60 MODEL AVIATION

BY JEFF TROY

Plane Talk: Hangar 9 27% Extra 260 ARF

With the Saito 2.20 four-stroke engine

for power, the Extra 260 cruises at just

above half throttle.

Minimal mixing is required to hold the Extra

on knife edge. No special programming is

required, as the author notes.

The Extra 260’s midwing design is the

preferred layout for precision and 3-D

aerobatic pilots.

HANGAR 9 HAS produced several ARFs that Mike McConville, an

acclaimed RC pilot, has designed. The Extra 260 is one of several

McConville aircraft for multistyle aerobatics. It can handle precision

Scale Aerobatics flying with ease and is ideal for visually stunning 3-D

aerobatics. This model is extremely nice and goes together quickly.

The 260 is approximately 90% factory-built. Primary airframe

components are of conventional laser-cut balsa-and-light plywood

construction with an almost countless number of lightening holes.

Each of those major components comes expertly covered in Hangar

9 UltraCote. A factory-painted fiberglass cowl and wheel pants

complement the three-color UltraCote trim scheme. All parts and

accessories are of exceptionally high quality.

Thanks to individual wing panels and removable horizontal

stabilizers, no epoxy center joints or dihedral braces are required. That

helps prepare the Extra 260 to finish quickly.

Construction: Assembly begins with hinging the ailerons, and Hangar

9 provided a nice set of heavy-duty point-type hinges to handle the task.

I used Hangar 9 30-minute epoxy for this procedure; it gave me time to

align the hinge barrels and correctly position a control surface against

the appropriate flying surface before the adhesive began to cure.

I have found that the easiest way to assure drag-free point-hinge

installation is to apply the adhesive, insert the pointed hinges in the

flying surface, and then fit the control surface to the exposed opposite

points.

When the surfaces are correctly aligned I deflect the control surface

up and down several times to line up the hinge barrels and then allow

the adhesive to cure overnight. I sealed my hinge gaps with Dave

Brown Products’ Trimseal.

I chose the recommended JR 8231 digital servos for aileron control,

although I replaced them later with JR 8611 servos because they had

more power. Each aileron servo got a 12-inch extension before

installation, and I used a 1-inch length of 1/2-inch-diameter heat-shrink

tubing to lock the extensions onto the servo leads.

I used a weighted length of string to thread the servo lead through

each wing panel. The servo bays required no cutting or trimming to

accommodate the JR servos.

I am impressed with the Extra’s control horns. An 8-32 x 21/2-inch

screw was inserted through each aileron’s upper surface and captured at

the underside with a flanged hex nut. A molded swivel link threaded onto

the end of the screw, and the link accepted the 4-40 threaded end of the

pushrod. Be sure to assemble these parts with thread-locking compound.

A midwing sport-scale aircraft for advanced

Pattern and 3-D aerobatics

Mike McConville designed the Extra 260 to be lightweight and potent regardless of the power plant the builder chooses.

December 2007 61

Photos by the author

The wing and stabilizers assemble onto the fuselage with aluminum

tubes for support. Incidence angles are set at the factory.

Removing the large hatch reveals the location of the receiver

and battery, just in front of the rudder servo.

The plywood framework is lightweight. The

forward structure ties the engine mount,

landing gear, and wing into a sturdy unit.

The Saito 2.20 fits best mounted sideways on the plywood engine box. The aluminum

engine rails are adjustable to suit any glow-engine application.

Ball-link hardware and pull-pull linkages are included. A location in the tail is reserved

in case the builder prefers the rudder servo to be farther aft.

The single JR DS8231 digital servo is

more than enough for the large ailerons

on the aircraft.

62 MODEL AVIATION

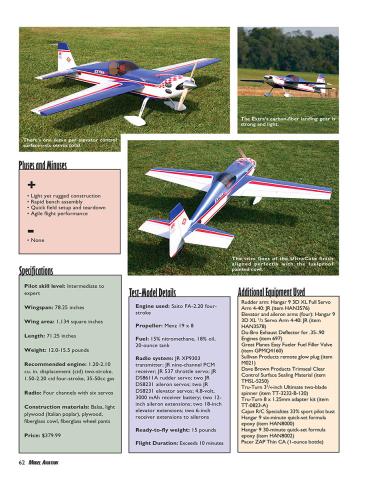

The trim lines of the UltraCote finish

aligned perfectly with the fuelproof

painted cowl.

The Extra’s carbon-fiber landing gear is

strong and light.

There’s one servo per elevator control

surface—six servos total.

Pluses and Minuses

+

• Light yet rugged construction

• Rapid bench assembly

• Quick field setup and teardown

• Agile flight performance

-• None

Test-Model Details

Specifications

Pilot skill level: Intermediate to

expert

Wingspan: 78.25 inches

Wing area: 1,134 square inches

Length: 71.25 inches

Weight: 12.0-15.5 pounds

Recommended engine: 1.20-2.10

cu. in. displacement (cid) two-stroke,

1.50-2.20 cid four-stroke, 35-50cc gas

Radio: Four channels with six servos

Construction materials: Balsa, light

plywood (Italian poplar), plywood,

fiberglass cowl, fiberglass wheel pants

Price: $379.99

Engine used: Saito FA-2.20 fourstroke

Propeller: Menz 19 x 8

Fuel: 15% nitromethane, 18% oil,

20-ounce tank

Radio system: JR XP9303

transmitter; JR nine-channel PCM

receiver; JR 537 throttle servo; JR

DS8611A rudder servo; two JR

DS8231 aileron servos; two JR

DS8231 elevator servos; 4.8-volt,

3000 mAh receiver battery; two 12-

inch aileron extensions; two 18-inch

elevator extensions; two 6-inch

receiver extensions to ailerons

Ready-to-fly weight: 15 pounds

Flight Duration: Exceeds 10 minutes

Additional Equipment Used

Rudder arm: Hangar 9 3D XL Full Servo

Arm 4-40: JR (item HAN3576)

Elevator and aileron arms (four): Hangar 9

3D XL 1/2 Servo Arm 4-40: JR (item

HAN3578)

Du-Bro Exhaust Deflector for .35-.90

Engines (item 697)

Great Planes Easy Fueler Fuel Filler Valve

(item GPMQ4160)

Sullivan Products remote glow plug (item

M021)

Dave Brown Products Trimseal Clear

Control Surface Sealing Material (item

TMSL-5250)

Tru-Turn 31/4-inch Ultimate two-blade

spinner (item TT-3232-B-120)

Tru-Turn 8 x 1.25mm adapter kit (item

TT-0823-A)

Cajun R/C Specialties 33% sport pilot bust

Hangar 9 six-minute quick-set formula

epoxy (item HAN8000)

Hangar 9 30-minute quick-set formula

epoxy (item HAN8002)

Pacer ZAP Thin CA (1-ounce bottle)

December 2007 63

The opposite end of the rod was also threaded, and it fit into a

ball link that secured to the aileron servo arm. I chose the

recommended Hangar 9 anodized aluminum arms, which look

great while increasing the amount of available throw for the

control surfaces.

The wing panels fit onto the fuselage over an aluminum tube,

and alignment pins toward the rear of the root rib fit into holes in

the fuselage to assure that the panels maintain the correct angle

of attack. Each panel is held securely with a 1/4-20 nylon

thumbscrew, making setup and teardown at the field a twominute

quickie.

The horizontal stabilizers are also removable, and they are

almost a complete repop of the wing-panel assembly, except that

the elevator servos ride in bays at the rear of the fuselage sides

instead of in the flying surfaces. An 18-inch extension is required

for each elevator servo.

