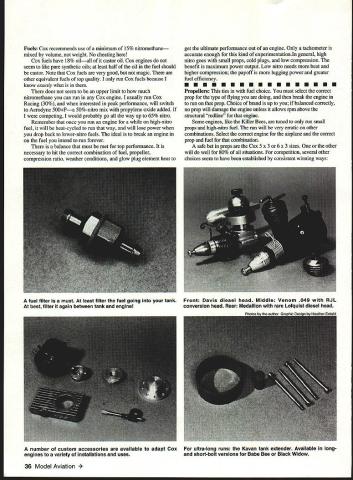

Running Tips Care Repair Customizing EE.EE EE...E n Part June 1996 issue author provided background history Cox E engines Now can learn about care feeding Engine Running Tips essential points consider running Cox engines Choice fuelU Choice propeller Prop balancingU Mounting Starting battery andU Fuel filtration glow-plug clip systemU Cleanliness Break-in COX ENGINES U COX ENGINES U COX ENGINES U 0 0 x m z 0 z m CD U 0 0 x m z 0 ni CD U 0 0 x ENGINES U COX ENGINES U COX ENGIN U.. ENS care & PART II IN feed II I ing Pistonlrod socket tightener Work out aggressions hammer July1996 35 U COX U 41 Fuels Cox recommends use minimum 15% nitromethane mixed volume weight No cheating Cox fuels have 18% oilall castor oil Cox engines seem like pure synthetic oils least half oil fuel should castor Note Cox fuels very good magic other equivalent fuels top quality run Cox fuels because know exactly what does seem upper limit much nitromethane can run Cox engine usually run Cox Racing 30% interested peak performance will switch Aerodyne 500Pa 50%-intro mix propylene oxide added competing would probably go way up 65% nitro Remember once run engine high-nitro fuel will heat-cycled run way will lose power drop back lower-nitro fuels ideal break engine fuel intend run forever balance must met top performance necessary hit correct combination fuel propeller compression ratio weather conditions glow plug element heat get ultimate performance out engine Only tachometer accurate enough kind experimentationIn general high nitro goes small props cold plugs low compression benefit maximum power output Low intro needs heat higher compression payoff lugging power greater fuel efficiency Propellers ties fuel choice must select correct prop type flying doing break engine m run prop Choice brand up balanced correctly no prop will damage engine unless allows rpm above structural redline engine Some engines like Killer Bees tuned run small props high-nitro fuel run will very erratic other combinations Select correct engine airplane correct prop fuel combination safe bet props Cox 5 x 3 6 x 3 sizes other will well 80% situations competition several other choices seem have established consistent winning ways 36 Model Aviation filter must least filter fuel going tank Front Davis diesel head Middle Venom 049 RJL best filter again between tank engine conversion head Rear Medallion rare Lofquist diesel head number custom accessories available adapt Cox ultra-long runs Kavan tank extender Available long engines variety installations uses short-bolt versions Babe Bee Black Widow Texaco events typically use props large size starting 7 x 35 8 x 4 props other end scale Nostalgia Free Flight fliers seem prefer very small propsliketheTomado5x3andAPC55x2 Mouse Racers Combat fliers seem like Tornado 5 x 4 Prop Balancing very important running Cox engines Small models need power can get engine will put out oomph technical term itis running smoothly addition extra power engine airplane will last longer prefer Top Flite magnetic balancer head-and-shoulders better rest Second-best large-wheel variety typified Du-Bro Generally anything better nothing though balancing across knife blade really close worse-than-nothing Balancers will never wear out can used engine prop own Mounting solidly engine mounted faster will run Soft mounts intended reduce noise damageto airframe soft mount always costs rpm unnecessary small engine Use correct size screws large head possible spread loads out Very important mounting surface must flat Any mounting distortion will least cost power worst may trash engine Starting Battery Clips starting system use should provide mediumorange glow glow plug filament times plug just has little visible glow bottom element guaranteed have hard-starting engine Plugs take high current flow poor battery thin wires dirty wealdy attached clip will cause lots grief glow-driver system best because will adapt weather battery charge flooding etc still fire up engine glow driver will overcome poor wiring connections some extent simplest system find effective pair alkaline D-cells soldered parallel cable clip should lamp cord clip must clean provide both friction spring force assure high current flow Fuel Filtration Yes filter fuelwithout