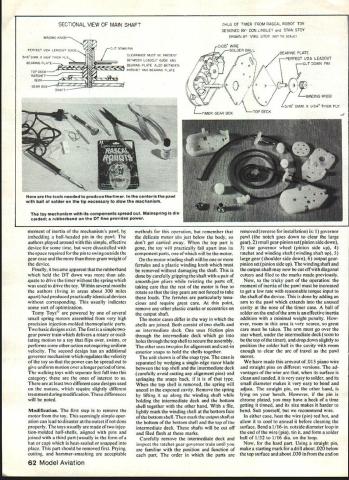

A simple modification toatoy motorproducesthis simple repeatable light DTtimer atypical installation sail thetimeryou see its installed Dave Lindleys Max Flier HLG mount vacu-formed light sheet plastic MECHANICAL DETHERMALIZERtimer weighs less two grams will time accurately over 10 minutes likely say Well timer pictured article weighs 185 grams repeatable within four seconds two-minute level 10 minutes repeatable within 20 seconds size very compact7/32 x 17/32 x 1-1/16 Finally note can constructed less hour toy costs less $2 fact recently built four less two hours development gadget result work people selflessly shared ideas through various newsletters pub lications Two people deserve special mention first Jim Lewis back 1977 made use clockwork mechanism Mini Bathtubby actuate tail surfaces Hand-Launched Glider Publication Bill Mathews FF Fliar started people thinking However wasnt until 1980 Dr Edmond Liem A-2 Glider team Holland solved problem slowing timer down maximum run 20 seconds over two minutes did increasing HOT STUFF TEFLON TUBING HOT STUFF & MICROBALLOONS 10 LB TEST DACRON TIMER MOUNTED THROUGH CASTING LINEWING S FINGER REST IN VACU-FORMED CUP LINE TO DT DRILL THROUGH 1/32 ON FUSELAGE CENTER LINE INSERT 1/32 WIRE & BEND BACK CRUSHING WOOD TO FORM RADII STAPLES BENT FROM STRAIGHT PINS TIMER MOUNT MAX FLIER June 198261 0 U 0 n C 5 0 V 0 0 SECTIONAL VIEW OF MAIN SHAFT WINDING KNOB PERFECT l/2A EADGUT GUIDE CLEARANCE MUST BE PRESENT 5/16 DIAM S 1/64 THICK PLY BETWEEN LEADGJT AJIDE ANG BEARING PLATEBEARING PATE SLAG BETWEEN RATCHET AND BEARING PLATE SHAFT toy mechanism its components spread out Mainspring dis carded rubberband DT line provides power OHLG CT TIMER FROM RASCAL ROBOT TOY DESIGNED BY CON LINCLEY Qfld STAN STOY DRAWN BY MIKE STOY NOT TA SCAE1 SOLDER BALL BEARING PLATE PERFECT I/2A LEADOUT CUT DOWN PIN WINCING KNOB 51W ClAM X I/E4 THICK PLY TIMER GEAR BOX moment inertia mechanisms pawi imbedding ball-headed pin pawi authors played around simple effective device some time dissatisfied space required forthe pin swingoutside gear case three-gram weight device Finally became apparentthat rubberband held DT down ade quate drive timer spring used drive toy Within several months authors living areas about 300 miles apart produced practically identical devices corresponding usually indicates some sort optimization Tomy Toys powered several small spring motors assembled very high precision injection-molded thermoplastic parts Two basic designs exist first simple twogear power train delivers rotary oscil lating motion toy flips over swims performs some other action requiring uniform velocity second design has additional governor mechanism regulates velocity toy power can spread out give uniform motion over longer period time walking toys separate feet fall category ones interest us least two different case designs used motors require slightly different treatment during modification differences will noted Modification first step remove motor toy seemingly simple oper ation can lead disaster outset done properly toys usually made two injec tion-molded half-shells aiigned pins joined third part usually form hat cap heat-sealed snapped place part should removed first Prying cutting hammer-smashing acceptable methods operation remember delicate motor sits just below body dont get carried away top part gone toy will practically fall apart its component parts will motor motor winding shaft will ferrules plastic winding knob must removed damaging shaft done carefully gripping shaft pair smooth-jaw pliers twisting parts off taking care rest motor free rotate tiny gears forced take loads ferrules particularly tena cious require great care point remove other plastic cranks eccentrics output shaft motor cases differ way shells joined Both consist two shells intermediate deck uses friction pins through intermediate deck go holes through top shell secure assembly other uses two pins alignment cast-in exterior snaps hold shells together unit shown snap type case separated wedging single-edge razor blade between top shell intermediate deck carefully avoid cutting alignment pins springing snaps back type top shell removed spring will uncoil exposed cavity Remove spring lifting up along winding shaft holding intermediate deck bottom shell together other hand file lightly mark winding shaft bottom face bottom shell mark output shaft bottom bottom shell top intermediate deck shafts will cut off filed flush marks Carefully remove intermediate deck inspect ratchet-gear-governor train until familiar position function part order parts removed reverse installation 1 governor pawl notch goes down clear large gear 2 small gear-pinion setpinion side down 3 star governor wheel pinion side up 4 ratchet winding shaft winding shaft up 5 large gear shoulder side down 6 output gearpinion set pinion side up winding shaft output shaft may now cut off diagonal cutters filed marks made previously Now tricky part operation moment inertia pawl must increased get low rate reasonable torque input shaft device done adding arm pawl extends unused cavity nose timer case ball solder end arm effective inertia addition minimal weight penalty ever room area very scarce great care must taken arm must go over star wheel under intermediate deck soon top timer drop down slightly position solder ball cavity room enough clear arc travel pawl moves have made arm out 015 piano wire straight pins different versions ad vantages wire its surface clean sanded very easy solder its small diameter makes very easy bend adjust straight pin other hand lying bench However pin chrome plated may have heck time getting tinned its size makes harder bend Suit yourself recommend wire either case heat wire pin red hot allow cool anneal before cleaning surface Bend 1 / 16-in outside diameter loop end wire pin tin form solder ball 1/32 1/16 dia loop Now hard part Using straight pin make starting mark drill about 020 below top surface about 030 end 62 Model Aviation tools needed produce timer center pawi ball solder tip necessary slow machanism Mike Stays Wasp HL Glider shows small can make installa tion timer Forward mount reduces needed ballast Hubberband winds around timer shaft powers timer end run band released DT actuates face pawi nearest cavity will face opposite notch clears large gear wire drill 002 003 larger wire pin mounted pin vise used drill perpen dicular face through back pawi directional accuracy hole critical long doesnt break through top surface wire can bent later make up small goofs Through work subsequent manip ulation arm sure dont damage sharp comers pawl engage star wheel will cause unit malfunction wear out early Assemble entire gear train star wheel insert wire through pawl mount position Push wire through pawl until solder ball centered cavity outboard star wheel small gear-pinion assembly Mark wire intersects back face pawl cut off about 1/16 outside mark Remove pawl wire case pull wire back side until solder ball flush pawl face grasp wire long-nose pliers about 1/64 inside mark Bend wire match angle between hole back face pawl pulled through bent end wire should lie back face solder ball should about 1/64-in short correct position everything checks heat bent end wire soldering iron force Con tinued page 127 411 Cecil Psoli Twin Pusher Refuelling Danbury Airport June 198263 Drilling hole governor pawl extension arm sensitive operation Use pin vise hold drill bit correct size Extension arm heat-sealed place 375 venturi difference drawing ability nearly 45% hadnt made test read answers myself would never have guessed would much increase Learn something new day next effort will try evaluate some venturi shapes anybody out has some pet ideas theory hat would like share let know well give em try Bill Lee 3522 Tamarisk Lane Missouri City TX 77459 Time/Lindley-Stoy Continued page 63 pawi Keep heat wire bury plastic neat strong mechanical joint will result Check clearance arm over star wheel ball cavity Bend required remaining operation gear train removal two ears winding ratchet retained spring cut off flush bottom slot through winding shaft runs using slot bottom guide Carefully reassemble gear train slip intermediate deck place hold everything position problem now bearing hole through winding shaft runs has too much slop solve problem use part original top plate bearing original case snap-retained design drill through alignment pin holes top shell #61 039 drill Cut away skirt around top shell leavingonly 1/32-in thick top Score top razor about 1/16-in beyond winding shaft hole Break off scored line Cut off projections inter mediate deck associated reten tion power spring Leave parts bottom deck serve align deck bottom shell Reassemble intermediate deck bottom shell gear train taking last look see everything positioned properly should last look sure chips