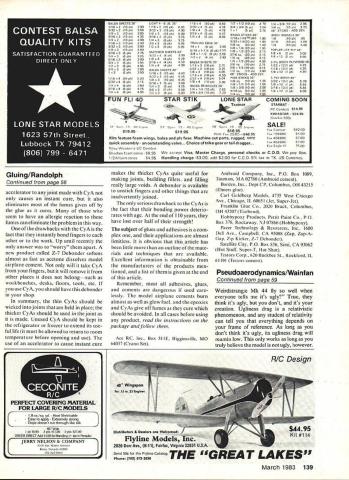

Cellulose white aliphatic resin epoxy cyanoacrylate glue stickthese among adhesives regularly used model airplane building Some have properties make better particular applications others article skims surface very broad subject may provide information some things youve wondered aboutE LF Randolph MORE THAN LIKELY first glue used man animal blood Although over shadowed newer products animal protein glues still very much part joining process glues much too heavy slow-working value modelers have armies full-scale aircraft built theory possible polish two pieces wood until molecularly smooth touched together would become nojoint would exist Glue designed fool two pieces think ing smooth suppose join modeling glues adhe 52 Model Aviation sives designed other uses found way hobby because fulfilled need Some glues have modified packaged make compatible application some have completely changed concept gluing Nitrocellulose glues supreme years term model airplane cement synonymous Frank Zaics new book Model Airplanes American Boy 19271934 Model Aero nautic Publications Box 135 Northbridge CA 91328 available AMA HQ Supply Service $800 Ambroid cement mentioned earliest issues term used generic sense well brand name Model airplane glues Am broid Comet Testors etc aeromatic glues cure drying evaporation carrier case acetone reigned supreme model airplane hobby until introduction glow engine glow fuel dissolves Yet model airplanes built glues 3040 years ago still flying still very popular building Rubber models Gliders internal structure small RC models first fast drying glues degree model airplane cements gap-filling means will form bridge between parts inti mate contact However glues shrink dry can pull away widejoint leave void shrinking advantage tight joint pulls pieces closely together very strong joint properly cellulose glues should applied both pieces joined allowed dry another thin coat applied wher pieces brought together glue ends absorbed March 1983 53 parts joined some cement should squeeze out pressure applied joint case pins hold pressure cement dries Model airplane cement sands very well Author uses Visine eye drop bottle hvpodermic needle spout filled 5050 Ambroid cement acetoneas applicator small iiohtweiaht structures Part provides Its own gluing pressure Epoxy glue comes two parts must mixed just before use Pre-cut pieces bond paper card stock discarded after use handy mixing Sometimes epoxy can mixed right part Heat applied epoxy causes become thin allows absorbed wood joints T-nuts epoxied back firewali manner will hold tight Epoxy seals against grease oil laminating plywood balsa fuselage sides wltfl wnite giue aliphatic resin spread glue thinly evenly both plywood balsa avoid warping dampen outside pieces water after joining clamp pieces between flat boards Clamping important part gluing jobs pressure applied should enough squeeze glue out joint form thin glue iine loint Wipe away excess gluE oniy adds weight end-grain balsa rib leading trailing edges notches spar ends double-gluing areas Important Joints model airplane cement must held place external means such pins clamps until glue dries After thejoint made additional glue can applied form fillet around thejoint glues does strengthen thejoint somewhat Model airplane glue can dissolved thinned acetone quite handy ajoint found wrong needs changed fingernail polish bottle cleaned filled acetone just right purpose Glue thinned acetone excellent adhesive Indoor Rubber small Out door Rubber models photo shows Visine eye-drop bottle hypodermic needle spout 015 wire stopper filled 50-50 Ambroid acetone years glues held firewalls engine ideal building small lightweight struc- mounts rest airplane gas tures quite fast drying models sand almost well summary model airplane glues balsa itself thejoints tend disappear fine balsa structure will come sanded smooth tube model air contact alcohol fuel Properly made plane cement belongs modelers joints stronger wood workshop glue very lightweight has dried plywood hardwood much better glues available will see Wiiite glues first generally-used glues replace model airplane cements engine areas aircraft used alcohol fuel time advent aliphatic resin glues replaced white Both glues water-based air-cure just model airplane cement does can used same way get really goodjoints clamping should used Clamping forces glue wood forms very thin glue line develops strongest bond Excess glue squeezed 54 Model Aviation unique properties aliphatic resin allow glue used ironing-on sheet balsa photo sequence shows Above right Mark areas will contact another sheet structure come together case leading edge ribs spar Below left Apply aliphatic resin glue areas contactstructure well sheeting Below right Wipe off glue wilh paper towel cloth leaving thin coating Let glue dry completely Bottom left Position sheeting over structure hot iron wool setting household irons iron sheeting structure Aliphatic resin glue polymerizes heat bond instant permanent Additional heat wont affect bond Bottom right Foam cores can covered sheet balsa same way Spread coating aliphatic resin both wipe off let dry Position sheeting core iron place balsa protects foam heat iron just does iron-on plastic covering used joint should wiped away aliphatic resin glues sand well soften become brittle age glues used laminate two sheets together plywood fuselage doublers water glue causes wood expand therefore opposite side sheets away glue should moistened water help eliminate warping An important property aliphatic resin glues fact heat causes polymerize can utilized pro vide iron-on capabilities sheet balsa Spread glue areas will come contact other sheet place Wipe off allow dry completely Put sheet place hot iron wool setting iron sheet onto frame workjust would heatshrink films bond instantaneous system opinion best way apply balsa skins foam cores Coat foam balsa sheet ali phatic resin glue wipe off allow dry use light pressure iron sheet core Once glue has polymerized addition heat will have no effect bond White glue can thinned water used brushing adhesive tissue silk span silk After dries bond unaffected application water dope covering White resin glues work well foam airplanes well plywood hardwood resin glues sand better white glues both can cleaned hands soap water before completely cure glue stick subject cover ing found office supply fabric stores very easy-to-use adhesive attaching condenser paper tissue light weight structures scale will weigh 1/150th gram can detect no difference weight between glue-stickapplied paper applied white glue water mixed 1-100 Intended pri marily paper glue water soluble covering water-shrunk cannot used way procedure simple rub stick gently over sur face covered smooth paper can lifted gently remove wrinkles once rubbed place bond secure Epoxies two-part glues resin hardener glues cure chemical action need air evaporation set Because heaviest glues used modeling Once two parts mixed together working life glue can minutes hours depending upon type glue first really quick-curing glues epoxies still excellent rapid field repairs slower-setting epoxy glues can used same white resin glues ihe gap-filling ability much superior application somewhat sloppvjoint usually produces good bond Because epoxies shrink cured excellent laminat ing plywood balsa warping best joints made applying thin coat both sjrfaces joining holding p ace pins clamps until cured application heat will cause epoxy thin consistency water will absorbed joint Plywood firewa[ls mounted epoxy coated same glue both front back ar effectively sealed fuel oil glues work well foam good rapid repair foam airplanes field Epoxies heavy good joint formed thin coat excess can wiped away Before cures epoxy can washed hands soap water Some people however allergic epoxy best avoid skin contact Cyanoacrylates CyA have changed whole concept gluing time spent waiting glues cure has com pletely eliminated now possible build large RC airplane evening cover next fly third March 1983 55 glue stick can used covering very lightweight structures tissue Its easy use doesnt penetrate wood Condenser paper considered difficult use covering glue stick method makes quite easy Just mooth smooth out glue water-soluble washes easily