qualification fuel passages Cox engine tiny takes almost nothing plug up needle valve will either prevent running make run erratic ideal filter fuel can tank again between tank engine Cox fuel cans have built-in filter Break-In Break-in process both polishing parts mate other stress-relieving parts heat-cycling As prop fuel break-in technique depends use engine Casual flying requires casual break-in full performance requires closer attention sport flying need run engine rich opening needle valve add fuel fuel/air mixture minute begin leaning out closing needle valve somewhat bit time Listen engine attempting sag off overheating suddenly slowing down richen up let cool few moments before leaning out again As soon will hold solid two-cycle peak ready fly will find engine will gain performance over period time probably sacrifice small amount peak performance sport flying cares get peak performance out engine competition may need bit careful break-in first phase let parts polish themselves bit avoid galling scuffing like using low-intro fuel 15% slightly smaller prop planned run bit rich side plan get rpm close final planned range engine lightly loaded running cool About five minutes running way should give surfaces imtial polish clean out assembly oil may have left engine during manufacturing attempting minimize heat stress initial run reason running engine speed finally hope achieve have inertial vibration levels correct rockin-and-rollin happening same running flat-out point need begin heatcycle engine get parts final relaxed shape recommend switching final nitro prop fur type running part run seems like sport breakin intensified Start engine lean out scream Immediately back off rich setting Re-lean engine run high speed few moments longer Continue process longer longer peaks until engine will hold full steady high rpm no tendency sag time peak engine builds heat metal moves bit wear factor goes up engine repolishes itself extra heat generated reason engine will suddenly try sag-off lean Too much heat heating cooling cycles longer heat periods run closer metal will settle its final shape continuous re-fitting process cannot achieved factory During break-in process never let engine sag off lean Dont just let engine run itself Break-in boring process requires constant attention Again engine under maximum stress want rpm roughly will finally run engine properly broken-in engine will easier start will last longer will less sensitive needlevalve setting Basically engine has blueprinted itself Cox tried grinding engine precise fit piston/cylinder tapers Precision Power Tools power better n.Iitv Rip Fence lade Guard Mitre-Guide Cooled Motor Blades Cuts wood up 1/4 thick Tools require Minicraft Power Supply Universal Van-Speed Transformer 1 tool MB730$3495 3 tools MB750$7195 Minicraft tools available oar new home page Internet HTTPJMrWWCFORCCOM/HANGAR Send 2 Minicraft 20 nane Color Catalon Wing span WingArea2455q1n Length ngine049 099 2-4 Ch Mini Radio Req d HOBBY HANGAR 1862 Petersburg Rd Hebron KY 41048 1-800-611-3880 Orders Only 606-334-4330 Customer Serve 606-334-4333 FaxTITh Prices Subject Change Any Time July1996 37 $12995 MB490 with a 5mm Safety Stroke sturdy Die Cast construction y Blade Position Balsa up to 1 5/8 thick & Plywood up 1/2 thick e Size 7 1/2 x 7 1/2 Cooled Motor uIpuvu Iuqu au dsage Lightweight Keyless Chuck Speed Extendable cable st ways keep cool 0 maintain control ROBART HINGE POINTS Simply best hinging system available application Drill hole add drop glue Hinge Point youre hinged DON TEFA ROBART CONTROL HORNS accurate on-center control linkage No need bent kinked control lines use horns built-in rotating ball link Reach other tine ROBART products hobby dealers nationwide ROBART MFG POBOX 1247 STCHARLES IL 60174 708-584-7616 really good-running well-broken-rn engine result awful As soon engine run promptly changed shape wore some other fit didnt work well Cleanliness As fuel filtration must small engines A engine has half larger engines clearance between piston cylinder makes dust dirt twice big hit dirt engine take home clean properly alternative will lose significant amount performance engines life first part next run Engine Care Cleaning clean engine remove backplate head cylinder piston rotating crankshaft