shavings gone Slip short piece original top shell have cut down coupon-shaped slab over winding shaft line up alignment pins Push down flush inter mediate deck Hand-twist winding shaft holding case closed make sure everything runs smoothly fingers arent interfering pawl squeezing too tight unit should buzz away offering good resistance high torque because increased inertia pawl Check winding shaft make sure has about 010 end play housing critical end play does exist add paper shims between deck bearing plate until proper play achieved everything looks right cut off alignment pins and/or snaps flush top surface weld remaining stubs deck soldering iron Check unit again have go back point can carefully cut welds snap clips pop welds alignment pins wedging razor slot last chance Get right time everything OK use iron tack-weld intermediate deck bottom shell bearing plate complete timing assembly bearing plate must welded around its whole outside edge piece takes entire force rubberband Cut 5/16-in dia disc 1/64 plywood drill 3/32-in hole middle Insert Continued page 130 Iteut Pwdud Pressurizer al Pressure Without Pump 4 z z 5 LIFETIMEGUARANTEEAGAINST FAILURE DUE TO MANUFACTURING DEFECTS *CALIF RESIDENTS ADD 60/0 TAX * No fuel pump special carburetor needed * Works planes boats cars helicop ters..2 stroke engines Irom 10 90 muffler pipe * No adjustments necessary except simple carburetor adjustments * Extends engine life helping prevent lean engine runs INUCTORY OFFER $1695* PLUS $1 OD FOR SHIPPING $1995 after July 15th SEND CHECK OR MONEY ORDER ro VISTAEDS MODEL PRODUCTS AHERMOSA WALNUT CREEK CA 94596 OR 4830 ZUBE CT CARMICHAEL CA 95608 June 1982 127 RIC PILOT LOGBOOK AND FLIGHT RECORD *AIRCRAFT FLOWN *FLyING FIELDS *FLIGHT INSTRUCTOR *TOTAL HOURS *WEATHER CONDITIONS *FLIGHT DURATION *TRIM ADJUSTMENTS above can entered own personal flight log first time R/G LOGBOOK designed specifically pilot minitiature aircraft Whatever particular skill level may LOGBOOK will add enjoyment R/G flying LOGBOOK has durable hard-bound cover contains sufficient pages record years flying average R/G pilotel 81 Champion Hobbies$695 Postage Paid Dealer/Distributor inquiries welcomeOhio esidents odd 320 sIes tool CHAMPION HOBBIES 3715 Reemelin Cincinnati 01-145211 513 481-6961 ACTUAL SIZE 1/4 INCH LONG OR Propeller new wood blades have phenolic coating extra stiffness makes propeller stiffer stronger yet thinner best efficiency 24 x 9 Propeller $20 HARDER STIFFER Other sizes will soon available AT YOUR DEALER GRISH BROS ST JOHN INO 46373 Perfect AA control line leadout eyelet 3/32in hole cement its flange plywood high-viscosity cyanoacrylates fiveminute epoxy Cut straight pin point length will project about 1/32-in overthe edge disc radial orientation same cement acts DT release Clean roughen winding shaft piece sandpaper needle file slip disc assembly 005 010-in shim single-edge razor blade works between flange eyelet top timer Cement eyelet shaft being sure dont let cement run down bearing use hi-vis cement Push original plastic winding knob down shaft until bottoms end eyelet Cut off protruding shaft file flush top winding knob Remove shim com pletes timer timer powered rubberband remem ber removed spring Typically rubberband made Win loop 030-050 Indoor rubber hooked over projecting end straight pin disc timer rubber stretched about twice its normal length position string DT fastened other end rubberband rubber wound around shaft eyelet twisting winding knob allowing rubber climb shaft time deter mined number turns nature rubberband used reason disc very little torque required run timer lot needed get clean release pin Therefore last half-turn timer made run higher rate torque get clean release life expectancy timer really known point prototype has run over 100 cycles room temperature clean con ditions no apparent wear timing change timers used Texas Nats no temperature problems certainly will least sensitive dust dirt Seelig Tatone dont use lubricants seal welL timer protection mounted pocket airplane sure seal interior balsa dust doesnt find its way gears Scotch Magic Tape can used cover outside face timer piece typing paper should cut fit over part covers ends shafts goo tape wont get bearings now making vacuum-formed cups timers mounted photos show timer mounted nose Mike Stoys Wasp MA plan No 343 Don Lindley prefers mount timer wing using finger rest falring get necessary depth shown picture Max Flyer case have number choices timer consider gadget perfected finished product simply reasonable plateau development program therefore worth noting hoped others will pick up go ahead other improvements mechanics techniques make item usefuL FF Duration/Meuser Con finued page 65 crumble mini-comfiakes put through water-soak routine Thats abso lute disaster irreplaceable rare Old-Timer kit According ModelAviation 130 Model Aviation LARGE Plasticote LIGHTER 1GLOW lireb PLUGS 0 Blow Proof Seal OSix Types in3 Heat Ranges S Longer Life 0 Flash Starting Only $120 SWANSON PO Box 151Since 7948 Wayne NJ 07470 SILK ~" DISCOUNTS ON $ 50 YD ROLLS495/YD RedYellow Royal Ukie Fine Quality Model Building AlyLenghMoii5OYd SILK COVERS 8EST LIGHT- STRONG- ECONOMICAL SHIPPING ADO 50 FOREIGN 150/ ORDER l RES Add 4% 8ROWNSELL FLAG & DECAL CO 121 LAUREL ROAD NEW CITY NY 914-634-850010956

Edition: Model Aviation - 1982/06

Page Numbers: 61, 62, 63, 127, 130

A simple modification toatoy motorproducesthis simple repeatable light DTtimer atypical installation sail thetimeryou see its installed Dave Lindleys Max Flier HLG mount vacu-formed light sheet plastic MECHANICAL DETHERMALIZERtimer weighs less two grams will time accurately over 10 minutes likely say Well timer pictured article weighs 185 grams repeatable within four seconds two-minute level 10 minutes repeatable within 20 seconds size very compact7/32 x 17/32 x 1-1/16 Finally note can constructed less hour toy costs less $2 fact recently built four less two hours development gadget result work people selflessly shared ideas through various newsletters pub lications Two people deserve special mention first Jim Lewis back 1977 made use clockwork mechanism Mini Bathtubby actuate tail surfaces Hand-Launched Glider Publication Bill Mathews FF Fliar started people thinking However wasnt until 1980 Dr Edmond Liem A-2 Glider team Holland solved problem slowing timer down maximum run 20 seconds over two minutes did increasing HOT STUFF TEFLON TUBING HOT STUFF & MICROBALLOONS 10 LB TEST DACRON TIMER MOUNTED THROUGH CASTING LINEWING S FINGER REST IN VACU-FORMED CUP LINE TO DT DRILL THROUGH 1/32 ON FUSELAGE CENTER LINE INSERT 1/32 WIRE & BEND BACK CRUSHING WOOD TO FORM RADII STAPLES BENT FROM STRAIGHT PINS TIMER MOUNT MAX FLIER June 198261 0 U 0 n C 5 0 V 0 0 SECTIONAL VIEW OF MAIN SHAFT WINDING KNOB PERFECT l/2A EADGUT GUIDE CLEARANCE MUST BE PRESENT 5/16 DIAM S 1/64 THICK PLY BETWEEN LEADGJT AJIDE ANG BEARING PLATEBEARING PATE SLAG BETWEEN RATCHET AND BEARING PLATE SHAFT toy mechanism its components spread out Mainspring dis carded rubberband DT line provides power OHLG CT TIMER FROM RASCAL ROBOT TOY DESIGNED BY CON LINCLEY Qfld STAN STOY DRAWN BY MIKE STOY NOT TA SCAE1 SOLDER BALL BEARING PLATE PERFECT I/2A LEADOUT CUT DOWN PIN WINCING KNOB 51W ClAM X I/E4 THICK PLY TIMER GEAR BOX moment inertia mechanisms pawi imbedding ball-headed pin pawi authors played around simple effective device some time dissatisfied space required forthe pin swingoutside gear case three-gram weight device Finally became apparentthat rubberband held DT down ade quate drive timer spring used drive toy Within several months authors living areas about 300 miles apart produced practically identical devices corresponding usually indicates some sort optimization Tomy Toys powered several small spring motors assembled very high precision injection-molded thermoplastic parts Two basic designs exist first simple twogear power train delivers rotary oscil lating motion toy flips over swims performs some other action requiring uniform velocity second design has additional governor mechanism regulates velocity toy power can spread out give uniform motion over longer period time walking toys separate feet fall category ones interest us least two different case designs used motors require slightly different treatment during modification differences will noted Modification first step remove motor toy seemingly simple oper ation can lead disaster outset done properly toys usually made two injec tion-molded half-shells aiigned pins joined third part usually form hat cap heat-sealed snapped place part should removed first Prying cutting hammer-smashing acceptable methods operation remember delicate motor sits just below body dont get carried away top part gone toy will practically fall apart its component parts will motor motor winding shaft will ferrules plastic winding knob must removed damaging shaft done