The rudder linkage is pull-pull, and it sets up nicely with the

infinitely adjustable hardware provided in the kit. My servo

choice was the JR DS8611A digital with a full-length Hangar 9

anodized arm fitted to the output shaft. The carbon-fiber tailwheel

assembly mounts under the rear of the fuselage and uses a

pair of springs to connect the tiller arms to the steering yoke on

the lower edge of the rudder.

Hangar 9 provided a heavy-duty, one-piece, painted carbonfiber

landing-gear assembly and 4-inch wheels for the Extra 260.

These were complemented by a pair of factory-painted fiberglass

wheel pants, which secured to the gear legs with the axle lock

nut and 4-40 socket-head capscrew.

The airplane’s front end could accommodate a number of

power options, from a 1.20 two-stroke glow engine to a 50cc

gasoline power plant and anything in between. I chose the new

Saito 2.20 four-stroke to power my Extra.

At the time the Saito 2.20 was the largest single-cylinder

four-stroke available. It starts easily, runs smoothly, and

produces plenty of power for advanced aerobatics.

Hangar 9 supplied a mount in the 260 kit, and I added a

standard JR 537 servo for throttle control. I also used an Easy

Fueler quick-fueling valve from Great Planes and a remote glow

driver from Sullivan Products. Those two extras allowed me to

access the fuel tank and get light to the engine under that huge

fiberglass cowl.

The Extra’s final assembly involved the fuel tank, fiberglass

cowl, and tinted canopy. Little trimming was required for the

Saito, and I chose a 1/3-scale, factory-painted sport pilot bust

from Cajun R/C to “drive” my Extra. The last steps before flight

were to set the control-surface throws and radio programming,

set the correct CG, and charge the RC system.

Flying the Extra was a kick and a half. I fueled the Saito with

Byron’s 15%-nitro fuel (18% oil), connected my Du-Bro glow

driver, and gave the Tru-Turn 31/4-inch Ultimate spinner a hit

with my Sullivan Megatron starter. The 2.20 fired instantly and

took only a tweak or two to set perfectly.

Pointing the nose into the wind, I powered up, lifted the tail,

and the model gently broke ground. The Extra climbs like a

bandit on the Saito 2.20. Vertical performance is excellent, and

this airplane is capable of anything I can ask for—and much

more.

I performed the rudimentary routine of rolls, loops, inverted

flight, and Split “S” turns. Then I handed the JR XP9303

transmitter to my friend, Brandon Wright, who wrung out the

airplane for the camera and everyone at the flying site.

Spanning slightly more than 76 inches, Hangar 9’s Extra 260

is large. It’s an extremely stable sport flier, yet it can easily

perform any known precision aerobatics schedule or 3-D

maneuver in a capable pilot’s hands. Landings are predictable,

and the airplane exhibits no tendency to drop a tip at low speed.

You can almost bring this one in like a trainer.

Saito 2.20 Four-Stroke

Saito’s FA-220A weighs 42 ounces and

turns 1,900-10,000 rpm with a 17 x 12-20 x

8 propeller. The benchmark is 8,100 rpm

with an APC 19 x 8 propeller.

Complete with Saito’s three-year

warranty from Horizon Hobby, this huge

single-cylinder engine features a swivel

muffler for optimum fitting, a chrome-plated

cylinder, and a new head design for improved

airflow.

Hangar 9 provides a sturdy, adjustable

aluminum engine mount to accommodate all

appropriate glow engines. Side-mounting the

big FA-220A gets the engine inside the cowl

and keeps the cylinder in the airstream.

Fitting a Sullivan Products Head Lock

Remote glow-plug adapter and a Great

Planes Easy Fueler Fuel Filler Valve under the

Extra’s huge fiberglass cowl allows

immediate access for filling or dumping the

tank and starting the engine.

Tru-Turn sells a 31/4-inch machinedaluminum

spinner and an 8 x 1.25mm

spinner adapter kit to fit the FA-220A. The

company offers specialty custom cutting to

accommodate specific propeller brands and

blade counts. MA

—Jeff Troy

The combination of the Hangar 9 Extra Patented!

260, the Saito 2.20 four-stroke, and the JR

XP9303 RC system with digital servos on

the control surfaces produces a top-shelf

model. I’ve had a great time with mine, and

I think most intermediate to advanced RC

pilots will enjoy using the 260 to stretch

their current skills. It’s a nice airplane. MA

Manufacturer/Distributor:

Horizon Hobby

4105 Fieldstone Rd.

Champaign IL 61822

(877) 504-0233

www.horizonhobby.com

Products Used in Review:

Exhaust deflector, glow driver:

Du-Bro

(800) 848-9411

www.dubro.com

Remote glow plug, Megatron starter:

Sullivan Products

(410) 732-3500

www.sullivanproducts.com

Spinner, adapter kit:

Tru-Turn

(281) 479-9600

www.tru-turn.com

Trimseal:

Dave Brown Products

(513) 738-1576

www.dbproducts.com

Pilot bust:

Cajun R/C Specialties

(337) 269-5177

www.cajunrc.com

Other Review Sources:

Fly RC: January 2006

Model Airplane News: April 2006

RCR: April 2006

RCM&E: September 2006

Edition: Model Aviation - 2007/12

Page Numbers: 60,61,62,63,65

Edition: Model Aviation - 2007/12

Page Numbers: 60,61,62,63,65

60 MODEL AVIATION

BY JEFF TROY

Plane Talk: Hangar 9 27% Extra 260 ARF

With the Saito 2.20 four-stroke engine

for power, the Extra 260 cruises at just

above half throttle.

Minimal mixing is required to hold the Extra

on knife edge. No special programming is

required, as the author notes.

The Extra 260’s midwing design is the

preferred layout for precision and 3-D

aerobatic pilots.

HANGAR 9 HAS produced several ARFs that Mike McConville, an

acclaimed RC pilot, has designed. The Extra 260 is one of several

McConville aircraft for multistyle aerobatics. It can handle precision

Scale Aerobatics flying with ease and is ideal for visually stunning 3-D

aerobatics. This model is extremely nice and goes together quickly.

The 260 is approximately 90% factory-built. Primary airframe

components are of conventional laser-cut balsa-and-light plywood

construction with an almost countless number of lightening holes.

Each of those major components comes expertly covered in Hangar

9 UltraCote. A factory-painted fiberglass cowl and wheel pants

complement the three-color UltraCote trim scheme. All parts and

accessories are of exceptionally high quality.

Thanks to individual wing panels and removable horizontal

stabilizers, no epoxy center joints or dihedral braces are required. That

helps prepare the Extra 260 to finish quickly.

Construction: Assembly begins with hinging the ailerons, and Hangar

9 provided a nice set of heavy-duty point-type hinges to handle the task.

I used Hangar 9 30-minute epoxy for this procedure; it gave me time to

align the hinge barrels and correctly position a control surface against

the appropriate flying surface before the adhesive began to cure.

I have found that the easiest way to assure drag-free point-hinge

installation is to apply the adhesive, insert the pointed hinges in the

flying surface, and then fit the control surface to the exposed opposite

points.

When the surfaces are correctly aligned I deflect the control surface

up and down several times to line up the hinge barrels and then allow

the adhesive to cure overnight. I sealed my hinge gaps with Dave

Brown Products’ Trimseal.

I chose the recommended JR 8231 digital servos for aileron control,

although I replaced them later with JR 8611 servos because they had

more power. Each aileron servo got a 12-inch extension before

installation, and I used a 1-inch length of 1/2-inch-diameter heat-shrink

tubing to lock the extensions onto the servo leads.

I used a weighted length of string to thread the servo lead through

each wing panel. The servo bays required no cutting or trimming to

accommodate the JR servos.