Usually necessary pull crankshaft case rotary engine crashed really fine dust tear engine down completely Use good solvent like denatured alcohol kerosene model fuel Use brushes paper towels physically remove dirt just sloshing part solvent somewhat effective necessary remove crankshaft removal reassembly procedure Removal screw size crankshaft 5 x 40 commonly found hobby shops standard hardware size Purchase some hex-head /2-inch 5 x 40 machine screws matching hex wrench After removing backplate cylinder piston engine insert screws shaft far will go Place crankcase rear-end down sheet cardboard cement floor cement solid backing cardboard crankcase wont marred Whup puppy hammer until shaft slides free drive washer Keep screw just removing shafts Reinstallation bit tricky After thoroughly cleaning oiling parts slip shaft engine gently reassemble thrust washer used prop drive plate onto shaft Get drive plate started same grooves used original assembly use stack washers hex screws pull drive plate way down stop shaft Recheck drive plate runs true no wobble Note specify hex-head screw because requires no pushing turned got screwdriver three stitches deep palm hand trying standard slotted screw warned engine apart examine parts damage wear needed use piston reset tool tighten up piston ball socket good time consider removing accumulated varnish cylinder walls see below Reassemble engine good grade oil WD-40 Marvel Mystery 3-InOne seem work OK After-run oils should good preference BreakFreea gun oil Teflon particles wont say sure improvement can bit Teflon hurt Varnish Removal As engine runs certain amount burned oil will accumulate cylinder walls varnish does two things reduces clearance between cylinder piston may generate heat tends get sticky heats up result engine suddenly has difficult time being run up peak rpm holding seems exactly though engine unbroken-in remove varnish coating remove cylinder head head gasket cylinder engine Get pad 000-grade steel wool Wrap strip steel wool around clean dowel scour inside cylinder bore until completely silvery again very difficult harm cylinder bore technique steel wool softer steel cylinder its much harder varnish Clean cylinder solvent Use brush assure residue wool hairs have removed reassemble engine above Piston Resetting technique allows tighten fit between conrod ball socket piston Allowing fit get too loose can cause vibration inaccurate timing breakage find socket usually needs tightened once twice life engine metal eventually wears very smooth work-hardens itself fit eventually remains constant using socket-setter use hammer gently first keep moving position tool around socket key tighten socket evenly possible Keep checking resulting fit achieved no noticeable slop between ball socket no bind Clean piston rod oil socket before reassembling engine Storage keep engines sealed metal box Prior storage get liberal dousing inside out oil again favorite Break-Free would excellent idea throw bag desiccant engines stop rust Miscellaneous Thoughts Keep screws tight Plastic can cold-flow check screws remain snugly tight Tee Dee Medallion engines check carburetor body retaining nut silver ring behind prop drive snug Air leaks place another source starting problems Glow heads loosen up themselves check tightness run gasket looks worn torn replace Look plastic parts cracks rubber Hycar washers back tank can harden should replaced 38 Model Aviation RT HINGE POINTS AND CONTROL HORNS. look suspicious Backplates rotary-valve engines can also loosen themselves Castor oil gums up engine used expect have clean out fuel system run full tank through engine slow speed fire up again Fuel absorbs water amazing rate keep fuel can sealed well between flights Engine Repair isnt really much can repair model engine Generally situation finding problem replacing parts hobby shop cant get parts distributor tell Cox has no-minimum policy part purchases dealers addition can purchase parts direct Cox through Customer Service toll-free hot line 800 451-0339 Some things worth knowing about servicing engines can free up old gunky engine warming film-shrinking iron boiling water can clean almost anything off old engine boiling dishwasher detergent screws Cox engines standard sizes2-56 3-48 4-40 5-40 etc None other threads