DID YOU EVER have a great piece of balsa wood that you just

couldn’t bring yourself to use, because once you used it, it would be

gone? How’s that for warped logic?

I have such a piece of balsa. It’s a light block, approximately 4

inches square and roughly 40 inches long. I’ve had it since the late

1960s, and I have carried it with me from location to location as I’ve

moved a few times through the years. I was away from modeling from

1973 through 1987, and I still kept lugging that piece of balsa around

with me.

However, this article is not about an old block of balsa. It is about a

Stunt-model design that I flew from 1969 through 1971: the Patriot. I

mention the balsa story only because of the parallel I can draw in

deciding when to recreate the Patriot design.

Since getting back into flying Stunt in 1988, I planned to re-create

the Patriot someday, but I figured that once I had built it, I had built it.

I would no longer have the project to look forward to. And what if it

didn’t fly as well as I remembered the original two models of this

design flying? I felt that I would be disappointed. Boy, was I wrong!

I began remaking the Patriot in the fall of 2001 and finished it in

time to take it to the March 2002 Vintage Stunt Championships (VSC)

in Tucson, Arizona—unflown, I might add. I had more fun that week

than I had had in a long time. The engine (a Randy Smith AeroTiger

.36) ran great, and the airplane flew wonderfully right off the board

with no adjustments. That’s rare.

The airplane drew quite a bit of attention, and I received many

positive comments from the other contestants. I was wrong not to have

built this Classic design sooner, and I regret waiting as long as I did.

You know what? I’m going to use that light balsa block the next

chance I get—perhaps on another Patriot.

The nose’s sleek, jetlike looks are more than cosmetic.

Simulated air intakes add torsional rigidity to front end.

40 MODEL AVIATION

by Gerry Phelps

06sig2.QXD 3/24/04 3:19 pm Page 40

June 2004 41

Design Origin: In the fall of 1968 I began

thinking about what I might build during the

winter for the next flying season. Having

built several Fox .35-powered I-Beam

airplanes and Noblers throughout the years—

and based on what was becoming a trend

toward slightly larger airplanes—I wanted

something a little bigger.

At that time, several of my friends were

having success with the venerable McCoy .40

in the somewhat larger designs. Although the

McCoy .40 did not hold up well if exposed to

even one extended lean run, it did appear to

offer the best Stunt-run characteristics and

power for that displacement. So a McCoy .40

it was.

Several jet-type designs showed up during

that time period, and Jim Kostecky’s were the

most inspiring to me—especially his Formula

S. With what I thought to be the Formula S’s

best appearance characteristics in mind, I

drew a set of plans. I incorporated the

forward canopy, the air-intake scoops at the

wing root, and the jet-style fin and rudder into

the design.

When I finished the first airplane built

from those plans in the spring of 1969, it was

adorned with a Thunderbird paint scheme but

did not have a name. It weighed 43 ounces

and performed quite well. However, I

regretted having made equal wing panels for

the initial design.

The model began life with a 56-inch

wingspan, but I had enough leadout material

exposed to significantly extend the inboard

wing, and I did just that. I removed the

inboard tip and added 1.5 inches to the span,

bringing it up to 57.5 inches.

Hoping that I wouldn’t be asking too

much from the McCoy .40, that modification

turned a good airplane into a great airplane. It

grooved well, turned well, and stayed out on

the lines. What else can you ask for? The

model was definitely the best thing I had built

up to that point.

I flew the airplane successfully at local

meets that year and finished third in the Open

classification at the Philadelphia,

Pennsylvania, Nats behind Al Rabe (second)

and Bob Lampione (first).

At the beginning of the 1969 flying

The winning 1970 United States F2B team (L-R): the author with the Patriot, that year’s

World Champion Bill Werwage, and Bob Gieseke.

Plenty of cooling air gets to the head of the engine through that massive scoop! The

“chip”-type muffler and hole allow engine prime in the venturi.

“Aggressive” might be the best word to describe the aesthetics of this competitive

model. The author does outstanding paintwork!

Wheel covers are attached to main

landing-gear struts with small machine

screws. Wide gear placement yields great

ground handling.

Photos courtesy the author

06sig2.QXD 3/24/04 3:21 pm Page 41

season, I had no intention of trying out for the FAI team that would

attend the World Championships in Namur, Belgium, in 1970.

However, Bob Gieseke approached me at the 1969 Nats and

encouraged me to attend the Team Trials. He told me that based on

how I was flying that year, I had as good a chance at making the team

as anybody. Not only did I make the team, but I placed first in the

team-selection competition. That was my “shining moment” in CL

Stunt.

Once I made the team, there was never a doubt about what I was

going to build for the 1970 world competition. It would be the same

design, but with a splashy paint scheme that represented the good, old

USA. I chose the name “Patriot.” With a light-blue base coat, I added

stars and stripes to my liking.

The 1970 airplane also flew great, and its handling characteristics

were almost identical to that of the 1969 airplane. The Patriot and I

ended up in fourth place at the 1970 World Championships. Bill

Werwage finished first, Bob Gieseke finished second, and

Czechoslovakia’s Gabris nudged me out of third place by 11 points

(1,897 to 1,886). The US team finished in first place. It was a great

experience.

My 2002 model has the exact paint scheme I used on the 1970

airplane that went to Belgium. Using the original trim, name, and

AMA-number stencils I made in 1969/1970, I re-created the colorful

trim as accurately as possible. I even duplicated the cockpit detail

accurately based on plan detail and an old close-up photo of the 1969

airplane cockpit that I got from Jack Sheeks a few years ago.

When I finally flew the new airplane in Tucson, seeing it out there

You can see the bellcrank mount and landing-gear mount plates.

Check out the lightening holes! Save weight where you can!

The flaps are made from stiff 1⁄4 balsa and joined with the flap

horn. They are shown ready to be hinged to the wing.

The completed

airframe is ready

for finish. Strip of

.02-ounce carbon

mat on the TE of

the stabilizer

provides extra

strength. Do the

bottom the same

way.

42 MODEL AVIATION

Adjustable leadout guide is installed in the wingtip. Note

clearance slot in spar and lightening holes in tip plate.

06sig2.QXD 3/24/04 3:22 pm Page 42

on the end of the lines was like coming home.

It was no secret that I was a happy camper.

Bob Hunt even dubbed me the “Happy

Patriot” while we were at the VSC.

CONSTRUCTION

If you want to end up with a light model,

you have to build light from the start. Use

only contest-grade balsa (4- to 6-pound

density). Where plywood is used, try to

lighten it significantly by drilling holes in

places where its strength is not a factor. Refer

to the holes in the wing landing-gear

platforms and the nose doublers in the fueltank

compartment on the plans. You should

also drill out the engine rails in the tankcompartment

area to eliminate weight that

isn’t really doing anything for you.

When you use cyanoacrylate glue or

epoxy, remember that you get what you put

in. These bonding agents do not lighten as

they dry, as do acetone-based glues (such as

Sig-Ment) or aliphatic-resin glues (such as

Sig-Bond, Titebond, or Elmer’s carpenter’s

glue). Choose the proper glue for the

application, and try not to use excessive

amounts.

As far as the actual construction, you

should have no trouble with this project if

you’ve built a Nobler or any similarly

constructed model.

Wing: The wing is a conventional D-tube

design with a 1⁄16-inch planked LE and a 3⁄32-

inch planked TE. The D-tube spar is 3⁄32 balsa

notched for the ribs like a Nobler (first rib top

half, second rib bottom half, etc.). The LE is a

1⁄4-inch spar. For strength, the LE is

subplanked with 1⁄16 balsa through rib number

3. The center-section itself is planked with 3⁄32

balsa.

The TE is finished with a 1⁄8 balsa cap.

Before capping the LE with 1⁄8 or 3⁄32 balsa,

plane the planked LE flat, removing stock

until most of the glue joint between the

planking and the LE spar is removed. Then

cement the cap in place.

When giving the LE its final shape, make

sure you achieve a radius no less than 1⁄4 inch.

I like to make a small sanding block from

balsa with the desired radius, and this also

June 2004 43

Rib-Making Procedure

Left: For the first cut, position the master template in line with centerline on the rib

material. Make sure the TE of the template is positioned at one “rib length” mark. Cut

all the way around the TE of the template, but only as far forward as the vertical line on

the template. Right: Result of the first cut.

Left: For the second cut, slide the rib template back so that the inside of the LE notch

lines up with the other “rib length” mark. Using the point of a compass (or similar

device) positioned in the notch, pivot the rear of the template downward until the top of

the template is tangent with the first cut. Cut from the LE back to, and connecting with,

the first cut. Right: Result of the second cut.