I am impressed with the Extra’s control horns. An 8-32 x 21/2-inch

screw was inserted through each aileron’s upper surface and captured at

the underside with a flanged hex nut. A molded swivel link threaded onto

the end of the screw, and the link accepted the 4-40 threaded end of the

pushrod. Be sure to assemble these parts with thread-locking compound.

A midwing sport-scale aircraft for advanced

Pattern and 3-D aerobatics

Mike McConville designed the Extra 260 to be lightweight and potent regardless of the power plant the builder chooses.

December 2007 61

Photos by the author

The wing and stabilizers assemble onto the fuselage with aluminum

tubes for support. Incidence angles are set at the factory.

Removing the large hatch reveals the location of the receiver

and battery, just in front of the rudder servo.

The plywood framework is lightweight. The

forward structure ties the engine mount,

landing gear, and wing into a sturdy unit.

The Saito 2.20 fits best mounted sideways on the plywood engine box. The aluminum

engine rails are adjustable to suit any glow-engine application.

Ball-link hardware and pull-pull linkages are included. A location in the tail is reserved

in case the builder prefers the rudder servo to be farther aft.

The single JR DS8231 digital servo is

more than enough for the large ailerons

on the aircraft.

62 MODEL AVIATION

The trim lines of the UltraCote finish

aligned perfectly with the fuelproof

painted cowl.

The Extra’s carbon-fiber landing gear is

strong and light.

There’s one servo per elevator control

surface—six servos total.

Pluses and Minuses

+

• Light yet rugged construction

• Rapid bench assembly

• Quick field setup and teardown

• Agile flight performance

-• None

Test-Model Details

Specifications

Pilot skill level: Intermediate to

expert

Wingspan: 78.25 inches

Wing area: 1,134 square inches

Length: 71.25 inches

Weight: 12.0-15.5 pounds

Recommended engine: 1.20-2.10

cu. in. displacement (cid) two-stroke,

1.50-2.20 cid four-stroke, 35-50cc gas

Radio: Four channels with six servos

Construction materials: Balsa, light

plywood (Italian poplar), plywood,

fiberglass cowl, fiberglass wheel pants

Price: $379.99

Engine used: Saito FA-2.20 fourstroke

Propeller: Menz 19 x 8

Fuel: 15% nitromethane, 18% oil,

20-ounce tank

Radio system: JR XP9303

transmitter; JR nine-channel PCM

receiver; JR 537 throttle servo; JR

DS8611A rudder servo; two JR

DS8231 aileron servos; two JR

DS8231 elevator servos; 4.8-volt,

3000 mAh receiver battery; two 12-

inch aileron extensions; two 18-inch

elevator extensions; two 6-inch

receiver extensions to ailerons

Ready-to-fly weight: 15 pounds

Flight Duration: Exceeds 10 minutes

Additional Equipment Used

Rudder arm: Hangar 9 3D XL Full Servo

Arm 4-40: JR (item HAN3576)

Elevator and aileron arms (four): Hangar 9

3D XL 1/2 Servo Arm 4-40: JR (item

HAN3578)

Du-Bro Exhaust Deflector for .35-.90

Engines (item 697)

Great Planes Easy Fueler Fuel Filler Valve

(item GPMQ4160)

Sullivan Products remote glow plug (item

M021)

Dave Brown Products Trimseal Clear

Control Surface Sealing Material (item

TMSL-5250)

Tru-Turn 31/4-inch Ultimate two-blade

spinner (item TT-3232-B-120)

Tru-Turn 8 x 1.25mm adapter kit (item

TT-0823-A)

Cajun R/C Specialties 33% sport pilot bust

Hangar 9 six-minute quick-set formula

epoxy (item HAN8000)

Hangar 9 30-minute quick-set formula

epoxy (item HAN8002)

Pacer ZAP Thin CA (1-ounce bottle)

December 2007 63

The opposite end of the rod was also threaded, and it fit into a

ball link that secured to the aileron servo arm. I chose the

recommended Hangar 9 anodized aluminum arms, which look

great while increasing the amount of available throw for the

control surfaces.

The wing panels fit onto the fuselage over an aluminum tube,

and alignment pins toward the rear of the root rib fit into holes in

the fuselage to assure that the panels maintain the correct angle

of attack. Each panel is held securely with a 1/4-20 nylon

thumbscrew, making setup and teardown at the field a twominute

quickie.

The horizontal stabilizers are also removable, and they are

almost a complete repop of the wing-panel assembly, except that

the elevator servos ride in bays at the rear of the fuselage sides

instead of in the flying surfaces. An 18-inch extension is required

for each elevator servo.

The rudder linkage is pull-pull, and it sets up nicely with the

infinitely adjustable hardware provided in the kit. My servo

choice was the JR DS8611A digital with a full-length Hangar 9

anodized arm fitted to the output shaft. The carbon-fiber tailwheel

assembly mounts under the rear of the fuselage and uses a

pair of springs to connect the tiller arms to the steering yoke on

the lower edge of the rudder.

Hangar 9 provided a heavy-duty, one-piece, painted carbonfiber

landing-gear assembly and 4-inch wheels for the Extra 260.

These were complemented by a pair of factory-painted fiberglass

wheel pants, which secured to the gear legs with the axle lock

nut and 4-40 socket-head capscrew.

The airplane’s front end could accommodate a number of

power options, from a 1.20 two-stroke glow engine to a 50cc

gasoline power plant and anything in between. I chose the new

Saito 2.20 four-stroke to power my Extra.

At the time the Saito 2.20 was the largest single-cylinder

four-stroke available. It starts easily, runs smoothly, and

produces plenty of power for advanced aerobatics.

Hangar 9 supplied a mount in the 260 kit, and I added a

standard JR 537 servo for throttle control. I also used an Easy

Fueler quick-fueling valve from Great Planes and a remote glow

driver from Sullivan Products. Those two extras allowed me to

access the fuel tank and get light to the engine under that huge

fiberglass cowl.

The Extra’s final assembly involved the fuel tank, fiberglass

cowl, and tinted canopy. Little trimming was required for the

Saito, and I chose a 1/3-scale, factory-painted sport pilot bust

from Cajun R/C to “drive” my Extra. The last steps before flight

were to set the control-surface throws and radio programming,

set the correct CG, and charge the RC system.

Flying the Extra was a kick and a half. I fueled the Saito with

Byron’s 15%-nitro fuel (18% oil), connected my Du-Bro glow

driver, and gave the Tru-Turn 31/4-inch Ultimate spinner a hit

with my Sullivan Megatron starter. The 2.20 fired instantly and

took only a tweak or two to set perfectly.

Pointing the nose into the wind, I powered up, lifted the tail,

and the model gently broke ground. The Extra climbs like a

bandit on the Saito 2.20. Vertical performance is excellent, and

this airplane is capable of anything I can ask for—and much

more.

I performed the rudimentary routine of rolls, loops, inverted

flight, and Split “S” turns. Then I handed the JR XP9303

transmitter to my friend, Brandon Wright, who wrung out the

airplane for the camera and everyone at the flying site.

Spanning slightly more than 76 inches, Hangar 9’s Extra 260

is large. It’s an extremely stable sport flier, yet it can easily

perform any known precision aerobatics schedule or 3-D

maneuver in a capable pilot’s hands. Landings are predictable,

and the airplane exhibits no tendency to drop a tip at low speed.

You can almost bring this one in like a trainer.

Saito 2.20 Four-Stroke

Saito’s FA-220A weighs 42 ounces and

turns 1,900-10,000 rpm with a 17 x 12-20 x

8 propeller. The benchmark is 8,100 rpm

with an APC 19 x 8 propeller.

Complete with Saito’s three-year

warranty from Horizon Hobby, this huge

single-cylinder engine features a swivel

muffler for optimum fitting, a chrome-plated

cylinder, and a new head design for improved

airflow.