used anyone else get all-custom taps Customer Service has list thread definitions just have have Glow heads can bad variety reasons obvious dont glow also possible upper seals leak element have aluminum coating fused will limit ability catalyze combustion process doubt look element under microscope element shiny like jewelry probably shot usually good idea keep pistons cylinders matched pairs Once parts have broken together lose fit sport flying can mix performance will vary wildly LDM Industries Model Accessories Universal Servo Tray measures 23 42 inches designed hold over 50 different standard mid-size servos 2 yle tray features adjustable mounting brackets molded tough glass filled nylon durability Part #6000 . Universal Servo Tray .. $495 Con-Do-It Con-Do-It clear PVC tubing withal /2 outside diameter 023 wall thickness Con-Do-It provides neat simple way running servo lead extensions fuel lines air lines wiring harnesses through model package contains two 24 pieces Con-Do-It Part #7500Con-Do-It$495 Model Chocks lock place models axles prevent model rolling around car during transport flying field packaged sets two designed fit 5/32 axles up 3 diameter wheels Part #7000Model Chocks$395 order send check money order including $400 S&H LDM Industries Inc PO Box 292396 Tampa FL 33687-2396 Phone 813 991-4277 Fax 813 991-4810 Florida residents add 6% sales tax VISA and MASTER CARD Accepted 1996 LDM Industries Inc A~[W IN Pa N 4161 IIU INN IN 4 .This product am going use time go flying Dick Pettit RC Report .I have using Advanced Aero Fueler past several months problems associated fuel have gone away~ Paul Tradelius Model Aviation Safe easy use Advanced Aero Fueler will enhance modelers flight kit Helps prevent fuel evaporation moisture absorption possible spills may lead fires explosions Gas glow bottles cans $1495 22nd Century Aero Products 2763 West Ave L Suite 295 Lancaster CA 93536 800 273-AERO Distributed Horizon Hobby Distributors Ask local retailer order direct Please add $400 S/H July1996 39 Universal Servo Tray Model Chocks SERVO SLOW MAY SAVE YOUR PLANE lOSxs Servo Slow feature allows adjustment servo speed electronically its fastest speed down 10/sec rate flaps brakes canopies naturals Servo Slow other applications may provide great benefit creative modelers possibility throttle fire walling throttle takeoff sudden increase torque can cause plane ground loop worse rudder added too little too late difficult coordination maneuver compounded because things happen fast Now lets slow throttle servo down After throttle response made linear using lOSx Lo-Base feature can digitally reduce servo speed Experimentation will provide answer right speed application sport taildragger choose 400/sec rate gave 3 second transit advantage obvious After firewalling throttle steering adjust ments made stick against stop Since airplane accelerates smooth ly rudder corrections infinitely easier air smoother throttle helped flying over landing minor throttle adjustments happen fast enough servo slow unnoticeable Try Servo Slow JR technology makes modeling enjoyable JR Customizing Any modfication Ccx engine voids warranty Read section own risk Several modifications mentioned can work done right will always make engine warranty kaput two types engine rework best type simply assemble engine need specific application correct set parts second type hop-up tuning will deal topics separately Custom Setups trick understand what need application know what parts available let achieve result few standard applications get given below Control Line Stunt need engine good power key achieve ultimate steady running usually necessary muffle engine too Two examples shown photograph engine use Me-109 stunter other set up flying fully competitive Stunt model Engine uses crankcase crankshaft cylinder piston Killer Bee smooth out run increase ability run large prop standard ready-to-fly product backplate substituted bored-out provided Killer Bee Again achieve steady run under varied loads plus provide extra cooling head Texaco engine substituted high-compression head normally found Killer Bee second engine started Tee Dee R/C 05 Control Line venturi substituted RC carburetor Texaco head substituted same reasons before addition steadier run can achieved tapping muffler