Left: For the third cut, pivot the template upward until the bottom of the template is

tangent with the first cut. Cut from the LE back to, and connecting with, the first cut.

Right: Result of the third cut.

Left: For the last cut, pivot the template back up so that the centerlines match.

Complete the two small cuts at the LE notch. At this point, the basic rib shape cut is

complete. Right: Result of the last cut.

Type: CL Classic Stunt

Wingspan: 57.5 inches

Engine: AeroTiger .36

Flying weight: 46 ounces

Construction: Balsa and plywood

Covering/finish: Tissue and dope

06sig2.QXD 3/24/04 3:23 pm Page 43

Full-Size Plans Available—see page 199

44 MODEL AVIATION

06sig2.QXD 3/24/04 3:23 pm Page 44

ensures that the whole LE is consistent in

shape.

The procedure for making this model’s

ribs is a bit different from what you may be

used to, so I have presented it in a sidebar.

The photos depict laying out a representative

rib on a piece of white card stock. This was

done to allow good definition for the

procedure. In actual practice, the ribs would

be laid out on the actual balsa rib stock.

The wingtips start as a piece of 1⁄16 balsa

(see plans for location of holes to lighten)

with edges laminated with scrap 1⁄4 balsa, top

and bottom. Once cemented in place, you can

notch the laminations to accept 1⁄16-inch

planking at the LE and 3⁄32 inch at the TE.

Leave the wing TE planking long during wing

construction, and then simply pinch it

together and cement it in notches in the

wingtip edge laminations.

Before I install the wingtip ribs, I like to

contour and taper the rest of the tip

laminations so that they blend in with the end

wing rib. To accomplish this, I use a large

sanding block and a straightedge to check for

surface continuity. I also try to attain an

approximately 1⁄4-inch rounded edge along

most of the tip’s perimeter. Then I can install

and block-sand the tip ribs to match the rest of

the tip surface contour. Although the 2002

model has a tip weight box and an adjustable

leadout guide, these items are optional.

The original models had 3-inch bellcranks,

but I chose a Brodak 4-inch nylon bellcrank

this time around. (Modern thinking, you

know.) Installation is conventional with a

plywood floor. For added strength I support

the top of the bellcrank bolt with another

section of plywood running to the first inside

panel rib and reinforced appropriately to the

spar and center-section planking.

Make the flaps from 1⁄4 balsa, and taper

them to approximately 1⁄8-inch thickness at

the TE. I make my own control horns, but

there are enough quality products on the

market from which to choose if you elect to

purchase these items. The original models

also had handmade plywood and piano-wire

hinges, as shown in the plans. I chose tissue

taffeta hinges (100% polyester) for the 2002

model to achieve a totally sealed hinge line.

Conventional nylon hinges are another option.

If you use cloth hinges, make sure they are

100% polyester. Even if you purchase

material that is labeled 100% polyester, test it

before you use it. Apply a few drops of thin

cyanoacrylate on a test piece and allow it to

dry thoroughly. Once it has dried, bend the

test area back and forth several times and tug

at it to make sure it will not fatigue and

eventually fail.

Empennage: Cut the stabilizer and elevator

from 3⁄8 balsa sheet, shape them to achieve the

cross-section foil shown, and then hollow

them as shown on the planform. Then add the

1⁄16-inch ribs.

I covered the original versions with

medium-weight silkspan, and that provided

adequate strength for the stabilizer. However,

I covered almost the entire 2002 model with

light plyspan (Sig Japanese tissue). Because

of that, I covered the stabilizer with two

layers of medium plyspan to achieve the

needed strength.

Another method of increasing this fairly

fragile stabilizer’s strength is to cement thin

unidirectional carbon tape to the inside of the

cutout area before installing the ribs. Run the

carbon out from the center approximately 5

inches before installing the ribs. On the new

model I applied a layer of thin carbon mat on

the top and bottom of the stabilizer’s TE, but

I’m sure that did not provide as much

strength as the unidirectional carbon tape

would have.

The rudder and fin are also made from 3⁄8

sheet balsa and covered with thin carbon mat

for strength. I also used carbon mat on the

flaps for rigidity and on the model’s nose for

durability.

Fuselage: The fuselage also uses fairly

conventional construction, with 1⁄8-inch sides,

1⁄16 plywood nose doublers, and adequate

bulkhead placement. However, the bulkheads

are built up.

Glue 1⁄16 balsa that is approximately 1⁄2

inch wide vertically to the inside of each

fuselage side as indicated on the planform.

Invert the fuselage sides and place them on a

flat building surface for further assembly.

Using a centerline on the building surface,

complete the tank-compartment area as the

first step in joining the halves. Cut and install

horizontal bulkhead stringers in the remainder

of the fuselage (where the 1⁄2-inch vertical

bulkheads strips are located), achieving the

appropriate width as indicated on the

planform. These horizontal stringers can be

made from 1⁄8 or 3⁄16 balsa, and they only need

to be roughly 3⁄8 inch wide.

Temporarily remove the fuselage side

sections under the wing for wing installation.

Employ top and bottom blocks to achieve

desired shapes, and then hollow them to a

wall thickness of approximately 1⁄8 inch.

Build the cowl from sheet and blocks, and

then shape and hollow it. I continue to use

one of the oldest cowl-hold-down techniques

on most of my models: a bicycle spoke and a

spoke nut. It works well and presents well.

I cut the canopy from a Sig 11-inch

bubble and soaked it in blue Rit dye to

achieve desired tint intensity.

Finish: I finished the 2002 model with

Brodak dope and was extremely satisfied

with the results. As a matter of fact, the

model won the pilots’ choice award

(Concours award) at the 2002 Vintage Stunt

Championships.

Much has been written about finishing, so

I won’t elaborate on my technique in this

article. Whatever approach you do use for the

finish, I can’t stress enough the importance of

your keeping the weight down.

If you do build this model, and you build it

light and straight, you will absolutely love the

way it flies. Have fun, and let me know what

you think of your Patriot. I think I hear my

balsa block calling me. MA

Gerry Phelps

4175 Sacramento Blvd.

Medina OH 44256

(Editor’s note: Gerry is one of those rare

CL Stunt pilots who flies his models in a

clockwise direction [when the model is in the

upright position]. Because of that, his control

system is set up with the leadouts running out

the right wing.

His plan drawing depicts this preference

and shows the right wing panel as the longer

of the two. For those of you who fly the other

way, you will need to build the left wing as the

longer wing and reverse the control system as

it is depicted.)

46 MODEL AVIATION

06sig2.QXD 3/24/04 3:23 pm Page 46

F u l l - S i z e P l a n s

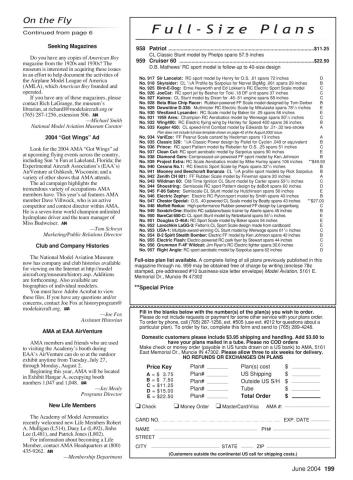

958 Patriot ...........................................................................................................$11.25

CL Classic Stunt model by Phelps spans 57.5 inches

959 Cruiser 60 ...................................................................................................$22.50

D.B. Mathews’ RC sport model is follow-up to 40-size design

No. 917 Sir Lancelot: RC sport model by Henry for O.S. .61 spans 72 inches D

No. 918 Skyraider: CL 1/2A Profile by Sarpolus for Norvel BigMig .061 spans 29 inches B

No. 925 Bird-E-Dog: Ernie Heyworth and Ed Lokken’s RC Electric Sport Scale model C

No. 926 JoeCat: RC sport jet by Beshar for Toki .18 DF unit spans 37 inches C

No. 927 Kairos: CL Stunt model by Dixon for .46-.61 engine spans 58 inches C

No. 928 Beta Blue Chip Racer: Rubber-powered FF Scale model designed by Tom Derber B

No. 929 Dewoitine D.338: Multimotor RC Electric Scale by Mikulasko spans 781/2 inches E

No. 930 Westland Lysander: RC Scale model by Baker for .25 spans 56 inches E

No. 931 1959 Ares: Champion RC Aerobatics model by Werwage spans 501/2 inches C

No. 932 Wing400: RC Electric flying wing by Hanley for Speed 400 spans 36 inches B

No. 933 Kepler 450: CL speed-limit Combat model by Edwards for .21-.32 two-stroke A

Plan does not include full-size template shown on page 40 of the August 2002 issue.

