in rolls with a

width of 1 inch.

You can buy Blenderm at drugstores. I believe Du-Bro offers it as

catalog item 916: Electric Flyer Hinge Tape.

Blenderm is soft and flexible, so it imposes very little drag on

typical micro-size servos. It also has excellent adhesive qualities; those

hinges won’t work loose easily for sure.

Keep in mind that applying hinge tape is far easier than cutting slots

for individual hinges. Using tape works best on hinge areas prepared

with bevels that are appropriate for top hinging.

The last thing to be concerned with when using hinge tape is the

spacing between the control surface and the main aircraft surface. If

there is too little space, the control surface will bind, thus restricting the

amount of control throw. If there is too much space, the control surface

might flap or vibrate in flight.

Rather than guess at this spacing, I use scrap pieces of 1/16 balsa as

my spacers. I use painter’s blue masking tape to hold both surfaces on

my building board.

Once everything is locked in place, the balsa scraps are removed.

Then I apply the tape, pressing it down thoroughly. Doing it this

way provides an even spacing that is the proper distance running

along the entire control surface.

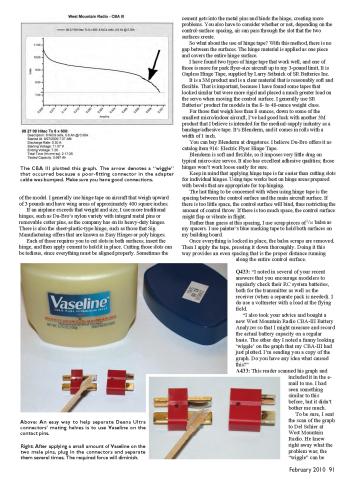

Q433: “I noted in several of your recent

answers that you encourage modelers to

regularly check their RC system batteries,

both for the transmitter as well as the

receiver (when a separate pack is needed). I

do use a voltmeter with a load at the flying

field.

“I also took your advice and bought a

new West Mountain Radio CBA-III Battery

Analyzer so that I might measure and record

the actual battery capacity on a regular

basis. The other day I noted a funny looking

‘wiggle’ on the graph that my CBA-III had

just plotted. I’m sending you a copy of the

graph. Do you have any idea what caused

this?”

A433: This reader scanned his graph and

included it in the email

to me. I had

seen something

similar to this

before, but it didn’t

bother me much.

To be sure, I sent

the scan of the graph

to Del Schier at

West Mountain

Radio. He knew

right away what the

problem was; the

“wiggle” can be

Right: After applying a small amount of Vaseline on the

two male pins, plug in the connectors and separate

them several times. The required force will diminish.

Above: An easy way to help separate Deans Ultra

connectors’ mating halves is to use Vaseline on the

contact pins.

The CBA III plotted this graph. The arrow denotes a “wiggle”

that occurred because a poor-fitting connector in the adapter

cable was bumped. Make sure you have good connections.

of the model. I generally use hinge tape on aircraft that weigh upward

of 3 pounds and have wing areas of approximately 400 square inches.

If an airplane exceeds that weight and size, I use more traditional

hinges, such as Du-Bro’s nylon variety with integral metal pins or

removable cotter pins, as the company has on its heavy-duty hinges.

There is also the sheet-plastic-type hinge, such as those that Sig

Manufacturing offers that are known as Easy Hinges or poly hinges.

Each of those requires you to cut slots in both surfaces, insert the

hinge, and then apply cement to hold it in place. Cutting those slots can

be tedious, since everything must be aligned properly. Sometimes the

02sig3_00MSTRPG.QXD 12/21/09 11:28 AM Page 91

caused by a loose connection between the

battery and the CBA III.

To attach my eight-cell RC transmitter

pack, I used two types of adapter cables.

One of the connectors was apparently not a

good fit. When I moved the cable, I got the

same “wiggle” in the graph that the reader

got.