pressure tank still power needed drill out venturi bigger diameter use side tap engine per free flight engine instructions Diesel Several diesel-type conversions shown photo two heads currently available RJL Box 5 Sierra Madre CA 91025 Davis Diesel Box 141 Milford CT 06460 RJL uses 0-ring seal Davis uses Teflon disks destructible seal RJL has lock arm fix compression lever Davis uses spring system knob Both work just fine both will instantly void warranty engine keys successful diesel operation pick adequately strong components use absolutely fresh fuel high ether content Small diesels need lots etherup 50% engines shown Venom Medallion crankshafts engines least likely break under mistreatment dished out diesel operation Since goal running diesel get long duration swing large props ideal engine would Venom front end Texaco tank backplate Venom will punch out power durable Texaco tank backplate have small venturi maximum duration smooth running low speeds couple words about using mufflers exhaust restrictors RC throttling As mentioned first engine article thing exhaust ports called sub-piston induction SPI piston uncovers bottom exhaust port top-dead-center some air allowed go under piston crankcase used open-exhaust engines get last little bit performance SPI instant death running muffler exhaust restriction throttle system going use muffler sure select cylinder no SPI using muffler SPI exhaust gas pumped down crankcase good 2000 3000 lost rpm Longer Runs addition running diesel couple techniques get longer engine-run times first use tank Dragonfly has 11cc capacity compared Black WidowNenomlTexaco capacity 8cc addition shown photo tank extender Kavan available through Hobby Lobby International 5614 Franklin Pike Circle Brentwood TN 37027 Tel [615] 373-1444 Different Heads least four manufacturers heads allow use standard glow plugs special plugs Cox engines units may used economy sport engines higher performance competition depending unit selected RJL Charlies conversions allow use short regular plugs GloBee Galbreath heads allow use GloBee inserts Nelson plugs pay money get out tachometer start experimenting find what best GloBee heads available number distributors Galbreath heads available Doug Galbreath 3408 Topsail P1 Davis CA 95616 Hop-Ups practical hop-up average individual carefully tune combination bead gaskets nitro content prop match airplane will get 90% way next-most-effective procedure set up pressure fuel system drill out venturi allow air enter engine will get 98% maximum possible performance Beyond get pro stuff Serious engine hop-up involves lots experimentation scrapped parts 40 Model Aviation ER SEVEN IN SERIES Experience testing patience deep wallet main requirements success casual modeler doesnt record results experiments really own Any stuff will void warranty often will hop-down engine rather hop up An entire new article expert engine hop-up would needed really cover subject will describe types true modifications people Hop-ups usually start custom fitting parts selection lapping techniques people modify timing cylinder ports crankshaft ports Shimming cylinder up down achieve timing changes way done Another technique timing changes actually machine dimensions parts differently Extreme hop-ups involve engine re-design use such things full Schnuerle porting ball bearings People machine own cylinders crankcases tuned-pipe systems depends what want much time expertise money have Conclusions First can have terrific amount fun small engines Cox leader worldwide currently about dozen Cox 049 variations suit possible needs hobby exact combination need isnt available can put together what want Second get satisfactory peiformance small engines need care big enginesnot less rarely get kind careful attention need Think flying engine after crash just slosh fuel hose off dirt similar pouring cup sand down Weber carbs Ferrari Third best performance what need easy sensible stuff 95% what need know nutshell Cleanliness Have realistic understanding what engines can dont overprop over rev Select right engine airplane Choose fuel high enough nitro oil content few items will make seem instant expert point hobby have fun Learning get out engines will make lot easier have fun hope pair articles has provided basics need piqued