No. 934 VariEze: FF Peanut Scale canard by Heckman spans 13 inches A

No. 935 Classic 320: 1/2A Classic Power design by Pailet for Cyclon .049 or equivalent B

No. 936 Prince: RC sport Pattern model by Robelen for O.S. .25 spans 51 inches C

No. 937 Clean Cut: RC sport aerobatic model by Sarpolus spans 90 inches E

No. 938 Diamond Gem: Compressed-air-powered FF sport model by Ken Johnson B

No. 939 Project Extra: RC Scale Aerobatics model by Mike Hurley spans 106 inches **$49.50

No. 940 Cessna No.1: RC Electric Sport Scale by Papic spans 321/2 inches B

No. 941 Mooney and Beechcraft Bonanza CL 1/2A profile sport models by Rick Sarpolus B

No. 942 Zenith CH 801: FF Rubber Scale model by Fineman spans 20 inches A

No. 943 Wildman 60: Old-Time Ignition CL Stunt model by Carter spans 591/2 inches C

No. 944 Shoestring: Semiscale RC sport Pattern design by deBolt spans 60 inches D

No. 945 F-86 Sabre: Semiscale CL Stunt model by Hutchinson spans 56 inches E

No. 946 Electric Zephyr: Electric RC Pylon/sport model by Smith spans 40 inches B

No. 947 Chester Special: O.S. .40-powered CL Scale model by Beatty spans 43 inches **$27.00

No. 948 Moffett Redux: High-performance Rubber-powered FF design by Langenberg C

No. 949 Scratch-One: Electric RC sailplane/basic trainer by Aberle spans 45 inches B

No. 950 BareCat 650-C: CL sport Stunt model by Netzeband spans 541/4 inches E

No. 951 Douglas O-46A: RC Sport Scale model by Baker spans 54 inches E

No. 952 Lavochkin LaGG-3: Felton’s CL Sport Scale design made from cardboard E

No. 953 USA-1: Multiple-award-winning CL Stunt model by Werwage spans 611/2 inches C

No. 954 B-2 Spirit Stealth Bomber: Electric FF model by Ken Johnson spans 42 inches B

No. 955 Electric Flash: Electric-powered RC park flyer by Stewart spans 44 inches C

No. 956 Grumman F-4F Wildcat: Jim Ryan’s RC Electric fighter spans 30.6 inches C

No. 957 Right Angle: RC sport aerobatic model by Sarpolus spans 62 inches D

Full-size plan list available. A complete listing of all plans previously published in this

magazine through no. 959 may be obtained free of charge by writing (enclose 78¢

stamped, pre-addressed #10 business-size letter envelope) Model Aviation, 5161 E.

Memorial Dr., Muncie IN 47302

**Special Price

Edition: Model Aviation - 2004/06

Page Numbers: 40,41,42,43,44,46,199

Edition: Model Aviation - 2004/06

Page Numbers: 40,41,42,43,44,46,199

DID YOU EVER have a great piece of balsa wood that you just

couldn’t bring yourself to use, because once you used it, it would be

gone? How’s that for warped logic?

I have such a piece of balsa. It’s a light block, approximately 4

inches square and roughly 40 inches long. I’ve had it since the late

1960s, and I have carried it with me from location to location as I’ve

moved a few times through the years. I was away from modeling from

1973 through 1987, and I still kept lugging that piece of balsa around

with me.

However, this article is not about an old block of balsa. It is about a

Stunt-model design that I flew from 1969 through 1971: the Patriot. I

mention the balsa story only because of the parallel I can draw in

deciding when to recreate the Patriot design.

Since getting back into flying Stunt in 1988, I planned to re-create

the Patriot someday, but I figured that once I had built it, I had built it.

I would no longer have the project to look forward to. And what if it

didn’t fly as well as I remembered the original two models of this

design flying? I felt that I would be disappointed. Boy, was I wrong!

I began remaking the Patriot in the fall of 2001 and finished it in

time to take it to the March 2002 Vintage Stunt Championships (VSC)

in Tucson, Arizona—unflown, I might add. I had more fun that week

than I had had in a long time. The engine (a Randy Smith AeroTiger

.36) ran great, and the airplane flew wonderfully right off the board

with no adjustments. That’s rare.

The airplane drew quite a bit of attention, and I received many

positive comments from the other contestants. I was wrong not to have

built this Classic design sooner, and I regret waiting as long as I did.

You know what? I’m going to use that light balsa block the next

chance I get—perhaps on another Patriot.

The nose’s sleek, jetlike looks are more than cosmetic.

Simulated air intakes add torsional rigidity to front end.

40 MODEL AVIATION

by Gerry Phelps

06sig2.QXD 3/24/04 3:19 pm Page 40

June 2004 41

Design Origin: In the fall of 1968 I began

thinking about what I might build during the

winter for the next flying season. Having

built several Fox .35-powered I-Beam

airplanes and Noblers throughout the years—

and based on what was becoming a trend

toward slightly larger airplanes—I wanted

something a little bigger.

At that time, several of my friends were

having success with the venerable McCoy .40

in the somewhat larger designs. Although the

McCoy .40 did not hold up well if exposed to

even one extended lean run, it did appear to

offer the best Stunt-run characteristics and

power for that displacement. So a McCoy .40

it was.

Several jet-type designs showed up during

that time period, and Jim Kostecky’s were the

most inspiring to me—especially his Formula

S. With what I thought to be the Formula S’s

best appearance characteristics in mind, I

drew a set of plans. I incorporated the

forward canopy, the air-intake scoops at the

wing root, and the jet-style fin and rudder into

the design.

When I finished the first airplane built

from those plans in the spring of 1969, it was

adorned with a Thunderbird paint scheme but

did not have a name. It weighed 43 ounces

and performed quite well. However, I

regretted having made equal wing panels for

the initial design.

The model began life with a 56-inch

wingspan, but I had enough leadout material

exposed to significantly extend the inboard

wing, and I did just that. I removed the

inboard tip and added 1.5 inches to the span,

bringing it up to 57.5 inches.

Hoping that I wouldn’t be asking too

much from the McCoy .40, that modification

turned a good airplane into a great airplane. It

grooved well, turned well, and stayed out on

the lines. What else can you ask for? The

model was definitely the best thing I had built

up to that point.

I flew the airplane successfully at local

meets that year and finished third in the Open

classification at the Philadelphia,

Pennsylvania, Nats behind Al Rabe (second)

and Bob Lampione (first).

At the beginning of the 1969 flying

The winning 1970 United States F2B team (L-R): the author with the Patriot, that year’s

World Champion Bill Werwage, and Bob Gieseke.

Plenty of cooling air gets to the head of the engine through that massive scoop! The

“chip”-type muffler and hole allow engine prime in the venturi.

“Aggressive” might be the best word to describe the aesthetics of this competitive

model. The author does outstanding paintwork!

Wheel covers are attached to main

landing-gear struts with small machine

screws. Wide gear placement yields great

ground handling.

Photos courtesy the author

06sig2.QXD 3/24/04 3:21 pm Page 41

season, I had no intention of trying out for the FAI team that would

attend the World Championships in Namur, Belgium, in 1970.

However, Bob Gieseke approached me at the 1969 Nats and

encouraged me to attend the Team Trials. He told me that based on

how I was flying that year, I had as good a chance at making the team

as anybody. Not only did I make the team, but I placed first in the

team-selection competition. That was my “shining moment” in CL

Stunt.

Once I made the team, there was never a doubt about what I was

going to build for the 1970 world competition. It would be the same

design, but with a splashy paint scheme that represented the good, old

USA. I chose the name “Patriot.” With a light-blue base coat, I added

stars and stripes to my liking.

The 1970 airplane also flew great, and its handling characteristics

were almost identical to that of the 1969 airplane. The Patriot and I

ended up in fourth place at the 1970 World Championships. Bill

Werwage finished first, Bob Gieseke finished second, and

Czechoslovakia’s Gabris nudged me out of third place by 11 points

(1,897 to 1,886). The US team finished in first place. It was a great

experience.

My 2002 model has the exact paint scheme I used on the 1970

airplane that went to Belgium. Using the original trim, name, and

AMA-number stencils I made in 1969/1970, I re-created the colorful

trim as accurately as possible. I even duplicated the cockpit detail

accurately based on plan detail and an old close-up photo of the 1969

airplane cockpit that I got from Jack Sheeks a few years ago.