Hangar 9 provides a sturdy, adjustable

aluminum engine mount to accommodate all

appropriate glow engines. Side-mounting the

big FA-220A gets the engine inside the cowl

and keeps the cylinder in the airstream.

Fitting a Sullivan Products Head Lock

Remote glow-plug adapter and a Great

Planes Easy Fueler Fuel Filler Valve under the

Extra’s huge fiberglass cowl allows

immediate access for filling or dumping the

tank and starting the engine.

Tru-Turn sells a 31/4-inch machinedaluminum

spinner and an 8 x 1.25mm

spinner adapter kit to fit the FA-220A. The

company offers specialty custom cutting to

accommodate specific propeller brands and

blade counts. MA

—Jeff Troy

The combination of the Hangar 9 Extra Patented!

260, the Saito 2.20 four-stroke, and the JR

XP9303 RC system with digital servos on

the control surfaces produces a top-shelf

model. I’ve had a great time with mine, and

I think most intermediate to advanced RC

pilots will enjoy using the 260 to stretch

their current skills. It’s a nice airplane. MA

Manufacturer/Distributor:

Horizon Hobby

4105 Fieldstone Rd.

Champaign IL 61822

(877) 504-0233

www.horizonhobby.com

Products Used in Review:

Exhaust deflector, glow driver:

Du-Bro

(800) 848-9411

www.dubro.com

Remote glow plug, Megatron starter:

Sullivan Products

(410) 732-3500

www.sullivanproducts.com

Spinner, adapter kit:

Tru-Turn

(281) 479-9600

www.tru-turn.com

Trimseal:

Dave Brown Products

(513) 738-1576

www.dbproducts.com

Pilot bust:

Cajun R/C Specialties

(337) 269-5177

www.cajunrc.com

Other Review Sources:

Fly RC: January 2006

Model Airplane News: April 2006

RCR: April 2006

RCM&E: September 2006

Edition: Model Aviation - 2007/12

Page Numbers: 60,61,62,63,65

60 MODEL AVIATION

BY JEFF TROY

Plane Talk: Hangar 9 27% Extra 260 ARF

With the Saito 2.20 four-stroke engine

for power, the Extra 260 cruises at just

above half throttle.

Minimal mixing is required to hold the Extra

on knife edge. No special programming is

required, as the author notes.

The Extra 260’s midwing design is the

preferred layout for precision and 3-D

aerobatic pilots.

HANGAR 9 HAS produced several ARFs that Mike McConville, an

acclaimed RC pilot, has designed. The Extra 260 is one of several

McConville aircraft for multistyle aerobatics. It can handle precision

Scale Aerobatics flying with ease and is ideal for visually stunning 3-D

aerobatics. This model is extremely nice and goes together quickly.

The 260 is approximately 90% factory-built. Primary airframe

components are of conventional laser-cut balsa-and-light plywood

construction with an almost countless number of lightening holes.

Each of those major components comes expertly covered in Hangar

9 UltraCote. A factory-painted fiberglass cowl and wheel pants

complement the three-color UltraCote trim scheme. All parts and

accessories are of exceptionally high quality.

Thanks to individual wing panels and removable horizontal

stabilizers, no epoxy center joints or dihedral braces are required. That

helps prepare the Extra 260 to finish quickly.

Construction: Assembly begins with hinging the ailerons, and Hangar

9 provided a nice set of heavy-duty point-type hinges to handle the task.

I used Hangar 9 30-minute epoxy for this procedure; it gave me time to

align the hinge barrels and correctly position a control surface against

the appropriate flying surface before the adhesive began to cure.

I have found that the easiest way to assure drag-free point-hinge

installation is to apply the adhesive, insert the pointed hinges in the

flying surface, and then fit the control surface to the exposed opposite

points.

When the surfaces are correctly aligned I deflect the control surface

up and down several times to line up the hinge barrels and then allow

the adhesive to cure overnight. I sealed my hinge gaps with Dave

Brown Products’ Trimseal.

I chose the recommended JR 8231 digital servos for aileron control,

although I replaced them later with JR 8611 servos because they had

more power. Each aileron servo got a 12-inch extension before

installation, and I used a 1-inch length of 1/2-inch-diameter heat-shrink

tubing to lock the extensions onto the servo leads.

I used a weighted length of string to thread the servo lead through

each wing panel. The servo bays required no cutting or trimming to

accommodate the JR servos.

I am impressed with the Extra’s control horns. An 8-32 x 21/2-inch

screw was inserted through each aileron’s upper surface and captured at

the underside with a flanged hex nut. A molded swivel link threaded onto

the end of the screw, and the link accepted the 4-40 threaded end of the

pushrod. Be sure to assemble these parts with thread-locking compound.

A midwing sport-scale aircraft for advanced

Pattern and 3-D aerobatics

Mike McConville designed the Extra 260 to be lightweight and potent regardless of the power plant the builder chooses.

December 2007 61

Photos by the author

The wing and stabilizers assemble onto the fuselage with aluminum

tubes for support. Incidence angles are set at the factory.

Removing the large hatch reveals the location of the receiver

and battery, just in front of the rudder servo.

The plywood framework is lightweight. The

forward structure ties the engine mount,

landing gear, and wing into a sturdy unit.

The Saito 2.20 fits best mounted sideways on the plywood engine box. The aluminum

engine rails are adjustable to suit any glow-engine application.

Ball-link hardware and pull-pull linkages are included. A location in the tail is reserved

in case the builder prefers the rudder servo to be farther aft.

The single JR DS8231 digital servo is

more than enough for the large ailerons

on the aircraft.

62 MODEL AVIATION

The trim lines of the UltraCote finish

aligned perfectly with the fuelproof

painted cowl.

The Extra’s carbon-fiber landing gear is

strong and light.

There’s one servo per elevator control

surface—six servos total.

Pluses and Minuses

+

• Light yet rugged construction

• Rapid bench assembly

• Quick field setup and teardown

• Agile flight performance

-• None

Test-Model Details

Specifications

Pilot skill level: Intermediate to

expert

Wingspan: 78.25 inches

Wing area: 1,134 square inches

Length: 71.25 inches

Weight: 12.0-15.5 pounds

Recommended engine: 1.20-2.10

cu. in. displacement (cid) two-stroke,

1.50-2.20 cid four-stroke, 35-50cc gas

Radio: Four channels with six servos

Construction materials: Balsa, light

plywood (Italian poplar), plywood,

fiberglass cowl, fiberglass wheel pants

Price: $379.99

Engine used: Saito FA-2.20 fourstroke

Propeller: Menz 19 x 8

Fuel: 15% nitromethane, 18% oil,

20-ounce tank

Radio system: JR XP9303

transmitter; JR nine-channel PCM

receiver; JR 537 throttle servo; JR

DS8611A rudder servo; two JR

DS8231 aileron servos; two JR

DS8231 elevator servos; 4.8-volt,

3000 mAh receiver battery; two 12-

inch aileron extensions; two 18-inch

elevator extensions; two 6-inch

receiver extensions to ailerons

Ready-to-fly weight: 15 pounds

Flight Duration: Exceeds 10 minutes

Additional Equipment Used

Rudder arm: Hangar 9 3D XL Full Servo

Arm 4-40: JR (item HAN3576)

Elevator and aileron arms (four): Hangar 9

3D XL 1/2 Servo Arm 4-40: JR (item

HAN3578)

Du-Bro Exhaust Deflector for .35-.90

Engines (item 697)

Great Planes Easy Fueler Fuel Filler Valve

(item GPMQ4160)

Sullivan Products remote glow plug (item

M021)

Dave Brown Products Trimseal Clear

Control Surface Sealing Material (item

TMSL-5250)

Tru-Turn 31/4-inch Ultimate two-blade

spinner (item TT-3232-B-120)

Tru-Turn 8 x 1.25mm adapter kit (item

TT-0823-A)

Cajun R/C Specialties 33% sport pilot bust

Hangar 9 six-minute quick-set formula

epoxy (item HAN8000)

Hangar 9 30-minute quick-set formula

epoxy (item HAN8002)

Pacer ZAP Thin CA (1-ounce bottle)

December 2007 63

The opposite end of the rod was also threaded, and it fit into a

ball link that secured to the aileron servo arm. I chose the

recommended Hangar 9 anodized aluminum arms, which look

great while increasing the amount of available throw for the

control surfaces.