interest learning about fascinating bits running jewelry y Renger 13182 Sutton St Cerritos CA 90703 Wh&s&Wmg Orders Only Please ft Wont Undersold see lower price call! Shipping 495! Futaba ml 6VAS19999 4NBF $13999 4NBL 1~lQQ S-148 SPECIAL rnrn 3 3999 1299 en addI eutana ervos S132H Sl48w/Hdwe S300 I/metal S3002Mini S3003 SId 53101 micro S3002mini 53302 114 53303 l/4Mtl S5IOIBB 55102 Micro BB 59101 RB MS S9102 BB LP S9202 BB SHT 59203 RB S9303 RB MG MT 59402 BB HS S9601 BR Mini 3594 1694 2594 5794 1594 3594 5594 5694 5794 4294 5594 5694 7994 5594 9494 6994 9494 5694 Futaba Accessories CiystalsCall AileronExt594to79 AECI3 V Harness9.9 Tx RX batteries froml59 Trainer Cordl39 Glow Plug Speeiaia Fox RIC Long 6for 1299 l2for 1799 K&B R/C Long 6 1499 12 2299 McDaniel NiStarters 101/2011999/2299 Coverite 21st Century Iron 2899 Sullivan 600/6013299/3599 Dynatron5299 JR Radios XF-62226494 F-40015894 XP783FM38894 XP783PCM44894 PCMIOS 899 Free shipping JR Servos 5071794 5172394 3413894 41316494 47216994 HiteclRCD Servos 0300S SId 1199 0422 Pro 1699 0605 Ultra 3599 0705 Giants 4299 Specify Air Fut Jr qp MIDWEST g paomucrS CO. INC Super Hots 8999 Malibu 5799 Aero-Star 406999 Aero-Star 6011699 Mustng/Mssrschmt 7399 Sukhoi 8299 Mustang 6011599 Corsair 408599 Cherokee 409699 AT6/Extra30023499 ~ARL GOLDBERG Electra Dlx Mirage 550 Falcon Ill Super Chipnmk Ultimate Ripe Extra 300 Eagle2 Sophistd Lady Gentle Lady Anniver Cub Tiger 2 40 Tiger 2 60 Sukhoi Float Kit 5199 5999 6199 10899 13299 12699 5499 3499 2899 6699 6199 8899 14399 3799 I20% Off Retail @miiu Lanier RC SIG US Air Coree will honor advertised price magazine! call other models 3 Ril5pdal 3Ragfm $2199 Ultracote Jltracote99 earls & Flrscnt139 Jtracote Plus114 Jitracote PIs FIr139 AoKoTE paque 92 earls/Metallics 119 eons 139 25 3 799/4599/ 479 Coverite 21st Century film 889 21st Cent fabric 1389 21st Fabric 15 JetSuper Slow 2 oz $679 Buy 3 & Save 60 ea 3 S1857 NHP CA Glues Thin Medium Thick oz28 oz49 Guaranteed freshest Epoxies 6 0 Minute 9 ounce 699 A-50 18494 A-65 19394 A-80 21394 A-9lS 24494 A-l20S 34894 Salto 150 L Retail Onh $599953699 Upgrade Golden Knight $17 f shipping GP 15ABC4994 GP 25ARC5694 GP 40ARC5994 GP6IABC9494 PRO2SABC8494 PR036ABC8994 PRO4OARC9494 PR046 ARC9994 PRO6I ARC14894 PRO9I22494 prices include shipping rn 05 45 FP 5794 0565 PP10494 0540 SF9994 0546 SF4694 0546 ASC15594 OS 61SF 21594 prices include shipping coil other models webra Silverline40 6994 Silverilne 61 9894 Speed 120 24994 Fox 40 BR STD 7799 40 SB DLX 8794 46 RB ARC 9794 MAcfl 45 Sportster 65 Sportster 40 w/mfi 61 R/C w/m 6499 6799 6799 8499 Add 5495 5 H & ins up en 56 0/S pkgs mis S795 2nd day & Next Day available COD orders available continental USA add $595 COD fee PricesarecaslspricexCCsurclsg i9% Money Ordon ship withouc delay Allow 14 days personal checks clear Due advertising deadlines & circumstances beyond ourcontrol availability specs & prices subject change merchandise cames tisanufacisseers wamuty Retssnts subject restocking fee Wheels & Wings etca 7620 LyndaleAveS MinneapolisMN 55423 1-800-896-2582 Orders Only Please! Information other inquiries call 1-612-861-6261 Name _____________ Order City _________________St_____ Zip CodePhone_________ Form ItemDescrlolionPrice CCMO/Check_____Subtotal_________ Credit Card#_________________ SalesTax:________ SignatureTOTAL $ July1996 43

Edition: Model Aviation - 1996/07

Page Numbers: 35, 36, 37, 38, 39, 40, 43

Running Tips Care Repair Customizing EE.EE EE...E n Part June 1996 issue author provided background history Cox E engines Now can learn about care feeding Engine Running Tips essential points consider running Cox engines Choice fuelU Choice propeller Prop balancingU Mounting Starting battery andU Fuel filtration glow-plug clip systemU Cleanliness Break-in COX ENGINES U COX ENGINES U COX ENGINES U 0 0 x m z 0 z m CD U 0 0 x m z 0 ni CD U 0 0 x ENGINES U COX ENGINES U COX ENGIN U.. ENS care & PART II IN feed II I ing Pistonlrod socket tightener Work out aggressions hammer July1996 35 U COX U 41 Fuels Cox recommends use minimum 15% nitromethane mixed volume weight No cheating Cox fuels have 18% oilall castor oil Cox engines seem like pure synthetic oils least half oil fuel should castor Note Cox fuels very good magic other equivalent fuels top quality run