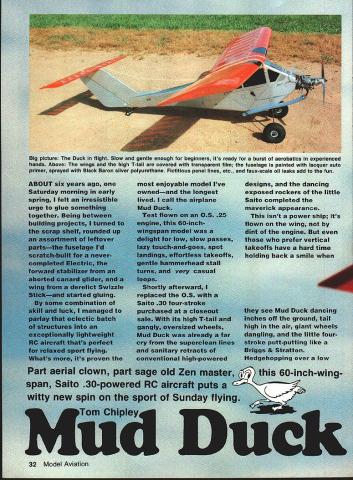

nicture Duck Above winy r sprayed Bla Ic enough beginners its ready burst aerobatics experienced re covered transparent film fuselage painted polyurethane Fictitious panel lines etc faux-scale oil leaks enjoyable r 11 th afti 4 fout dancing sed rockers c completed isnt pc n wir e en o prefe have back SI off thE rig six year lay I felt glue Aviatior fence turning ridiculously tight wing vertical hopping back over lower Duck makes laugh out loud Pylon turns around killer tree field also hoot model aerial clown irreverent puppy sage old Zen master 4fst d tli Just gentle touch stick firm hand throttle Like Old-Timer aircraft characteristically graceful lines mod isnt intended push th4 frontiers aeronautic. science Its airplane bas warmth Mud Duck subtle grace tallenges flight eels ii aesthetically occasions have handed transmitter absolute neophytes proceeded talk through standard turns level flight ant speed beginner has plenty time May 1992 33 n fly qui4 wind Left high I-tall gangly oversize wheels dancing exposed rockers little Salto 30 far cry superolean lines sanitary retracts conventional high-powered designs Right Transparent film wing tall casts interesting shadows ground comprehend react what model does contrast high-performance aircraft can fly entirely reaction time inviting certain destruction Mud Duck its safe fall behind curve hands seasoned pilot though Mud Duck will perform like air-show Super Cublow-altitude loops steep turns hedgehops kamikaze power dives one-wheel touch-and-goes stall characteristics user friendlyshell hang nose up gently drop nose mush way good breeze can pull nose up reduce throttle shell hang air like stringless kite As wind picks up lightness becomes liability ground Mud Duck requires some tie-down security Dont try land model very low altitude turbulence experienced hand controls designed penetrate structure will withstand stress normal flight landing loads wing despite its lightness has proven adequate loads possible Saito 30 four-stroke given frontal area Mud Duck tested known package Changing part requires changing other areas turn insisted attaching larger engine example youd have beef up wing thicker materials leading edge sheeting dont recommend making modifications Construction structure all-balsa except plywood used firewall wing dihedral brace sheeting vertical fin landing gear mounting panel fuselage bottom less conventional construction techniques used Use 1/16-thick sheet balsa wing fuselage additional thickness unnecessary square rectangular 34 Model Aviation Left Close-up pushrod/rudder coupling steerable tall wheel connection Right scratch-built muffler mounted place Left Salto 30 up close Note exposed pushrods open-air valves springs Center Scratch-built muffler uses small aerosol can brass tubing epoxy small section silicone tubing Right author paid serious attention replicating full-scale detail BLR SlEET 6 55 DflLS SFqR FLS YE 4EALSR RS59 4 HRRDWQD DOJEL 4B4LbflRIEBOThEND5 AND iWO CENTD BRLSR SHEET NOTE GRIN DIRECflON i LSR B FINALLY FOUND CfN LANDN ThIN ONCE SPINNER OU N TYISINThEEEOFTEHOLDERPCEU NJ 4SSPRUC TOP 6 RIBS I BLSR\ Q MLSA RILS -7 ADI MUSIC/ IG WHEEL5 3C PIINIMUP4 77 7 7 ELS LE SHEET ORBIN FRflME EILSA SHEET TOP&Eon-j .77 7 7 7zz SHEET SIDE TWO PLY NOSE ONLY NOrE GRRI DIPECnON MRLL EOUR STROKE ENGINE SHEET Th - 5QBPLSR ELEVATOR PUS-I ROD PRAWN 8 lbPi CHIPLa~* QSIGNP & STAB 490WSHEET CABIN 46 E1LSP IEET TOP&aOTlOM SIDES \ \ \ /7 7/ -716I F. SHRME T3 50 UGUI THOUGH RC Mud Duck sections used frame fuselage aligned follow forces imparted wing during flight landing gear upon contacting ground Sheet entire fuselage including vertical fin since contains elevator pushrod balsa thin ply recommend paint sheeting rather covering heat-shrink film time Ive tried iron-on films Duck Ive problems fuel seeping under covering eventually soaking engine area oil Painting fuselage requires work time finish should last longer give less trouble Also painted finish lends itself lettering other creative graphicsfaux oil leaks weatheringthat can applied fine-line permanent marker such Sanford brand Sharpie used lacquer auto primer followed spray coat Black Baron silver polyurethane drew completely fictitious panel lines ports inspection n -I I -xflA S plates louvers using penny small bottle cap circle templates small ______7 __________________ U______ __ 4 777 ii // N NK NNK / 6 [2 triangle straight lines create fake oil leaks wear smudges simply dragged thumb over still-wet inked line Another method turn business card face down scrub Left The wing balsa sheet except A-ln-sq-balsa LE TE spars low Note lightening holes A-in balsa wing tips clothespin clamps used tip assembly LE cut too short pieced fit Right wing stab ready covering finished wing struc ture weighed just seven ounces 36 Model Aviation Type Sport Wingspan 60 inches Recommended engine size type Saito 30 four-stroke Number RC channels recommended Three Expected flying weight available Type construction Built-up Type covering/finish recommended Transparent coveringwing tail paint lacquer auto primer polyurethane spray 0 Full-Size Plans Available . See Page 204 ____________ L __________ ___________ i4___ ___ ___I____I__ Horizontal Stabilizer 7 0 ____________________ Elevator tUC1 RN FROPLRB WB U &S OU HUMOR DRJ&NOO RY rofr COIPLOY BOURN BY UTURW gRCUER TCO 9Z IU3 45B III edge No 2 pencil position card painted surface want smudge rub off some graphite finger leaves realistic smudge straight edge Scale aircraftsort faux-scale technique Its wonderful recreation maybe bit heavy-handed fun graphics weathering have applied spray epoxy clear-coat two parts superior fuel proofing experience supposedly fuelproof spray-on polyurethane finishes fact readily attacked hot fuel exhaust certainly arent sufficiently fuelproof please Most steps construction should adequately explained photos captions Keep mind however joints must neatly done especially using rapid-cure CyA cyanoaciylate adhesives Fuzzy ends seem work nicely epoxy aliphatic resin adhesives CyAs thrive precise fit strength wood-to-wood joint directly related surface area covered adhesive glue bonds surface material has no effect wood beneath Like woods balsa quite strong used compression tension relatively thin sections can safely used Its important however reinforce joint area gussets triangle stock corner fillers provide great strength minimum weight After attaching top bottom wing leading edge sheeting slow-setting CyA coated interior joint lines aliphatic resin applied small brush before attaching spar webbing also used aliphatic resin webbing assure best possible jointlarea coverage D-tube wing structure extremely strong light resists twisting almost much resists bending May 1992 37 Dont omit spar webbing prevents spars flexing compression forces top spar down tension pulls lower spar straight taut Likewise its important make sure web grain vertical forces trying either compress web stretch out small section wood will withstand forces rather well load applied along direction grain will fail miserably forces applied across grain Wood very linear building material Let add point compression strength balsa varies greatly weight hardness sample Bitter experience has taught very soft balsa used extremely lightweight wing spars example will compress rather easily permitting top spar cave upon itself destroy wing same lightweight material however performs much better used tension assure structural integrity top spar should 114-in-sq spruce indicated plan desired may scarf join balsa spar beyond sixth wing rib case make joint least three times long high 1/4-in-sq stick would least 3/4 long advice based empirical data acquired prototypes suffered top spar compressive failure during full-speed power dive things considered fuselage survived vertical impact rather well tail section broke away completely easily reattached Since blow concentrated toward bottom plane slightly inverted instant impact V 1-385Q K I I I / 4 SRUC 5PR VERT ~RLA SI-iET Y4 RIB lower fuselage sheeting popped off cleanly through plywood landing gear mounting platform too easily refitted