The wing panels fit onto the fuselage over an aluminum tube,

and alignment pins toward the rear of the root rib fit into holes in

the fuselage to assure that the panels maintain the correct angle

of attack. Each panel is held securely with a 1/4-20 nylon

thumbscrew, making setup and teardown at the field a twominute

quickie.

The horizontal stabilizers are also removable, and they are

almost a complete repop of the wing-panel assembly, except that

the elevator servos ride in bays at the rear of the fuselage sides

instead of in the flying surfaces. An 18-inch extension is required

for each elevator servo.

The rudder linkage is pull-pull, and it sets up nicely with the

infinitely adjustable hardware provided in the kit. My servo

choice was the JR DS8611A digital with a full-length Hangar 9

anodized arm fitted to the output shaft. The carbon-fiber tailwheel

assembly mounts under the rear of the fuselage and uses a

pair of springs to connect the tiller arms to the steering yoke on

the lower edge of the rudder.

Hangar 9 provided a heavy-duty, one-piece, painted carbonfiber

landing-gear assembly and 4-inch wheels for the Extra 260.

These were complemented by a pair of factory-painted fiberglass

wheel pants, which secured to the gear legs with the axle lock

nut and 4-40 socket-head capscrew.

The airplane’s front end could accommodate a number of

power options, from a 1.20 two-stroke glow engine to a 50cc

gasoline power plant and anything in between. I chose the new

Saito 2.20 four-stroke to power my Extra.

At the time the Saito 2.20 was the largest single-cylinder

four-stroke available. It starts easily, runs smoothly, and

produces plenty of power for advanced aerobatics.

Hangar 9 supplied a mount in the 260 kit, and I added a

standard JR 537 servo for throttle control. I also used an Easy

Fueler quick-fueling valve from Great Planes and a remote glow

driver from Sullivan Products. Those two extras allowed me to

access the fuel tank and get light to the engine under that huge

fiberglass cowl.

The Extra’s final assembly involved the fuel tank, fiberglass

cowl, and tinted canopy. Little trimming was required for the

Saito, and I chose a 1/3-scale, factory-painted sport pilot bust

from Cajun R/C to “drive” my Extra. The last steps before flight

were to set the control-surface throws and radio programming,

set the correct CG, and charge the RC system.

Flying the Extra was a kick and a half. I fueled the Saito with

Byron’s 15%-nitro fuel (18% oil), connected my Du-Bro glow

driver, and gave the Tru-Turn 31/4-inch Ultimate spinner a hit

with my Sullivan Megatron starter. The 2.20 fired instantly and

took only a tweak or two to set perfectly.

Pointing the nose into the wind, I powered up, lifted the tail,

and the model gently broke ground. The Extra climbs like a

bandit on the Saito 2.20. Vertical performance is excellent, and

this airplane is capable of anything I can ask for—and much

more.

I performed the rudimentary routine of rolls, loops, inverted

flight, and Split “S” turns. Then I handed the JR XP9303

transmitter to my friend, Brandon Wright, who wrung out the

airplane for the camera and everyone at the flying site.

Spanning slightly more than 76 inches, Hangar 9’s Extra 260

is large. It’s an extremely stable sport flier, yet it can easily

perform any known precision aerobatics schedule or 3-D

maneuver in a capable pilot’s hands. Landings are predictable,

and the airplane exhibits no tendency to drop a tip at low speed.

You can almost bring this one in like a trainer.

Saito 2.20 Four-Stroke

Saito’s FA-220A weighs 42 ounces and

turns 1,900-10,000 rpm with a 17 x 12-20 x

8 propeller. The benchmark is 8,100 rpm

with an APC 19 x 8 propeller.

Complete with Saito’s three-year

warranty from Horizon Hobby, this huge

single-cylinder engine features a swivel

muffler for optimum fitting, a chrome-plated

cylinder, and a new head design for improved

airflow.

Hangar 9 provides a sturdy, adjustable

aluminum engine mount to accommodate all

appropriate glow engines. Side-mounting the

big FA-220A gets the engine inside the cowl

and keeps the cylinder in the airstream.

Fitting a Sullivan Products Head Lock

Remote glow-plug adapter and a Great

Planes Easy Fueler Fuel Filler Valve under the

Extra’s huge fiberglass cowl allows

immediate access for filling or dumping the

tank and starting the engine.

Tru-Turn sells a 31/4-inch machinedaluminum

spinner and an 8 x 1.25mm

spinner adapter kit to fit the FA-220A. The

company offers specialty custom cutting to

accommodate specific propeller brands and

blade counts. MA

—Jeff Troy

The combination of the Hangar 9 Extra Patented!

260, the Saito 2.20 four-stroke, and the JR

XP9303 RC system with digital servos on

the control surfaces produces a top-shelf

model. I’ve had a great time with mine, and

I think most intermediate to advanced RC

pilots will enjoy using the 260 to stretch

their current skills. It’s a nice airplane. MA

Manufacturer/Distributor:

Horizon Hobby

4105 Fieldstone Rd.

Champaign IL 61822

(877) 504-0233

www.horizonhobby.com

Products Used in Review:

Exhaust deflector, glow driver:

Du-Bro

(800) 848-9411

www.dubro.com

Remote glow plug, Megatron starter:

Sullivan Products

(410) 732-3500

www.sullivanproducts.com

Spinner, adapter kit:

Tru-Turn

(281) 479-9600

www.tru-turn.com

Trimseal:

Dave Brown Products

(513) 738-1576

www.dbproducts.com

Pilot bust:

Cajun R/C Specialties

(337) 269-5177

www.cajunrc.com

Other Review Sources:

Fly RC: January 2006

Model Airplane News: April 2006

RCR: April 2006

RCM&E: September 2006

Edition: Model Aviation - 2007/12

Page Numbers: 60,61,62,63,65

60 MODEL AVIATION

BY JEFF TROY

Plane Talk: Hangar 9 27% Extra 260 ARF

With the Saito 2.20 four-stroke engine

for power, the Extra 260 cruises at just

above half throttle.

Minimal mixing is required to hold the Extra

on knife edge. No special programming is

required, as the author notes.

The Extra 260’s midwing design is the

preferred layout for precision and 3-D

aerobatic pilots.

HANGAR 9 HAS produced several ARFs that Mike McConville, an

acclaimed RC pilot, has designed. The Extra 260 is one of several

McConville aircraft for multistyle aerobatics. It can handle precision

Scale Aerobatics flying with ease and is ideal for visually stunning 3-D

aerobatics. This model is extremely nice and goes together quickly.

The 260 is approximately 90% factory-built. Primary airframe

components are of conventional laser-cut balsa-and-light plywood

construction with an almost countless number of lightening holes.

Each of those major components comes expertly covered in Hangar

9 UltraCote. A factory-painted fiberglass cowl and wheel pants

complement the three-color UltraCote trim scheme. All parts and

accessories are of exceptionally high quality.

Thanks to individual wing panels and removable horizontal

stabilizers, no epoxy center joints or dihedral braces are required. That

helps prepare the Extra 260 to finish quickly.