When I finally flew the new airplane in Tucson, seeing it out there

You can see the bellcrank mount and landing-gear mount plates.

Check out the lightening holes! Save weight where you can!

The flaps are made from stiff 1⁄4 balsa and joined with the flap

horn. They are shown ready to be hinged to the wing.

The completed

airframe is ready

for finish. Strip of

.02-ounce carbon

mat on the TE of

the stabilizer

provides extra

strength. Do the

bottom the same

way.

42 MODEL AVIATION

Adjustable leadout guide is installed in the wingtip. Note

clearance slot in spar and lightening holes in tip plate.

06sig2.QXD 3/24/04 3:22 pm Page 42

on the end of the lines was like coming home.

It was no secret that I was a happy camper.

Bob Hunt even dubbed me the “Happy

Patriot” while we were at the VSC.

CONSTRUCTION

If you want to end up with a light model,

you have to build light from the start. Use

only contest-grade balsa (4- to 6-pound

density). Where plywood is used, try to

lighten it significantly by drilling holes in

places where its strength is not a factor. Refer

to the holes in the wing landing-gear

platforms and the nose doublers in the fueltank

compartment on the plans. You should

also drill out the engine rails in the tankcompartment

area to eliminate weight that

isn’t really doing anything for you.

When you use cyanoacrylate glue or

epoxy, remember that you get what you put

in. These bonding agents do not lighten as

they dry, as do acetone-based glues (such as

Sig-Ment) or aliphatic-resin glues (such as

Sig-Bond, Titebond, or Elmer’s carpenter’s

glue). Choose the proper glue for the

application, and try not to use excessive

amounts.

As far as the actual construction, you

should have no trouble with this project if

you’ve built a Nobler or any similarly

constructed model.

Wing: The wing is a conventional D-tube

design with a 1⁄16-inch planked LE and a 3⁄32-

inch planked TE. The D-tube spar is 3⁄32 balsa

notched for the ribs like a Nobler (first rib top

half, second rib bottom half, etc.). The LE is a

1⁄4-inch spar. For strength, the LE is

subplanked with 1⁄16 balsa through rib number

3. The center-section itself is planked with 3⁄32

balsa.

The TE is finished with a 1⁄8 balsa cap.

Before capping the LE with 1⁄8 or 3⁄32 balsa,

plane the planked LE flat, removing stock

until most of the glue joint between the

planking and the LE spar is removed. Then

cement the cap in place.

When giving the LE its final shape, make

sure you achieve a radius no less than 1⁄4 inch.

I like to make a small sanding block from

balsa with the desired radius, and this also

June 2004 43

Rib-Making Procedure

Left: For the first cut, position the master template in line with centerline on the rib

material. Make sure the TE of the template is positioned at one “rib length” mark. Cut

all the way around the TE of the template, but only as far forward as the vertical line on

the template. Right: Result of the first cut.

Left: For the second cut, slide the rib template back so that the inside of the LE notch

lines up with the other “rib length” mark. Using the point of a compass (or similar

device) positioned in the notch, pivot the rear of the template downward until the top of

the template is tangent with the first cut. Cut from the LE back to, and connecting with,

the first cut. Right: Result of the second cut.

Left: For the third cut, pivot the template upward until the bottom of the template is

tangent with the first cut. Cut from the LE back to, and connecting with, the first cut.

Right: Result of the third cut.

Left: For the last cut, pivot the template back up so that the centerlines match.

Complete the two small cuts at the LE notch. At this point, the basic rib shape cut is

complete. Right: Result of the last cut.

Type: CL Classic Stunt

Wingspan: 57.5 inches

Engine: AeroTiger .36

Flying weight: 46 ounces

Construction: Balsa and plywood

Covering/finish: Tissue and dope

06sig2.QXD 3/24/04 3:23 pm Page 43

Full-Size Plans Available—see page 199

44 MODEL AVIATION

06sig2.QXD 3/24/04 3:23 pm Page 44

ensures that the whole LE is consistent in

shape.

The procedure for making this model’s

ribs is a bit different from what you may be

used to, so I have presented it in a sidebar.

The photos depict laying out a representative

rib on a piece of white card stock. This was

done to allow good definition for the

procedure. In actual practice, the ribs would

be laid out on the actual balsa rib stock.

The wingtips start as a piece of 1⁄16 balsa

(see plans for location of holes to lighten)

with edges laminated with scrap 1⁄4 balsa, top

and bottom. Once cemented in place, you can

notch the laminations to accept 1⁄16-inch

planking at the LE and 3⁄32 inch at the TE.

Leave the wing TE planking long during wing

construction, and then simply pinch it

together and cement it in notches in the

wingtip edge laminations.

Before I install the wingtip ribs, I like to

contour and taper the rest of the tip

laminations so that they blend in with the end

wing rib. To accomplish this, I use a large

sanding block and a straightedge to check for

surface continuity. I also try to attain an

approximately 1⁄4-inch rounded edge along

most of the tip’s perimeter. Then I can install

and block-sand the tip ribs to match the rest of

the tip surface contour. Although the 2002

model has a tip weight box and an adjustable

leadout guide, these items are optional.

The original models had 3-inch bellcranks,

but I chose a Brodak 4-inch nylon bellcrank

this time around. (Modern thinking, you

know.) Installation is conventional with a

plywood floor. For added strength I support

the top of the bellcrank bolt with another

section of plywood running to the first inside

panel rib and reinforced appropriately to the

spar and center-section planking.

Make the flaps from 1⁄4 balsa, and taper

them to approximately 1⁄8-inch thickness at

the TE. I make my own control horns, but

there are enough quality products on the

market from which to choose if you elect to

purchase these items. The original models

also had handmade plywood and piano-wire

hinges, as shown in the plans. I chose tissue

taffeta hinges (100% polyester) for the 2002

model to achieve a totally sealed hinge line.

Conventional nylon hinges are another option.

If you use cloth hinges, make sure they are

100% polyester. Even if you purchase

material that is labeled 100% polyester, test it

before you use it. Apply a few drops of thin

cyanoacrylate on a test piece and allow it to

dry thoroughly. Once it has dried, bend the

test area back and forth several times and tug

at it to make sure it will not fatigue and

eventually fail.

Empennage: Cut the stabilizer and elevator

from 3⁄8 balsa sheet, shape them to achieve the

cross-section foil shown, and then hollow

them as shown on the planform. Then add the

1⁄16-inch ribs.

I covered the original versions with

medium-weight silkspan, and that provided

adequate strength for the stabilizer. However,

I covered almost the entire 2002 model with

light plyspan (Sig Japanese tissue). Because

of that, I covered the stabilizer with two

layers of medium plyspan to achieve the

needed strength.

Another method of increasing this fairly

fragile stabilizer’s strength is to cement thin

unidirectional carbon tape to the inside of the

cutout area before installing the ribs. Run the

carbon out from the center approximately 5

inches before installing the ribs. On the new

model I applied a layer of thin carbon mat on

the top and bottom of the stabilizer’s TE, but

I’m sure that did not provide as much

strength as the unidirectional carbon tape

would have.

The rudder and fin are also made from 3⁄8

sheet balsa and covered with thin carbon mat

for strength. I also used carbon mat on the

flaps for rigidity and on the model’s nose for

durability.

Fuselage: The fuselage also uses fairly

conventional construction, with 1⁄8-inch sides,

1⁄16 plywood nose doublers, and adequate

bulkhead placement. However, the bulkheads

are built up.

Glue 1⁄16 balsa that is approximately 1⁄2

inch wide vertically to the inside of each

fuselage side as indicated on the planform.

Invert the fuselage sides and place them on a

flat building surface for further assembly.

Using a centerline on the building surface,

complete the tank-compartment area as the

first step in joining the halves. Cut and install

horizontal bulkhead stringers in the remainder

of the fuselage (where the 1⁄2-inch vertical

bulkheads strips are located), achieving the

appropriate width as indicated on the

planform. These horizontal stringers can be

made from 1⁄8 or 3⁄16 balsa, and they only need

to be roughly 3⁄8 inch wide.

Temporarily remove the fuselage side

sections under the wing for wing installation.

Employ top and bottom blocks to achieve

desired shapes, and then hollow them to a

wall thickness of approximately 1⁄8 inch.

Build the cowl from sheet and blocks, and

then shape and hollow it. I continue to use

one of the oldest cowl-hold-down techniques

on most of my models: a bicycle spoke and a

spoke nut. It works well and presents well.