engine attached its plastic mount screws rather bolts broke free minor damage cast metal corner engine mounting flange carburetor mounting flange absorbed some impact accident far total loss learned build wing throttle servo mounted removable side panel through servo arm projects operate external wire pushrod method throttle 38 Model Aviation Above Detail cross brace upper forward fuselage corner Note triangle stock brace thin coating CyA soft balsa becomes rigid sectIon Below sec ond fuselage side being bulit over first waxed paper protecting joints curved top bottom stringers pinned place instant CyA cures Right Build pushrods place before sheeting fuselage Note use horseshoe fasteners Full-Size Plans Available Page 204 N N BLS RI x 1 rE___ K-i _____2/ _L7 — f YeoIMUsc WIRE--- F MUD DUCK $N Thi C4IPV DRW 8ARaR F39 99Z IQtOI~ PI11 operation obviates difficulty routing throttle pushrod through rather tightly filled forward fuselage also permitting access lower central fuselage area installation removal batteries etc exterior control look reminiscent Ford Trimotor consider important part models aesthetics fuselage built two major sections nose main structure Construct Left The second layer i/i sheet sides nose being installed cross grained first Note opening throttie servo panel Below Fitting scrap piece compiete second iayer sheet ing Mark underedge trim giuc May 1992 39 main fuselage first order accurately fit nose piece build up Note nose structure double sheeted strength Use /16 balsa both basic structure doubler material try attach second layer balsa grain running different direction used scrap pieces nose doublers satisfied results nose simply glued main fuselage make effort fit joining surfaces nicely absolute rigidity make final attachment epoxy Blend edges smoothly careful sanding unconventional effective way achieving nicely tapered nose photographic purposes side fuselage left uncovered better show pushrod fuel tank installations servo locations should cover fuselage half completed since strength sheeting helpful pulling tail together gluing fact 1/16 balsa top bottom sheeting serves cross-fuselage bracing pull fuselage halves together after installing cross braces corners cabin area youll see sides take natural curve sheeting will permanently locate curve Tail surfaces prototype used horizontal stabilizer having few ribs covered /32 sheet balsa no spars Finding difficult fabricate though quite strong opted conventional rib-and-spar technique version shown reduce weight enhance appearance removed excess material trailing edges both wing stab result wing tail structures resemble another Once get started little sanding drum Dremel balsa goes flying cloud dust No wood should given free ride doesnt work living convert sawdust vertical fin lamination 1/32 ply 14-in-sq balsa sticks contains pushrod enclosure tube elevator Build /4-in-sq balsa structure over plans glue thin ply sides side should cut bit oversize permit accurate trimming later Notch balsa sticks pushrod slip pushrod housing place glue either five-minute epoxy CyA accelerator like roughen pushrod tube sandpaper before gluing Trim ply sheeting first side glue second side complete sandwich Trim turn dry sand nice contour leading edge shallow V trailing edge rudder attachment point Since 1/4-in-sq sticks leading edge extend through fuselage glued bottom sheeting hard balsa must used contrast interior balsa sticks can dead-soft material Position horizontal stab vertical fin carefully adjust alignment As shown photos set fuselage tabletop shimmed final leveling adjustment pages spiral-bound book permits very accurate adjustments height stabilizer plane above fuselage wing saddle indicated plan Take time make sure everything accurate alignment use five-minute epoxy join stab fin little time care will repaid true-flying fuselage Wing Conventional construction used simplify building tips however cut leading edge sheeting sufficiently long include wing tips neglected to piece tip sheeting together 40 Model Aviation Completed fuselage vertical fin fuel iine exit hoie wili sealed silicone rubber after fuse has painted/finished fin LE stick giued bottom sheeting pushrod fiows smoothiy tin servo minimizing friction inner rod Using piywood tempiate cut stabi iizer ribs scrap material Make sure grain runs front rear Epoxying stab fin drafting trian gle squares fin tabletop spiralbound book useful fine adjustments Continued page 140 basic nose section frame has built over waxed paper-covered plan side has sheeted Sand necessary ne iuei tank has secured foam balsa cross brace fuel line exits through top sheeting behind firewall F3A F3C F3D held together did 90% model helicopterrelated industry fail respond request financial support F3A included public awards ceremony closing day need begin raising money 1993 F3C team now RC Mud DucklChipley Continued page 40 Thats lot trouble tips look unsightly through translucent covering correct length sheeting shown plan vertical-grain balsa webs glued outside trailing edge spars easier sandwiching between spars arent quite strong compression difference mostly academic Dont consider omitting webs Youd risking inflight wing failure As know having wing fail flight explosive frightening dangerousand expensive chose very hard trailing edge stock wing removed much sanding drum after construction finished wing extremely light its area hasnt failed under maximum stresses possible Saito 30 Let remind again little plane simulates slow-motion look full-scale flight aerobatics such structure safely adequate Installing larger engine would require both bit wing structure tad judgment flight Mud Duck represents balance power weight surface area Flown designed will provide years safe enjoyable recreation Happy landings lying/Myers Continued page 59 $43000000 got $30000000 year will have lay off two-thirds its full-time employees political mathematics defeats engineers logic Two MAPTs built abandoned dumps modelers handed paved runways over county after money spent clubs use facilities LIDS Merokes Cobras police activities including providing RC frequency management volunteer field controllers safety rules enforcement instructor pilots license examiners county spent money MAPTs effect mighty hard see still reach over potholed dirt paths through 140 Model Aviation TAKE THE HOBBY SHOP HOME WITH YOUM THE 15th ANNUAL RADIO CONTROL BUYERS GUIDE reference guide oil R/C hobbies Browse through guide find items need ond youll know]ust whot osk ot fovorite hobby shop RADIO CONTROL BUYERS GUIDE lets turn wish list shopping list knowing whats available con plon new projects improve existing projects Price inform otion also helps odd up lust whot plans will cost Look RADIO CONTROL BUYERS GUIDE local hobby shop coil 800 533 6644 order 000000000000000000000000000000000000 order send Dept X0479 RADIO CONTROL BUYERS GUIDE PO Box 1612 WaukesbaWi 53181-1612 YES Id like order _____ RADIO CONTROL BUYERS GUIDES #13002 $ ______ l Payment enclosed J Obarge account Please print Name_______________________________________________ Street______________________________________________________[v33][b22231207163510430]] City State Zip_______________________________________________ Country_____________________________________________________[v33][b23741288183511130]] Charge ercard American Express mm $15 Card#_________________________ Exp Date_____________ Signature Include postage handling US 5300 canadian foreign add 18% minimum $400 Wisconsin residents add 5% sales tax canadian Orders add 7% G51 total Price availability subject change Payable US tunds Dept X0479 0 WW1 AERO 1900-1919 SKYWAYS 1920-1940 restorer builder & serious modeller early aircraft information current projects histc.rical research news museums airshows workshop notes technical drawings data information painticolor photographs aeroplanes engines parts acale modelling material sale news current publications ycur wants disposals 1 year subscription $25Overseas $30Sample issues $4 Published WORLD WAR 1 Gepw INC 15 Crescent Road Paughkeepsie NY 12601 USA 914 473-3679

Edition: Model Aviation - 1992/05