hands VI build fillet spread bead thick cyanoacrylate glue joint Thin cyanoacrylate glues flowed joint alter made spray accelerator fillet made just tiny amount glue used rather being placed joint application thick CyA accelerator Fcra bigger fillet apply other blues joint must have close fit CyA spray again family rapid cure universal adhe sives discovered technicians Eastman Kodak labs experimenting entirely different field 910th formula studied Formula 910 became name under first offered public model airplanehobby field marketed under number labels Zap Jet Hot Stuff name few Generally two types CyAs thin rapid-curing thicker gap-filling type cures slightly slower two types CyAs will satisfy almost situa tion might arise modeling Currently bonding foam certain plastics about gluing jobs CyA suited due change new products soon released CyAs certainly universal adhesives thin CyAs Jet Zap Hot Stuff etc require different technique other forms adhesives use modeling Whenjoining wood balsa applied after joint made rather time pieces joined CyA flows joint joint wick good example what can done completely assemble wing building board apply thin CyA wood-to-wood joint immediately lift complete wing board actual practice joint usually glued assembled forgotten Care must taken joint good tight CyA will wick properly form good bond extent baking soda can dusted areas firmly touching soda will form bridge-bond CyA applied application thin CyA areas balsa extra strength desired locations control horns drilling necessary almost like magic glue wicks wood firms tempering does metal Edge-gluing sheets balsa achieve wider sheets fuselage sides wing skins can easily accomplished dusting both joining edges baking soda hold ing two edges together masking tape applying CyA continuous line along joint cases bond formed CyA almost instantaneous large extent CyA can used place pins form bond parts held alignment hands especially true thicker slowercuring CyAs term slower curing no means indicates thick gap-filling CyAs much slower thin almost instant-cure cousins time lapse tween joining curing order 30 seconds comparison fastest epoxies fast indeed family CyAs Zap-A-Gap Super Jet Super-T etc used very similarly model airplane cements resin glues applying glue parts before joining Unlike slower-curing glues / thick CyAs need no pins jigs hold parts place Hand pressure short time necessary cure usually enough slower curing time allows some shifting parts proper align ment before bond made Long glue lines such longerons glued sheet fuselage sides made apply ing bead thick CyA along surface placing other part position cure begins both parts joined An accelerator has recently intro duced market makes CyAs cure instantly combination makes possible actually build fillets thicke CyAs Trade names accelerators include Zip Kicker Hot Shot Cyano Set application Continued page 139 / HE DOCTOR WILL NOW sEE THE -E~4TLfe-1AN WI-40 &LUE 141s HANDS TO NOKL5ENCH 56 Model Aviation Oftentimes parts can held place own weight joint can made simply applying CyA thin CyA will flow theOneoftheinconveniencesofuslngcyanoacrylategluesistheeaseand joint wick thicker CyA will form fillet used inspeed glues human skin product called Z-7 Debonder will conjunction acceleratorremove CyA tools benches etc Just squirt wipe off BALSA SHEETS 36 1/16x2 1056290 3/32 2 10 p6398 1/8 2 10 ph385 3/16 2 10 skI435 1/4 2 10 pk499 1/163 10 pk 330 3/32 3 10 pk390 1/8 /3 10 pk480 3/16 3 5 pk275 1/4 3 5 phI325 5/16 3 5 pk350 3/8 3 5 pk395 5/2 3 5 pk495 3/4 32 pk280 1 s32p6350 1/18 4 10 pk520 3/32 4 5 ph315 1/9 a4 6 pk360 3/16n4 5561415 1/4 a4 5 skI495 LIGHT 4 6 LB 36 1/16s3lOpk430 3/32 310 pk490 1/8 s310 ph580 3/16 35 pk325 1/4 s39 pk375 3/8 35 pk495 1/2 n35 pk598 MATCHED SHEETS 42 3/32 44pk399 1/8 sd4pk429 3/16 445k459 1/4s44pk499 SALSASHEETS 46 1/16s310 ph440 3/32-5310 pk515 1/9 s310 pk635 3/16s35skI369 1/4 38pk425 3/8 35phI558 1/2 34ph960 1164lOphI680 3/32a 45pk419 1/6s45pk475 3/1645pk547 1/445ph600 T8AILING EDGE 36 14 xl6 pk200 6/1611/46pk250 3/S 1-1/2 6 ph 295 1/2 s2 4 ph299 BALSASHEETS 30 1/16 s310 pk275 3/32 310 pk325 1/8 s310 pk405 1/16x410 phI430 3/32 410 pk504 1/8s410 pk590 BALSA TRIANGLES 36 1/41/4 10 pk250 3/9 3/8 10 ph225 1/2 s 1/2 10 EkI 4 50 3/4a 3/4 5 pL209 1 15 ph275 BALSA STICKS 36 1/16s1/4170ph180 3/32 1/420 pk190 1/8 sq20 ph140 i/S sl/420 phI195 1/Sn1/220 pk315 3/16 sq20 pk215 1/4 sq20 ph315 1/4 sl/220 ph430 3/8 5910 pk275 3/8 s 1/210 pk315 1/2 sq10 ph360 48 STICKS ADO 25% PINESTICKS 36 1/8 sq10 pk125 1/8 si/A10 ph155 1/8 3/810 ph200 3/16 sq10 ph165 1/4 as110 014255 1/4 s3/8 10 pk295 3/8 sq10 pk320 48 STICKS ADD 25% BIRCH DOWELS 36~ 1/810pk85 3/1610pls109 1/410ph140 POPLAR LITE PLY 48 1/86 2 ph300 1/8s12 2 ph600 3ply 8IRCH PLYWOOD 48 1/32s12l ph425 1/16s121 ph435 1/8 s12 1 pk450 PLY BIRCH48 3/32s121ph520 1/8 a12 1 501585 3/16x121 pk585 1/4s12 1 pk600 FUN FLI 40STAR STIKLONE STARCOMING SOON raIner~vSTARRAT jSC Combat 51495 KWIKSTAR $2495 00 cke 500 51 SI/aS IS 40Eqoe151SSALE 51 Spas4DYsqoe48 Spos35 Enqos $1995Si 995$1895Fos Comoa54200 P55 25 9CS4895Fos 1 9858C5400 Kits feature foam wings balsa ply fuse Machine cut parts rugged VeryFos 4068RC5700 quick assembly outstanding value. Choice trike gear Bail dragger.Fox 45 668C5700 Fox Eagle III7500 Rdey Woolens UC Combat Shadom foam Cores-$t95 accept Visa Master Charge personal checks COD pay UpS 1/2Afoam Cores$495Handling charge -$300 add $200 COD 5% las TX US Carrency accelerator anyjoint made CyA causes instant cure also eliminates fumes given off glue cures seem have allergic reaction fumes can eliminate problem way drawbacks CyA fact instantly bond fingers other work Up until recently answer worry apart new product called Z-7 Debonder softens almost fast acetone dissolves model airplane cement will take CyA fingers will remove other places does belongsuch workbenches desks floors tools etc use CyA should have debonder shop summary thin CyAs should wicked intojoints held place thicker CyAs should used joint made Unused CyA should kept refrigerator freezer extend its use ful life must allowed return room temperature before opening use use accelerator cause instant cure makes thicker CyAs quite useful making joints building fillets filling really large voids debonder available unstick fingers other things inadvertently joined serious drawback CyAs fact bonding power deterio rates age end 110 years have lost over half strength subject glues adhesives com plex their-applications almost limitless obvious article has little outline mate rials techniques available Excellent information obtainable manufacturers products men tioned list given theend article Remember adhesives glues cements dangerous used care lessly model airplane cements burn almost well glow fuel epoxies CyAs give off fumes cure should avoided cases before using product read instructions package follow Ace RC Inc Box 51 IF Higginsville MO 64037 Cyano Set Ambroid Company Inc PO Box 1089 Taunton MA 02780 Ambroid cement Borden Inc Dept CP Columbus OH 43215 Elmers glue Carl Goldberg Models 4735 West Chicago Ave Chicago II 60651 Jet Super-Jet Franklin Glue Co 2020 Bruck Columbus OH 43207 Titebond Hobbypoxy Products Pettit Paint Co PO Box 378 Rockaway NJ 07866 tHobbypoxy Pacer Technology & Resources Inc 1600 Dell Ave Campbell CA 95008 Zap Zap-AGap Zip Kicker Z-7 Debonder Satellite City PO Box 836 Simi CA 93062 Hot Stuff Super-T Hot Shot Testors Corp 620 Buckbee St Rockford IL 61101 Testors cement Pseudoaerodynamics/Wainfan Continued page 59 Weirdstrangie Mk 44 fly well everyone tells its ugly True think its ugly dont its creation Ugliness drag relativistic phenomenon student relativity can tell everything depends frame reference As long dont think its ugly its ugliness drag will reamin low works long truly believe model ugly however PERFECT COVERING MATERIAL FOR LARGE RIC MODELS 1 8 oz /sq yd Shnnkable Dope Easy apply Extremely strong doesn t run through like silk March 1983 139 Gluing/Randolph Continued page 56 66 90de 1 pd$585 3yds 81750 Syds 52750 ORDER DB8ECT Add 5100 HosdIin 5- tao ii ifosada JERRY NELSON & COMPANY OSlO San Maiso Asenus 6c,, Nesad 49509 102325-OhM DIstrIbutors & Dealers Welcomed Flyline Models 2820 Don Ave B-i 1 Fairfax Virginia 22931 USA Send 505 Fyline catalog lifE T LAKES

Edition: Model Aviation - 1983/03