I cut the canopy from a Sig 11-inch

bubble and soaked it in blue Rit dye to

achieve desired tint intensity.

Finish: I finished the 2002 model with

Brodak dope and was extremely satisfied

with the results. As a matter of fact, the

model won the pilots’ choice award

(Concours award) at the 2002 Vintage Stunt

Championships.

Much has been written about finishing, so

I won’t elaborate on my technique in this

article. Whatever approach you do use for the

finish, I can’t stress enough the importance of

your keeping the weight down.

If you do build this model, and you build it

light and straight, you will absolutely love the

way it flies. Have fun, and let me know what

you think of your Patriot. I think I hear my

balsa block calling me. MA

Gerry Phelps

4175 Sacramento Blvd.

Medina OH 44256

(Editor’s note: Gerry is one of those rare

CL Stunt pilots who flies his models in a

clockwise direction [when the model is in the

upright position]. Because of that, his control

system is set up with the leadouts running out

the right wing.

His plan drawing depicts this preference

and shows the right wing panel as the longer

of the two. For those of you who fly the other

way, you will need to build the left wing as the

longer wing and reverse the control system as

it is depicted.)

46 MODEL AVIATION

06sig2.QXD 3/24/04 3:23 pm Page 46

F u l l - S i z e P l a n s

958 Patriot ...........................................................................................................$11.25

CL Classic Stunt model by Phelps spans 57.5 inches

959 Cruiser 60 ...................................................................................................$22.50

D.B. Mathews’ RC sport model is follow-up to 40-size design

No. 917 Sir Lancelot: RC sport model by Henry for O.S. .61 spans 72 inches D

No. 918 Skyraider: CL 1/2A Profile by Sarpolus for Norvel BigMig .061 spans 29 inches B

No. 925 Bird-E-Dog: Ernie Heyworth and Ed Lokken’s RC Electric Sport Scale model C

No. 926 JoeCat: RC sport jet by Beshar for Toki .18 DF unit spans 37 inches C

No. 927 Kairos: CL Stunt model by Dixon for .46-.61 engine spans 58 inches C

No. 928 Beta Blue Chip Racer: Rubber-powered FF Scale model designed by Tom Derber B

No. 929 Dewoitine D.338: Multimotor RC Electric Scale by Mikulasko spans 781/2 inches E

No. 930 Westland Lysander: RC Scale model by Baker for .25 spans 56 inches E

No. 931 1959 Ares: Champion RC Aerobatics model by Werwage spans 501/2 inches C

No. 932 Wing400: RC Electric flying wing by Hanley for Speed 400 spans 36 inches B

No. 933 Kepler 450: CL speed-limit Combat model by Edwards for .21-.32 two-stroke A

Plan does not include full-size template shown on page 40 of the August 2002 issue.

No. 934 VariEze: FF Peanut Scale canard by Heckman spans 13 inches A

No. 935 Classic 320: 1/2A Classic Power design by Pailet for Cyclon .049 or equivalent B

No. 936 Prince: RC sport Pattern model by Robelen for O.S. .25 spans 51 inches C

No. 937 Clean Cut: RC sport aerobatic model by Sarpolus spans 90 inches E

No. 938 Diamond Gem: Compressed-air-powered FF sport model by Ken Johnson B

No. 939 Project Extra: RC Scale Aerobatics model by Mike Hurley spans 106 inches **$49.50

No. 940 Cessna No.1: RC Electric Sport Scale by Papic spans 321/2 inches B

No. 941 Mooney and Beechcraft Bonanza CL 1/2A profile sport models by Rick Sarpolus B

No. 942 Zenith CH 801: FF Rubber Scale model by Fineman spans 20 inches A

No. 943 Wildman 60: Old-Time Ignition CL Stunt model by Carter spans 591/2 inches C

No. 944 Shoestring: Semiscale RC sport Pattern design by deBolt spans 60 inches D

No. 945 F-86 Sabre: Semiscale CL Stunt model by Hutchinson spans 56 inches E

No. 946 Electric Zephyr: Electric RC Pylon/sport model by Smith spans 40 inches B

No. 947 Chester Special: O.S. .40-powered CL Scale model by Beatty spans 43 inches **$27.00

No. 948 Moffett Redux: High-performance Rubber-powered FF design by Langenberg C

No. 949 Scratch-One: Electric RC sailplane/basic trainer by Aberle spans 45 inches B

No. 950 BareCat 650-C: CL sport Stunt model by Netzeband spans 541/4 inches E

No. 951 Douglas O-46A: RC Sport Scale model by Baker spans 54 inches E

No. 952 Lavochkin LaGG-3: Felton’s CL Sport Scale design made from cardboard E

No. 953 USA-1: Multiple-award-winning CL Stunt model by Werwage spans 611/2 inches C

No. 954 B-2 Spirit Stealth Bomber: Electric FF model by Ken Johnson spans 42 inches B

No. 955 Electric Flash: Electric-powered RC park flyer by Stewart spans 44 inches C

No. 956 Grumman F-4F Wildcat: Jim Ryan’s RC Electric fighter spans 30.6 inches C

No. 957 Right Angle: RC sport aerobatic model by Sarpolus spans 62 inches D

Full-size plan list available. A complete listing of all plans previously published in this

magazine through no. 959 may be obtained free of charge by writing (enclose 78¢

stamped, pre-addressed #10 business-size letter envelope) Model Aviation, 5161 E.

Memorial Dr., Muncie IN 47302

**Special Price

Edition: Model Aviation - 2004/06

Page Numbers: 40,41,42,43,44,46,199

DID YOU EVER have a great piece of balsa wood that you just

couldn’t bring yourself to use, because once you used it, it would be

gone? How’s that for warped logic?

I have such a piece of balsa. It’s a light block, approximately 4

inches square and roughly 40 inches long. I’ve had it since the late

1960s, and I have carried it with me from location to location as I’ve

moved a few times through the years. I was away from modeling from

1973 through 1987, and I still kept lugging that piece of balsa around

with me.

However, this article is not about an old block of balsa. It is about a

Stunt-model design that I flew from 1969 through 1971: the Patriot. I

mention the balsa story only because of the parallel I can draw in

deciding when to recreate the Patriot design.

Since getting back into flying Stunt in 1988, I planned to re-create

the Patriot someday, but I figured that once I had built it, I had built it.

I would no longer have the project to look forward to. And what if it

didn’t fly as well as I remembered the original two models of this

design flying? I felt that I would be disappointed. Boy, was I wrong!

I began remaking the Patriot in the fall of 2001 and finished it in

time to take it to the March 2002 Vintage Stunt Championships (VSC)

in Tucson, Arizona—unflown, I might add. I had more fun that week

than I had had in a long time. The engine (a Randy Smith AeroTiger

.36) ran great, and the airplane flew wonderfully right off the board

with no adjustments. That’s rare.

The airplane drew quite a bit of attention, and I received many

positive comments from the other contestants. I was wrong not to have

built this Classic design sooner, and I regret waiting as long as I did.

You know what? I’m going to use that light balsa block the next

chance I get—perhaps on another Patriot.

The nose’s sleek, jetlike looks are more than cosmetic.

Simulated air intakes add torsional rigidity to front end.

40 MODEL AVIATION

by Gerry Phelps

06sig2.QXD 3/24/04 3:19 pm Page 40

June 2004 41

Design Origin: In the fall of 1968 I began

thinking about what I might build during the

winter for the next flying season. Having

built several Fox .35-powered I-Beam

airplanes and Noblers throughout the years—

and based on what was becoming a trend

toward slightly larger airplanes—I wanted

something a little bigger.

At that time, several of my friends were

having success with the venerable McCoy .40

in the somewhat larger designs. Although the

McCoy .40 did not hold up well if exposed to

even one extended lean run, it did appear to

offer the best Stunt-run characteristics and

power for that displacement. So a McCoy .40

it was.

Several jet-type designs showed up during

that time period, and Jim Kostecky’s were the

most inspiring to me—especially his Formula

S. With what I thought to be the Formula S’s

best appearance characteristics in mind, I

drew a set of plans. I incorporated the

forward canopy, the air-intake scoops at the

wing root, and the jet-style fin and rudder into

the design.

When I finished the first airplane built

from those plans in the spring of 1969, it was

adorned with a Thunderbird paint scheme but

did not have a name. It weighed 43 ounces

and performed quite well. However, I

regretted having made equal wing panels for

the initial design.