Page Numbers: 32, 33, 34, 35, 36, 37, 38, 39, 40, 140

nicture Duck Above winy r sprayed Bla Ic enough beginners its ready burst aerobatics experienced re covered transparent film fuselage painted polyurethane Fictitious panel lines etc faux-scale oil leaks enjoyable r 11 th afti 4 fout dancing sed rockers c completed isnt pc n wir e en o prefe have back SI off thE rig six year lay I felt glue Aviatior fence turning ridiculously tight wing vertical hopping back over lower Duck makes laugh out loud Pylon turns around killer tree field also hoot model aerial clown irreverent puppy sage old Zen master 4fst d tli Just gentle touch stick firm hand throttle Like Old-Timer aircraft characteristically graceful lines mod isnt intended push th4 frontiers aeronautic. science Its airplane bas warmth Mud Duck subtle grace tallenges flight eels ii aesthetically occasions have handed transmitter absolute neophytes proceeded talk through standard turns level flight ant speed beginner has plenty time May 1992 33 n fly qui4 wind Left high I-tall gangly oversize wheels dancing exposed rockers little Salto 30 far cry superolean lines sanitary retracts conventional high-powered designs Right Transparent film wing tall casts interesting shadows ground comprehend react what model does contrast high-performance aircraft can fly entirely reaction time inviting certain destruction Mud Duck its safe fall behind curve hands seasoned pilot though Mud Duck will perform like air-show Super Cublow-altitude loops steep turns hedgehops kamikaze power dives one-wheel touch-and-goes stall characteristics user friendlyshell hang nose up gently drop nose mush way good breeze can pull nose up reduce throttle shell hang air like stringless kite As wind picks up lightness becomes liability ground Mud Duck requires some tie-down security Dont try land model very low altitude turbulence experienced hand controls designed penetrate structure will withstand stress normal flight landing loads wing despite its lightness has proven adequate loads possible Saito 30 four-stroke given frontal area Mud Duck tested known package Changing part requires changing other areas turn insisted attaching larger engine example youd have beef up wing thicker materials leading edge sheeting dont recommend making modifications Construction structure all-balsa except plywood used firewall wing dihedral brace sheeting vertical fin landing gear mounting panel fuselage bottom less conventional construction techniques used Use 1/16-thick sheet balsa wing fuselage additional thickness unnecessary square rectangular 34 Model Aviation Left Close-up pushrod/rudder coupling steerable tall wheel connection Right scratch-built muffler mounted place Left Salto 30 up close Note exposed pushrods open-air valves springs Center Scratch-built muffler uses small aerosol can brass tubing epoxy small section silicone tubing Right author paid serious attention replicating full-scale detail BLR SlEET 6 55 DflLS SFqR FLS YE 4EALSR RS59 4 HRRDWQD DOJEL 4B4LbflRIEBOThEND5 AND iWO CENTD BRLSR SHEET NOTE GRIN DIRECflON i LSR B FINALLY FOUND CfN LANDN ThIN ONCE SPINNER OU N TYISINThEEEOFTEHOLDERPCEU NJ 4SSPRUC TOP 6 RIBS I BLSR\ Q MLSA RILS -7 ADI MUSIC/ IG WHEEL5 3C PIINIMUP4 77 7 7 ELS LE SHEET ORBIN FRflME EILSA SHEET TOP&Eon-j .77 7 7 7zz SHEET SIDE TWO PLY NOSE ONLY NOrE GRRI DIPECnON MRLL EOUR STROKE ENGINE SHEET Th - 5QBPLSR ELEVATOR PUS-I ROD PRAWN 8 lbPi CHIPLa~* QSIGNP & STAB 490WSHEET CABIN 46 E1LSP IEET TOP&aOTlOM SIDES \ \ \ /7 7/ -716I F. SHRME T3 50 UGUI THOUGH RC Mud Duck sections used frame fuselage aligned follow forces imparted wing during flight landing gear upon contacting ground Sheet entire fuselage including vertical fin since contains elevator pushrod balsa thin ply recommend paint sheeting rather covering heat-shrink film time Ive tried iron-on films Duck Ive problems fuel seeping under covering eventually soaking engine area oil Painting fuselage requires work time finish should last longer give less trouble Also painted finish lends itself lettering other creative graphicsfaux oil leaks weatheringthat can applied fine-line permanent marker such Sanford brand Sharpie used lacquer auto primer followed spray coat Black Baron silver polyurethane drew completely fictitious panel lines ports inspection n -I I -xflA S plates louvers using penny small bottle cap circle templates small ______7 __________________ U______ __ 4 777 ii // N NK NNK / 6 [2 triangle straight lines create fake oil leaks wear smudges simply dragged thumb over still-wet inked line Another method turn business card face down scrub Left The wing balsa sheet except A-ln-sq-balsa LE TE spars low Note lightening holes A-in balsa wing tips clothespin clamps used tip assembly LE cut too short pieced fit Right wing stab ready covering finished wing struc ture weighed just seven ounces 36 Model Aviation Type Sport Wingspan 60 inches Recommended engine size type Saito 30 four-stroke Number RC channels recommended Three Expected flying weight available Type construction Built-up Type covering/finish recommended Transparent coveringwing tail paint lacquer auto primer polyurethane spray 0 Full-Size Plans Available . See Page 204 ____________ L __________ ___________ i4___ ___ ___I____I__ Horizontal Stabilizer 7 0 ____________________ Elevator tUC1 RN FROPLRB WB U &S OU HUMOR DRJ&NOO RY rofr COIPLOY BOURN BY UTURW gRCUER TCO 9Z IU3 45B III edge No 2 pencil position card painted surface want smudge rub off some graphite finger leaves realistic smudge straight edge Scale aircraftsort faux-scale technique Its wonderful recreation maybe bit heavy-handed fun graphics weathering have applied spray epoxy clear-coat two parts superior fuel proofing experience supposedly fuelproof spray-on polyurethane finishes fact readily attacked hot fuel exhaust certainly arent sufficiently fuelproof please Most steps construction should adequately explained photos captions Keep mind however joints must neatly done especially using rapid-cure CyA cyanoaciylate adhesives Fuzzy ends seem work nicely epoxy aliphatic resin adhesives CyAs thrive precise fit strength wood-to-wood joint directly related surface area covered adhesive glue bonds surface material has no effect wood beneath Like woods balsa quite strong used compression tension relatively thin sections can safely used Its important however reinforce joint area gussets triangle stock corner fillers provide great strength minimum weight After attaching top bottom wing leading edge sheeting slow-setting CyA coated interior joint lines aliphatic resin applied small brush before attaching spar webbing also used aliphatic resin webbing assure best possible jointlarea coverage D-tube wing structure extremely strong light resists twisting almost much resists bending May 1992 37 Dont omit spar webbing prevents spars flexing compression forces top spar down tension pulls lower spar straight taut Likewise its important make sure web grain vertical forces trying either compress web stretch out small section wood will withstand forces rather well load applied along direction grain will fail miserably forces applied across grain Wood very linear building material Let add point compression strength balsa varies greatly weight hardness sample Bitter experience has taught very soft balsa used extremely lightweight wing spars example will compress rather easily permitting top spar cave upon itself destroy wing same lightweight material however performs much better used tension assure structural integrity top spar should 114-in-sq spruce indicated plan desired may scarf join balsa spar beyond sixth wing rib case make joint least three times long high 1/4-in-sq stick would least 3/4 long advice based empirical data acquired prototypes suffered top spar compressive failure during full-speed power dive things considered fuselage survived vertical impact rather well tail section broke away completely easily reattached Since blow concentrated toward bottom plane slightly inverted instant impact V 1-385Q K I I I / 4 SRUC 5PR VERT ~RLA SI-iET Y4 RIB lower fuselage sheeting popped off cleanly through plywood landing gear mounting platform too easily refitted engine