Page Numbers: 52, 53, 54, 55, 56, 139

Cellulose white aliphatic resin epoxy cyanoacrylate glue stickthese among adhesives regularly used model airplane building Some have properties make better particular applications others article skims surface very broad subject may provide information some things youve wondered aboutE LF Randolph MORE THAN LIKELY first glue used man animal blood Although over shadowed newer products animal protein glues still very much part joining process glues much too heavy slow-working value modelers have armies full-scale aircraft built theory possible polish two pieces wood until molecularly smooth touched together would become nojoint would exist Glue designed fool two pieces think ing smooth suppose join modeling glues adhe 52 Model Aviation sives designed other uses found way hobby because fulfilled need Some glues have modified packaged make compatible application some have completely changed concept gluing Nitrocellulose glues supreme years term model airplane cement synonymous Frank Zaics new book Model Airplanes American Boy 19271934 Model Aero nautic Publications Box 135 Northbridge CA 91328 available AMA HQ Supply Service $800 Ambroid cement mentioned earliest issues term used generic sense well brand name Model airplane glues Am broid Comet Testors etc aeromatic glues cure drying evaporation carrier case acetone reigned supreme model airplane hobby until introduction glow engine glow fuel dissolves Yet model airplanes built glues 3040 years ago still flying still very popular building Rubber models Gliders internal structure small RC models first fast drying glues degree model airplane cements gap-filling means will form bridge between parts inti mate contact However glues shrink dry can pull away widejoint leave void shrinking advantage tight joint pulls pieces closely together very strong joint properly cellulose glues should applied both pieces joined allowed dry another thin coat applied wher pieces brought together glue ends absorbed March 1983 53 parts joined some cement should squeeze out pressure applied joint case pins hold pressure cement dries Model airplane cement sands very well Author uses Visine eye drop bottle hvpodermic needle spout filled 5050 Ambroid cement acetoneas applicator small iiohtweiaht structures Part provides Its own gluing pressure Epoxy glue comes two parts must mixed just before use Pre-cut pieces bond paper card stock discarded after use handy mixing Sometimes epoxy can mixed right part Heat applied epoxy causes become thin allows absorbed wood joints T-nuts epoxied back firewali manner will hold tight Epoxy seals against grease oil laminating plywood balsa fuselage sides wltfl wnite giue aliphatic resin spread glue thinly evenly both plywood balsa avoid warping dampen outside pieces water after joining clamp pieces between flat boards Clamping important part gluing jobs pressure applied should enough squeeze glue out joint form thin glue iine loint Wipe away excess gluE oniy adds weight end-grain balsa rib leading trailing edges notches spar ends double-gluing areas Important Joints model airplane cement must held place external means such pins clamps until glue dries After thejoint made additional glue can applied form fillet around thejoint glues does strengthen thejoint somewhat Model airplane glue can dissolved thinned acetone quite handy ajoint found wrong needs changed fingernail polish bottle cleaned filled acetone just right purpose Glue thinned acetone excellent adhesive Indoor Rubber small Out door Rubber models photo shows Visine eye-drop bottle hypodermic needle spout 015 wire stopper filled 50-50 Ambroid acetone years glues held firewalls engine ideal building small lightweight struc- mounts rest airplane gas tures quite fast drying models sand almost well summary model airplane glues balsa itself thejoints tend disappear fine balsa structure will come sanded smooth tube model air contact alcohol fuel Properly made plane cement belongs modelers joints stronger wood workshop glue very lightweight has dried plywood hardwood much better glues available will see Wiiite glues first generally-used glues replace model airplane cements engine areas aircraft used alcohol fuel time advent aliphatic resin glues replaced white Both glues water-based air-cure just model airplane cement does can used same way get really goodjoints clamping should used Clamping forces glue wood forms very thin glue line develops strongest bond Excess glue squeezed 54 Model Aviation unique properties aliphatic resin allow glue used ironing-on sheet balsa photo sequence shows Above right Mark areas will contact another sheet structure come together case leading edge ribs spar Below left Apply aliphatic resin glue areas contactstructure well sheeting Below right Wipe off glue wilh paper towel cloth leaving thin coating Let glue dry completely Bottom left Position sheeting over structure hot iron wool setting household irons iron sheeting structure Aliphatic resin glue polymerizes heat bond instant permanent Additional heat wont affect bond Bottom right Foam cores can covered sheet balsa same way Spread coating aliphatic resin both wipe off let dry Position sheeting core iron place balsa protects foam heat iron just does iron-on plastic covering used joint should wiped away aliphatic resin glues sand well soften become brittle age glues used laminate two sheets together plywood fuselage doublers water glue causes wood expand therefore opposite side sheets away glue should moistened water help eliminate warping An important property aliphatic resin glues fact heat causes polymerize can utilized pro vide iron-on capabilities sheet balsa Spread glue areas will come contact other sheet place Wipe off allow dry completely Put sheet place hot iron wool setting iron sheet onto frame workjust would heatshrink films bond instantaneous system opinion best way apply balsa skins foam cores Coat foam balsa sheet ali phatic resin glue wipe off allow dry use light pressure iron sheet core Once glue has polymerized addition heat will have no effect bond White glue can thinned water used brushing adhesive tissue silk span silk After dries bond unaffected application water dope covering White resin glues work well foam airplanes well plywood hardwood resin glues sand better white glues both can cleaned hands soap water before completely cure glue stick subject cover ing found office supply fabric stores very easy-to-use adhesive attaching condenser paper tissue light weight structures scale will weigh 1/150th gram can detect no difference weight between glue-stickapplied paper applied white glue water mixed 1-100 Intended pri marily paper glue water soluble covering water-shrunk cannot used way procedure simple rub stick gently over sur face covered smooth paper can lifted gently remove wrinkles once rubbed place bond secure Epoxies two-part glues resin hardener glues cure chemical action need air evaporation set Because heaviest glues used modeling Once two parts mixed together working life glue can minutes hours depending upon type glue first really quick-curing glues epoxies still excellent rapid field repairs slower-setting epoxy glues can used same white resin glues ihe gap-filling ability much superior application somewhat sloppvjoint usually produces good bond Because epoxies shrink cured excellent laminat ing plywood balsa warping best joints made applying thin coat both sjrfaces joining holding p ace pins clamps until cured application heat will cause epoxy thin consistency water will absorbed joint Plywood firewa[ls mounted epoxy coated same glue both front back ar effectively sealed fuel oil glues work well foam good rapid repair foam airplanes field Epoxies heavy good joint formed thin coat excess can wiped away Before cures epoxy can washed hands soap water Some people however allergic epoxy best avoid skin contact Cyanoacrylates CyA have changed whole concept gluing time spent waiting glues cure has com pletely eliminated now possible build large RC airplane evening cover next fly third March 1983 55 glue stick can used covering very lightweight structures tissue Its easy use doesnt penetrate wood Condenser paper considered difficult use covering glue stick method makes quite easy Just mooth smooth out glue water-soluble washes easily hands VI build