I made a new adapter cable with a new

connector and ran the discharge test again.

It was perfectly smooth.

Q434: “I noted several months back in

Dave Mathewson’s column in Model

Aviation that a new AMA Forum was being

established. Can you tell me more about

this outreach to the membership?”

434: The new AMA forums are building

as I write this. There is a lot going on with

the AMA Web site. I recently asked why

there isn’t a reference to the forum on the

home page. The answer I received was

that there is, but it does help to know

where to look.

There are a couple of places where you

can enter the forums. At the top of the

AMA homepage, under “Bringing

Modelers Together,” are several tabs.

From the left is “Join/Renew,” “Member

Services,” then “Community.” Click on

Community, and one of the first items is

“AMA Forums.”

Then along the bottom of the homepage

is a series of letters and/or symbols that

ends on the right with “FORUMS.” When

you click on that, “Forum Navigation”

comes up. This is probably the better place

to start.

When you get there, you will be asked to

read a forum agreement statement; accept it

if you agree to the terms. At this point, you

will need to establish a Username and

Password. I had trouble at this point and

had to ask for help.

The best AMA department to contact is

Information Systems. As of this writing (in

October 2009), some staff members will

soon be changing positions, so I’m unable

to give you a name at Headquarters to

contact.

If you have questions, the best thing to

do is click on the “Ask AMA” tab at the top

right corner of the homepage. Then click on

“staff directory.” Scroll down until you

reach the Information Systems department.

There will be names, telephone number

extensions, and e-mail addresses.

I found these people to be helpful, and

I was soon on the forums. There isn’t

much there at the moment, because

members are only now starting to join.

But they will grow with everyone’s help,

so please give them a try.

Q418 Follow-Up: I received feedback that

readers liked the scheme I showed in the

October 2009 column for separating those

stubborn Deans Ultra connectors. I used a

clothespin to easily force the connector

halves apart. This technique works well,

because you don’t have to get both of your

hands inside your aircraft’s RC

compartment.

But after reading this, a member wrote

in letting me know that there is a much

easier solution to this problem. He uses

common Vaseline petroleum jelly. He

wipes it on the connector blades and then

pulls the connector halves out and pushes

them in a few times. As the Vaseline

works in, the connector separation works

easier.

I tried this technique and it works. It

turns out that a noted modeler, Dick Allen,

originated the idea. He used this method for

many years while working as a qualitycontrol

engineer for IBM. The company

believed that Vaseline was one of the best

contact lubricants it could come up with.

Red Scholefield, MA’s battery

columnist, supplied me with that

background info. Red said he has used this

technique for years, applying a thin film to

the connector pins. MA

Sources:

Du-Bro

(800) 848-9411

www.dubro.com

Sig Manufacturing Co.

(641) 623-5154

www.sigmfg.com

SR Batteries Inc.

(631) 286-0079

www.srbatteries.com

West Mountain Radio

(203) 853-8080

www.westmountainradio.com

AMA

(765) 287-1256

www.modelaircraft.org

Edition: Model Aviation - 2010/02

Page Numbers: 90,91,92

Edition: Model Aviation - 2010/02

Page Numbers: 90,91,92

PLEASE WRITE in with your questions;

that is the only way we can keep this

column format going. When referring to

questions and answers that have been

published (for follow-ups), provide the

number as a reference.

References to addresses and Web sites

are placed in a group, separate from the text,

at the end of this column under “Sources.”

Q432: “I’ve noted quite often in your

various construction articles that you

recommend a hinge tape. This just doesn’t

seem practical for every model aircraft

application. What are the limits when it

comes to using a tape material as a hinge?”

A432: It’s true; I have used tape as a

control-surface hinge for a long time. There

are certain limitations, as you’ve pointed

out, and there are different types of tape for

different applications.

Very few tapes you select will be

fuelproof. So a limitation is that hinge tape

is restricted to nonfueled models, such as

those that use electric power and sailplanes.