The model began life with a 56-inch

wingspan, but I had enough leadout material

exposed to significantly extend the inboard

wing, and I did just that. I removed the

inboard tip and added 1.5 inches to the span,

bringing it up to 57.5 inches.

Hoping that I wouldn’t be asking too

much from the McCoy .40, that modification

turned a good airplane into a great airplane. It

grooved well, turned well, and stayed out on

the lines. What else can you ask for? The

model was definitely the best thing I had built

up to that point.

I flew the airplane successfully at local

meets that year and finished third in the Open

classification at the Philadelphia,

Pennsylvania, Nats behind Al Rabe (second)

and Bob Lampione (first).

At the beginning of the 1969 flying

The winning 1970 United States F2B team (L-R): the author with the Patriot, that year’s

World Champion Bill Werwage, and Bob Gieseke.

Plenty of cooling air gets to the head of the engine through that massive scoop! The

“chip”-type muffler and hole allow engine prime in the venturi.

“Aggressive” might be the best word to describe the aesthetics of this competitive

model. The author does outstanding paintwork!

Wheel covers are attached to main

landing-gear struts with small machine

screws. Wide gear placement yields great

ground handling.

Photos courtesy the author

06sig2.QXD 3/24/04 3:21 pm Page 41

season, I had no intention of trying out for the FAI team that would

attend the World Championships in Namur, Belgium, in 1970.

However, Bob Gieseke approached me at the 1969 Nats and

encouraged me to attend the Team Trials. He told me that based on

how I was flying that year, I had as good a chance at making the team

as anybody. Not only did I make the team, but I placed first in the

team-selection competition. That was my “shining moment” in CL

Stunt.

Once I made the team, there was never a doubt about what I was

going to build for the 1970 world competition. It would be the same

design, but with a splashy paint scheme that represented the good, old

USA. I chose the name “Patriot.” With a light-blue base coat, I added

stars and stripes to my liking.

The 1970 airplane also flew great, and its handling characteristics

were almost identical to that of the 1969 airplane. The Patriot and I

ended up in fourth place at the 1970 World Championships. Bill

Werwage finished first, Bob Gieseke finished second, and

Czechoslovakia’s Gabris nudged me out of third place by 11 points

(1,897 to 1,886). The US team finished in first place. It was a great

experience.

My 2002 model has the exact paint scheme I used on the 1970

airplane that went to Belgium. Using the original trim, name, and

AMA-number stencils I made in 1969/1970, I re-created the colorful

trim as accurately as possible. I even duplicated the cockpit detail

accurately based on plan detail and an old close-up photo of the 1969

airplane cockpit that I got from Jack Sheeks a few years ago.

When I finally flew the new airplane in Tucson, seeing it out there

You can see the bellcrank mount and landing-gear mount plates.

Check out the lightening holes! Save weight where you can!

The flaps are made from stiff 1⁄4 balsa and joined with the flap

horn. They are shown ready to be hinged to the wing.

The completed

airframe is ready

for finish. Strip of

.02-ounce carbon

mat on the TE of

the stabilizer

provides extra

strength. Do the

bottom the same

way.

42 MODEL AVIATION

Adjustable leadout guide is installed in the wingtip. Note

clearance slot in spar and lightening holes in tip plate.

06sig2.QXD 3/24/04 3:22 pm Page 42

on the end of the lines was like coming home.

It was no secret that I was a happy camper.

Bob Hunt even dubbed me the “Happy

Patriot” while we were at the VSC.

CONSTRUCTION

If you want to end up with a light model,

you have to build light from the start. Use

only contest-grade balsa (4- to 6-pound

density). Where plywood is used, try to

lighten it significantly by drilling holes in

places where its strength is not a factor. Refer

to the holes in the wing landing-gear

platforms and the nose doublers in the fueltank

compartment on the plans. You should

also drill out the engine rails in the tankcompartment

area to eliminate weight that

isn’t really doing anything for you.

When you use cyanoacrylate glue or

epoxy, remember that you get what you put

in. These bonding agents do not lighten as

they dry, as do acetone-based glues (such as

Sig-Ment) or aliphatic-resin glues (such as

Sig-Bond, Titebond, or Elmer’s carpenter’s

glue). Choose the proper glue for the

application, and try not to use excessive

amounts.

As far as the actual construction, you

should have no trouble with this project if

you’ve built a Nobler or any similarly

constructed model.

Wing: The wing is a conventional D-tube

design with a 1⁄16-inch planked LE and a 3⁄32-

inch planked TE. The D-tube spar is 3⁄32 balsa

notched for the ribs like a Nobler (first rib top

half, second rib bottom half, etc.). The LE is a

1⁄4-inch spar. For strength, the LE is

subplanked with 1⁄16 balsa through rib number

3. The center-section itself is planked with 3⁄32

balsa.

The TE is finished with a 1⁄8 balsa cap.

Before capping the LE with 1⁄8 or 3⁄32 balsa,

plane the planked LE flat, removing stock

until most of the glue joint between the

planking and the LE spar is removed. Then

cement the cap in place.

When giving the LE its final shape, make

sure you achieve a radius no less than 1⁄4 inch.

I like to make a small sanding block from

balsa with the desired radius, and this also

June 2004 43

Rib-Making Procedure

Left: For the first cut, position the master template in line with centerline on the rib

material. Make sure the TE of the template is positioned at one “rib length” mark. Cut

all the way around the TE of the template, but only as far forward as the vertical line on

the template. Right: Result of the first cut.

Left: For the second cut, slide the rib template back so that the inside of the LE notch

lines up with the other “rib length” mark. Using the point of a compass (or similar

device) positioned in the notch, pivot the rear of the template downward until the top of

the template is tangent with the first cut. Cut from the LE back to, and connecting with,

the first cut. Right: Result of the second cut.

Left: For the third cut, pivot the template upward until the bottom of the template is

tangent with the first cut. Cut from the LE back to, and connecting with, the first cut.

Right: Result of the third cut.

Left: For the last cut, pivot the template back up so that the centerlines match.

Complete the two small cuts at the LE notch. At this point, the basic rib shape cut is

complete. Right: Result of the last cut.

Type: CL Classic Stunt

Wingspan: 57.5 inches

Engine: AeroTiger .36

Flying weight: 46 ounces

Construction: Balsa and plywood

Covering/finish: Tissue and dope

06sig2.QXD 3/24/04 3:23 pm Page 43

Full-Size Plans Available—see page 199

44 MODEL AVIATION

06sig2.QXD 3/24/04 3:23 pm Page 44

ensures that the whole LE is consistent in

shape.

The procedure for making this model’s

ribs is a bit different from what you may be

used to, so I have presented it in a sidebar.

The photos depict laying out a representative

rib on a piece of white card stock. This was

done to allow good definition for the

procedure. In actual practice, the ribs would

be laid out on the actual balsa rib stock.

The wingtips start as a piece of 1⁄16 balsa

(see plans for location of holes to lighten)

with edges laminated with scrap 1⁄4 balsa, top

and bottom. Once cemented in place, you can

notch the laminations to accept 1⁄16-inch

planking at the LE and 3⁄32 inch at the TE.

Leave the wing TE planking long during wing

construction, and then simply pinch it

together and cement it in notches in the

wingtip edge laminations.

Before I install the wingtip ribs, I like to

contour and taper the rest of the tip

laminations so that they blend in with the end

wing rib. To accomplish this, I use a large

sanding block and a straightedge to check for

surface continuity. I also try to attain an

approximately 1⁄4-inch rounded edge along

most of the tip’s perimeter. Then I can install

and block-sand the tip ribs to match the rest of

the tip surface contour. Although the 2002

model has a tip weight box and an adjustable

leadout guide, these items are optional.

The original models had 3-inch bellcranks,

but I chose a Brodak 4-inch nylon bellcrank

this time around. (Modern thinking, you

know.) Installation is conventional with a

plywood floor. For added strength I support

the top of the bellcrank bolt with another

section of plywood running to the first inside

panel rib and reinforced appropriately to the

spar and center-section planking.

Make the flaps from 1⁄4 balsa, and taper

them to approximately 1⁄8-inch thickness at

the TE. I make my own control horns, but

there are enough quality products on the

market from which to choose if you elect to

purchase these items. The original models

also had handmade plywood and piano-wire

hinges, as shown in the plans. I chose tissue

taffeta hinges (100% polyester) for the 2002

model to achieve a totally sealed hinge line.

Conventional nylon hinges are another option.