fillet spread bead thick cyanoacrylate glue joint Thin cyanoacrylate glues flowed joint alter made spray accelerator fillet made just tiny amount glue used rather being placed joint application thick CyA accelerator Fcra bigger fillet apply other blues joint must have close fit CyA spray again family rapid cure universal adhe sives discovered technicians Eastman Kodak labs experimenting entirely different field 910th formula studied Formula 910 became name under first offered public model airplanehobby field marketed under number labels Zap Jet Hot Stuff name few Generally two types CyAs thin rapid-curing thicker gap-filling type cures slightly slower two types CyAs will satisfy almost situa tion might arise modeling Currently bonding foam certain plastics about gluing jobs CyA suited due change new products soon released CyAs certainly universal adhesives thin CyAs Jet Zap Hot Stuff etc require different technique other forms adhesives use modeling Whenjoining wood balsa applied after joint made rather time pieces joined CyA flows joint joint wick good example what can done completely assemble wing building board apply thin CyA wood-to-wood joint immediately lift complete wing board actual practice joint usually glued assembled forgotten Care must taken joint good tight CyA will wick properly form good bond extent baking soda can dusted areas firmly touching soda will form bridge-bond CyA applied application thin CyA areas balsa extra strength desired locations control horns drilling necessary almost like magic glue wicks wood firms tempering does metal Edge-gluing sheets balsa achieve wider sheets fuselage sides wing skins can easily accomplished dusting both joining edges baking soda hold ing two edges together masking tape applying CyA continuous line along joint cases bond formed CyA almost instantaneous large extent CyA can used place pins form bond parts held alignment hands especially true thicker slowercuring CyAs term slower curing no means indicates thick gap-filling CyAs much slower thin almost instant-cure cousins time lapse tween joining curing order 30 seconds comparison fastest epoxies fast indeed family CyAs Zap-A-Gap Super Jet Super-T etc used very similarly model airplane cements resin glues applying glue parts before joining Unlike slower-curing glues / thick CyAs need no pins jigs hold parts place Hand pressure short time necessary cure usually enough slower curing time allows some shifting parts proper align ment before bond made Long glue lines such longerons glued sheet fuselage sides made apply ing bead thick CyA along surface placing other part position cure begins both parts joined An accelerator has recently intro duced market makes CyAs cure instantly combination makes possible actually build fillets thicke CyAs Trade names accelerators include Zip Kicker Hot Shot Cyano Set application Continued page 139 / HE DOCTOR WILL NOW sEE THE -E~4TLfe-1AN WI-40 &LUE 141s HANDS TO NOKL5ENCH 56 Model Aviation Oftentimes parts can held place own weight joint can made simply applying CyA thin CyA will flow theOneoftheinconveniencesofuslngcyanoacrylategluesistheeaseand joint wick thicker CyA will form fillet used inspeed glues human skin product called Z-7 Debonder will conjunction acceleratorremove CyA tools benches etc Just squirt wipe off BALSA SHEETS 36 1/16x2 1056290 3/32 2 10 p6398 1/8 2 10 ph385 3/16 2 10 skI435 1/4 2 10 pk499 1/163 10 pk 330 3/32 3 10 pk390 1/8 /3 10 pk480 3/16 3 5 pk275 1/4 3 5 phI325 5/16 3 5 pk350 3/8 3 5 pk395 5/2 3 5 pk495 3/4 32 pk280 1 s32p6350 1/18 4 10 pk520 3/32 4 5 ph315 1/9 a4 6 pk360 3/16n4 5561415 1/4 a4 5 skI495 LIGHT 4 6 LB 36 1/16s3lOpk430 3/32 310 pk490 1/8 s310 ph580 3/16 35 pk325 1/4 s39 pk375 3/8 35 pk495 1/2 n35 pk598 MATCHED SHEETS 42 3/32 44pk399 1/8 sd4pk429 3/16 445k459 1/4s44pk499 SALSASHEETS 46 1/16s310 ph440 3/32-5310 pk515 1/9 s310 pk635 3/16s35skI369 1/4 38pk425 3/8 35phI558 1/2 34ph960 1164lOphI680 3/32a 45pk419 1/6s45pk475 3/1645pk547 1/445ph600 T8AILING EDGE 36 14 xl6 pk200 6/1611/46pk250 3/S 1-1/2 6 ph 295 1/2 s2 4 ph299 BALSASHEETS 30 1/16 s310 pk275 3/32 310 pk325 1/8 s310 pk405 1/16x410 phI430 3/32 410 pk504 1/8s410 pk590 BALSA TRIANGLES 36 1/41/4 10 pk250 3/9 3/8 10 ph225 1/2 s 1/2 10 EkI 4 50 3/4a 3/4 5 pL209 1 15 ph275 BALSA STICKS 36 1/16s1/4170ph180 3/32 1/420 pk190 1/8 sq20 ph140 i/S sl/420 phI195 1/Sn1/220 pk315 3/16 sq20 pk215 1/4 sq20 ph315 1/4 sl/220 ph430 3/8 5910 pk275 3/8 s 1/210 pk315 1/2 sq10 ph360 48 STICKS ADO 25% PINESTICKS 36 1/8 sq10 pk125 1/8 si/A10 ph155 1/8 3/810 ph200 3/16 sq10 ph165 1/4 as110 014255 1/4 s3/8 10 pk295 3/8 sq10 pk320 48 STICKS ADD 25% BIRCH DOWELS 36~ 1/810pk85 3/1610pls109 1/410ph140 POPLAR LITE PLY 48 1/86 2 ph300 1/8s12 2 ph600 3ply 8IRCH PLYWOOD 48 1/32s12l ph425 1/16s121 ph435 1/8 s12 1 pk450 PLY BIRCH48 3/32s121ph520 1/8 a12 1 501585 3/16x121 pk585 1/4s12 1 pk600 FUN FLI 40STAR STIKLONE STARCOMING SOON raIner~vSTARRAT jSC Combat 51495 KWIKSTAR $2495 00 cke 500 51 SI/aS IS 40Eqoe151SSALE 51 Spas4DYsqoe48 Spos35 Enqos $1995Si 995$1895Fos Comoa54200 P55 25 9CS4895Fos 1 9858C5400 Kits feature foam wings balsa ply fuse Machine cut parts rugged VeryFos 4068RC5700 quick assembly outstanding value. Choice trike gear Bail dragger.Fox 45 668C5700 Fox Eagle III7500 Rdey Woolens UC Combat Shadom foam Cores-$t95 accept Visa Master Charge personal checks COD pay UpS 1/2Afoam Cores$495Handling charge -$300 add $200 COD 5% las TX US Carrency accelerator anyjoint made CyA causes instant cure also eliminates fumes given off glue cures seem have allergic reaction fumes can eliminate problem way drawbacks CyA fact instantly bond fingers other work Up until recently answer worry apart new product called Z-7 Debonder softens almost fast acetone dissolves model airplane cement will take CyA fingers will remove other places does belongsuch workbenches desks floors tools etc use CyA should have debonder shop summary thin CyAs should wicked intojoints held place thicker CyAs should used joint made Unused CyA should kept refrigerator freezer extend its use ful life must allowed return room temperature before opening use use accelerator cause instant cure makes thicker CyAs quite useful making joints building fillets filling really large voids debonder available unstick fingers other things inadvertently joined serious drawback CyAs fact bonding power deterio rates age end 110 years have lost over half strength subject glues adhesives com plex their-applications almost limitless obvious article has little outline mate rials techniques available Excellent information obtainable manufacturers products men tioned list given theend article Remember adhesives glues cements dangerous used care lessly model airplane cements burn almost well glow fuel epoxies CyAs give off fumes cure should avoided cases before using product read instructions package follow Ace RC Inc Box 51 IF Higginsville MO 64037 Cyano Set Ambroid Company Inc PO Box 1089 Taunton MA 02780 Ambroid cement Borden Inc Dept CP Columbus OH 43215 Elmers glue Carl Goldberg Models 4735 West Chicago Ave Chicago II 60651 Jet Super-Jet Franklin Glue Co 2020 Bruck Columbus OH 43207 Titebond Hobbypoxy Products Pettit Paint Co PO Box 378 Rockaway NJ 07866 tHobbypoxy Pacer Technology & Resources Inc 1600 Dell Ave Campbell CA 95008 Zap Zap-AGap Zip Kicker Z-7 Debonder Satellite City PO Box 836 Simi CA 93062 Hot Stuff Super-T Hot Shot Testors Corp 620 Buckbee St Rockford IL 61101 Testors cement Pseudoaerodynamics/Wainfan Continued page 59 Weirdstrangie Mk 44 fly well everyone tells its ugly True think its ugly dont its creation Ugliness drag relativistic phenomenon student relativity can tell everything depends frame reference As long dont think its ugly its ugliness drag will reamin low works long truly believe model ugly however PERFECT COVERING MATERIAL FOR LARGE RIC MODELS 1 8 oz /sq yd Shnnkable Dope Easy apply Extremely strong doesn t run through like silk March 1983 139 Gluing/Randolph Continued page 56 66 90de 1 pd$585 3yds 81750 Syds 52750 ORDER DB8ECT Add 5100 HosdIin 5- tao ii ifosada JERRY NELSON & COMPANY OSlO San Maiso Asenus 6c,, Nesad 49509 102325-OhM DIstrIbutors & Dealers Welcomed Flyline Models 2820 Don Ave B-i 1 Fairfax Virginia 22931 USA Send 505 Fyline catalog lifE T LAKES

Edition: Model Aviation - 1983/03