Cox fuels because know exactly what does seem upper limit much nitromethane can run Cox engine usually run Cox Racing 30% interested peak performance will switch Aerodyne 500Pa 50%-intro mix propylene oxide added competing would probably go way up 65% nitro Remember once run engine high-nitro fuel will heat-cycled run way will lose power drop back lower-nitro fuels ideal break engine fuel intend run forever balance must met top performance necessary hit correct combination fuel propeller compression ratio weather conditions glow plug element heat get ultimate performance out engine Only tachometer accurate enough kind experimentationIn general high nitro goes small props cold plugs low compression benefit maximum power output Low intro needs heat higher compression payoff lugging power greater fuel efficiency Propellers ties fuel choice must select correct prop type flying doing break engine m run prop Choice brand up balanced correctly no prop will damage engine unless allows rpm above structural redline engine Some engines like Killer Bees tuned run small props high-nitro fuel run will very erratic other combinations Select correct engine airplane correct prop fuel combination safe bet props Cox 5 x 3 6 x 3 sizes other will well 80% situations competition several other choices seem have established consistent winning ways 36 Model Aviation filter must least filter fuel going tank Front Davis diesel head Middle Venom 049 RJL best filter again between tank engine conversion head Rear Medallion rare Lofquist diesel head number custom accessories available adapt Cox ultra-long runs Kavan tank extender Available long engines variety installations uses short-bolt versions Babe Bee Black Widow Texaco events typically use props large size starting 7 x 35 8 x 4 props other end scale Nostalgia Free Flight fliers seem prefer very small propsliketheTomado5x3andAPC55x2 Mouse Racers Combat fliers seem like Tornado 5 x 4 Prop Balancing very important running Cox engines Small models need power can get engine will put out oomph technical term itis running smoothly addition extra power engine airplane will last longer prefer Top Flite magnetic balancer head-and-shoulders better rest Second-best large-wheel variety typified Du-Bro Generally anything better nothing though balancing across knife blade really close worse-than-nothing Balancers will never wear out can used engine prop own Mounting solidly engine mounted faster will run Soft mounts intended reduce noise damageto airframe soft mount always costs rpm unnecessary small engine Use correct size screws large head possible spread loads out Very important mounting surface must flat Any mounting distortion will least cost power worst may trash engine Starting Battery Clips starting system use should provide mediumorange glow glow plug filament times plug just has little visible glow bottom element guaranteed have hard-starting engine Plugs take high current flow poor battery thin wires dirty wealdy attached clip will cause lots grief glow-driver system best because will adapt weather battery charge flooding etc still fire up engine glow driver will overcome poor wiring connections some extent simplest system find effective pair alkaline D-cells soldered parallel cable clip should lamp cord clip must clean provide both friction spring force assure high current flow Fuel Filtration Yes filter fuelwithout qualification fuel passages Cox engine tiny takes almost nothing plug up needle valve will either prevent running make run erratic ideal filter fuel can tank again between tank engine Cox fuel cans have built-in filter Break-In Break-in process both polishing parts mate other stress-relieving parts heat-cycling As prop fuel break-in technique depends use engine Casual flying requires casual break-in full performance requires closer attention sport flying need run engine rich opening needle valve add fuel fuel/air mixture minute begin leaning out closing needle valve somewhat bit time Listen engine attempting sag off overheating suddenly slowing down richen up let cool few moments before leaning out again As soon will hold solid two-cycle peak ready fly will find engine will gain performance over period time probably sacrifice small amount peak performance sport flying cares get peak performance