attached its plastic mount screws rather bolts broke free minor damage cast metal corner engine mounting flange carburetor mounting flange absorbed some impact accident far total loss learned build wing throttle servo mounted removable side panel through servo arm projects operate external wire pushrod method throttle 38 Model Aviation Above Detail cross brace upper forward fuselage corner Note triangle stock brace thin coating CyA soft balsa becomes rigid sectIon Below sec ond fuselage side being bulit over first waxed paper protecting joints curved top bottom stringers pinned place instant CyA cures Right Build pushrods place before sheeting fuselage Note use horseshoe fasteners Full-Size Plans Available Page 204 N N BLS RI x 1 rE___ K-i _____2/ _L7 — f YeoIMUsc WIRE--- F MUD DUCK $N Thi C4IPV DRW 8ARaR F39 99Z IQtOI~ PI11 operation obviates difficulty routing throttle pushrod through rather tightly filled forward fuselage also permitting access lower central fuselage area installation removal batteries etc exterior control look reminiscent Ford Trimotor consider important part models aesthetics fuselage built two major sections nose main structure Construct Left The second layer i/i sheet sides nose being installed cross grained first Note opening throttie servo panel Below Fitting scrap piece compiete second iayer sheet ing Mark underedge trim giuc May 1992 39 main fuselage first order accurately fit nose piece build up Note nose structure double sheeted strength Use /16 balsa both basic structure doubler material try attach second layer balsa grain running different direction used scrap pieces nose doublers satisfied results nose simply glued main fuselage make effort fit joining surfaces nicely absolute rigidity make final attachment epoxy Blend edges smoothly careful sanding unconventional effective way achieving nicely tapered nose photographic purposes side fuselage left uncovered better show pushrod fuel tank installations servo locations should cover fuselage half completed since strength sheeting helpful pulling tail together gluing fact 1/16 balsa top bottom sheeting serves cross-fuselage bracing pull fuselage halves together after installing cross braces corners cabin area youll see sides take natural curve sheeting will permanently locate curve Tail surfaces prototype used horizontal stabilizer having few ribs covered /32 sheet balsa no spars Finding difficult fabricate though quite strong opted conventional rib-and-spar technique version shown reduce weight enhance appearance removed excess material trailing edges both wing stab result wing tail structures resemble another Once get started little sanding drum Dremel balsa goes flying cloud dust No wood should given free ride doesnt work living convert sawdust vertical fin lamination 1/32 ply 14-in-sq balsa sticks contains pushrod enclosure tube elevator Build /4-in-sq balsa structure over plans glue thin ply sides side should cut bit oversize permit accurate trimming later Notch balsa sticks pushrod slip pushrod housing place glue either five-minute epoxy CyA accelerator like roughen pushrod tube sandpaper before gluing Trim ply sheeting first side glue second side complete sandwich Trim turn dry sand nice contour leading edge shallow V trailing edge rudder attachment point Since 1/4-in-sq sticks leading edge extend through fuselage glued bottom sheeting hard balsa must used contrast interior balsa sticks can dead-soft material Position horizontal stab vertical fin carefully adjust alignment As shown photos set fuselage tabletop shimmed final leveling adjustment pages spiral-bound book permits very accurate adjustments height stabilizer plane above fuselage wing saddle indicated plan Take time make sure everything accurate alignment use five-minute epoxy join stab fin little time care will repaid true-flying fuselage Wing Conventional construction used simplify building tips however cut leading edge sheeting sufficiently long include wing tips neglected to piece tip sheeting together 40 Model Aviation Completed fuselage vertical fin fuel iine exit hoie wili sealed silicone rubber after fuse has painted/finished fin LE stick giued bottom sheeting pushrod fiows smoothiy tin servo minimizing friction inner rod Using piywood tempiate cut stabi iizer ribs scrap material Make sure grain runs front rear Epoxying stab fin drafting trian gle squares fin tabletop spiralbound book useful fine adjustments Continued page 140 basic nose section frame has built over waxed paper-covered plan side has sheeted Sand necessary ne iuei tank has secured foam balsa cross brace fuel line exits through top sheeting behind firewall F3A F3C F3D held together did 90% model helicopterrelated industry fail respond request financial support F3A included public awards ceremony closing day need begin raising money 1993 F3C team now RC Mud DucklChipley Continued page 40 Thats lot trouble tips look unsightly through translucent covering correct length sheeting shown plan vertical-grain balsa webs glued outside trailing edge spars easier sandwiching between spars arent quite strong compression difference mostly academic Dont consider omitting webs Youd risking inflight wing failure As know having wing fail flight explosive frightening dangerousand expensive chose very hard trailing edge stock wing removed much sanding drum after construction finished wing extremely light its area hasnt failed under maximum stresses possible Saito 30 Let remind again little plane simulates slow-motion look full-scale flight aerobatics such structure safely adequate Installing larger engine would require both bit wing structure tad judgment flight Mud Duck represents balance power weight surface area Flown designed will provide years safe enjoyable recreation Happy landings lying/Myers Continued page 59 $43000000 got $30000000 year will have lay off two-thirds its full-time employees political mathematics defeats engineers logic Two MAPTs built abandoned dumps modelers handed paved runways over county after money spent clubs use facilities LIDS Merokes Cobras police activities including providing RC frequency management volunteer field controllers safety rules enforcement instructor pilots license examiners county spent money MAPTs effect mighty hard see still reach over potholed dirt paths through 140 Model Aviation TAKE THE HOBBY SHOP HOME WITH YOUM THE 15th ANNUAL RADIO CONTROL BUYERS GUIDE reference guide oil R/C hobbies Browse through guide find items need ond youll know]ust whot osk ot fovorite hobby shop RADIO CONTROL BUYERS GUIDE lets turn wish list shopping list knowing whats available con plon new projects improve existing projects Price inform otion also helps odd up lust whot plans will cost Look RADIO CONTROL BUYERS GUIDE local hobby shop coil 800 533 6644 order 000000000000000000000000000000000000 order send Dept X0479 RADIO CONTROL BUYERS GUIDE PO Box 1612 WaukesbaWi 53181-1612 YES Id like order _____ RADIO CONTROL BUYERS GUIDES #13002 $ ______ l Payment enclosed J Obarge account Please print Name_______________________________________________ Street______________________________________________________[v33][b22231207163510430]] City State Zip_______________________________________________ Country_____________________________________________________[v33][b23741288183511130]] Charge ercard American Express mm $15 Card#_________________________ Exp Date_____________ Signature Include postage handling US 5300 canadian foreign add 18% minimum $400 Wisconsin residents add 5% sales tax canadian Orders add 7% G51 total Price availability subject change Payable US tunds Dept X0479 0 WW1 AERO 1900-1919 SKYWAYS 1920-1940 restorer builder & serious modeller early aircraft information current projects histc.rical research news museums airshows workshop notes technical drawings data information painticolor photographs aeroplanes engines parts acale modelling material sale news current publications ycur wants disposals 1 year subscription $25Overseas $30Sample issues $4 Published WORLD WAR 1 Gepw INC 15 Crescent Road Paughkeepsie NY 12601 USA 914 473-3679

Edition: Model Aviation - 1992/05

Page Numbers: 32, 33, 34, 35, 36, 37, 38, 39, 40, 140