Page Numbers: 52, 53, 54, 55, 56, 139

Cellulose white aliphatic resin epoxy cyanoacrylate glue stickthese among adhesives regularly used model airplane building Some have properties make better particular applications others article skims surface very broad subject may provide information some things youve wondered aboutE LF Randolph MORE THAN LIKELY first glue used man animal blood Although over shadowed newer products animal protein glues still very much part joining process glues much too heavy slow-working value modelers have armies full-scale aircraft built theory possible polish two pieces wood until molecularly smooth touched together would become nojoint would exist Glue designed fool two pieces think ing smooth suppose join modeling glues adhe 52 Model Aviation sives designed other uses found way hobby because fulfilled need Some glues have modified packaged make compatible application some have completely changed concept gluing Nitrocellulose glues supreme years term model airplane cement synonymous Frank Zaics new book Model Airplanes American Boy 19271934 Model Aero nautic Publications Box 135 Northbridge CA 91328 available AMA HQ Supply Service $800 Ambroid cement mentioned earliest issues term used generic sense well brand name Model airplane glues Am broid Comet Testors etc aeromatic glues cure drying evaporation carrier case acetone reigned supreme model airplane hobby until introduction glow engine glow fuel dissolves Yet model airplanes built glues 3040 years ago still flying still very popular building Rubber models Gliders internal structure small RC models first fast drying glues degree model airplane cements gap-filling means will form bridge between parts inti mate contact However glues shrink dry can pull away widejoint leave void shrinking advantage tight joint pulls pieces closely together very strong joint properly cellulose glues should applied both pieces joined allowed dry another thin coat applied wher pieces brought together glue ends absorbed March 1983 53 parts joined some cement should squeeze out pressure applied joint case pins hold pressure cement dries Model airplane cement sands very well Author uses Visine eye drop bottle hvpodermic needle spout filled 5050 Ambroid cement acetoneas applicator small iiohtweiaht structures Part provides Its own gluing pressure Epoxy glue comes two parts must mixed just before use Pre-cut pieces bond paper card stock discarded after use handy mixing Sometimes epoxy can mixed right part Heat applied epoxy causes become thin allows absorbed wood joints T-nuts epoxied back firewali manner will hold tight Epoxy seals against grease oil laminating plywood balsa fuselage sides wltfl wnite giue aliphatic resin spread glue thinly evenly both plywood balsa avoid warping dampen outside pieces water after joining clamp pieces between flat boards Clamping important part gluing jobs pressure applied should enough squeeze glue out joint form thin glue iine loint Wipe away excess gluE oniy adds weight end-grain balsa rib leading trailing edges notches spar ends double-gluing areas Important Joints model airplane cement must held place external means such pins clamps until glue dries After thejoint made additional glue can applied form fillet around thejoint glues does strengthen thejoint somewhat Model airplane glue can dissolved thinned acetone quite handy ajoint found wrong needs changed fingernail polish bottle cleaned filled acetone just right purpose Glue thinned acetone excellent adhesive Indoor Rubber small Out door Rubber models photo shows Visine eye-drop bottle hypodermic needle spout 015 wire stopper filled 50-50 Ambroid acetone years glues held firewalls engine ideal building small lightweight struc- mounts rest airplane gas tures quite fast drying models sand almost well summary model airplane glues balsa itself thejoints tend disappear fine balsa structure will come sanded smooth tube model air contact alcohol fuel Properly made plane cement belongs modelers joints stronger wood workshop glue very lightweight has dried plywood hardwood much better glues available will see Wiiite glues first generally-used glues replace model airplane cements engine areas aircraft used alcohol fuel time advent aliphatic resin glues replaced white Both glues water-based air-cure just model airplane cement does can used same way get really goodjoints clamping should used Clamping forces glue wood forms very thin glue line develops strongest bond Excess glue squeezed 54 Model Aviation unique properties aliphatic resin allow glue used ironing-on sheet balsa photo sequence shows Above right Mark areas will contact another sheet structure come together case leading edge ribs spar Below left Apply aliphatic resin glue areas contactstructure well sheeting Below right Wipe off glue wilh paper towel cloth leaving thin coating Let glue dry completely Bottom left Position sheeting over structure hot iron wool setting household irons iron sheeting structure Aliphatic resin glue polymerizes heat bond instant permanent Additional heat wont affect bond Bottom right Foam cores can covered sheet balsa same way Spread coating aliphatic resin both wipe off let dry Position sheeting core iron place balsa protects foam heat iron just does iron-on plastic covering used joint should wiped away aliphatic resin glues sand well soften become brittle age glues used laminate two sheets together plywood fuselage doublers water glue causes wood expand therefore opposite side sheets away glue should moistened water help eliminate warping An important property aliphatic resin glues fact heat causes polymerize can utilized pro vide iron-on capabilities sheet balsa Spread glue areas will come contact other sheet place Wipe off allow dry completely Put sheet place hot iron wool setting iron sheet onto frame workjust would heatshrink films bond instantaneous system opinion best way apply balsa skins foam cores Coat foam balsa sheet ali phatic resin glue wipe off allow dry use light pressure iron sheet core Once glue has polymerized addition heat will have no effect bond White glue can thinned water used brushing adhesive tissue silk span silk After dries bond unaffected application water dope covering White resin glues work well foam airplanes well plywood hardwood resin glues sand better white glues both can cleaned hands soap water before completely cure glue stick subject cover ing found office supply fabric stores very easy-to-use adhesive attaching condenser paper tissue light weight structures scale will weigh 1/150th gram can detect no difference weight between glue-stickapplied paper applied white glue water mixed 1-100 Intended pri marily paper glue water soluble covering water-shrunk cannot used way procedure simple rub stick gently over sur face covered smooth paper can lifted gently remove wrinkles once rubbed place bond secure Epoxies two-part glues resin hardener glues cure chemical action need air evaporation set Because heaviest glues used modeling Once two parts mixed together working life glue can minutes hours depending upon type glue first really quick-curing glues epoxies still excellent rapid field repairs slower-setting epoxy glues can used same white resin glues ihe gap-filling ability much superior application somewhat sloppvjoint usually produces good bond Because epoxies shrink cured excellent laminat ing plywood balsa warping best joints made applying thin coat both sjrfaces joining holding p ace pins clamps until cured application heat will cause epoxy thin consistency water will absorbed joint Plywood firewa[ls mounted epoxy coated same glue both front back ar effectively sealed fuel oil glues work well foam good rapid repair foam airplanes field Epoxies heavy good joint formed thin coat excess can wiped away Before cures epoxy can washed hands soap water Some people however allergic epoxy best avoid skin contact Cyanoacrylates CyA have changed whole concept gluing time spent waiting glues cure has com pletely eliminated now possible build large RC airplane evening cover next fly third March 1983 55 glue stick can used covering very lightweight structures tissue Its easy use doesnt penetrate wood Condenser paper considered difficult use covering glue stick method makes quite easy Just mooth smooth out glue water-soluble washes easily hands VI build fillet