carefully gripping shaft pair smooth-jaw pliers twisting parts off taking care rest motor free rotate tiny gears forced take loads ferrules particularly tena cious require great care point remove other plastic cranks eccentrics output shaft motor cases differ way shells joined Both consist two shells intermediate deck uses friction pins through intermediate deck go holes through top shell secure assembly other uses two pins alignment cast-in exterior snaps hold shells together unit shown snap type case separated wedging single-edge razor blade between top shell intermediate deck carefully avoid cutting alignment pins springing snaps back type top shell removed spring will uncoil exposed cavity Remove spring lifting up along winding shaft holding intermediate deck bottom shell together other hand file lightly mark winding shaft bottom face bottom shell mark output shaft bottom bottom shell top intermediate deck shafts will cut off filed flush marks Carefully remove intermediate deck inspect ratchet-gear-governor train until familiar position function part order parts removed reverse installation 1 governor pawl notch goes down clear large gear 2 small gear-pinion setpinion side down 3 star governor wheel pinion side up 4 ratchet winding shaft winding shaft up 5 large gear shoulder side down 6 output gearpinion set pinion side up winding shaft output shaft may now cut off diagonal cutters filed marks made previously Now tricky part operation moment inertia pawl must increased get low rate reasonable torque input shaft device done adding arm pawl extends unused cavity nose timer case ball solder end arm effective inertia addition minimal weight penalty ever room area very scarce great care must taken arm must go over star wheel under intermediate deck soon top timer drop down slightly position solder ball cavity room enough clear arc travel pawl moves have made arm out 015 piano wire straight pins different versions ad vantages wire its surface clean sanded very easy solder its small diameter makes very easy bend adjust straight pin other hand lying bench However pin chrome plated may have heck time getting tinned its size makes harder bend Suit yourself recommend wire either case heat wire pin red hot allow cool anneal before cleaning surface Bend 1 / 16-in outside diameter loop end wire pin tin form solder ball 1/32 1/16 dia loop Now hard part Using straight pin make starting mark drill about 020 below top surface about 030 end 62 Model Aviation tools needed produce timer center pawi ball solder tip necessary slow machanism Mike Stays Wasp HL Glider shows small can make installa tion timer Forward mount reduces needed ballast Hubberband winds around timer shaft powers timer end run band released DT actuates face pawi nearest cavity will face opposite notch clears large gear wire drill 002 003 larger wire pin mounted pin vise used drill perpen dicular face through back pawi directional accuracy hole critical long doesnt break through top surface wire can bent later make up small goofs Through work subsequent manip ulation arm sure dont damage sharp comers pawl engage star wheel will cause unit malfunction wear out early Assemble entire gear train star wheel insert wire through pawl mount position Push wire through pawl until solder ball centered cavity outboard star wheel small gear-pinion assembly Mark wire intersects back face pawl cut off about 1/16 outside mark Remove pawl wire case pull wire back side until solder ball flush pawl face grasp wire long-nose pliers about 1/64 inside mark Bend wire match angle between hole back face pawl pulled through bent end wire should lie back face solder ball should about 1/64-in short correct position everything checks heat bent end wire soldering iron force Con tinued page 127 411 Cecil Psoli Twin Pusher Refuelling Danbury Airport June 198263 Drilling hole governor pawl extension arm sensitive operation Use pin vise hold drill bit correct size Extension arm heat-sealed place 375 venturi difference drawing ability nearly 45% hadnt made test read answers myself would never have guessed would much increase Learn something new day next effort will try evaluate some venturi shapes anybody out has some pet ideas theory hat would like share let know well give em try Bill Lee 3522 Tamarisk Lane Missouri City TX 77459 Time/Lindley-Stoy Continued page 63 pawi Keep heat wire bury plastic neat strong mechanical joint will result Check clearance arm over star wheel ball cavity Bend required remaining operation gear train removal two ears winding ratchet retained spring cut off flush bottom slot through winding shaft runs using slot bottom guide Carefully reassemble gear train slip intermediate deck place hold everything position problem now bearing hole through winding shaft runs has too much slop solve problem use part original top plate bearing original case snap-retained design drill through alignment pin holes top shell #61 039 drill Cut away skirt around top shell leavingonly 1/32-in thick top Score top razor about 1/16-in beyond winding shaft hole Break off scored line Cut off projections inter mediate deck associated reten tion power spring Leave parts bottom deck serve align deck bottom shell Reassemble intermediate deck bottom shell gear train taking last look see everything positioned properly should last look sure chips shavings gone Slip short piece original top shell have cut down coupon-shaped slab over winding shaft line up alignment pins Push down flush inter mediate deck Hand-twist winding shaft holding case closed make sure everything runs smoothly fingers arent interfering pawl squeezing too tight unit should buzz away offering good resistance high torque because increased inertia pawl Check winding shaft make sure has about 010 end play housing critical end play does exist add paper shims between deck bearing plate until proper play achieved everything looks right cut off alignment pins and/or snaps flush top surface weld remaining stubs deck soldering iron Check unit again have go back point can carefully cut welds snap clips pop welds alignment pins wedging razor slot last chance Get right time everything OK use iron tack-weld intermediate deck bottom shell bearing plate complete timing assembly bearing plate must welded around its whole outside edge piece takes entire force rubberband Cut 5/16-in dia disc 1/64 plywood drill 3/32-in hole middle Insert Continued page 130 Iteut Pwdud Pressurizer al Pressure Without Pump 4 z z 5 LIFETIMEGUARANTEEAGAINST FAILURE DUE TO MANUFACTURING DEFECTS *CALIF RESIDENTS ADD 60/0 TAX * No fuel pump special carburetor needed * Works planes boats cars helicop ters..2 stroke engines Irom 10 90 muffler pipe * No adjustments necessary except simple carburetor adjustments * Extends engine life helping prevent lean engine runs INUCTORY OFFER $1695* PLUS $1 OD FOR SHIPPING $1995 after July 15th SEND CHECK OR MONEY ORDER ro VISTAEDS MODEL PRODUCTS AHERMOSA WALNUT CREEK CA 94596 OR 4830 ZUBE CT CARMICHAEL CA 95608 June 1982 127 RIC PILOT LOGBOOK AND FLIGHT RECORD *AIRCRAFT FLOWN *FLyING FIELDS *FLIGHT INSTRUCTOR *TOTAL HOURS *WEATHER CONDITIONS *FLIGHT DURATION *TRIM ADJUSTMENTS above can entered own personal flight log first time R/G LOGBOOK designed specifically pilot minitiature aircraft Whatever particular skill level may LOGBOOK will add enjoyment R/G flying LOGBOOK has durable hard-bound cover contains sufficient pages record years flying average R/G pilotel 81 Champion Hobbies$695 Postage Paid Dealer/Distributor inquiries welcomeOhio esidents odd 320 sIes tool CHAMPION HOBBIES 3715 Reemelin Cincinnati 01-145211 513 481-6961 ACTUAL SIZE 1/4 INCH LONG OR Propeller new wood blades have phenolic coating extra stiffness makes propeller stiffer stronger yet thinner best efficiency 24 x 9 Propeller $20 HARDER STIFFER Other sizes will soon available AT YOUR DEALER GRISH BROS ST JOHN INO 46373 Perfect AA control line leadout eyelet 3/32in hole cement its flange plywood high-viscosity cyanoacrylates fiveminute epoxy Cut straight pin point length will project about 1/32-in overthe edge disc radial orientation same cement acts DT release Clean roughen winding shaft piece sandpaper needle file slip disc assembly 005 010-in shim single-edge razor blade works between flange eyelet top timer Cement eyelet shaft being sure dont let cement run down bearing use hi-vis cement Push original plastic winding knob down shaft until bottoms end eyelet Cut off protruding shaft file flush top winding knob Remove shim com pletes timer timer powered rubberband remem ber removed spring Typically rubberband made Win loop 030-050 Indoor rubber hooked over projecting end straight pin disc timer rubber stretched about twice its normal length position string DT fastened other end rubberband rubber wound around shaft eyelet twisting winding knob allowing rubber climb shaft time deter mined number turns nature