nicture Duck Above winy r sprayed Bla Ic enough beginners its ready burst aerobatics experienced re covered transparent film fuselage painted polyurethane Fictitious panel lines etc faux-scale oil leaks enjoyable r 11 th afti 4 fout dancing sed rockers c completed isnt pc n wir e en o prefe have back SI off thE rig six year lay I felt glue Aviatior fence turning ridiculously tight wing vertical hopping back over lower Duck makes laugh out loud Pylon turns around killer tree field also hoot model aerial clown irreverent puppy sage old Zen master 4fst d tli Just gentle touch stick firm hand throttle Like Old-Timer aircraft characteristically graceful lines mod isnt intended push th4 frontiers aeronautic. science Its airplane bas warmth Mud Duck subtle grace tallenges flight eels ii aesthetically occasions have handed transmitter absolute neophytes proceeded talk through standard turns level flight ant speed beginner has plenty time May 1992 33 n fly qui4 wind Left high I-tall gangly oversize wheels dancing exposed rockers little Salto 30 far cry superolean lines sanitary retracts conventional high-powered designs Right Transparent film wing tall casts interesting shadows ground comprehend react what model does contrast high-performance aircraft can fly entirely reaction time inviting certain destruction Mud Duck its safe fall behind curve hands seasoned pilot though Mud Duck will perform like air-show Super Cublow-altitude loops steep turns hedgehops kamikaze power dives one-wheel touch-and-goes stall characteristics user friendlyshell hang nose up gently drop nose mush way good breeze can pull nose up reduce throttle shell hang air like stringless kite As wind picks up lightness becomes liability ground Mud Duck requires some tie-down security Dont try land model very low altitude turbulence experienced hand controls designed penetrate structure will withstand stress normal flight landing loads wing despite its lightness has proven adequate loads possible Saito 30 four-stroke given frontal area Mud Duck tested known package Changing part requires changing other areas turn insisted attaching larger engine example youd have beef up wing thicker materials leading edge sheeting dont recommend making modifications Construction structure all-balsa except plywood used firewall wing dihedral brace sheeting vertical fin landing gear mounting panel fuselage bottom less conventional construction techniques used Use 1/16-thick sheet balsa wing fuselage additional thickness unnecessary square rectangular 34 Model Aviation Left Close-up pushrod/rudder coupling steerable tall wheel connection Right scratch-built muffler mounted place Left Salto 30 up close Note exposed pushrods open-air valves springs Center Scratch-built muffler uses small aerosol can brass tubing epoxy small section silicone tubing Right author paid serious attention replicating full-scale detail BLR SlEET 6 55 DflLS SFqR FLS YE 4EALSR RS59 4 HRRDWQD DOJEL 4B4LbflRIEBOThEND5 AND iWO CENTD BRLSR SHEET NOTE GRIN DIRECflON i LSR B FINALLY FOUND CfN LANDN ThIN ONCE SPINNER OU N TYISINThEEEOFTEHOLDERPCEU NJ 4SSPRUC TOP 6 RIBS I BLSR\ Q MLSA RILS -7 ADI MUSIC/ IG WHEEL5 3C PIINIMUP4 77 7 7 ELS LE SHEET ORBIN FRflME EILSA SHEET TOP&Eon-j .77 7 7 7zz SHEET SIDE TWO PLY NOSE ONLY NOrE GRRI DIPECnON MRLL EOUR STROKE ENGINE SHEET Th - 5QBPLSR ELEVATOR PUS-I ROD PRAWN 8 lbPi CHIPLa~* QSIGNP & STAB 490WSHEET CABIN 46 E1LSP IEET TOP&aOTlOM SIDES \ \ \ /7 7/ -716I F. SHRME T3 50 UGUI THOUGH RC Mud Duck sections used frame fuselage aligned follow forces imparted wing during flight landing gear upon contacting ground Sheet entire fuselage including vertical fin since contains elevator pushrod balsa thin ply recommend paint sheeting rather covering heat-shrink film time Ive tried iron-on films Duck Ive problems fuel seeping under covering eventually soaking engine area oil Painting fuselage requires work time finish should last longer give less trouble Also painted finish lends itself lettering other creative graphicsfaux oil leaks weatheringthat can applied fine-line permanent marker such Sanford brand Sharpie used lacquer auto primer followed spray coat Black Baron silver polyurethane drew completely fictitious panel lines ports inspection n -I I -xflA S plates louvers using penny small bottle cap circle templates small ______7 __________________ U______ __ 4 777 ii // N NK NNK / 6 [2 triangle straight lines create fake oil leaks wear smudges simply dragged thumb over still-wet inked line Another method turn business card face down scrub Left The wing balsa sheet except A-ln-sq-balsa LE TE spars low Note lightening holes A-in balsa wing tips clothespin clamps used tip assembly LE cut too short pieced fit Right wing stab ready covering finished wing struc ture weighed just seven ounces 36 Model Aviation Type Sport Wingspan 60 inches Recommended engine size type Saito 30 four-stroke Number RC channels recommended Three Expected flying weight available Type construction Built-up Type covering/finish recommended Transparent coveringwing tail paint lacquer auto primer polyurethane spray 0 Full-Size Plans Available . See Page 204 ____________ L __________ ___________ i4___ ___ ___I____I__ Horizontal Stabilizer 7 0 ____________________ Elevator tUC1 RN FROPLRB WB U &S OU HUMOR DRJ&NOO RY rofr COIPLOY BOURN BY UTURW gRCUER TCO 9Z IU3 45B III edge No 2 pencil position card painted surface want smudge rub off some graphite finger leaves realistic smudge straight edge Scale aircraftsort faux-scale technique Its wonderful recreation maybe bit heavy-handed fun graphics weathering have applied spray epoxy clear-coat two parts superior fuel proofing experience supposedly fuelproof spray-on polyurethane finishes fact readily attacked hot fuel exhaust certainly arent sufficiently fuelproof please Most steps construction should adequately explained photos captions Keep mind however joints must neatly done especially using rapid-cure CyA cyanoaciylate adhesives Fuzzy ends seem work nicely epoxy aliphatic resin adhesives CyAs thrive precise fit strength wood-to-wood joint directly related surface area covered adhesive glue bonds surface material has no effect wood beneath Like woods balsa quite strong used compression tension relatively thin sections can safely used Its important however reinforce joint area gussets triangle stock corner fillers provide great strength minimum weight After attaching top bottom wing leading edge sheeting slow-setting CyA coated interior joint lines aliphatic resin applied small brush before attaching spar webbing also used aliphatic resin webbing assure best possible jointlarea coverage D-tube wing structure extremely strong light resists twisting almost much resists bending May 1992 37 Dont omit spar webbing prevents spars flexing compression forces top spar down tension pulls lower spar straight taut Likewise its important make sure web grain vertical forces trying either compress web stretch out small section wood will withstand forces rather well load applied along direction grain will fail miserably forces applied across grain Wood very linear building material Let add point compression strength balsa varies greatly weight hardness sample Bitter experience has taught very soft balsa used extremely lightweight wing spars example will compress rather easily permitting top spar cave upon itself destroy wing same lightweight material however performs much better used tension assure structural integrity top spar should 114-in-sq spruce indicated plan desired may scarf join balsa spar beyond sixth wing rib case make joint least three times long high 1/4-in-sq stick would least 3/4 long advice based empirical data acquired prototypes suffered top spar compressive failure during full-speed power dive things considered fuselage survived vertical impact rather well tail section broke away completely easily reattached Since blow concentrated toward bottom plane slightly inverted instant impact V 1-385Q K I I I / 4 SRUC 5PR VERT ~RLA SI-iET Y4 RIB lower fuselage sheeting popped off cleanly through plywood landing gear mounting platform too easily refitted engine attached