If you use cloth hinges, make sure they are

100% polyester. Even if you purchase

material that is labeled 100% polyester, test it

before you use it. Apply a few drops of thin

cyanoacrylate on a test piece and allow it to

dry thoroughly. Once it has dried, bend the

test area back and forth several times and tug

at it to make sure it will not fatigue and

eventually fail.

Empennage: Cut the stabilizer and elevator

from 3⁄8 balsa sheet, shape them to achieve the

cross-section foil shown, and then hollow

them as shown on the planform. Then add the

1⁄16-inch ribs.

I covered the original versions with

medium-weight silkspan, and that provided

adequate strength for the stabilizer. However,

I covered almost the entire 2002 model with

light plyspan (Sig Japanese tissue). Because

of that, I covered the stabilizer with two

layers of medium plyspan to achieve the

needed strength.

Another method of increasing this fairly

fragile stabilizer’s strength is to cement thin

unidirectional carbon tape to the inside of the

cutout area before installing the ribs. Run the

carbon out from the center approximately 5

inches before installing the ribs. On the new

model I applied a layer of thin carbon mat on

the top and bottom of the stabilizer’s TE, but

I’m sure that did not provide as much

strength as the unidirectional carbon tape

would have.

The rudder and fin are also made from 3⁄8

sheet balsa and covered with thin carbon mat

for strength. I also used carbon mat on the

flaps for rigidity and on the model’s nose for

durability.

Fuselage: The fuselage also uses fairly

conventional construction, with 1⁄8-inch sides,

1⁄16 plywood nose doublers, and adequate

bulkhead placement. However, the bulkheads

are built up.

Glue 1⁄16 balsa that is approximately 1⁄2

inch wide vertically to the inside of each

fuselage side as indicated on the planform.

Invert the fuselage sides and place them on a

flat building surface for further assembly.

Using a centerline on the building surface,

complete the tank-compartment area as the

first step in joining the halves. Cut and install

horizontal bulkhead stringers in the remainder

of the fuselage (where the 1⁄2-inch vertical

bulkheads strips are located), achieving the

appropriate width as indicated on the

planform. These horizontal stringers can be

made from 1⁄8 or 3⁄16 balsa, and they only need

to be roughly 3⁄8 inch wide.

Temporarily remove the fuselage side

sections under the wing for wing installation.

Employ top and bottom blocks to achieve

desired shapes, and then hollow them to a

wall thickness of approximately 1⁄8 inch.

Build the cowl from sheet and blocks, and

then shape and hollow it. I continue to use

one of the oldest cowl-hold-down techniques

on most of my models: a bicycle spoke and a

spoke nut. It works well and presents well.

I cut the canopy from a Sig 11-inch

bubble and soaked it in blue Rit dye to

achieve desired tint intensity.

Finish: I finished the 2002 model with

Brodak dope and was extremely satisfied

with the results. As a matter of fact, the

model won the pilots’ choice award

(Concours award) at the 2002 Vintage Stunt

Championships.

Much has been written about finishing, so

I won’t elaborate on my technique in this

article. Whatever approach you do use for the

finish, I can’t stress enough the importance of

your keeping the weight down.

If you do build this model, and you build it

light and straight, you will absolutely love the

way it flies. Have fun, and let me know what

you think of your Patriot. I think I hear my

balsa block calling me. MA

Gerry Phelps

4175 Sacramento Blvd.

Medina OH 44256

(Editor’s note: Gerry is one of those rare

CL Stunt pilots who flies his models in a

clockwise direction [when the model is in the

upright position]. Because of that, his control

system is set up with the leadouts running out

the right wing.

His plan drawing depicts this preference

and shows the right wing panel as the longer

of the two. For those of you who fly the other

way, you will need to build the left wing as the

longer wing and reverse the control system as

it is depicted.)

46 MODEL AVIATION

06sig2.QXD 3/24/04 3:23 pm Page 46

F u l l - S i z e P l a n s

958 Patriot ...........................................................................................................$11.25

CL Classic Stunt model by Phelps spans 57.5 inches

959 Cruiser 60 ...................................................................................................$22.50

D.B. Mathews’ RC sport model is follow-up to 40-size design

No. 917 Sir Lancelot: RC sport model by Henry for O.S. .61 spans 72 inches D

No. 918 Skyraider: CL 1/2A Profile by Sarpolus for Norvel BigMig .061 spans 29 inches B

No. 925 Bird-E-Dog: Ernie Heyworth and Ed Lokken’s RC Electric Sport Scale model C

No. 926 JoeCat: RC sport jet by Beshar for Toki .18 DF unit spans 37 inches C

No. 927 Kairos: CL Stunt model by Dixon for .46-.61 engine spans 58 inches C

No. 928 Beta Blue Chip Racer: Rubber-powered FF Scale model designed by Tom Derber B

No. 929 Dewoitine D.338: Multimotor RC Electric Scale by Mikulasko spans 781/2 inches E

No. 930 Westland Lysander: RC Scale model by Baker for .25 spans 56 inches E

No. 931 1959 Ares: Champion RC Aerobatics model by Werwage spans 501/2 inches C

No. 932 Wing400: RC Electric flying wing by Hanley for Speed 400 spans 36 inches B

No. 933 Kepler 450: CL speed-limit Combat model by Edwards for .21-.32 two-stroke A

Plan does not include full-size template shown on page 40 of the August 2002 issue.

No. 934 VariEze: FF Peanut Scale canard by Heckman spans 13 inches A

No. 935 Classic 320: 1/2A Classic Power design by Pailet for Cyclon .049 or equivalent B

No. 936 Prince: RC sport Pattern model by Robelen for O.S. .25 spans 51 inches C

No. 937 Clean Cut: RC sport aerobatic model by Sarpolus spans 90 inches E

No. 938 Diamond Gem: Compressed-air-powered FF sport model by Ken Johnson B

No. 939 Project Extra: RC Scale Aerobatics model by Mike Hurley spans 106 inches **$49.50

No. 940 Cessna No.1: RC Electric Sport Scale by Papic spans 321/2 inches B

No. 941 Mooney and Beechcraft Bonanza CL 1/2A profile sport models by Rick Sarpolus B

No. 942 Zenith CH 801: FF Rubber Scale model by Fineman spans 20 inches A

No. 943 Wildman 60: Old-Time Ignition CL Stunt model by Carter spans 591/2 inches C

No. 944 Shoestring: Semiscale RC sport Pattern design by deBolt spans 60 inches D

No. 945 F-86 Sabre: Semiscale CL Stunt model by Hutchinson spans 56 inches E

No. 946 Electric Zephyr: Electric RC Pylon/sport model by Smith spans 40 inches B

No. 947 Chester Special: O.S. .40-powered CL Scale model by Beatty spans 43 inches **$27.00

No. 948 Moffett Redux: High-performance Rubber-powered FF design by Langenberg C

No. 949 Scratch-One: Electric RC sailplane/basic trainer by Aberle spans 45 inches B

No. 950 BareCat 650-C: CL sport Stunt model by Netzeband spans 541/4 inches E

No. 951 Douglas O-46A: RC Sport Scale model by Baker spans 54 inches E

No. 952 Lavochkin LaGG-3: Felton’s CL Sport Scale design made from cardboard E

No. 953 USA-1: Multiple-award-winning CL Stunt model by Werwage spans 611/2 inches C

No. 954 B-2 Spirit Stealth Bomber: Electric FF model by Ken Johnson spans 42 inches B

No. 955 Electric Flash: Electric-powered RC park flyer by Stewart spans 44 inches C

No. 956 Grumman F-4F Wildcat: Jim Ryan’s RC Electric fighter spans 30.6 inches C

No. 957 Right Angle: RC sport aerobatic model by Sarpolus spans 62 inches D

Full-size plan list available. A complete listing of all plans previously published in this

magazine through no. 959 may be obtained free of charge by writing (enclose 78¢

stamped, pre-addressed #10 business-size letter envelope) Model Aviation, 5161 E.

Memorial Dr., Muncie IN 47302

**Special Price

Edition: Model Aviation - 2004/06

Page Numbers: 40,41,42,43,44,46,199

DID YOU EVER have a great piece of balsa wood that you just

couldn’t bring yourself to use, because once you used it, it would be

gone? How’s that for warped logic?

I have such a piece of balsa. It’s a light block, approximately 4

inches square and roughly 40 inches long. I’ve had it since the late

1960s, and I have carried it with me from location to location as I’ve

moved a few times through the years. I was away from modeling from

1973 through 1987, and I still kept lugging that piece of balsa around

with me.