rubberband used reason disc very little torque required run timer lot needed get clean release pin Therefore last half-turn timer made run higher rate torque get clean release life expectancy timer really known point prototype has run over 100 cycles room temperature clean con ditions no apparent wear timing change timers used Texas Nats no temperature problems certainly will least sensitive dust dirt Seelig Tatone dont use lubricants seal welL timer protection mounted pocket airplane sure seal interior balsa dust doesnt find its way gears Scotch Magic Tape can used cover outside face timer piece typing paper should cut fit over part covers ends shafts goo tape wont get bearings now making vacuum-formed cups timers mounted photos show timer mounted nose Mike Stoys Wasp MA plan No 343 Don Lindley prefers mount timer wing using finger rest falring get necessary depth shown picture Max Flyer case have number choices timer consider gadget perfected finished product simply reasonable plateau development program therefore worth noting hoped others will pick up go ahead other improvements mechanics techniques make item usefuL FF Duration/Meuser Con finued page 65 crumble mini-comfiakes put through water-soak routine Thats abso lute disaster irreplaceable rare Old-Timer kit According ModelAviation 130 Model Aviation LARGE Plasticote LIGHTER 1GLOW lireb PLUGS 0 Blow Proof Seal OSix Types in3 Heat Ranges S Longer Life 0 Flash Starting Only $120 SWANSON PO Box 151Since 7948 Wayne NJ 07470 SILK ~" DISCOUNTS ON $ 50 YD ROLLS495/YD RedYellow Royal Ukie Fine Quality Model Building AlyLenghMoii5OYd SILK COVERS 8EST LIGHT- STRONG- ECONOMICAL SHIPPING ADO 50 FOREIGN 150/ ORDER l RES Add 4% 8ROWNSELL FLAG & DECAL CO 121 LAUREL ROAD NEW CITY NY 914-634-850010956

Edition: Model Aviation - 1982/06

Page Numbers: 61, 62, 63, 127, 130

A simple modification toatoy motorproducesthis simple repeatable light DTtimer atypical installation sail thetimeryou see its installed Dave Lindleys Max Flier HLG mount vacu-formed light sheet plastic MECHANICAL DETHERMALIZERtimer weighs less two grams will time accurately over 10 minutes likely say Well timer pictured article weighs 185 grams repeatable within four seconds two-minute level 10 minutes repeatable within 20 seconds size very compact7/32 x 17/32 x 1-1/16 Finally note can constructed less hour toy costs less $2 fact recently built four less two hours development gadget result work people selflessly shared ideas through various newsletters pub lications Two people deserve special mention first Jim Lewis back 1977 made use clockwork mechanism Mini Bathtubby actuate tail surfaces Hand-Launched Glider Publication Bill Mathews FF Fliar started people thinking However wasnt until 1980 Dr Edmond Liem A-2 Glider team Holland solved problem slowing timer down maximum run 20 seconds over two minutes did increasing HOT STUFF TEFLON TUBING HOT STUFF & MICROBALLOONS 10 LB TEST DACRON TIMER MOUNTED THROUGH CASTING LINEWING S FINGER REST IN VACU-FORMED CUP LINE TO DT DRILL THROUGH 1/32 ON FUSELAGE CENTER LINE INSERT 1/32 WIRE & BEND BACK CRUSHING WOOD TO FORM RADII STAPLES BENT FROM STRAIGHT PINS TIMER MOUNT MAX FLIER June 198261 0 U 0 n C 5 0 V 0 0 SECTIONAL VIEW OF MAIN SHAFT WINDING KNOB PERFECT l/2A EADGUT GUIDE CLEARANCE MUST BE PRESENT 5/16 DIAM S 1/64 THICK PLY BETWEEN LEADGJT AJIDE ANG BEARING PLATEBEARING PATE SLAG BETWEEN RATCHET AND BEARING PLATE SHAFT toy mechanism its components spread out Mainspring dis carded rubberband DT line provides power OHLG CT TIMER FROM RASCAL ROBOT TOY DESIGNED BY CON LINCLEY Qfld STAN STOY DRAWN BY MIKE STOY NOT TA SCAE1 SOLDER BALL BEARING PLATE PERFECT I/2A LEADOUT CUT DOWN PIN WINCING KNOB 51W ClAM X I/E4 THICK PLY TIMER GEAR BOX moment inertia mechanisms pawi imbedding ball-headed pin pawi authors played around simple effective device some time dissatisfied space required forthe pin swingoutside gear case three-gram weight device Finally became apparentthat rubberband held DT down ade quate drive timer spring used drive toy Within several months authors living areas about 300 miles apart produced practically identical devices corresponding usually indicates some sort optimization Tomy Toys powered several small spring motors assembled very high precision injection-molded thermoplastic parts Two basic designs exist first simple twogear power train delivers rotary oscil lating motion toy flips over swims performs some other action requiring uniform velocity second design has additional governor mechanism regulates velocity toy power can spread out give uniform motion over longer period time walking toys separate feet fall category ones interest us least two different case designs used motors require slightly different treatment during modification differences will noted Modification first step remove motor toy seemingly simple oper ation can lead disaster outset done properly toys usually made two injec tion-molded half-shells aiigned pins joined third part usually form hat cap heat-sealed snapped place part should removed first Prying cutting hammer-smashing acceptable methods operation remember delicate motor sits just below body dont get carried away top part gone toy will practically fall apart its component parts will motor motor winding shaft will ferrules plastic winding knob must removed damaging shaft done carefully gripping shaft pair smooth-jaw pliers twisting parts off taking care rest motor free rotate tiny gears forced take loads ferrules particularly tena cious require great care point remove other plastic cranks eccentrics output shaft motor cases differ way shells joined Both consist two shells intermediate deck uses friction pins through intermediate deck go holes through top shell secure assembly other uses two pins alignment cast-in exterior snaps hold shells together unit shown snap type case separated wedging single-edge razor blade between top shell intermediate deck carefully avoid cutting alignment pins springing snaps back type top shell removed spring will uncoil exposed cavity Remove spring lifting up along winding shaft holding intermediate deck bottom shell together other hand file lightly mark winding shaft bottom face bottom shell mark output shaft bottom bottom shell top intermediate deck shafts will cut off filed flush marks Carefully remove intermediate deck inspect ratchet-gear-governor train until familiar position function part order parts removed reverse installation 1 governor pawl notch goes down clear large gear 2 small gear-pinion setpinion side down 3 star governor wheel pinion side up 4 ratchet winding shaft winding shaft up 5 large gear shoulder side down 6 output gearpinion set pinion side up winding shaft output shaft may now cut off diagonal cutters filed marks made previously Now tricky part operation moment inertia pawl must increased get low rate reasonable torque input shaft device done adding arm pawl extends unused cavity nose timer case ball solder end arm effective inertia addition minimal weight penalty ever room area very scarce great care must taken arm must go over star wheel under intermediate deck soon top timer drop down slightly position solder ball cavity room enough clear arc travel pawl moves have made arm out 015 piano wire straight pins different versions ad vantages wire its surface clean sanded very easy solder its small diameter makes very easy bend adjust straight pin other hand lying bench However pin chrome plated may have heck time getting tinned its size makes harder bend Suit yourself recommend wire either case heat wire pin red hot allow cool anneal before cleaning surface Bend 1 / 16-in outside diameter loop end wire pin tin form solder ball 1/32 1/16 dia loop Now hard part Using straight pin make starting mark drill about 020 below top surface about 030 end 62 Model Aviation tools needed produce timer center pawi ball solder tip necessary slow machanism Mike Stays Wasp HL Glider shows small can make installa tion timer Forward mount reduces needed ballast Hubberband winds around timer shaft powers timer end run band released DT actuates face pawi nearest cavity will face opposite notch clears large gear wire drill 002 003 larger wire pin mounted pin vise used drill perpen dicular face through back pawi directional accuracy hole critical long doesnt break through top surface wire can bent later make up small goofs Through work subsequent manip ulation arm sure dont damage sharp comers pawl engage star wheel will cause unit malfunction wear out early Assemble entire gear train star wheel insert wire through pawl mount position Push wire through pawl until solder ball centered cavity outboard star wheel small gear-pinion assembly Mark wire intersects back face pawl cut off about 1/16 outside mark Remove pawl wire case pull wire back side until solder ball flush pawl face grasp wire long-nose pliers about 1/64 inside mark Bend wire