its plastic mount screws rather bolts broke free minor damage cast metal corner engine mounting flange carburetor mounting flange absorbed some impact accident far total loss learned build wing throttle servo mounted removable side panel through servo arm projects operate external wire pushrod method throttle 38 Model Aviation Above Detail cross brace upper forward fuselage corner Note triangle stock brace thin coating CyA soft balsa becomes rigid sectIon Below sec ond fuselage side being bulit over first waxed paper protecting joints curved top bottom stringers pinned place instant CyA cures Right Build pushrods place before sheeting fuselage Note use horseshoe fasteners Full-Size Plans Available Page 204 N N BLS RI x 1 rE___ K-i _____2/ _L7 — f YeoIMUsc WIRE--- F MUD DUCK $N Thi C4IPV DRW 8ARaR F39 99Z IQtOI~ PI11 operation obviates difficulty routing throttle pushrod through rather tightly filled forward fuselage also permitting access lower central fuselage area installation removal batteries etc exterior control look reminiscent Ford Trimotor consider important part models aesthetics fuselage built two major sections nose main structure Construct Left The second layer i/i sheet sides nose being installed cross grained first Note opening throttie servo panel Below Fitting scrap piece compiete second iayer sheet ing Mark underedge trim giuc May 1992 39 main fuselage first order accurately fit nose piece build up Note nose structure double sheeted strength Use /16 balsa both basic structure doubler material try attach second layer balsa grain running different direction used scrap pieces nose doublers satisfied results nose simply glued main fuselage make effort fit joining surfaces nicely absolute rigidity make final attachment epoxy Blend edges smoothly careful sanding unconventional effective way achieving nicely tapered nose photographic purposes side fuselage left uncovered better show pushrod fuel tank installations servo locations should cover fuselage half completed since strength sheeting helpful pulling tail together gluing fact 1/16 balsa top bottom sheeting serves cross-fuselage bracing pull fuselage halves together after installing cross braces corners cabin area youll see sides take natural curve sheeting will permanently locate curve Tail surfaces prototype used horizontal stabilizer having few ribs covered /32 sheet balsa no spars Finding difficult fabricate though quite strong opted conventional rib-and-spar technique version shown reduce weight enhance appearance removed excess material trailing edges both wing stab result wing tail structures resemble another Once get started little sanding drum Dremel balsa goes flying cloud dust No wood should given free ride doesnt work living convert sawdust vertical fin lamination 1/32 ply 14-in-sq balsa sticks contains pushrod enclosure tube elevator Build /4-in-sq balsa structure over plans glue thin ply sides side should cut bit oversize permit accurate trimming later Notch balsa sticks pushrod slip pushrod housing place glue either five-minute epoxy CyA accelerator like roughen pushrod tube sandpaper before gluing Trim ply sheeting first side glue second side complete sandwich Trim turn dry sand nice contour leading edge shallow V trailing edge rudder attachment point Since 1/4-in-sq sticks leading edge extend through fuselage glued bottom sheeting hard balsa must used contrast interior balsa sticks can dead-soft material Position horizontal stab vertical fin carefully adjust alignment As shown photos set fuselage tabletop shimmed final leveling adjustment pages spiral-bound book permits very accurate adjustments height stabilizer plane above fuselage wing saddle indicated plan Take time make sure everything accurate alignment use five-minute epoxy join stab fin little time care will repaid true-flying fuselage Wing Conventional construction used simplify building tips however cut leading edge sheeting sufficiently long include wing tips neglected to piece tip sheeting together 40 Model Aviation Completed fuselage vertical fin fuel iine exit hoie wili sealed silicone rubber after fuse has painted/finished fin LE stick giued bottom sheeting pushrod fiows smoothiy tin servo minimizing friction inner rod Using piywood tempiate cut stabi iizer ribs scrap material Make sure grain runs front rear Epoxying stab fin drafting trian gle squares fin tabletop spiralbound book useful fine adjustments Continued page 140 basic nose section frame has built over waxed paper-covered plan side has sheeted Sand necessary ne iuei tank has secured foam balsa cross brace fuel line exits through top sheeting behind firewall F3A F3C F3D held together did 90% model helicopterrelated industry fail respond request financial support F3A included public awards ceremony closing day need begin raising money 1993 F3C team now RC Mud DucklChipley Continued page 40 Thats lot trouble tips look unsightly through translucent covering correct length sheeting shown plan vertical-grain balsa webs glued outside trailing edge spars easier sandwiching between spars arent quite strong compression difference mostly academic Dont consider omitting webs Youd risking inflight wing failure As know having wing fail flight explosive frightening dangerousand expensive chose very hard trailing edge stock wing removed much sanding drum after construction finished wing extremely light its area hasnt failed under maximum stresses possible Saito 30 Let remind again little plane simulates slow-motion look full-scale flight aerobatics such structure safely adequate Installing larger engine would require both bit wing structure tad judgment flight Mud Duck represents balance power weight surface area Flown designed will provide years safe enjoyable recreation Happy landings lying/Myers Continued page 59 $43000000 got $30000000 year will have lay off two-thirds its full-time employees political mathematics defeats engineers logic Two MAPTs built abandoned dumps modelers handed paved runways over county after money spent clubs use facilities LIDS Merokes Cobras police activities including providing RC frequency management volunteer field controllers safety rules enforcement instructor pilots license examiners county spent money MAPTs effect mighty hard see still reach over potholed dirt paths through 140 Model Aviation TAKE THE HOBBY SHOP HOME WITH YOUM THE 15th ANNUAL RADIO CONTROL BUYERS GUIDE reference guide oil R/C hobbies Browse through guide find items need ond youll know]ust whot osk ot fovorite hobby shop RADIO CONTROL BUYERS GUIDE lets turn wish list shopping list knowing whats available con plon new projects improve existing projects Price inform otion also helps odd up lust whot plans will cost Look RADIO CONTROL BUYERS GUIDE local hobby shop coil 800 533 6644 order 000000000000000000000000000000000000 order send Dept X0479 RADIO CONTROL BUYERS GUIDE PO Box 1612 WaukesbaWi 53181-1612 YES Id like order _____ RADIO CONTROL BUYERS GUIDES #13002 $ ______ l Payment enclosed J Obarge account Please print Name_______________________________________________ Street______________________________________________________[v33][b22231207163510430]] City State Zip_______________________________________________ Country_____________________________________________________[v33][b23741288183511130]] Charge ercard American Express mm $15 Card#_________________________ Exp Date_____________ Signature Include postage handling US 5300 canadian foreign add 18% minimum $400 Wisconsin residents add 5% sales tax canadian Orders add 7% G51 total Price availability subject change Payable US tunds Dept X0479 0 WW1 AERO 1900-1919 SKYWAYS 1920-1940 restorer builder & serious modeller early aircraft information current projects histc.rical research news museums airshows workshop notes technical drawings data information painticolor photographs aeroplanes engines parts acale modelling material sale news current publications ycur wants disposals 1 year subscription $25Overseas $30Sample issues $4 Published WORLD WAR 1 Gepw INC 15 Crescent Road Paughkeepsie NY 12601 USA 914 473-3679

Edition: Model Aviation - 1992/05

Page Numbers: 32, 33, 34, 35, 36, 37, 38, 39, 40, 140