spread bead thick cyanoacrylate glue joint Thin cyanoacrylate glues flowed joint alter made spray accelerator fillet made just tiny amount glue used rather being placed joint application thick CyA accelerator Fcra bigger fillet apply other blues joint must have close fit CyA spray again family rapid cure universal adhe sives discovered technicians Eastman Kodak labs experimenting entirely different field 910th formula studied Formula 910 became name under first offered public model airplanehobby field marketed under number labels Zap Jet Hot Stuff name few Generally two types CyAs thin rapid-curing thicker gap-filling type cures slightly slower two types CyAs will satisfy almost situa tion might arise modeling Currently bonding foam certain plastics about gluing jobs CyA suited due change new products soon released CyAs certainly universal adhesives thin CyAs Jet Zap Hot Stuff etc require different technique other forms adhesives use modeling Whenjoining wood balsa applied after joint made rather time pieces joined CyA flows joint joint wick good example what can done completely assemble wing building board apply thin CyA wood-to-wood joint immediately lift complete wing board actual practice joint usually glued assembled forgotten Care must taken joint good tight CyA will wick properly form good bond extent baking soda can dusted areas firmly touching soda will form bridge-bond CyA applied application thin CyA areas balsa extra strength desired locations control horns drilling necessary almost like magic glue wicks wood firms tempering does metal Edge-gluing sheets balsa achieve wider sheets fuselage sides wing skins can easily accomplished dusting both joining edges baking soda hold ing two edges together masking tape applying CyA continuous line along joint cases bond formed CyA almost instantaneous large extent CyA can used place pins form bond parts held alignment hands especially true thicker slowercuring CyAs term slower curing no means indicates thick gap-filling CyAs much slower thin almost instant-cure cousins time lapse tween joining curing order 30 seconds comparison fastest epoxies fast indeed family CyAs Zap-A-Gap Super Jet Super-T etc used very similarly model airplane cements resin glues applying glue parts before joining Unlike slower-curing glues / thick CyAs need no pins jigs hold parts place Hand pressure short time necessary cure usually enough slower curing time allows some shifting parts proper align ment before bond made Long glue lines such longerons glued sheet fuselage sides made apply ing bead thick CyA along surface placing other part position cure begins both parts joined An accelerator has recently intro duced market makes CyAs cure instantly combination makes possible actually build fillets thicke CyAs Trade names accelerators include Zip Kicker Hot Shot Cyano Set application Continued page 139 / HE DOCTOR WILL NOW sEE THE -E~4TLfe-1AN WI-40 &LUE 141s HANDS TO NOKL5ENCH 56 Model Aviation Oftentimes parts can held place own weight joint can made simply applying CyA thin CyA will flow theOneoftheinconveniencesofuslngcyanoacrylategluesistheeaseand joint wick thicker CyA will form fillet used inspeed glues human skin product called Z-7 Debonder will conjunction acceleratorremove CyA tools benches etc Just squirt wipe off BALSA SHEETS 36 1/16x2 1056290 3/32 2 10 p6398 1/8 2 10 ph385 3/16 2 10 skI435 1/4 2 10 pk499 1/163 10 pk 330 3/32 3 10 pk390 1/8 /3 10 pk480 3/16 3 5 pk275 1/4 3 5 phI325 5/16 3 5 pk350 3/8 3 5 pk395 5/2 3 5 pk495 3/4 32 pk280 1 s32p6350 1/18 4 10 pk520 3/32 4 5 ph315 1/9 a4 6 pk360 3/16n4 5561415 1/4 a4 5 skI495 LIGHT 4 6 LB 36 1/16s3lOpk430 3/32 310 pk490 1/8 s310 ph580 3/16 35 pk325 1/4 s39 pk375 3/8 35 pk495 1/2 n35 pk598 MATCHED SHEETS 42 3/32 44pk399 1/8 sd4pk429 3/16 445k459 1/4s44pk499 SALSASHEETS 46 1/16s310 ph440 3/32-5310 pk515 1/9 s310 pk635 3/16s35skI369 1/4 38pk425 3/8 35phI558 1/2 34ph960 1164lOphI680 3/32a 45pk419 1/6s45pk475 3/1645pk547 1/445ph600 T8AILING EDGE 36 14 xl6 pk200 6/1611/46pk250 3/S 1-1/2 6 ph 295 1/2 s2 4 ph299 BALSASHEETS 30 1/16 s310 pk275 3/32 310 pk325 1/8 s310 pk405 1/16x410 phI430 3/32 410 pk504 1/8s410 pk590 BALSA TRIANGLES 36 1/41/4 10 pk250 3/9 3/8 10 ph225 1/2 s 1/2 10 EkI 4 50 3/4a 3/4 5 pL209 1 15 ph275 BALSA STICKS 36 1/16s1/4170ph180 3/32 1/420 pk190 1/8 sq20 ph140 i/S sl/420 phI195 1/Sn1/220 pk315 3/16 sq20 pk215 1/4 sq20 ph315 1/4 sl/220 ph430 3/8 5910 pk275 3/8 s 1/210 pk315 1/2 sq10 ph360 48 STICKS ADO 25% PINESTICKS 36 1/8 sq10 pk125 1/8 si/A10 ph155 1/8 3/810 ph200 3/16 sq10 ph165 1/4 as110 014255 1/4 s3/8 10 pk295 3/8 sq10 pk320 48 STICKS ADD 25% BIRCH DOWELS 36~ 1/810pk85 3/1610pls109 1/410ph140 POPLAR LITE PLY 48 1/86 2 ph300 1/8s12 2 ph600 3ply 8IRCH PLYWOOD 48 1/32s12l ph425 1/16s121 ph435 1/8 s12 1 pk450 PLY BIRCH48 3/32s121ph520 1/8 a12 1 501585 3/16x121 pk585 1/4s12 1 pk600 FUN FLI 40STAR STIKLONE STARCOMING SOON raIner~vSTARRAT jSC Combat 51495 KWIKSTAR $2495 00 cke 500 51 SI/aS IS 40Eqoe151SSALE 51 Spas4DYsqoe48 Spos35 Enqos $1995Si 995$1895Fos Comoa54200 P55 25 9CS4895Fos 1 9858C5400 Kits feature foam wings balsa ply fuse Machine cut parts rugged VeryFos 4068RC5700 quick assembly outstanding value. Choice trike gear Bail dragger.Fox 45 668C5700 Fox Eagle III7500 Rdey Woolens UC Combat Shadom foam Cores-$t95 accept Visa Master Charge personal checks COD pay UpS 1/2Afoam Cores$495Handling charge -$300 add $200 COD 5% las TX US Carrency accelerator anyjoint made CyA causes instant cure also eliminates fumes given off glue cures seem have allergic reaction fumes can eliminate problem way drawbacks CyA fact instantly bond fingers other work Up until recently answer worry apart new product called Z-7 Debonder softens almost fast acetone dissolves model airplane cement will take CyA fingers will remove other places does belongsuch workbenches desks floors tools etc use CyA should have debonder shop summary thin CyAs should wicked intojoints held place thicker CyAs should used joint made Unused CyA should kept refrigerator freezer extend its use ful life must allowed return room temperature before opening use use accelerator cause instant cure makes thicker CyAs quite useful making joints building fillets filling really large voids debonder available unstick fingers other things inadvertently joined serious drawback CyAs fact bonding power deterio rates age end 110 years have lost over half strength subject glues adhesives com plex their-applications almost limitless obvious article has little outline mate rials techniques available Excellent information obtainable manufacturers products men tioned list given theend article Remember adhesives glues cements dangerous used care lessly model airplane cements burn almost well glow fuel epoxies CyAs give off fumes cure should avoided cases before using product read instructions package follow Ace RC Inc Box 51 IF Higginsville MO 64037 Cyano Set Ambroid Company Inc PO Box 1089 Taunton MA 02780 Ambroid cement Borden Inc Dept CP Columbus OH 43215 Elmers glue Carl Goldberg Models 4735 West Chicago Ave Chicago II 60651 Jet Super-Jet Franklin Glue Co 2020 Bruck Columbus OH 43207 Titebond Hobbypoxy Products Pettit Paint Co PO Box 378 Rockaway NJ 07866 tHobbypoxy Pacer Technology & Resources Inc 1600 Dell Ave Campbell CA 95008 Zap Zap-AGap Zip Kicker Z-7 Debonder Satellite City PO Box 836 Simi CA 93062 Hot Stuff Super-T Hot Shot Testors Corp 620 Buckbee St Rockford IL 61101 Testors cement Pseudoaerodynamics/Wainfan Continued page 59 Weirdstrangie Mk 44 fly well everyone tells its ugly True think its ugly dont its creation Ugliness drag relativistic phenomenon student relativity can tell everything depends frame reference As long dont think its ugly its ugliness drag will reamin low works long truly believe model ugly however PERFECT COVERING MATERIAL FOR LARGE RIC MODELS 1 8 oz /sq yd Shnnkable Dope Easy apply Extremely strong doesn t run through like silk March 1983 139 Gluing/Randolph Continued page 56 66 90de 1 pd$585 3yds 81750 Syds 52750 ORDER DB8ECT Add 5100 HosdIin 5- tao ii ifosada JERRY NELSON & COMPANY OSlO San Maiso Asenus 6c,, Nesad 49509 102325-OhM DIstrIbutors & Dealers Welcomed Flyline Models 2820 Don Ave B-i 1 Fairfax Virginia 22931 USA Send 505 Fyline catalog lifE T LAKES

Edition: Model Aviation - 1983/03

Page Numbers: 52, 53, 54, 55, 56, 139