Another limitation is the size and weight

February 2010 91

cement gets into the metal pins and binds the hinge, creating more

problems. You also have to consider whether or not, depending on the

control-surface spacing, air can pass through the slot that the two

surfaces create.

So what about the use of hinge tape? With this method, there is no

gap between the surfaces. The hinge material is applied as one piece

and covers the entire hinge surface.

I have found two types of hinge tape that work well, and one of

those is more for park flyer-size aircraft up to my 3-pound limit. It is

Gapless Hinge Tape, supplied by Larry Sribnick of SR Batteries Inc.

It is a 3M product and is a clear material that is reasonably soft and

flexible. That is important, because I have found some tapes that

looked similar but were more rigid and placed a much greater load on

the servo when moving the control surface. I generally use SR

Batteries’ product for models in the 8- to 48-ounce weight class.

For those that weigh less than 8 ounces, down to some of the

smallest micro/indoor aircraft, I’ve had good luck with another 3M

product that I believe is intended for the medical-supply industry as a

bandage/adhesive tape. It’s Blenderm, and it comes in rolls with a

width of 1 inch.

You can buy Blenderm at drugstores. I believe Du-Bro offers it as

catalog item 916: Electric Flyer Hinge Tape.

Blenderm is soft and flexible, so it imposes very little drag on

typical micro-size servos. It also has excellent adhesive qualities; those

hinges won’t work loose easily for sure.

Keep in mind that applying hinge tape is far easier than cutting slots

for individual hinges. Using tape works best on hinge areas prepared

with bevels that are appropriate for top hinging.

The last thing to be concerned with when using hinge tape is the

spacing between the control surface and the main aircraft surface. If

there is too little space, the control surface will bind, thus restricting the

amount of control throw. If there is too much space, the control surface

might flap or vibrate in flight.

Rather than guess at this spacing, I use scrap pieces of 1/16 balsa as

my spacers. I use painter’s blue masking tape to hold both surfaces on

my building board.

Once everything is locked in place, the balsa scraps are removed.

Then I apply the tape, pressing it down thoroughly. Doing it this

way provides an even spacing that is the proper distance running

along the entire control surface.

Q433: “I noted in several of your recent

answers that you encourage modelers to

regularly check their RC system batteries,

both for the transmitter as well as the

receiver (when a separate pack is needed). I

do use a voltmeter with a load at the flying

field.

“I also took your advice and bought a

new West Mountain Radio CBA-III Battery

Analyzer so that I might measure and record

the actual battery capacity on a regular

basis. The other day I noted a funny looking

‘wiggle’ on the graph that my CBA-III had

just plotted. I’m sending you a copy of the

graph. Do you have any idea what caused

this?”

A433: This reader scanned his graph and

included it in the email

to me. I had

seen something

similar to this

before, but it didn’t

bother me much.

To be sure, I sent

the scan of the graph

to Del Schier at

West Mountain

Radio. He knew

right away what the

problem was; the

“wiggle” can be

Right: After applying a small amount of Vaseline on the

two male pins, plug in the connectors and separate

them several times. The required force will diminish.

Above: An easy way to help separate Deans Ultra

connectors’ mating halves is to use Vaseline on the

contact pins.

The CBA III plotted this graph. The arrow denotes a “wiggle”

that occurred because a poor-fitting connector in the adapter

cable was bumped. Make sure you have good connections.

of the model. I generally use hinge tape on aircraft that weigh upward

of 3 pounds and have wing areas of approximately 400 square inches.

If an airplane exceeds that weight and size, I use more traditional

hinges, such as Du-Bro’s nylon variety with integral metal pins or

removable cotter pins, as the company has on its heavy-duty hinges.

There is also the sheet-plastic-type hinge, such as those that Sig

Manufacturing offers that are known as Easy Hinges or poly hinges.