match angle between hole back face pawl pulled through bent end wire should lie back face solder ball should about 1/64-in short correct position everything checks heat bent end wire soldering iron force Con tinued page 127 411 Cecil Psoli Twin Pusher Refuelling Danbury Airport June 198263 Drilling hole governor pawl extension arm sensitive operation Use pin vise hold drill bit correct size Extension arm heat-sealed place 375 venturi difference drawing ability nearly 45% hadnt made test read answers myself would never have guessed would much increase Learn something new day next effort will try evaluate some venturi shapes anybody out has some pet ideas theory hat would like share let know well give em try Bill Lee 3522 Tamarisk Lane Missouri City TX 77459 Time/Lindley-Stoy Continued page 63 pawi Keep heat wire bury plastic neat strong mechanical joint will result Check clearance arm over star wheel ball cavity Bend required remaining operation gear train removal two ears winding ratchet retained spring cut off flush bottom slot through winding shaft runs using slot bottom guide Carefully reassemble gear train slip intermediate deck place hold everything position problem now bearing hole through winding shaft runs has too much slop solve problem use part original top plate bearing original case snap-retained design drill through alignment pin holes top shell #61 039 drill Cut away skirt around top shell leavingonly 1/32-in thick top Score top razor about 1/16-in beyond winding shaft hole Break off scored line Cut off projections inter mediate deck associated reten tion power spring Leave parts bottom deck serve align deck bottom shell Reassemble intermediate deck bottom shell gear train taking last look see everything positioned properly should last look sure chips shavings gone Slip short piece original top shell have cut down coupon-shaped slab over winding shaft line up alignment pins Push down flush inter mediate deck Hand-twist winding shaft holding case closed make sure everything runs smoothly fingers arent interfering pawl squeezing too tight unit should buzz away offering good resistance high torque because increased inertia pawl Check winding shaft make sure has about 010 end play housing critical end play does exist add paper shims between deck bearing plate until proper play achieved everything looks right cut off alignment pins and/or snaps flush top surface weld remaining stubs deck soldering iron Check unit again have go back point can carefully cut welds snap clips pop welds alignment pins wedging razor slot last chance Get right time everything OK use iron tack-weld intermediate deck bottom shell bearing plate complete timing assembly bearing plate must welded around its whole outside edge piece takes entire force rubberband Cut 5/16-in dia disc 1/64 plywood drill 3/32-in hole middle Insert Continued page 130 Iteut Pwdud Pressurizer al Pressure Without Pump 4 z z 5 LIFETIMEGUARANTEEAGAINST FAILURE DUE TO MANUFACTURING DEFECTS *CALIF RESIDENTS ADD 60/0 TAX * No fuel pump special carburetor needed * Works planes boats cars helicop ters..2 stroke engines Irom 10 90 muffler pipe * No adjustments necessary except simple carburetor adjustments * Extends engine life helping prevent lean engine runs INUCTORY OFFER $1695* PLUS $1 OD FOR SHIPPING $1995 after July 15th SEND CHECK OR MONEY ORDER ro VISTAEDS MODEL PRODUCTS AHERMOSA WALNUT CREEK CA 94596 OR 4830 ZUBE CT CARMICHAEL CA 95608 June 1982 127 RIC PILOT LOGBOOK AND FLIGHT RECORD *AIRCRAFT FLOWN *FLyING FIELDS *FLIGHT INSTRUCTOR *TOTAL HOURS *WEATHER CONDITIONS *FLIGHT DURATION *TRIM ADJUSTMENTS above can entered own personal flight log first time R/G LOGBOOK designed specifically pilot minitiature aircraft Whatever particular skill level may LOGBOOK will add enjoyment R/G flying LOGBOOK has durable hard-bound cover contains sufficient pages record years flying average R/G pilotel 81 Champion Hobbies$695 Postage Paid Dealer/Distributor inquiries welcomeOhio esidents odd 320 sIes tool CHAMPION HOBBIES 3715 Reemelin Cincinnati 01-145211 513 481-6961 ACTUAL SIZE 1/4 INCH LONG OR Propeller new wood blades have phenolic coating extra stiffness makes propeller stiffer stronger yet thinner best efficiency 24 x 9 Propeller $20 HARDER STIFFER Other sizes will soon available AT YOUR DEALER GRISH BROS ST JOHN INO 46373 Perfect AA control line leadout eyelet 3/32in hole cement its flange plywood high-viscosity cyanoacrylates fiveminute epoxy Cut straight pin point length will project about 1/32-in overthe edge disc radial orientation same cement acts DT release Clean roughen winding shaft piece sandpaper needle file slip disc assembly 005 010-in shim single-edge razor blade works between flange eyelet top timer Cement eyelet shaft being sure dont let cement run down bearing use hi-vis cement Push original plastic winding knob down shaft until bottoms end eyelet Cut off protruding shaft file flush top winding knob Remove shim com pletes timer timer powered rubberband remem ber removed spring Typically rubberband made Win loop 030-050 Indoor rubber hooked over projecting end straight pin disc timer rubber stretched about twice its normal length position string DT fastened other end rubberband rubber wound around shaft eyelet twisting winding knob allowing rubber climb shaft time deter mined number turns nature rubberband used reason disc very little torque required run timer lot needed get clean release pin Therefore last half-turn timer made run higher rate torque get clean release life expectancy timer really known point prototype has run over 100 cycles room temperature clean con ditions no apparent wear timing change timers used Texas Nats no temperature problems certainly will least sensitive dust dirt Seelig Tatone dont use lubricants seal welL timer protection mounted pocket airplane sure seal interior balsa dust doesnt find its way gears Scotch Magic Tape can used cover outside face timer piece typing paper should cut fit over part covers ends shafts goo tape wont get bearings now making vacuum-formed cups timers mounted photos show timer mounted nose Mike Stoys Wasp MA plan No 343 Don Lindley prefers mount timer wing using finger rest falring get necessary depth shown picture Max Flyer case have number choices timer consider gadget perfected finished product simply reasonable plateau development program therefore worth noting hoped others will pick up go ahead other improvements mechanics techniques make item usefuL FF Duration/Meuser Con finued page 65 crumble mini-comfiakes put through water-soak routine Thats abso lute disaster irreplaceable rare Old-Timer kit According ModelAviation 130 Model Aviation LARGE Plasticote LIGHTER 1GLOW lireb PLUGS 0 Blow Proof Seal OSix Types in3 Heat Ranges S Longer Life 0 Flash Starting Only $120 SWANSON PO Box 151Since 7948 Wayne NJ 07470 SILK ~" DISCOUNTS ON $ 50 YD ROLLS495/YD RedYellow Royal Ukie Fine Quality Model Building AlyLenghMoii5OYd SILK COVERS 8EST LIGHT- STRONG- ECONOMICAL SHIPPING ADO 50 FOREIGN 150/ ORDER l RES Add 4% 8ROWNSELL FLAG & DECAL CO 121 LAUREL ROAD NEW CITY NY 914-634-850010956

Edition: Model Aviation - 1982/06

Page Numbers: 61, 62, 63, 127, 130

A simple modification toatoy motorproducesthis simple repeatable light DTtimer atypical installation sail thetimeryou see its installed Dave Lindleys Max Flier HLG mount vacu-formed light sheet plastic MECHANICAL DETHERMALIZERtimer weighs less two grams will time accurately over 10 minutes likely say Well timer pictured article weighs 185 grams repeatable within four seconds two-minute level 10 minutes repeatable within 20 seconds size very compact7/32 x 17/32 x 1-1/16 Finally note can constructed less hour toy costs less $2 fact recently built four less two hours development gadget result work people selflessly shared ideas through various newsletters pub lications Two people deserve special mention first Jim Lewis back 1977 made use clockwork mechanism Mini Bathtubby actuate tail surfaces Hand-Launched Glider Publication Bill Mathews FF Fliar started people thinking However wasnt until 1980 Dr Edmond Liem A-2 Glider team Holland solved problem slowing timer down maximum run 20 seconds over two minutes did increasing HOT STUFF TEFLON TUBING HOT STUFF & MICROBALLOONS 10 LB TEST DACRON TIMER MOUNTED THROUGH CASTING LINEWING S FINGER REST IN VACU-FORMED CUP LINE TO DT DRILL THROUGH 1/32 ON FUSELAGE CENTER LINE INSERT 1/32 WIRE & BEND BACK CRUSHING WOOD TO FORM RADII STAPLES BENT FROM STRAIGHT PINS TIMER MOUNT MAX FLIER June 198261 0 U 0 n C 5 0 V 0 0 SECTIONAL VIEW OF MAIN SHAFT WINDING KNOB PERFECT l/2A EADGUT GUIDE CLEARANCE MUST BE PRESENT 5/16 DIAM S 1/64 THICK PLY BETWEEN LEADGJT AJIDE ANG BEARING PLATEBEARING PATE SLAG BETWEEN RATCHET AND BEARING PLATE SHAFT toy mechanism its components spread out Mainspring dis carded rubberband DT line provides power OHLG CT TIMER FROM RASCAL ROBOT TOY