However, this article is not about an old block of balsa. It is about a

Stunt-model design that I flew from 1969 through 1971: the Patriot. I

mention the balsa story only because of the parallel I can draw in

deciding when to recreate the Patriot design.

Since getting back into flying Stunt in 1988, I planned to re-create

the Patriot someday, but I figured that once I had built it, I had built it.

I would no longer have the project to look forward to. And what if it

didn’t fly as well as I remembered the original two models of this

design flying? I felt that I would be disappointed. Boy, was I wrong!

I began remaking the Patriot in the fall of 2001 and finished it in

time to take it to the March 2002 Vintage Stunt Championships (VSC)

in Tucson, Arizona—unflown, I might add. I had more fun that week

than I had had in a long time. The engine (a Randy Smith AeroTiger

.36) ran great, and the airplane flew wonderfully right off the board

with no adjustments. That’s rare.

The airplane drew quite a bit of attention, and I received many

positive comments from the other contestants. I was wrong not to have

built this Classic design sooner, and I regret waiting as long as I did.

You know what? I’m going to use that light balsa block the next

chance I get—perhaps on another Patriot.

The nose’s sleek, jetlike looks are more than cosmetic.

Simulated air intakes add torsional rigidity to front end.

40 MODEL AVIATION

by Gerry Phelps

06sig2.QXD 3/24/04 3:19 pm Page 40

June 2004 41

Design Origin: In the fall of 1968 I began

thinking about what I might build during the

winter for the next flying season. Having

built several Fox .35-powered I-Beam

airplanes and Noblers throughout the years—

and based on what was becoming a trend

toward slightly larger airplanes—I wanted

something a little bigger.

At that time, several of my friends were

having success with the venerable McCoy .40

in the somewhat larger designs. Although the

McCoy .40 did not hold up well if exposed to

even one extended lean run, it did appear to

offer the best Stunt-run characteristics and

power for that displacement. So a McCoy .40

it was.

Several jet-type designs showed up during

that time period, and Jim Kostecky’s were the

most inspiring to me—especially his Formula

S. With what I thought to be the Formula S’s

best appearance characteristics in mind, I

drew a set of plans. I incorporated the

forward canopy, the air-intake scoops at the

wing root, and the jet-style fin and rudder into

the design.

When I finished the first airplane built

from those plans in the spring of 1969, it was

adorned with a Thunderbird paint scheme but

did not have a name. It weighed 43 ounces

and performed quite well. However, I

regretted having made equal wing panels for

the initial design.

The model began life with a 56-inch

wingspan, but I had enough leadout material

exposed to significantly extend the inboard

wing, and I did just that. I removed the

inboard tip and added 1.5 inches to the span,

bringing it up to 57.5 inches.

Hoping that I wouldn’t be asking too

much from the McCoy .40, that modification

turned a good airplane into a great airplane. It

grooved well, turned well, and stayed out on

the lines. What else can you ask for? The

model was definitely the best thing I had built

up to that point.

I flew the airplane successfully at local

meets that year and finished third in the Open

classification at the Philadelphia,

Pennsylvania, Nats behind Al Rabe (second)

and Bob Lampione (first).

At the beginning of the 1969 flying

The winning 1970 United States F2B team (L-R): the author with the Patriot, that year’s

World Champion Bill Werwage, and Bob Gieseke.

Plenty of cooling air gets to the head of the engine through that massive scoop! The

“chip”-type muffler and hole allow engine prime in the venturi.

“Aggressive” might be the best word to describe the aesthetics of this competitive

model. The author does outstanding paintwork!

Wheel covers are attached to main

landing-gear struts with small machine

screws. Wide gear placement yields great

ground handling.

Photos courtesy the author

06sig2.QXD 3/24/04 3:21 pm Page 41

season, I had no intention of trying out for the FAI team that would

attend the World Championships in Namur, Belgium, in 1970.

However, Bob Gieseke approached me at the 1969 Nats and

encouraged me to attend the Team Trials. He told me that based on

how I was flying that year, I had as good a chance at making the team

as anybody. Not only did I make the team, but I placed first in the

team-selection competition. That was my “shining moment” in CL

Stunt.

Once I made the team, there was never a doubt about what I was

going to build for the 1970 world competition. It would be the same

design, but with a splashy paint scheme that represented the good, old

USA. I chose the name “Patriot.” With a light-blue base coat, I added

stars and stripes to my liking.

The 1970 airplane also flew great, and its handling characteristics

were almost identical to that of the 1969 airplane. The Patriot and I

ended up in fourth place at the 1970 World Championships. Bill

Werwage finished first, Bob Gieseke finished second, and

Czechoslovakia’s Gabris nudged me out of third place by 11 points

(1,897 to 1,886). The US team finished in first place. It was a great

experience.

My 2002 model has the exact paint scheme I used on the 1970

airplane that went to Belgium. Using the original trim, name, and

AMA-number stencils I made in 1969/1970, I re-created the colorful

trim as accurately as possible. I even duplicated the cockpit detail

accurately based on plan detail and an old close-up photo of the 1969

airplane cockpit that I got from Jack Sheeks a few years ago.

When I finally flew the new airplane in Tucson, seeing it out there

You can see the bellcrank mount and landing-gear mount plates.

Check out the lightening holes! Save weight where you can!

The flaps are made from stiff 1⁄4 balsa and joined with the flap

horn. They are shown ready to be hinged to the wing.

The completed

airframe is ready

for finish. Strip of

.02-ounce carbon

mat on the TE of

the stabilizer

provides extra

strength. Do the

bottom the same

way.

42 MODEL AVIATION

Adjustable leadout guide is installed in the wingtip. Note

clearance slot in spar and lightening holes in tip plate.

06sig2.QXD 3/24/04 3:22 pm Page 42

on the end of the lines was like coming home.

It was no secret that I was a happy camper.

Bob Hunt even dubbed me the “Happy

Patriot” while we were at the VSC.

CONSTRUCTION

If you want to end up with a light model,

you have to build light from the start. Use

only contest-grade balsa (4- to 6-pound

density). Where plywood is used, try to

lighten it significantly by drilling holes in

places where its strength is not a factor. Refer

to the holes in the wing landing-gear

platforms and the nose doublers in the fueltank

compartment on the plans. You should

also drill out the engine rails in the tankcompartment

area to eliminate weight that

isn’t really doing anything for you.

When you use cyanoacrylate glue or

epoxy, remember that you get what you put

in. These bonding agents do not lighten as

they dry, as do acetone-based glues (such as

Sig-Ment) or aliphatic-resin glues (such as

Sig-Bond, Titebond, or Elmer’s carpenter’s

glue). Choose the proper glue for the

application, and try not to use excessive

amounts.

As far as the actual construction, you

should have no trouble with this project if

you’ve built a Nobler or any similarly

constructed model.

Wing: The wing is a conventional D-tube

design with a 1⁄16-inch planked LE and a 3⁄32-

inch planked TE. The D-tube spar is 3⁄32 balsa

notched for the ribs like a Nobler (first rib top

half, second rib bottom half, etc.). The LE is a

1⁄4-inch spar. For strength, the LE is

subplanked with 1⁄16 balsa through rib number

3. The center-section itself is planked with 3⁄32

balsa.

The TE is finished with a 1⁄8 balsa cap.

Before capping the LE with 1⁄8 or 3⁄32 balsa,

plane the planked LE flat, removing stock

until most of the glue joint between the

planking and the LE spar is removed. Then

cement the cap in place.

When giving the LE its final shape, make

sure you achieve a radius no less than 1⁄4 inch.

I like to make a small sanding block from

balsa with the desired radius, and this also

June 2004 43

Rib-Making Procedure

Left: For the first cut, position the master template in line with centerline on the rib

material. Make sure the TE of the template is positioned at one “rib length” mark. Cut

all the way around the TE of the template, but only as far forward as the vertical line on

the template. Right: Result of the first cut.

Left: For the second cut, slide the rib template back so that the inside of the LE notch

lines up with the other “rib length” mark. Using the point of a compass (or similar

device) positioned in the notch, pivot the rear of the template downward until the top of

the template is tangent with the first cut. Cut from the LE back to, and connecting with,

the first cut. Right: Result of the second cut.

Left: For the third cut, pivot the template upward until the bottom of the template is

tangent with the first cut. Cut from the LE back to, and connecting with, the first cut.

Right: Result of the third cut.

Left: For the last cut, pivot the template back up so that the centerlines match.

Complete the two small cuts at the LE notch. At this point, the basic rib shape cut is