Each of those requires you to cut slots in both surfaces, insert the

hinge, and then apply cement to hold it in place. Cutting those slots can

be tedious, since everything must be aligned properly. Sometimes the

02sig3_00MSTRPG.QXD 12/21/09 11:28 AM Page 91

caused by a loose connection between the

battery and the CBA III.

To attach my eight-cell RC transmitter

pack, I used two types of adapter cables.

One of the connectors was apparently not a

good fit. When I moved the cable, I got the

same “wiggle” in the graph that the reader

got.

I made a new adapter cable with a new

connector and ran the discharge test again.

It was perfectly smooth.

Q434: “I noted several months back in

Dave Mathewson’s column in Model

Aviation that a new AMA Forum was being

established. Can you tell me more about

this outreach to the membership?”

434: The new AMA forums are building

as I write this. There is a lot going on with

the AMA Web site. I recently asked why

there isn’t a reference to the forum on the

home page. The answer I received was

that there is, but it does help to know

where to look.

There are a couple of places where you

can enter the forums. At the top of the

AMA homepage, under “Bringing

Modelers Together,” are several tabs.

From the left is “Join/Renew,” “Member

Services,” then “Community.” Click on

Community, and one of the first items is

“AMA Forums.”

Then along the bottom of the homepage

is a series of letters and/or symbols that

ends on the right with “FORUMS.” When

you click on that, “Forum Navigation”

comes up. This is probably the better place

to start.

When you get there, you will be asked to

read a forum agreement statement; accept it

if you agree to the terms. At this point, you

will need to establish a Username and

Password. I had trouble at this point and

had to ask for help.

The best AMA department to contact is

Information Systems. As of this writing (in

October 2009), some staff members will

soon be changing positions, so I’m unable

to give you a name at Headquarters to

contact.

If you have questions, the best thing to

do is click on the “Ask AMA” tab at the top

right corner of the homepage. Then click on

“staff directory.” Scroll down until you

reach the Information Systems department.

There will be names, telephone number

extensions, and e-mail addresses.

I found these people to be helpful, and

I was soon on the forums. There isn’t

much there at the moment, because

members are only now starting to join.

But they will grow with everyone’s help,

so please give them a try.

Q418 Follow-Up: I received feedback that

readers liked the scheme I showed in the

October 2009 column for separating those

stubborn Deans Ultra connectors. I used a

clothespin to easily force the connector

halves apart. This technique works well,

because you don’t have to get both of your

hands inside your aircraft’s RC

compartment.

But after reading this, a member wrote

in letting me know that there is a much

easier solution to this problem. He uses

common Vaseline petroleum jelly. He

wipes it on the connector blades and then

pulls the connector halves out and pushes

them in a few times. As the Vaseline

works in, the connector separation works

easier.

I tried this technique and it works. It

turns out that a noted modeler, Dick Allen,

originated the idea. He used this method for

many years while working as a qualitycontrol

engineer for IBM. The company

believed that Vaseline was one of the best

contact lubricants it could come up with.

Red Scholefield, MA’s battery

columnist, supplied me with that

background info. Red said he has used this

technique for years, applying a thin film to

the connector pins. MA

Sources:

Du-Bro

(800) 848-9411

www.dubro.com

Sig Manufacturing Co.

(641) 623-5154

www.sigmfg.com

SR Batteries Inc.

(631) 286-0079

www.srbatteries.com

West Mountain Radio

(203) 853-8080

www.westmountainradio.com

AMA

(765) 287-1256

www.modelaircraft.org

Edition: Model Aviation - 2010/02

Page Numbers: 90,91,92

PLEASE WRITE in with your questions;

that is the only way we can keep this

column format going. When referring to

questions and answers that have been

published (for follow-ups), provide the

number as a reference.

References to addresses and Web sites

are placed in a group, separate from the text,

at the end of this column under “Sources.”