Construction: Assembly begins with hinging the ailerons, and Hangar

9 provided a nice set of heavy-duty point-type hinges to handle the task.

I used Hangar 9 30-minute epoxy for this procedure; it gave me time to

align the hinge barrels and correctly position a control surface against

the appropriate flying surface before the adhesive began to cure.

I have found that the easiest way to assure drag-free point-hinge

installation is to apply the adhesive, insert the pointed hinges in the

flying surface, and then fit the control surface to the exposed opposite

points.

When the surfaces are correctly aligned I deflect the control surface

up and down several times to line up the hinge barrels and then allow

the adhesive to cure overnight. I sealed my hinge gaps with Dave

Brown Products’ Trimseal.

I chose the recommended JR 8231 digital servos for aileron control,

although I replaced them later with JR 8611 servos because they had

more power. Each aileron servo got a 12-inch extension before

installation, and I used a 1-inch length of 1/2-inch-diameter heat-shrink

tubing to lock the extensions onto the servo leads.

I used a weighted length of string to thread the servo lead through

each wing panel. The servo bays required no cutting or trimming to

accommodate the JR servos.

I am impressed with the Extra’s control horns. An 8-32 x 21/2-inch

screw was inserted through each aileron’s upper surface and captured at

the underside with a flanged hex nut. A molded swivel link threaded onto

the end of the screw, and the link accepted the 4-40 threaded end of the

pushrod. Be sure to assemble these parts with thread-locking compound.

A midwing sport-scale aircraft for advanced

Pattern and 3-D aerobatics

Mike McConville designed the Extra 260 to be lightweight and potent regardless of the power plant the builder chooses.

December 2007 61

Photos by the author

The wing and stabilizers assemble onto the fuselage with aluminum

tubes for support. Incidence angles are set at the factory.

Removing the large hatch reveals the location of the receiver

and battery, just in front of the rudder servo.

The plywood framework is lightweight. The

forward structure ties the engine mount,

landing gear, and wing into a sturdy unit.

The Saito 2.20 fits best mounted sideways on the plywood engine box. The aluminum

engine rails are adjustable to suit any glow-engine application.

Ball-link hardware and pull-pull linkages are included. A location in the tail is reserved

in case the builder prefers the rudder servo to be farther aft.

The single JR DS8231 digital servo is

more than enough for the large ailerons

on the aircraft.

62 MODEL AVIATION

The trim lines of the UltraCote finish

aligned perfectly with the fuelproof

painted cowl.

The Extra’s carbon-fiber landing gear is

strong and light.

There’s one servo per elevator control

surface—six servos total.

Pluses and Minuses

+

• Light yet rugged construction

• Rapid bench assembly

• Quick field setup and teardown

• Agile flight performance

-• None

Test-Model Details

Specifications

Pilot skill level: Intermediate to

expert

Wingspan: 78.25 inches

Wing area: 1,134 square inches

Length: 71.25 inches

Weight: 12.0-15.5 pounds

Recommended engine: 1.20-2.10

cu. in. displacement (cid) two-stroke,

1.50-2.20 cid four-stroke, 35-50cc gas

Radio: Four channels with six servos

Construction materials: Balsa, light

plywood (Italian poplar), plywood,

fiberglass cowl, fiberglass wheel pants

Price: $379.99

Engine used: Saito FA-2.20 fourstroke

Propeller: Menz 19 x 8

Fuel: 15% nitromethane, 18% oil,

20-ounce tank

Radio system: JR XP9303

transmitter; JR nine-channel PCM

receiver; JR 537 throttle servo; JR

DS8611A rudder servo; two JR

DS8231 aileron servos; two JR

DS8231 elevator servos; 4.8-volt,

3000 mAh receiver battery; two 12-

inch aileron extensions; two 18-inch

elevator extensions; two 6-inch

receiver extensions to ailerons

Ready-to-fly weight: 15 pounds

Flight Duration: Exceeds 10 minutes

Additional Equipment Used

Rudder arm: Hangar 9 3D XL Full Servo

Arm 4-40: JR (item HAN3576)

Elevator and aileron arms (four): Hangar 9

3D XL 1/2 Servo Arm 4-40: JR (item

HAN3578)

Du-Bro Exhaust Deflector for .35-.90

Engines (item 697)

Great Planes Easy Fueler Fuel Filler Valve

(item GPMQ4160)

Sullivan Products remote glow plug (item

M021)

Dave Brown Products Trimseal Clear

Control Surface Sealing Material (item

TMSL-5250)

Tru-Turn 31/4-inch Ultimate two-blade

spinner (item TT-3232-B-120)

Tru-Turn 8 x 1.25mm adapter kit (item

TT-0823-A)

Cajun R/C Specialties 33% sport pilot bust

Hangar 9 six-minute quick-set formula

epoxy (item HAN8000)

Hangar 9 30-minute quick-set formula

epoxy (item HAN8002)

Pacer ZAP Thin CA (1-ounce bottle)

December 2007 63

The opposite end of the rod was also threaded, and it fit into a

ball link that secured to the aileron servo arm. I chose the

recommended Hangar 9 anodized aluminum arms, which look

great while increasing the amount of available throw for the

control surfaces.

The wing panels fit onto the fuselage over an aluminum tube,

and alignment pins toward the rear of the root rib fit into holes in

the fuselage to assure that the panels maintain the correct angle

of attack. Each panel is held securely with a 1/4-20 nylon

thumbscrew, making setup and teardown at the field a twominute

quickie.

The horizontal stabilizers are also removable, and they are

almost a complete repop of the wing-panel assembly, except that

the elevator servos ride in bays at the rear of the fuselage sides

instead of in the flying surfaces. An 18-inch extension is required

for each elevator servo.

The rudder linkage is pull-pull, and it sets up nicely with the

infinitely adjustable hardware provided in the kit. My servo

choice was the JR DS8611A digital with a full-length Hangar 9

anodized arm fitted to the output shaft. The carbon-fiber tailwheel

assembly mounts under the rear of the fuselage and uses a

pair of springs to connect the tiller arms to the steering yoke on

the lower edge of the rudder.

Hangar 9 provided a heavy-duty, one-piece, painted carbonfiber

landing-gear assembly and 4-inch wheels for the Extra 260.

These were complemented by a pair of factory-painted fiberglass

wheel pants, which secured to the gear legs with the axle lock

nut and 4-40 socket-head capscrew.

The airplane’s front end could accommodate a number of

power options, from a 1.20 two-stroke glow engine to a 50cc

gasoline power plant and anything in between. I chose the new

Saito 2.20 four-stroke to power my Extra.

At the time the Saito 2.20 was the largest single-cylinder

four-stroke available. It starts easily, runs smoothly, and

produces plenty of power for advanced aerobatics.

Hangar 9 supplied a mount in the 260 kit, and I added a

standard JR 537 servo for throttle control. I also used an Easy

Fueler quick-fueling valve from Great Planes and a remote glow

driver from Sullivan Products. Those two extras allowed me to

access the fuel tank and get light to the engine under that huge

fiberglass cowl.

The Extra’s final assembly involved the fuel tank, fiberglass

cowl, and tinted canopy. Little trimming was required for the

Saito, and I chose a 1/3-scale, factory-painted sport pilot bust

from Cajun R/C to “drive” my Extra. The last steps before flight

were to set the control-surface throws and radio programming,

set the correct CG, and charge the RC system.

Flying the Extra was a kick and a half. I fueled the Saito with

Byron’s 15%-nitro fuel (18% oil), connected my Du-Bro glow

driver, and gave the Tru-Turn 31/4-inch Ultimate spinner a hit

with my Sullivan Megatron starter. The 2.20 fired instantly and

took only a tweak or two to set perfectly.