DESIGNED BY CON LINCLEY Qfld STAN STOY DRAWN BY MIKE STOY NOT TA SCAE1 SOLDER BALL BEARING PLATE PERFECT I/2A LEADOUT CUT DOWN PIN WINCING KNOB 51W ClAM X I/E4 THICK PLY TIMER GEAR BOX moment inertia mechanisms pawi imbedding ball-headed pin pawi authors played around simple effective device some time dissatisfied space required forthe pin swingoutside gear case three-gram weight device Finally became apparentthat rubberband held DT down ade quate drive timer spring used drive toy Within several months authors living areas about 300 miles apart produced practically identical devices corresponding usually indicates some sort optimization Tomy Toys powered several small spring motors assembled very high precision injection-molded thermoplastic parts Two basic designs exist first simple twogear power train delivers rotary oscil lating motion toy flips over swims performs some other action requiring uniform velocity second design has additional governor mechanism regulates velocity toy power can spread out give uniform motion over longer period time walking toys separate feet fall category ones interest us least two different case designs used motors require slightly different treatment during modification differences will noted Modification first step remove motor toy seemingly simple oper ation can lead disaster outset done properly toys usually made two injec tion-molded half-shells aiigned pins joined third part usually form hat cap heat-sealed snapped place part should removed first Prying cutting hammer-smashing acceptable methods operation remember delicate motor sits just below body dont get carried away top part gone toy will practically fall apart its component parts will motor motor winding shaft will ferrules plastic winding knob must removed damaging shaft done carefully gripping shaft pair smooth-jaw pliers twisting parts off taking care rest motor free rotate tiny gears forced take loads ferrules particularly tena cious require great care point remove other plastic cranks eccentrics output shaft motor cases differ way shells joined Both consist two shells intermediate deck uses friction pins through intermediate deck go holes through top shell secure assembly other uses two pins alignment cast-in exterior snaps hold shells together unit shown snap type case separated wedging single-edge razor blade between top shell intermediate deck carefully avoid cutting alignment pins springing snaps back type top shell removed spring will uncoil exposed cavity Remove spring lifting up along winding shaft holding intermediate deck bottom shell together other hand file lightly mark winding shaft bottom face bottom shell mark output shaft bottom bottom shell top intermediate deck shafts will cut off filed flush marks Carefully remove intermediate deck inspect ratchet-gear-governor train until familiar position function part order parts removed reverse installation 1 governor pawl notch goes down clear large gear 2 small gear-pinion setpinion side down 3 star governor wheel pinion side up 4 ratchet winding shaft winding shaft up 5 large gear shoulder side down 6 output gearpinion set pinion side up winding shaft output shaft may now cut off diagonal cutters filed marks made previously Now tricky part operation moment inertia pawl must increased get low rate reasonable torque input shaft device done adding arm pawl extends unused cavity nose timer case ball solder end arm effective inertia addition minimal weight penalty ever room area very scarce great care must taken arm must go over star wheel under intermediate deck soon top timer drop down slightly position solder ball cavity room enough clear arc travel pawl moves have made arm out 015 piano wire straight pins different versions ad vantages wire its surface clean sanded very easy solder its small diameter makes very easy bend adjust straight pin other hand lying bench However pin chrome plated may have heck time getting tinned its size makes harder bend Suit yourself recommend wire either case heat wire pin red hot allow cool anneal before cleaning surface Bend 1 / 16-in outside diameter loop end wire pin tin form solder ball 1/32 1/16 dia loop Now hard part Using straight pin make starting mark drill about 020 below top surface about 030 end 62 Model Aviation tools needed produce timer center pawi ball solder tip necessary slow machanism Mike Stays Wasp HL Glider shows small can make installa tion timer Forward mount reduces needed ballast Hubberband winds around timer shaft powers timer end run band released DT actuates face pawi nearest cavity will face opposite notch clears large gear wire drill 002 003 larger wire pin mounted pin vise used drill perpen dicular face through back pawi directional accuracy hole critical long doesnt break through top surface wire can bent later make up small goofs Through work subsequent manip ulation arm sure dont damage sharp comers pawl engage star wheel will cause unit malfunction wear out early Assemble entire gear train star wheel insert wire through pawl mount position Push wire through pawl until solder ball centered cavity outboard star wheel small gear-pinion assembly Mark wire intersects back face pawl cut off about 1/16 outside mark Remove pawl wire case pull wire back side until solder ball flush pawl face grasp wire long-nose pliers about 1/64 inside mark Bend wire match angle between hole back face pawl pulled through bent end wire should lie back face solder ball should about 1/64-in short correct position everything checks heat bent end wire soldering iron force Con tinued page 127 411 Cecil Psoli Twin Pusher Refuelling Danbury Airport June 198263 Drilling hole governor pawl extension arm sensitive operation Use pin vise hold drill bit correct size Extension arm heat-sealed place 375 venturi difference drawing ability nearly 45% hadnt made test read answers myself would never have guessed would much increase Learn something new day next effort will try evaluate some venturi shapes anybody out has some pet ideas theory hat would like share let know well give em try Bill Lee 3522 Tamarisk Lane Missouri City TX 77459 Time/Lindley-Stoy Continued page 63 pawi Keep heat wire bury plastic neat strong mechanical joint will result Check clearance arm over star wheel ball cavity Bend required remaining operation gear train removal two ears winding ratchet retained spring cut off flush bottom slot through winding shaft runs using slot bottom guide Carefully reassemble gear train slip intermediate deck place hold everything position problem now bearing hole through winding shaft runs has too much slop solve problem use part original top plate bearing original case snap-retained design drill through alignment pin holes top shell #61 039 drill Cut away skirt around top shell leavingonly 1/32-in thick top Score top razor about 1/16-in beyond winding shaft hole Break off scored line Cut off projections inter mediate deck associated reten tion power spring Leave parts bottom deck serve align deck bottom shell Reassemble intermediate deck bottom shell gear train taking last look see everything positioned properly should last look sure chips shavings gone Slip short piece original top shell have cut down coupon-shaped slab over winding shaft line up alignment pins Push down flush inter mediate deck Hand-twist winding shaft holding case closed make sure everything runs smoothly fingers arent interfering pawl squeezing too tight unit should buzz away offering good resistance high torque because increased inertia pawl Check winding shaft make sure has about 010 end play housing critical end play does exist add paper shims between deck bearing plate until proper play achieved everything looks right cut off alignment pins and/or snaps flush top surface weld remaining stubs deck soldering iron Check unit again have go back point can carefully cut welds snap clips pop welds alignment pins wedging razor slot last chance Get right time everything OK use iron tack-weld intermediate deck bottom shell bearing plate complete timing assembly bearing plate must welded around its whole outside edge piece takes entire force rubberband Cut 5/16-in dia disc 1/64 plywood drill 3/32-in hole middle Insert Continued page 130 Iteut Pwdud Pressurizer al Pressure Without Pump 4 z z 5 LIFETIMEGUARANTEEAGAINST FAILURE DUE TO MANUFACTURING DEFECTS *CALIF RESIDENTS ADD 60/0 TAX * No fuel pump special carburetor needed * Works planes boats cars helicop ters..2 stroke engines Irom 10 90 muffler pipe * No adjustments necessary except simple carburetor adjustments * Extends engine life helping prevent lean engine runs INUCTORY OFFER $1695* PLUS $1 OD FOR SHIPPING $1995 after July 15th SEND CHECK OR MONEY ORDER ro VISTAEDS MODEL PRODUCTS AHERMOSA WALNUT CREEK CA 94596 OR 4830 ZUBE CT CARMICHAEL CA 95608 June 1982 127 RIC PILOT LOGBOOK AND FLIGHT RECORD *AIRCRAFT FLOWN *FLyING FIELDS *FLIGHT INSTRUCTOR *TOTAL HOURS *WEATHER CONDITIONS *FLIGHT DURATION *TRIM ADJUSTMENTS above can entered own personal flight log first time R/G LOGBOOK designed specifically pilot minitiature aircraft Whatever particular skill level may LOGBOOK will add enjoyment R/G flying LOGBOOK has durable hard-bound cover contains sufficient pages record years flying average R/G pilotel 81 Champion Hobbies$695 Postage Paid Dealer/Distributor inquiries welcomeOhio esidents odd 320 sIes tool CHAMPION HOBBIES 3715 Reemelin Cincinnati 01-145211 513 481-6961 ACTUAL SIZE 1/4 INCH LONG OR Propeller new wood blades have phenolic coating extra stiffness makes propeller stiffer stronger yet thinner best efficiency 24 x 9 Propeller $20 HARDER STIFFER Other sizes will soon available AT YOUR DEALER GRISH BROS ST JOHN INO 46373 Perfect AA control line leadout eyelet 3/32in hole cement its flange plywood high-viscosity cyanoacrylates fiveminute epoxy Cut straight pin point length will project about 1/32-in overthe edge disc radial orientation same cement acts DT release Clean roughen winding shaft piece sandpaper needle file slip disc assembly 005 010-in shim single-edge razor blade works between flange eyelet top timer Cement eyelet shaft being sure dont let cement run down bearing use hi-vis cement Push original plastic winding knob down shaft until bottoms end eyelet Cut off protruding shaft file flush top winding knob Remove shim com pletes timer timer powered rubberband remem ber removed spring Typically rubberband made Win loop 030-050 Indoor rubber hooked over projecting end straight pin disc timer rubber stretched about twice its normal length position string DT fastened other end rubberband rubber wound around shaft eyelet twisting winding knob allowing rubber climb shaft time deter mined number turns nature rubberband used reason disc very little torque required run timer lot needed get clean release pin Therefore last half-turn timer made run higher rate torque get clean release life expectancy timer really known point prototype has run over 100 cycles room temperature clean con ditions no apparent wear timing change timers used Texas Nats no temperature problems certainly will least sensitive dust dirt Seelig Tatone dont use lubricants seal welL timer protection mounted pocket airplane sure seal interior balsa dust doesnt find its way gears Scotch Magic Tape can used cover outside face timer piece typing paper should cut fit over part covers ends shafts goo tape wont get bearings now making vacuum-formed cups timers mounted photos show timer mounted nose Mike Stoys Wasp MA plan No 343 Don Lindley prefers mount timer wing using finger rest falring get necessary depth shown picture Max Flyer case have number choices timer consider gadget perfected finished product simply reasonable plateau development program therefore worth noting hoped others will pick up go ahead other improvements mechanics techniques make item usefuL FF Duration/Meuser Con finued page 65 crumble mini-comfiakes put through water-soak routine Thats abso lute disaster irreplaceable rare Old-Timer kit According ModelAviation 130 Model Aviation LARGE Plasticote LIGHTER 1GLOW lireb PLUGS 0 Blow Proof Seal OSix Types in3 Heat Ranges S Longer Life 0 Flash Starting Only $120 SWANSON PO Box 151Since 7948 Wayne NJ 07470 SILK ~" DISCOUNTS ON $ 50 YD ROLLS495/YD RedYellow Royal Ukie Fine Quality Model Building AlyLenghMoii5OYd SILK COVERS 8EST LIGHT- STRONG- ECONOMICAL SHIPPING ADO 50 FOREIGN 150/ ORDER l RES Add 4% 8ROWNSELL FLAG & DECAL CO 121 LAUREL ROAD NEW CITY NY 914-634-850010956

Edition: Model Aviation - 1982/06

Page Numbers: 61, 62, 63, 127, 130

A simple modification toatoy motorproducesthis simple repeatable light DTtimer atypical installation sail thetimeryou see its installed Dave Lindleys Max Flier HLG mount vacu-formed light sheet plastic MECHANICAL DETHERMALIZERtimer weighs less two grams will time accurately over 10 minutes likely say Well timer pictured article weighs 185 grams repeatable within four seconds two-minute level 10 minutes repeatable within 20 seconds size very compact7/32 x 17/32 x 1-1/16 Finally note can constructed less hour toy costs less $2 fact recently built four less two hours development gadget result work people selflessly shared ideas through various newsletters pub lications Two people deserve special mention first Jim Lewis back 1977 made use clockwork mechanism Mini Bathtubby actuate tail surfaces Hand-Launched Glider Publication Bill Mathews FF Fliar started people thinking However wasnt until 1980 Dr Edmond Liem A-2 Glider team Holland solved problem slowing timer down maximum run 20 seconds over two minutes did increasing HOT STUFF TEFLON TUBING HOT STUFF & MICROBALLOONS 10 LB TEST DACRON TIMER MOUNTED THROUGH CASTING LINEWING S FINGER REST IN VACU-FORMED CUP LINE TO DT DRILL THROUGH 1/32 ON FUSELAGE CENTER LINE INSERT 1/32 WIRE & BEND BACK CRUSHING WOOD TO FORM RADII STAPLES BENT FROM STRAIGHT PINS TIMER MOUNT MAX FLIER June 198261 0 U 0 n C 5 0 V 0 0 SECTIONAL VIEW OF MAIN SHAFT WINDING KNOB PERFECT l/2A EADGUT GUIDE CLEARANCE MUST BE PRESENT 5/16 DIAM S 1/64 THICK PLY BETWEEN LEADGJT AJIDE ANG BEARING PLATEBEARING PATE SLAG BETWEEN RATCHET AND BEARING PLATE SHAFT toy mechanism its components spread out Mainspring dis carded rubberband DT line provides power OHLG CT TIMER FROM RASCAL ROBOT TOY DESIGNED BY CON LINCLEY Qfld STAN STOY DRAWN BY MIKE STOY NOT TA SCAE1 SOLDER BALL BEARING PLATE PERFECT I/2A LEADOUT CUT DOWN PIN WINCING KNOB 51W ClAM X I/E4 THICK PLY TIMER GEAR BOX moment inertia mechanisms pawi imbedding ball-headed pin pawi authors played around simple effective device some time dissatisfied space required forthe pin swingoutside gear case three-gram weight device Finally became apparentthat rubberband held DT down ade quate drive timer spring used drive toy Within several months authors living areas about 300 miles apart produced practically identical devices corresponding usually indicates some sort optimization Tomy Toys powered several small spring motors assembled very high precision injection-molded thermoplastic parts Two basic designs exist first simple twogear power train delivers rotary oscil lating motion toy flips over swims performs some other action requiring uniform velocity second design has additional governor mechanism regulates velocity toy power can spread out give uniform motion over longer period time walking toys separate feet fall category ones interest us least two different case designs used motors require slightly different treatment during modification differences will noted Modification first step remove motor toy seemingly simple oper ation can lead disaster outset done properly toys usually made two injec tion-molded half-shells aiigned pins joined third part usually form hat cap heat-sealed snapped place part should removed first Prying cutting hammer-smashing acceptable methods operation remember delicate motor sits just below body dont get carried away top part gone toy will practically fall apart its component parts will motor motor winding shaft will ferrules plastic winding knob must removed damaging shaft done carefully gripping shaft pair smooth-jaw pliers twisting parts off taking care rest motor free rotate tiny gears forced take loads ferrules particularly tena cious require great care point remove other plastic cranks eccentrics output shaft motor cases differ way shells joined Both consist two shells intermediate deck uses friction pins through intermediate deck go holes through top shell secure assembly other uses two pins alignment cast-in exterior snaps hold shells together unit shown snap type case separated wedging single-edge razor blade between top shell intermediate deck carefully avoid cutting alignment pins springing snaps back type top shell removed spring will uncoil exposed cavity Remove spring lifting up along winding shaft holding intermediate deck bottom shell together other hand file lightly mark winding shaft bottom face bottom shell mark output shaft bottom bottom shell top intermediate deck shafts will cut off filed flush marks Carefully remove intermediate deck inspect ratchet-gear-governor train until familiar position function part order parts removed reverse installation 1 governor pawl notch goes down clear large gear 2 small gear-pinion setpinion side down 3 star governor wheel pinion side up 4 ratchet winding shaft winding shaft up 5 large gear shoulder side down 6 output gearpinion set pinion side up winding shaft output shaft may now cut off diagonal cutters filed marks made previously Now tricky part operation moment inertia pawl must increased get low rate reasonable torque input shaft device done adding arm pawl extends unused cavity nose timer case ball solder end arm effective inertia addition minimal weight penalty ever room area very scarce great care must taken arm must go over star wheel under