Cellulose white aliphatic resin epoxy cyanoacrylate glue stickthese among adhesives regularly used model airplane building Some have properties make better particular applications others article skims surface very broad subject may provide information some things youve wondered aboutE LF Randolph MORE THAN LIKELY first glue used man animal blood Although over shadowed newer products animal protein glues still very much part joining process glues much too heavy slow-working value modelers have armies full-scale aircraft built theory possible polish two pieces wood until molecularly smooth touched together would become nojoint would exist Glue designed fool two pieces think ing smooth suppose join modeling glues adhe 52 Model Aviation sives designed other uses found way hobby because fulfilled need Some glues have modified packaged make compatible application some have completely changed concept gluing Nitrocellulose glues supreme years term model airplane cement synonymous Frank Zaics new book Model Airplanes American Boy 19271934 Model Aero nautic Publications Box 135 Northbridge CA 91328 available AMA HQ Supply Service $800 Ambroid cement mentioned earliest issues term used generic sense well brand name Model airplane glues Am broid Comet Testors etc aeromatic glues cure drying evaporation carrier case acetone reigned supreme model airplane hobby until introduction glow engine glow fuel dissolves Yet model airplanes built glues 3040 years ago still flying still very popular building Rubber models Gliders internal structure small RC models first fast drying glues degree model airplane cements gap-filling means will form bridge between parts inti mate contact However glues shrink dry can pull away widejoint leave void shrinking advantage tight joint pulls pieces closely together very strong joint properly cellulose glues should applied both pieces joined allowed dry another thin coat applied wher pieces brought together glue ends absorbed March 1983 53 parts joined some cement should squeeze out pressure applied joint case pins hold pressure cement dries Model airplane cement sands very well Author uses Visine eye drop bottle hvpodermic needle spout filled 5050 Ambroid cement acetoneas applicator small iiohtweiaht structures Part provides Its own gluing pressure Epoxy glue comes two parts must mixed just before use Pre-cut pieces bond paper card stock discarded after use handy mixing Sometimes epoxy can mixed right part Heat applied epoxy causes become thin allows absorbed wood joints T-nuts epoxied back firewali manner will hold tight Epoxy seals against grease oil laminating plywood balsa fuselage sides wltfl wnite giue aliphatic resin spread glue thinly evenly both plywood balsa avoid warping dampen outside pieces water after joining clamp pieces between flat boards Clamping important part gluing jobs pressure applied should enough squeeze glue out joint form thin glue iine loint Wipe away excess gluE oniy adds weight end-grain balsa rib leading trailing edges notches spar ends double-gluing areas Important Joints model airplane cement must held place external means such pins clamps until glue dries After thejoint made additional glue can applied form fillet around thejoint glues does strengthen thejoint somewhat Model airplane glue can dissolved thinned acetone quite handy ajoint found wrong needs changed fingernail polish bottle cleaned filled acetone just right purpose Glue thinned acetone excellent adhesive Indoor Rubber small Out door Rubber models photo shows Visine eye-drop bottle hypodermic needle spout 015 wire stopper filled 50-50 Ambroid acetone years glues held firewalls engine ideal building small lightweight struc- mounts rest airplane gas tures quite fast drying models sand almost well summary model airplane glues balsa itself thejoints tend disappear fine balsa structure will come sanded smooth tube model air contact alcohol fuel Properly made plane cement belongs modelers joints stronger wood workshop glue very lightweight has dried plywood hardwood much better glues available will see Wiiite glues first generally-used glues replace model airplane cements engine areas aircraft used alcohol fuel time advent aliphatic resin glues replaced white Both glues water-based air-cure just model airplane cement does can used same way get really goodjoints clamping should used Clamping forces glue wood forms very thin glue line develops strongest bond Excess glue squeezed 54 Model Aviation unique properties aliphatic resin allow glue used ironing-on sheet balsa photo sequence shows Above right Mark areas will contact another sheet structure come together case leading edge ribs spar Below left Apply aliphatic resin glue areas contactstructure well sheeting Below right Wipe off glue wilh paper towel cloth leaving thin coating Let glue dry completely Bottom left Position sheeting over structure hot iron wool setting household irons iron sheeting structure Aliphatic resin glue polymerizes heat bond instant permanent Additional heat wont affect bond Bottom right Foam cores can covered sheet balsa same way Spread coating aliphatic resin both wipe off let dry Position sheeting core iron place balsa protects foam heat iron just does iron-on plastic covering used joint should wiped away aliphatic resin glues sand well soften become brittle age glues used laminate two sheets together plywood fuselage doublers water glue causes wood expand therefore opposite side sheets away glue should moistened water help eliminate warping An important property aliphatic resin glues fact heat causes polymerize can utilized pro vide iron-on capabilities sheet balsa Spread glue areas will come contact other sheet place Wipe off allow dry completely Put sheet place hot iron wool setting iron sheet onto frame workjust would heatshrink films bond instantaneous system opinion best way apply balsa skins foam cores Coat foam balsa sheet ali phatic resin glue wipe off allow dry use light pressure iron sheet core Once glue has polymerized addition heat will have no effect bond White glue can thinned water used brushing adhesive tissue silk span silk After dries bond unaffected application water dope covering White resin glues work well foam airplanes well plywood hardwood resin glues sand better white glues both can cleaned hands soap water before completely cure glue stick subject cover ing found office supply fabric stores very easy-to-use adhesive attaching condenser paper tissue light weight structures scale will weigh 1/150th gram can detect no difference weight between glue-stickapplied paper applied white glue water mixed 1-100 Intended pri marily paper glue water soluble covering water-shrunk cannot used way procedure simple rub stick gently over sur face covered smooth paper can lifted gently remove wrinkles once rubbed place bond secure Epoxies two-part glues resin hardener glues cure chemical action need air evaporation set Because heaviest glues used modeling Once two parts mixed together working life glue can minutes hours depending upon type glue first really quick-curing glues epoxies still excellent rapid field repairs slower-setting epoxy glues can used same white resin glues ihe gap-filling ability much superior application somewhat sloppvjoint usually produces good bond Because epoxies shrink cured excellent laminat ing plywood balsa warping best joints made applying thin coat both sjrfaces joining holding p ace pins clamps until cured application heat will cause epoxy thin consistency water will absorbed joint Plywood firewa[ls mounted epoxy coated same glue both front back ar effectively sealed fuel oil glues work well foam good rapid repair foam airplanes field Epoxies heavy good joint formed thin coat excess can wiped away Before cures epoxy can washed hands soap water Some people however allergic epoxy best avoid skin contact Cyanoacrylates CyA have changed whole concept gluing time spent waiting glues cure has com pletely eliminated now possible build large RC airplane evening cover next fly third March 1983 55 glue stick can used covering very lightweight structures tissue Its easy use doesnt penetrate wood Condenser paper considered difficult use covering glue stick method makes quite easy Just mooth smooth out glue water-soluble washes easily hands VI build fillet spread bead