nicture Duck Above winy r sprayed Bla Ic enough beginners its ready burst aerobatics experienced re covered transparent film fuselage painted polyurethane Fictitious panel lines etc faux-scale oil leaks enjoyable r 11 th afti 4 fout dancing sed rockers c completed isnt pc n wir e en o prefe have back SI off thE rig six year lay I felt glue Aviatior fence turning ridiculously tight wing vertical hopping back over lower Duck makes laugh out loud Pylon turns around killer tree field also hoot model aerial clown irreverent puppy sage old Zen master 4fst d tli Just gentle touch stick firm hand throttle Like Old-Timer aircraft characteristically graceful lines mod isnt intended push th4 frontiers aeronautic. science Its airplane bas warmth Mud Duck subtle grace tallenges flight eels ii aesthetically occasions have handed transmitter absolute neophytes proceeded talk through standard turns level flight ant speed beginner has plenty time May 1992 33 n fly qui4 wind Left high I-tall gangly oversize wheels dancing exposed rockers little Salto 30 far cry superolean lines sanitary retracts conventional high-powered designs Right Transparent film wing tall casts interesting shadows ground comprehend react what model does contrast high-performance aircraft can fly entirely reaction time inviting certain destruction Mud Duck its safe fall behind curve hands seasoned pilot though Mud Duck will perform like air-show Super Cublow-altitude loops steep turns hedgehops kamikaze power dives one-wheel touch-and-goes stall characteristics user friendlyshell hang nose up gently drop nose mush way good breeze can pull nose up reduce throttle shell hang air like stringless kite As wind picks up lightness becomes liability ground Mud Duck requires some tie-down security Dont try land model very low altitude turbulence experienced hand controls designed penetrate structure will withstand stress normal flight landing loads wing despite its lightness has proven adequate loads possible Saito 30 four-stroke given frontal area Mud Duck tested known package Changing part requires changing other areas turn insisted attaching larger engine example youd have beef up wing thicker materials leading edge sheeting dont recommend making modifications Construction structure all-balsa except plywood used firewall wing dihedral brace sheeting vertical fin landing gear mounting panel fuselage bottom less conventional construction techniques used Use 1/16-thick sheet balsa wing fuselage additional thickness unnecessary square rectangular 34 Model Aviation Left Close-up pushrod/rudder coupling steerable tall wheel connection Right scratch-built muffler mounted place Left Salto 30 up close Note exposed pushrods open-air valves springs Center Scratch-built muffler uses small aerosol can brass tubing epoxy small section silicone tubing Right author paid serious attention replicating full-scale detail BLR SlEET 6 55 DflLS SFqR FLS YE 4EALSR RS59 4 HRRDWQD DOJEL 4B4LbflRIEBOThEND5 AND iWO CENTD BRLSR SHEET NOTE GRIN DIRECflON i LSR B FINALLY FOUND CfN LANDN ThIN ONCE SPINNER OU N TYISINThEEEOFTEHOLDERPCEU NJ 4SSPRUC TOP 6 RIBS I BLSR\ Q MLSA RILS -7 ADI MUSIC/ IG WHEEL5 3C PIINIMUP4 77 7 7 ELS LE SHEET ORBIN FRflME EILSA SHEET TOP&Eon-j .77 7 7 7zz SHEET SIDE TWO PLY NOSE ONLY NOrE GRRI DIPECnON MRLL EOUR STROKE ENGINE SHEET Th - 5QBPLSR ELEVATOR PUS-I ROD PRAWN 8 lbPi CHIPLa~* QSIGNP & STAB 490WSHEET CABIN 46 E1LSP IEET TOP&aOTlOM SIDES \ \ \ /7 7/ -716I F. SHRME T3 50 UGUI THOUGH RC Mud Duck sections used frame fuselage aligned follow forces imparted wing during flight landing gear upon contacting ground Sheet entire fuselage including vertical fin since contains elevator pushrod balsa thin ply recommend paint sheeting rather covering heat-shrink film time Ive tried iron-on films Duck Ive problems fuel seeping under covering eventually soaking engine area oil Painting fuselage requires work time finish should last longer give less trouble Also painted finish lends itself lettering other creative graphicsfaux oil leaks weatheringthat can applied fine-line permanent marker such Sanford brand Sharpie used lacquer auto primer followed spray coat Black Baron silver polyurethane drew completely fictitious panel lines ports inspection n -I I -xflA S plates louvers using penny small bottle cap circle templates small ______7 __________________ U______ __ 4 777 ii // N NK NNK / 6 [2 triangle straight lines create fake oil leaks wear smudges simply dragged thumb over still-wet inked line Another method turn business card face down scrub Left The wing balsa sheet except A-ln-sq-balsa LE TE spars low Note lightening holes A-in balsa wing tips clothespin clamps used tip assembly LE cut too short pieced fit Right wing stab ready covering finished wing struc ture weighed just seven ounces 36 Model Aviation Type Sport Wingspan 60 inches Recommended engine size type Saito 30 four-stroke Number RC channels recommended Three Expected flying weight available Type construction Built-up Type covering/finish recommended Transparent coveringwing tail paint lacquer auto primer polyurethane spray 0 Full-Size Plans Available . See Page 204 ____________ L __________ ___________ i4___ ___ ___I____I__ Horizontal Stabilizer 7 0 ____________________ Elevator tUC1 RN FROPLRB WB U &S OU HUMOR DRJ&NOO RY rofr COIPLOY BOURN BY UTURW gRCUER TCO 9Z IU3 45B III edge No 2 pencil position card painted surface want smudge rub off some graphite finger leaves realistic smudge straight edge Scale aircraftsort faux-scale technique Its wonderful recreation maybe bit heavy-handed fun graphics weathering have applied spray epoxy clear-coat two parts superior fuel proofing experience supposedly fuelproof spray-on polyurethane finishes fact readily attacked hot fuel exhaust certainly arent sufficiently fuelproof please Most steps construction should adequately explained photos captions Keep mind however joints must neatly done especially using rapid-cure CyA cyanoaciylate adhesives Fuzzy ends seem work nicely epoxy aliphatic resin adhesives CyAs thrive precise fit strength wood-to-wood joint directly related surface area covered adhesive glue bonds surface material has no effect wood beneath Like woods balsa quite strong used compression tension relatively thin sections can safely used Its important however reinforce joint area gussets triangle stock corner fillers provide great strength minimum weight After attaching top bottom wing leading edge sheeting slow-setting CyA coated interior joint lines aliphatic resin applied small brush before attaching spar webbing also used aliphatic resin webbing assure best possible jointlarea coverage D-tube wing structure extremely strong light resists twisting almost much resists bending May 1992 37 Dont omit spar webbing prevents spars flexing compression forces top spar down tension pulls lower spar straight taut Likewise its important make sure web grain vertical forces trying either compress web stretch out small section wood will withstand forces rather well load applied along direction grain will fail miserably forces applied across grain Wood very linear building material Let add point compression strength balsa varies greatly weight hardness sample Bitter experience has taught very soft balsa used extremely lightweight wing spars example will compress rather easily permitting top spar cave upon itself destroy wing same lightweight material however performs much better used tension assure structural integrity top spar should 114-in-sq spruce indicated plan desired may scarf join balsa spar beyond sixth wing rib case make joint least three times long high 1/4-in-sq stick would least 3/4 long advice based empirical data acquired prototypes suffered top spar compressive failure during full-speed power dive things considered fuselage survived vertical impact rather well tail section broke away completely easily reattached Since blow concentrated toward bottom plane slightly inverted instant impact V 1-385Q K I I I / 4 SRUC 5PR VERT ~RLA SI-iET Y4 RIB lower fuselage sheeting popped off cleanly through plywood landing gear mounting platform too easily refitted engine attached its plastic