Q432: “I’ve noted quite often in your

various construction articles that you

recommend a hinge tape. This just doesn’t

seem practical for every model aircraft

application. What are the limits when it

comes to using a tape material as a hinge?”

A432: It’s true; I have used tape as a

control-surface hinge for a long time. There

are certain limitations, as you’ve pointed

out, and there are different types of tape for

different applications.

Very few tapes you select will be

fuelproof. So a limitation is that hinge tape

is restricted to nonfueled models, such as

those that use electric power and sailplanes.

Another limitation is the size and weight

February 2010 91

cement gets into the metal pins and binds the hinge, creating more

problems. You also have to consider whether or not, depending on the

control-surface spacing, air can pass through the slot that the two

surfaces create.

So what about the use of hinge tape? With this method, there is no

gap between the surfaces. The hinge material is applied as one piece

and covers the entire hinge surface.

I have found two types of hinge tape that work well, and one of

those is more for park flyer-size aircraft up to my 3-pound limit. It is

Gapless Hinge Tape, supplied by Larry Sribnick of SR Batteries Inc.

It is a 3M product and is a clear material that is reasonably soft and

flexible. That is important, because I have found some tapes that

looked similar but were more rigid and placed a much greater load on

the servo when moving the control surface. I generally use SR

Batteries’ product for models in the 8- to 48-ounce weight class.

For those that weigh less than 8 ounces, down to some of the

smallest micro/indoor aircraft, I’ve had good luck with another 3M

product that I believe is intended for the medical-supply industry as a

bandage/adhesive tape. It’s Blenderm, and it comes in rolls with a

width of 1 inch.

You can buy Blenderm at drugstores. I believe Du-Bro offers it as

catalog item 916: Electric Flyer Hinge Tape.

Blenderm is soft and flexible, so it imposes very little drag on

typical micro-size servos. It also has excellent adhesive qualities; those

hinges won’t work loose easily for sure.

Keep in mind that applying hinge tape is far easier than cutting slots

for individual hinges. Using tape works best on hinge areas prepared

with bevels that are appropriate for top hinging.

The last thing to be concerned with when using hinge tape is the

spacing between the control surface and the main aircraft surface. If

there is too little space, the control surface will bind, thus restricting the

amount of control throw. If there is too much space, the control surface

might flap or vibrate in flight.

Rather than guess at this spacing, I use scrap pieces of 1/16 balsa as

my spacers. I use painter’s blue masking tape to hold both surfaces on

my building board.

Once everything is locked in place, the balsa scraps are removed.

Then I apply the tape, pressing it down thoroughly. Doing it this

way provides an even spacing that is the proper distance running

along the entire control surface.

Q433: “I noted in several of your recent

answers that you encourage modelers to

regularly check their RC system batteries,

both for the transmitter as well as the

receiver (when a separate pack is needed). I

do use a voltmeter with a load at the flying

field.

“I also took your advice and bought a

new West Mountain Radio CBA-III Battery

Analyzer so that I might measure and record

the actual battery capacity on a regular

basis. The other day I noted a funny looking

‘wiggle’ on the graph that my CBA-III had

just plotted. I’m sending you a copy of the

graph. Do you have any idea what caused

this?”

A433: This reader scanned his graph and

included it in the email

to me. I had

seen something

similar to this

before, but it didn’t

bother me much.

To be sure, I sent

the scan of the graph

to Del Schier at

West Mountain

Radio. He knew

right away what the

problem was; the

“wiggle” can be

Right: After applying a small amount of Vaseline on the

two male pins, plug in the connectors and separate

them several times. The required force will diminish.

Above: An easy way to help separate Deans Ultra

connectors’ mating halves is to use Vaseline on the

contact pins.

The CBA III plotted this graph. The arrow denotes a “wiggle”

that occurred because a poor-fitting connector in the adapter

cable was bumped. Make sure you have good connections.

of the model. I generally use hinge tape on aircraft that weigh upward

of 3 pounds and have wing areas of approximately 400 square inches.