intermediate deck soon top timer drop down slightly position solder ball cavity room enough clear arc travel pawl moves have made arm out 015 piano wire straight pins different versions ad vantages wire its surface clean sanded very easy solder its small diameter makes very easy bend adjust straight pin other hand lying bench However pin chrome plated may have heck time getting tinned its size makes harder bend Suit yourself recommend wire either case heat wire pin red hot allow cool anneal before cleaning surface Bend 1 / 16-in outside diameter loop end wire pin tin form solder ball 1/32 1/16 dia loop Now hard part Using straight pin make starting mark drill about 020 below top surface about 030 end 62 Model Aviation tools needed produce timer center pawi ball solder tip necessary slow machanism Mike Stays Wasp HL Glider shows small can make installa tion timer Forward mount reduces needed ballast Hubberband winds around timer shaft powers timer end run band released DT actuates face pawi nearest cavity will face opposite notch clears large gear wire drill 002 003 larger wire pin mounted pin vise used drill perpen dicular face through back pawi directional accuracy hole critical long doesnt break through top surface wire can bent later make up small goofs Through work subsequent manip ulation arm sure dont damage sharp comers pawl engage star wheel will cause unit malfunction wear out early Assemble entire gear train star wheel insert wire through pawl mount position Push wire through pawl until solder ball centered cavity outboard star wheel small gear-pinion assembly Mark wire intersects back face pawl cut off about 1/16 outside mark Remove pawl wire case pull wire back side until solder ball flush pawl face grasp wire long-nose pliers about 1/64 inside mark Bend wire match angle between hole back face pawl pulled through bent end wire should lie back face solder ball should about 1/64-in short correct position everything checks heat bent end wire soldering iron force Con tinued page 127 411 Cecil Psoli Twin Pusher Refuelling Danbury Airport June 198263 Drilling hole governor pawl extension arm sensitive operation Use pin vise hold drill bit correct size Extension arm heat-sealed place 375 venturi difference drawing ability nearly 45% hadnt made test read answers myself would never have guessed would much increase Learn something new day next effort will try evaluate some venturi shapes anybody out has some pet ideas theory hat would like share let know well give em try Bill Lee 3522 Tamarisk Lane Missouri City TX 77459 Time/Lindley-Stoy Continued page 63 pawi Keep heat wire bury plastic neat strong mechanical joint will result Check clearance arm over star wheel ball cavity Bend required remaining operation gear train removal two ears winding ratchet retained spring cut off flush bottom slot through winding shaft runs using slot bottom guide Carefully reassemble gear train slip intermediate deck place hold everything position problem now bearing hole through winding shaft runs has too much slop solve problem use part original top plate bearing original case snap-retained design drill through alignment pin holes top shell #61 039 drill Cut away skirt around top shell leavingonly 1/32-in thick top Score top razor about 1/16-in beyond winding shaft hole Break off scored line Cut off projections inter mediate deck associated reten tion power spring Leave parts bottom deck serve align deck bottom shell Reassemble intermediate deck bottom shell gear train taking last look see everything positioned properly should last look sure chips shavings gone Slip short piece original top shell have cut down coupon-shaped slab over winding shaft line up alignment pins Push down flush inter mediate deck Hand-twist winding shaft holding case closed make sure everything runs smoothly fingers arent interfering pawl squeezing too tight unit should buzz away offering good resistance high torque because increased inertia pawl Check winding shaft make sure has about 010 end play housing critical end play does exist add paper shims between deck bearing plate until proper play achieved everything looks right cut off alignment pins and/or snaps flush top surface weld remaining stubs deck soldering iron Check unit again have go back point can carefully cut welds snap clips pop welds alignment pins wedging razor slot last chance Get right time everything OK use iron tack-weld intermediate deck bottom shell bearing plate complete timing assembly bearing plate must welded around its whole outside edge piece takes entire force rubberband Cut 5/16-in dia disc 1/64 plywood drill 3/32-in hole middle Insert Continued page 130 Iteut Pwdud Pressurizer al Pressure Without Pump 4 z z 5 LIFETIMEGUARANTEEAGAINST FAILURE DUE TO MANUFACTURING DEFECTS *CALIF RESIDENTS ADD 60/0 TAX * No fuel pump special carburetor needed * Works planes boats cars helicop ters..2 stroke engines Irom 10 90 muffler pipe * No adjustments necessary except simple carburetor adjustments * Extends engine life helping prevent lean engine runs INUCTORY OFFER $1695* PLUS $1 OD FOR SHIPPING $1995 after July 15th SEND CHECK OR MONEY ORDER ro VISTAEDS MODEL PRODUCTS AHERMOSA WALNUT CREEK CA 94596 OR 4830 ZUBE CT CARMICHAEL CA 95608 June 1982 127 RIC PILOT LOGBOOK AND FLIGHT RECORD *AIRCRAFT FLOWN *FLyING FIELDS *FLIGHT INSTRUCTOR *TOTAL HOURS *WEATHER CONDITIONS *FLIGHT DURATION *TRIM ADJUSTMENTS above can entered own personal flight log first time R/G LOGBOOK designed specifically pilot minitiature aircraft Whatever particular skill level may LOGBOOK will add enjoyment R/G flying LOGBOOK has durable hard-bound cover contains sufficient pages record years flying average R/G pilotel 81 Champion Hobbies$695 Postage Paid Dealer/Distributor inquiries welcomeOhio esidents odd 320 sIes tool CHAMPION HOBBIES 3715 Reemelin Cincinnati 01-145211 513 481-6961 ACTUAL SIZE 1/4 INCH LONG OR Propeller new wood blades have phenolic coating extra stiffness makes propeller stiffer stronger yet thinner best efficiency 24 x 9 Propeller $20 HARDER STIFFER Other sizes will soon available AT YOUR DEALER GRISH BROS ST JOHN INO 46373 Perfect AA control line leadout eyelet 3/32in hole cement its flange plywood high-viscosity cyanoacrylates fiveminute epoxy Cut straight pin point length will project about 1/32-in overthe edge disc radial orientation same cement acts DT release Clean roughen winding shaft piece sandpaper needle file slip disc assembly 005 010-in shim single-edge razor blade works between flange eyelet top timer Cement eyelet shaft being sure dont let cement run down bearing use hi-vis cement Push original plastic winding knob down shaft until bottoms end eyelet Cut off protruding shaft file flush top winding knob Remove shim com pletes timer timer powered rubberband remem ber removed spring Typically rubberband made Win loop 030-050 Indoor rubber hooked over projecting end straight pin disc timer rubber stretched about twice its normal length position string DT fastened other end rubberband rubber wound around shaft eyelet twisting winding knob allowing rubber climb shaft time deter mined number turns nature rubberband used reason disc very little torque required run timer lot needed get clean release pin Therefore last half-turn timer made run higher rate torque get clean release life expectancy timer really known point prototype has run over 100 cycles room temperature clean con ditions no apparent wear timing change timers used Texas Nats no temperature problems certainly will least sensitive dust dirt Seelig Tatone dont use lubricants seal welL timer protection mounted pocket airplane sure seal interior balsa dust doesnt find its way gears Scotch Magic Tape can used cover outside face timer piece typing paper should cut fit over part covers ends shafts goo tape wont get bearings now making vacuum-formed cups timers mounted photos show timer mounted nose Mike Stoys Wasp MA plan No 343 Don Lindley prefers mount timer wing using finger rest falring get necessary depth shown picture Max Flyer case have number choices timer consider gadget perfected finished product simply reasonable plateau development program therefore worth noting hoped others will pick up go ahead other improvements mechanics techniques make item usefuL FF Duration/Meuser Con finued page 65 crumble mini-comfiakes put through water-soak routine Thats abso lute disaster irreplaceable rare Old-Timer kit According ModelAviation 130 Model Aviation LARGE Plasticote LIGHTER 1GLOW lireb PLUGS 0 Blow Proof Seal OSix Types in3 Heat Ranges S Longer Life 0 Flash Starting Only $120 SWANSON PO Box 151Since 7948 Wayne NJ 07470 SILK ~" DISCOUNTS ON $ 50 YD ROLLS495/YD RedYellow Royal Ukie Fine Quality Model Building AlyLenghMoii5OYd SILK COVERS 8EST LIGHT- STRONG- ECONOMICAL SHIPPING ADO 50 FOREIGN 150/ ORDER l RES Add 4% 8ROWNSELL FLAG & DECAL CO 121 LAUREL ROAD NEW CITY NY 914-634-850010956