mount screws rather bolts broke free minor damage cast metal corner engine mounting flange carburetor mounting flange absorbed some impact accident far total loss learned build wing throttle servo mounted removable side panel through servo arm projects operate external wire pushrod method throttle 38 Model Aviation Above Detail cross brace upper forward fuselage corner Note triangle stock brace thin coating CyA soft balsa becomes rigid sectIon Below sec ond fuselage side being bulit over first waxed paper protecting joints curved top bottom stringers pinned place instant CyA cures Right Build pushrods place before sheeting fuselage Note use horseshoe fasteners Full-Size Plans Available Page 204 N N BLS RI x 1 rE___ K-i _____2/ _L7 — f YeoIMUsc WIRE--- F MUD DUCK $N Thi C4IPV DRW 8ARaR F39 99Z IQtOI~ PI11 operation obviates difficulty routing throttle pushrod through rather tightly filled forward fuselage also permitting access lower central fuselage area installation removal batteries etc exterior control look reminiscent Ford Trimotor consider important part models aesthetics fuselage built two major sections nose main structure Construct Left The second layer i/i sheet sides nose being installed cross grained first Note opening throttie servo panel Below Fitting scrap piece compiete second iayer sheet ing Mark underedge trim giuc May 1992 39 main fuselage first order accurately fit nose piece build up Note nose structure double sheeted strength Use /16 balsa both basic structure doubler material try attach second layer balsa grain running different direction used scrap pieces nose doublers satisfied results nose simply glued main fuselage make effort fit joining surfaces nicely absolute rigidity make final attachment epoxy Blend edges smoothly careful sanding unconventional effective way achieving nicely tapered nose photographic purposes side fuselage left uncovered better show pushrod fuel tank installations servo locations should cover fuselage half completed since strength sheeting helpful pulling tail together gluing fact 1/16 balsa top bottom sheeting serves cross-fuselage bracing pull fuselage halves together after installing cross braces corners cabin area youll see sides take natural curve sheeting will permanently locate curve Tail surfaces prototype used horizontal stabilizer having few ribs covered /32 sheet balsa no spars Finding difficult fabricate though quite strong opted conventional rib-and-spar technique version shown reduce weight enhance appearance removed excess material trailing edges both wing stab result wing tail structures resemble another Once get started little sanding drum Dremel balsa goes flying cloud dust No wood should given free ride doesnt work living convert sawdust vertical fin lamination 1/32 ply 14-in-sq balsa sticks contains pushrod enclosure tube elevator Build /4-in-sq balsa structure over plans glue thin ply sides side should cut bit oversize permit accurate trimming later Notch balsa sticks pushrod slip pushrod housing place glue either five-minute epoxy CyA accelerator like roughen pushrod tube sandpaper before gluing Trim ply sheeting first side glue second side complete sandwich Trim turn dry sand nice contour leading edge shallow V trailing edge rudder attachment point Since 1/4-in-sq sticks leading edge extend through fuselage glued bottom sheeting hard balsa must used contrast interior balsa sticks can dead-soft material Position horizontal stab vertical fin carefully adjust alignment As shown photos set fuselage tabletop shimmed final leveling adjustment pages spiral-bound book permits very accurate adjustments height stabilizer plane above fuselage wing saddle indicated plan Take time make sure everything accurate alignment use five-minute epoxy join stab fin little time care will repaid true-flying fuselage Wing Conventional construction used simplify building tips however cut leading edge sheeting sufficiently long include wing tips neglected to piece tip sheeting together 40 Model Aviation Completed fuselage vertical fin fuel iine exit hoie wili sealed silicone rubber after fuse has painted/finished fin LE stick giued bottom sheeting pushrod fiows smoothiy tin servo minimizing friction inner rod Using piywood tempiate cut stabi iizer ribs scrap material Make sure grain runs front rear Epoxying stab fin drafting trian gle squares fin tabletop spiralbound book useful fine adjustments Continued page 140 basic nose section frame has built over waxed paper-covered plan side has sheeted Sand necessary ne iuei tank has secured foam balsa cross brace fuel line exits through top sheeting behind firewall F3A F3C F3D held together did 90% model helicopterrelated industry fail respond request financial support F3A included public awards ceremony closing day need begin raising money 1993 F3C team now RC Mud DucklChipley Continued page 40 Thats lot trouble tips look unsightly through translucent covering correct length sheeting shown plan vertical-grain balsa webs glued outside trailing edge spars easier sandwiching between spars arent quite strong compression difference mostly academic Dont consider omitting webs Youd risking inflight wing failure As know having wing fail flight explosive frightening dangerousand expensive chose very hard trailing edge stock wing removed much sanding drum after construction finished wing extremely light its area hasnt failed under maximum stresses possible Saito 30 Let remind again little plane simulates slow-motion look full-scale flight aerobatics such structure safely adequate Installing larger engine would require both bit wing structure tad judgment flight Mud Duck represents balance power weight surface area Flown designed will provide years safe enjoyable recreation Happy landings lying/Myers Continued page 59 $43000000 got $30000000 year will have lay off two-thirds its full-time employees political mathematics defeats engineers logic Two MAPTs built abandoned dumps modelers handed paved runways over county after money spent clubs use facilities LIDS Merokes Cobras police activities including providing RC frequency management volunteer field controllers safety rules enforcement instructor pilots license examiners county spent money MAPTs effect mighty hard see still reach over potholed dirt paths through 140 Model Aviation TAKE THE HOBBY SHOP HOME WITH YOUM THE 15th ANNUAL RADIO CONTROL BUYERS GUIDE reference guide oil R/C hobbies Browse through guide find items need ond youll know]ust whot osk ot fovorite hobby shop RADIO CONTROL BUYERS GUIDE lets turn wish list shopping list knowing whats available con plon new projects improve existing projects Price inform otion also helps odd up lust whot plans will cost Look RADIO CONTROL BUYERS GUIDE local hobby shop coil 800 533 6644 order 000000000000000000000000000000000000 order send Dept X0479 RADIO CONTROL BUYERS GUIDE PO Box 1612 WaukesbaWi 53181-1612 YES Id like order _____ RADIO CONTROL BUYERS GUIDES #13002 $ ______ l Payment enclosed J Obarge account Please print Name_______________________________________________ Street______________________________________________________[v33][b22231207163510430]] City State Zip_______________________________________________ Country_____________________________________________________[v33][b23741288183511130]] Charge ercard American Express mm $15 Card#_________________________ Exp Date_____________ Signature Include postage handling US 5300 canadian foreign add 18% minimum $400 Wisconsin residents add 5% sales tax canadian Orders add 7% G51 total Price availability subject change Payable US tunds Dept X0479 0 WW1 AERO 1900-1919 SKYWAYS 1920-1940 restorer builder & serious modeller early aircraft information current projects histc.rical research news museums airshows workshop notes technical drawings data information painticolor photographs aeroplanes engines parts acale modelling material sale news current publications ycur wants disposals 1 year subscription $25Overseas $30Sample issues $4 Published WORLD WAR 1 Gepw INC 15 Crescent Road Paughkeepsie NY 12601 USA 914 473-3679

Edition: Model Aviation - 1992/05

Page Numbers: 32, 33, 34, 35, 36, 37, 38, 39, 40, 140