If an airplane exceeds that weight and size, I use more traditional

hinges, such as Du-Bro’s nylon variety with integral metal pins or

removable cotter pins, as the company has on its heavy-duty hinges.

There is also the sheet-plastic-type hinge, such as those that Sig

Manufacturing offers that are known as Easy Hinges or poly hinges.

Each of those requires you to cut slots in both surfaces, insert the

hinge, and then apply cement to hold it in place. Cutting those slots can

be tedious, since everything must be aligned properly. Sometimes the

02sig3_00MSTRPG.QXD 12/21/09 11:28 AM Page 91

caused by a loose connection between the

battery and the CBA III.

To attach my eight-cell RC transmitter

pack, I used two types of adapter cables.

One of the connectors was apparently not a

good fit. When I moved the cable, I got the

same “wiggle” in the graph that the reader

got.

I made a new adapter cable with a new

connector and ran the discharge test again.

It was perfectly smooth.

Q434: “I noted several months back in

Dave Mathewson’s column in Model

Aviation that a new AMA Forum was being

established. Can you tell me more about

this outreach to the membership?”

434: The new AMA forums are building

as I write this. There is a lot going on with

the AMA Web site. I recently asked why

there isn’t a reference to the forum on the

home page. The answer I received was

that there is, but it does help to know

where to look.

There are a couple of places where you

can enter the forums. At the top of the

AMA homepage, under “Bringing

Modelers Together,” are several tabs.

From the left is “Join/Renew,” “Member

Services,” then “Community.” Click on

Community, and one of the first items is

“AMA Forums.”

Then along the bottom of the homepage

is a series of letters and/or symbols that

ends on the right with “FORUMS.” When

you click on that, “Forum Navigation”

comes up. This is probably the better place

to start.

When you get there, you will be asked to

read a forum agreement statement; accept it

if you agree to the terms. At this point, you

will need to establish a Username and

Password. I had trouble at this point and

had to ask for help.

The best AMA department to contact is

Information Systems. As of this writing (in

October 2009), some staff members will

soon be changing positions, so I’m unable

to give you a name at Headquarters to

contact.

If you have questions, the best thing to

do is click on the “Ask AMA” tab at the top

right corner of the homepage. Then click on

“staff directory.” Scroll down until you

reach the Information Systems department.

There will be names, telephone number

extensions, and e-mail addresses.

I found these people to be helpful, and

I was soon on the forums. There isn’t

much there at the moment, because

members are only now starting to join.

But they will grow with everyone’s help,

so please give them a try.

Q418 Follow-Up: I received feedback that

readers liked the scheme I showed in the

October 2009 column for separating those

stubborn Deans Ultra connectors. I used a

clothespin to easily force the connector

halves apart. This technique works well,

because you don’t have to get both of your

hands inside your aircraft’s RC

compartment.

But after reading this, a member wrote

in letting me know that there is a much

easier solution to this problem. He uses

common Vaseline petroleum jelly. He

wipes it on the connector blades and then

pulls the connector halves out and pushes

them in a few times. As the Vaseline

works in, the connector separation works

easier.

I tried this technique and it works. It

turns out that a noted modeler, Dick Allen,

originated the idea. He used this method for

many years while working as a qualitycontrol

engineer for IBM. The company

believed that Vaseline was one of the best

contact lubricants it could come up with.

Red Scholefield, MA’s battery

columnist, supplied me with that

background info. Red said he has used this

technique for years, applying a thin film to

the connector pins. MA

Sources:

Du-Bro

(800) 848-9411

www.dubro.com

Sig Manufacturing Co.

(641) 623-5154

www.sigmfg.com

SR Batteries Inc.

(631) 286-0079

www.srbatteries.com

West Mountain Radio

(203) 853-8080

www.westmountainradio.com

AMA

(765) 287-1256

www.modelaircraft.org