thick cyanoacrylate glue joint Thin cyanoacrylate glues flowed joint alter made spray accelerator fillet made just tiny amount glue used rather being placed joint application thick CyA accelerator Fcra bigger fillet apply other blues joint must have close fit CyA spray again family rapid cure universal adhe sives discovered technicians Eastman Kodak labs experimenting entirely different field 910th formula studied Formula 910 became name under first offered public model airplanehobby field marketed under number labels Zap Jet Hot Stuff name few Generally two types CyAs thin rapid-curing thicker gap-filling type cures slightly slower two types CyAs will satisfy almost situa tion might arise modeling Currently bonding foam certain plastics about gluing jobs CyA suited due change new products soon released CyAs certainly universal adhesives thin CyAs Jet Zap Hot Stuff etc require different technique other forms adhesives use modeling Whenjoining wood balsa applied after joint made rather time pieces joined CyA flows joint joint wick good example what can done completely assemble wing building board apply thin CyA wood-to-wood joint immediately lift complete wing board actual practice joint usually glued assembled forgotten Care must taken joint good tight CyA will wick properly form good bond extent baking soda can dusted areas firmly touching soda will form bridge-bond CyA applied application thin CyA areas balsa extra strength desired locations control horns drilling necessary almost like magic glue wicks wood firms tempering does metal Edge-gluing sheets balsa achieve wider sheets fuselage sides wing skins can easily accomplished dusting both joining edges baking soda hold ing two edges together masking tape applying CyA continuous line along joint cases bond formed CyA almost instantaneous large extent CyA can used place pins form bond parts held alignment hands especially true thicker slowercuring CyAs term slower curing no means indicates thick gap-filling CyAs much slower thin almost instant-cure cousins time lapse tween joining curing order 30 seconds comparison fastest epoxies fast indeed family CyAs Zap-A-Gap Super Jet Super-T etc used very similarly model airplane cements resin glues applying glue parts before joining Unlike slower-curing glues / thick CyAs need no pins jigs hold parts place Hand pressure short time necessary cure usually enough slower curing time allows some shifting parts proper align ment before bond made Long glue lines such longerons glued sheet fuselage sides made apply ing bead thick CyA along surface placing other part position cure begins both parts joined An accelerator has recently intro duced market makes CyAs cure instantly combination makes possible actually build fillets thicke CyAs Trade names accelerators include Zip Kicker Hot Shot Cyano Set application Continued page 139 / HE DOCTOR WILL NOW sEE THE -E~4TLfe-1AN WI-40 &LUE 141s HANDS TO NOKL5ENCH 56 Model Aviation Oftentimes parts can held place own weight joint can made simply applying CyA thin CyA will flow theOneoftheinconveniencesofuslngcyanoacrylategluesistheeaseand joint wick thicker CyA will form fillet used inspeed glues human skin product called Z-7 Debonder will conjunction acceleratorremove CyA tools benches etc Just squirt wipe off BALSA SHEETS 36 1/16x2 1056290 3/32 2 10 p6398 1/8 2 10 ph385 3/16 2 10 skI435 1/4 2 10 pk499 1/163 10 pk 330 3/32 3 10 pk390 1/8 /3 10 pk480 3/16 3 5 pk275 1/4 3 5 phI325 5/16 3 5 pk350 3/8 3 5 pk395 5/2 3 5 pk495 3/4 32 pk280 1 s32p6350 1/18 4 10 pk520 3/32 4 5 ph315 1/9 a4 6 pk360 3/16n4 5561415 1/4 a4 5 skI495 LIGHT 4 6 LB 36 1/16s3lOpk430 3/32 310 pk490 1/8 s310 ph580 3/16 35 pk325 1/4 s39 pk375 3/8 35 pk495 1/2 n35 pk598 MATCHED SHEETS 42 3/32 44pk399 1/8 sd4pk429 3/16 445k459 1/4s44pk499 SALSASHEETS 46 1/16s310 ph440 3/32-5310 pk515 1/9 s310 pk635 3/16s35skI369 1/4 38pk425 3/8 35phI558 1/2 34ph960 1164lOphI680 3/32a 45pk419 1/6s45pk475 3/1645pk547 1/445ph600 T8AILING EDGE 36 14 xl6 pk200 6/1611/46pk250 3/S 1-1/2 6 ph 295 1/2 s2 4 ph299 BALSASHEETS 30 1/16 s310 pk275 3/32 310 pk325 1/8 s310 pk405 1/16x410 phI430 3/32 410 pk504 1/8s410 pk590 BALSA TRIANGLES 36 1/41/4 10 pk250 3/9 3/8 10 ph225 1/2 s 1/2 10 EkI 4 50 3/4a 3/4 5 pL209 1 15 ph275 BALSA STICKS 36 1/16s1/4170ph180 3/32 1/420 pk190 1/8 sq20 ph140 i/S sl/420 phI195 1/Sn1/220 pk315 3/16 sq20 pk215 1/4 sq20 ph315 1/4 sl/220 ph430 3/8 5910 pk275 3/8 s 1/210 pk315 1/2 sq10 ph360 48 STICKS ADO 25% PINESTICKS 36 1/8 sq10 pk125 1/8 si/A10 ph155 1/8 3/810 ph200 3/16 sq10 ph165 1/4 as110 014255 1/4 s3/8 10 pk295 3/8 sq10 pk320 48 STICKS ADD 25% BIRCH DOWELS 36~ 1/810pk85 3/1610pls109 1/410ph140 POPLAR LITE PLY 48 1/86 2 ph300 1/8s12 2 ph600 3ply 8IRCH PLYWOOD 48 1/32s12l ph425 1/16s121 ph435 1/8 s12 1 pk450 PLY BIRCH48 3/32s121ph520 1/8 a12 1 501585 3/16x121 pk585 1/4s12 1 pk600 FUN FLI 40STAR STIKLONE STARCOMING SOON raIner~vSTARRAT jSC Combat 51495 KWIKSTAR $2495 00 cke 500 51 SI/aS IS 40Eqoe151SSALE 51 Spas4DYsqoe48 Spos35 Enqos $1995Si 995$1895Fos Comoa54200 P55 25 9CS4895Fos 1 9858C5400 Kits feature foam wings balsa ply fuse Machine cut parts rugged VeryFos 4068RC5700 quick assembly outstanding value. Choice trike gear Bail dragger.Fox 45 668C5700 Fox Eagle III7500 Rdey Woolens UC Combat Shadom foam Cores-$t95 accept Visa Master Charge personal checks COD pay UpS 1/2Afoam Cores$495Handling charge -$300 add $200 COD 5% las TX US Carrency accelerator anyjoint made CyA causes instant cure also eliminates fumes given off glue cures seem have allergic reaction fumes can eliminate problem way drawbacks CyA fact instantly bond fingers other work Up until recently answer worry apart new product called Z-7 Debonder softens almost fast acetone dissolves model airplane cement will take CyA fingers will remove other places does belongsuch workbenches desks floors tools etc use CyA should have debonder shop summary thin CyAs should wicked intojoints held place thicker CyAs should used joint made Unused CyA should kept refrigerator freezer extend its use ful life must allowed return room temperature before opening use use accelerator cause instant cure makes thicker CyAs quite useful making joints building fillets filling really large voids debonder available unstick fingers other things inadvertently joined serious drawback CyAs fact bonding power deterio rates age end 110 years have lost over half strength subject glues adhesives com plex their-applications almost limitless obvious article has little outline mate rials techniques available Excellent information obtainable manufacturers products men tioned list given theend article Remember adhesives glues cements dangerous used care lessly model airplane cements burn almost well glow fuel epoxies CyAs give off fumes cure should avoided cases before using product read instructions package follow Ace RC Inc Box 51 IF Higginsville MO 64037 Cyano Set Ambroid Company Inc PO Box 1089 Taunton MA 02780 Ambroid cement Borden Inc Dept CP Columbus OH 43215 Elmers glue Carl Goldberg Models 4735 West Chicago Ave Chicago II 60651 Jet Super-Jet Franklin Glue Co 2020 Bruck Columbus OH 43207 Titebond Hobbypoxy Products Pettit Paint Co PO Box 378 Rockaway NJ 07866 tHobbypoxy Pacer Technology & Resources Inc 1600 Dell Ave Campbell CA 95008 Zap Zap-AGap Zip Kicker Z-7 Debonder Satellite City PO Box 836 Simi CA 93062 Hot Stuff Super-T Hot Shot Testors Corp 620 Buckbee St Rockford IL 61101 Testors cement Pseudoaerodynamics/Wainfan Continued page 59 Weirdstrangie Mk 44 fly well everyone tells its ugly True think its ugly dont its creation Ugliness drag relativistic phenomenon student relativity can tell everything depends frame reference As long dont think its ugly its ugliness drag will reamin low works long truly believe model ugly however PERFECT COVERING MATERIAL FOR LARGE RIC MODELS 1 8 oz /sq yd Shnnkable Dope Easy apply Extremely strong doesn t run through like silk March 1983 139 Gluing/Randolph Continued page 56 66 90de 1 pd$585 3yds 81750 Syds 52750 ORDER DB8ECT Add 5100 HosdIin 5- tao ii ifosada JERRY NELSON & COMPANY OSlO San Maiso Asenus 6c,, Nesad 49509 102325-OhM DIstrIbutors & Dealers Welcomed Flyline Models 2820 Don Ave B-i 1 Fairfax Virginia 22931 USA Send 505 Fyline catalog lifE T LAKES

Edition: Model Aviation - 1983/03

Page Numbers: 52, 53, 54, 55, 56, 139