Pointing the nose into the wind, I powered up, lifted the tail,

and the model gently broke ground. The Extra climbs like a

bandit on the Saito 2.20. Vertical performance is excellent, and

this airplane is capable of anything I can ask for—and much

more.

I performed the rudimentary routine of rolls, loops, inverted

flight, and Split “S” turns. Then I handed the JR XP9303

transmitter to my friend, Brandon Wright, who wrung out the

airplane for the camera and everyone at the flying site.

Spanning slightly more than 76 inches, Hangar 9’s Extra 260

is large. It’s an extremely stable sport flier, yet it can easily

perform any known precision aerobatics schedule or 3-D

maneuver in a capable pilot’s hands. Landings are predictable,

and the airplane exhibits no tendency to drop a tip at low speed.

You can almost bring this one in like a trainer.

Saito 2.20 Four-Stroke

Saito’s FA-220A weighs 42 ounces and

turns 1,900-10,000 rpm with a 17 x 12-20 x

8 propeller. The benchmark is 8,100 rpm

with an APC 19 x 8 propeller.

Complete with Saito’s three-year

warranty from Horizon Hobby, this huge

single-cylinder engine features a swivel

muffler for optimum fitting, a chrome-plated

cylinder, and a new head design for improved

airflow.

Hangar 9 provides a sturdy, adjustable

aluminum engine mount to accommodate all

appropriate glow engines. Side-mounting the

big FA-220A gets the engine inside the cowl

and keeps the cylinder in the airstream.

Fitting a Sullivan Products Head Lock

Remote glow-plug adapter and a Great

Planes Easy Fueler Fuel Filler Valve under the

Extra’s huge fiberglass cowl allows

immediate access for filling or dumping the

tank and starting the engine.

Tru-Turn sells a 31/4-inch machinedaluminum

spinner and an 8 x 1.25mm

spinner adapter kit to fit the FA-220A. The

company offers specialty custom cutting to

accommodate specific propeller brands and

blade counts. MA

—Jeff Troy

The combination of the Hangar 9 Extra Patented!

260, the Saito 2.20 four-stroke, and the JR

XP9303 RC system with digital servos on

the control surfaces produces a top-shelf

model. I’ve had a great time with mine, and

I think most intermediate to advanced RC

pilots will enjoy using the 260 to stretch

their current skills. It’s a nice airplane. MA

Manufacturer/Distributor:

Horizon Hobby

4105 Fieldstone Rd.

Champaign IL 61822

(877) 504-0233

www.horizonhobby.com

Products Used in Review:

Exhaust deflector, glow driver:

Du-Bro

(800) 848-9411

www.dubro.com

Remote glow plug, Megatron starter:

Sullivan Products

(410) 732-3500

www.sullivanproducts.com

Spinner, adapter kit:

Tru-Turn

(281) 479-9600

www.tru-turn.com

Trimseal:

Dave Brown Products

(513) 738-1576

www.dbproducts.com

Pilot bust:

Cajun R/C Specialties

(337) 269-5177

www.cajunrc.com

Other Review Sources:

Fly RC: January 2006

Model Airplane News: April 2006

RCR: April 2006

RCM&E: September 2006

Edition: Model Aviation - 2007/12

Page Numbers: 60,61,62,63,65

60 MODEL AVIATION

BY JEFF TROY

Plane Talk: Hangar 9 27% Extra 260 ARF

With the Saito 2.20 four-stroke engine

for power, the Extra 260 cruises at just

above half throttle.

Minimal mixing is required to hold the Extra

on knife edge. No special programming is

required, as the author notes.

The Extra 260’s midwing design is the

preferred layout for precision and 3-D

aerobatic pilots.

HANGAR 9 HAS produced several ARFs that Mike McConville, an

acclaimed RC pilot, has designed. The Extra 260 is one of several

McConville aircraft for multistyle aerobatics. It can handle precision

Scale Aerobatics flying with ease and is ideal for visually stunning 3-D

aerobatics. This model is extremely nice and goes together quickly.

The 260 is approximately 90% factory-built. Primary airframe

components are of conventional laser-cut balsa-and-light plywood

construction with an almost countless number of lightening holes.

Each of those major components comes expertly covered in Hangar

9 UltraCote. A factory-painted fiberglass cowl and wheel pants

complement the three-color UltraCote trim scheme. All parts and

accessories are of exceptionally high quality.

Thanks to individual wing panels and removable horizontal

stabilizers, no epoxy center joints or dihedral braces are required. That

helps prepare the Extra 260 to finish quickly.

Construction: Assembly begins with hinging the ailerons, and Hangar

9 provided a nice set of heavy-duty point-type hinges to handle the task.

I used Hangar 9 30-minute epoxy for this procedure; it gave me time to

align the hinge barrels and correctly position a control surface against

the appropriate flying surface before the adhesive began to cure.

I have found that the easiest way to assure drag-free point-hinge

installation is to apply the adhesive, insert the pointed hinges in the

flying surface, and then fit the control surface to the exposed opposite

points.

When the surfaces are correctly aligned I deflect the control surface

up and down several times to line up the hinge barrels and then allow

the adhesive to cure overnight. I sealed my hinge gaps with Dave

Brown Products’ Trimseal.

I chose the recommended JR 8231 digital servos for aileron control,

although I replaced them later with JR 8611 servos because they had

more power. Each aileron servo got a 12-inch extension before

installation, and I used a 1-inch length of 1/2-inch-diameter heat-shrink

tubing to lock the extensions onto the servo leads.

I used a weighted length of string to thread the servo lead through

each wing panel. The servo bays required no cutting or trimming to

accommodate the JR servos.

I am impressed with the Extra’s control horns. An 8-32 x 21/2-inch

screw was inserted through each aileron’s upper surface and captured at

the underside with a flanged hex nut. A molded swivel link threaded onto

the end of the screw, and the link accepted the 4-40 threaded end of the

pushrod. Be sure to assemble these parts with thread-locking compound.

A midwing sport-scale aircraft for advanced

Pattern and 3-D aerobatics

Mike McConville designed the Extra 260 to be lightweight and potent regardless of the power plant the builder chooses.

December 2007 61

Photos by the author

The wing and stabilizers assemble onto the fuselage with aluminum

tubes for support. Incidence angles are set at the factory.

Removing the large hatch reveals the location of the receiver

and battery, just in front of the rudder servo.

The plywood framework is lightweight. The

forward structure ties the engine mount,

landing gear, and wing into a sturdy unit.

The Saito 2.20 fits best mounted sideways on the plywood engine box. The aluminum

engine rails are adjustable to suit any glow-engine application.

Ball-link hardware and pull-pull linkages are included. A location in the tail is reserved

in case the builder prefers the rudder servo to be farther aft.

The single JR DS8231 digital servo is

more than enough for the large ailerons

on the aircraft.

62 MODEL AVIATION

The trim lines of the UltraCote finish

aligned perfectly with the fuelproof

painted cowl.

The Extra’s carbon-fiber landing gear is

strong and light.

There’s one servo per elevator control

surface—six servos total.

Pluses and Minuses

+

• Light yet rugged construction

• Rapid bench assembly

• Quick field setup and teardown

• Agile flight performance

-• None

Test-Model Details

Specifications

Pilot skill level: Intermediate to

expert

Wingspan: 78.25 inches

Wing area: 1,134 square inches

Length: 71.25 inches

Weight: 12.0-15.5 pounds

Recommended engine: 1.20-2.10

cu. in. displacement (cid) two-stroke,

1.50-2.20 cid four-stroke, 35-50cc gas

Radio: Four channels with six servos

Construction materials: Balsa, light

plywood (Italian poplar), plywood,

fiberglass cowl, fiberglass wheel pants

Price: $379.99

Engine used: Saito FA-2.20 fourstroke

Propeller: Menz 19 x 8

Fuel: 15% nitromethane, 18% oil,

20-ounce tank

Radio system: JR XP9303

transmitter; JR nine-channel PCM

receiver; JR 537 throttle servo; JR

DS8611A rudder servo; two JR

DS8231 aileron servos; two JR

DS8231 elevator servos; 4.8-volt,

3000 mAh receiver battery; two 12-

inch aileron extensions; two 18-inch

elevator extensions; two 6-inch

receiver extensions to ailerons

Ready-to-fly weight: 15 pounds

Flight Duration: Exceeds 10 minutes

Additional Equipment Used

Rudder arm: Hangar 9 3D XL Full Servo

Arm 4-40: JR (item HAN3576)

Elevator and aileron arms (four): Hangar 9

3D XL 1/2 Servo Arm 4-40: JR (item

HAN3578)

Du-Bro Exhaust Deflector for .35-.90

Engines (item 697)

Great Planes Easy Fueler Fuel Filler Valve

(item GPMQ4160)

Sullivan Products remote glow plug (item

M021)

Dave Brown Products Trimseal Clear

Control Surface Sealing Material (item

TMSL-5250)

Tru-Turn 31/4-inch Ultimate two-blade

spinner (item TT-3232-B-120)

Tru-Turn 8 x 1.25mm adapter kit (item

TT-0823-A)

Cajun R/C Specialties 33% sport pilot bust

Hangar 9 six-minute quick-set formula

epoxy (item HAN8000)

Hangar 9 30-minute quick-set formula

epoxy (item HAN8002)

Pacer ZAP Thin CA (1-ounce bottle)

December 2007 63

The opposite end of the rod was also threaded, and it fit into a

ball link that secured to the aileron servo arm. I chose the

recommended Hangar 9 anodized aluminum arms, which look

great while increasing the amount of available throw for the

control surfaces.

The wing panels fit onto the fuselage over an aluminum tube,

and alignment pins toward the rear of the root rib fit into holes in

the fuselage to assure that the panels maintain the correct angle

of attack. Each panel is held securely with a 1/4-20 nylon

thumbscrew, making setup and teardown at the field a twominute

quickie.

The horizontal stabilizers are also removable, and they are

almost a complete repop of the wing-panel assembly, except that

the elevator servos ride in bays at the rear of the fuselage sides

instead of in the flying surfaces. An 18-inch extension is required

for each elevator servo.

The rudder linkage is pull-pull, and it sets up nicely with the

infinitely adjustable hardware provided in the kit. My servo

choice was the JR DS8611A digital with a full-length Hangar 9

anodized arm fitted to the output shaft. The carbon-fiber tailwheel

assembly mounts under the rear of the fuselage and uses a

pair of springs to connect the tiller arms to the steering yoke on

the lower edge of the rudder.

Hangar 9 provided a heavy-duty, one-piece, painted carbonfiber

landing-gear assembly and 4-inch wheels for the Extra 260.

These were complemented by a pair of factory-painted fiberglass

wheel pants, which secured to the gear legs with the axle lock

nut and 4-40 socket-head capscrew.

The airplane’s front end could accommodate a number of

power options, from a 1.20 two-stroke glow engine to a 50cc

gasoline power plant and anything in between. I chose the new

Saito 2.20 four-stroke to power my Extra.

At the time the Saito 2.20 was the largest single-cylinder

four-stroke available. It starts easily, runs smoothly, and

produces plenty of power for advanced aerobatics.

Hangar 9 supplied a mount in the 260 kit, and I added a

standard JR 537 servo for throttle control. I also used an Easy

Fueler quick-fueling valve from Great Planes and a remote glow

driver from Sullivan Products. Those two extras allowed me to

access the fuel tank and get light to the engine under that huge

fiberglass cowl.

The Extra’s final assembly involved the fuel tank, fiberglass

cowl, and tinted canopy. Little trimming was required for the

Saito, and I chose a 1/3-scale, factory-painted sport pilot bust

from Cajun R/C to “drive” my Extra. The last steps before flight

were to set the control-surface throws and radio programming,

set the correct CG, and charge the RC system.

Flying the Extra was a kick and a half. I fueled the Saito with

Byron’s 15%-nitro fuel (18% oil), connected my Du-Bro glow

driver, and gave the Tru-Turn 31/4-inch Ultimate spinner a hit

with my Sullivan Megatron starter. The 2.20 fired instantly and

took only a tweak or two to set perfectly.

Pointing the nose into the wind, I powered up, lifted the tail,

and the model gently broke ground. The Extra climbs like a

bandit on the Saito 2.20. Vertical performance is excellent, and

this airplane is capable of anything I can ask for—and much

more.

I performed the rudimentary routine of rolls, loops, inverted

flight, and Split “S” turns. Then I handed the JR XP9303

transmitter to my friend, Brandon Wright, who wrung out the

airplane for the camera and everyone at the flying site.

Spanning slightly more than 76 inches, Hangar 9’s Extra 260

is large. It’s an extremely stable sport flier, yet it can easily

perform any known precision aerobatics schedule or 3-D

maneuver in a capable pilot’s hands. Landings are predictable,

and the airplane exhibits no tendency to drop a tip at low speed.

You can almost bring this one in like a trainer.

Saito 2.20 Four-Stroke

Saito’s FA-220A weighs 42 ounces and

turns 1,900-10,000 rpm with a 17 x 12-20 x

8 propeller. The benchmark is 8,100 rpm

with an APC 19 x 8 propeller.

Complete with Saito’s three-year

warranty from Horizon Hobby, this huge

single-cylinder engine features a swivel

muffler for optimum fitting, a chrome-plated

cylinder, and a new head design for improved

airflow.

Hangar 9 provides a sturdy, adjustable

aluminum engine mount to accommodate all

appropriate glow engines. Side-mounting the

big FA-220A gets the engine inside the cowl

and keeps the cylinder in the airstream.

Fitting a Sullivan Products Head Lock

Remote glow-plug adapter and a Great

Planes Easy Fueler Fuel Filler Valve under the

Extra’s huge fiberglass cowl allows

immediate access for filling or dumping the

tank and starting the engine.

Tru-Turn sells a 31/4-inch machinedaluminum

spinner and an 8 x 1.25mm

spinner adapter kit to fit the FA-220A. The

company offers specialty custom cutting to

accommodate specific propeller brands and

blade counts. MA

—Jeff Troy

The combination of the Hangar 9 Extra Patented!

260, the Saito 2.20 four-stroke, and the JR

XP9303 RC system with digital servos on

the control surfaces produces a top-shelf

model. I’ve had a great time with mine, and

I think most intermediate to advanced RC

pilots will enjoy using the 260 to stretch

their current skills. It’s a nice airplane. MA

Manufacturer/Distributor:

Horizon Hobby

4105 Fieldstone Rd.

Champaign IL 61822

(877) 504-0233

www.horizonhobby.com

Products Used in Review:

Exhaust deflector, glow driver:

Du-Bro

(800) 848-9411

www.dubro.com

Remote glow plug, Megatron starter:

Sullivan Products

(410) 732-3500

www.sullivanproducts.com

Spinner, adapter kit:

Tru-Turn

(281) 479-9600

www.tru-turn.com

Trimseal:

Dave Brown Products

(513) 738-1576

www.dbproducts.com

Pilot bust:

Cajun R/C Specialties

(337) 269-5177

www.cajunrc.com

Other Review Sources:

Fly RC: January 2006

Model Airplane News: April 2006

RCR: April 2006

RCM&E: September 2006