out engine competition may need bit careful break-in first phase let parts polish themselves bit avoid galling scuffing like using low-intro fuel 15% slightly smaller prop planned run bit rich side plan get rpm close final planned range engine lightly loaded running cool About five minutes running way should give surfaces imtial polish clean out assembly oil may have left engine during manufacturing attempting minimize heat stress initial run reason running engine speed finally hope achieve have inertial vibration levels correct rockin-and-rollin happening same running flat-out point need begin heatcycle engine get parts final relaxed shape recommend switching final nitro prop fur type running part run seems like sport breakin intensified Start engine lean out scream Immediately back off rich setting Re-lean engine run high speed few moments longer Continue process longer longer peaks until engine will hold full steady high rpm no tendency sag time peak engine builds heat metal moves bit wear factor goes up engine repolishes itself extra heat generated reason engine will suddenly try sag-off lean Too much heat heating cooling cycles longer heat periods run closer metal will settle its final shape continuous re-fitting process cannot achieved factory During break-in process never let engine sag off lean Dont just let engine run itself Break-in boring process requires constant attention Again engine under maximum stress want rpm roughly will finally run engine properly broken-in engine will easier start will last longer will less sensitive needlevalve setting Basically engine has blueprinted itself Cox tried grinding engine precise fit piston/cylinder tapers Precision Power Tools power better n.Iitv Rip Fence lade Guard Mitre-Guide Cooled Motor Blades Cuts wood up 1/4 thick Tools require Minicraft Power Supply Universal Van-Speed Transformer 1 tool MB730$3495 3 tools MB750$7195 Minicraft tools available oar new home page Internet HTTPJMrWWCFORCCOM/HANGAR Send 2 Minicraft 20 nane Color Catalon Wing span WingArea2455q1n Length ngine049 099 2-4 Ch Mini Radio Req d HOBBY HANGAR 1862 Petersburg Rd Hebron KY 41048 1-800-611-3880 Orders Only 606-334-4330 Customer Serve 606-334-4333 FaxTITh Prices Subject Change Any Time July1996 37 $12995 MB490 with a 5mm Safety Stroke sturdy Die Cast construction y Blade Position Balsa up to 1 5/8 thick & Plywood up 1/2 thick e Size 7 1/2 x 7 1/2 Cooled Motor uIpuvu Iuqu au dsage Lightweight Keyless Chuck Speed Extendable cable st ways keep cool 0 maintain control ROBART HINGE POINTS Simply best hinging system available application Drill hole add drop glue Hinge Point youre hinged DON TEFA ROBART CONTROL HORNS accurate on-center control linkage No need bent kinked control lines use horns built-in rotating ball link Reach other tine ROBART products hobby dealers nationwide ROBART MFG POBOX 1247 STCHARLES IL 60174 708-584-7616 really good-running well-broken-rn engine result awful As soon engine run promptly changed shape wore some other fit didnt work well Cleanliness As fuel filtration must small engines A engine has half larger engines clearance between piston cylinder makes dust dirt twice big hit dirt engine take home clean properly alternative will lose significant amount performance engines life first part next run Engine Care Cleaning clean engine remove backplate head cylinder piston rotating crankshaft Usually necessary pull crankshaft case rotary engine crashed really fine dust tear engine down completely Use good solvent like denatured alcohol kerosene model fuel Use brushes paper towels physically remove dirt just sloshing part solvent somewhat effective necessary remove crankshaft removal reassembly procedure Removal screw size crankshaft 5 x 40 commonly found hobby shops standard hardware size Purchase some hex-head /2-inch 5 x 40 machine screws matching hex wrench After removing backplate cylinder piston engine insert screws shaft far will go Place crankcase rear-end down sheet cardboard cement floor cement solid backing cardboard crankcase wont marred Whup puppy hammer until shaft slides free drive washer Keep screw just removing shafts Reinstallation bit tricky After thoroughly cleaning oiling parts slip shaft engine gently reassemble thrust washer used prop drive plate onto shaft Get drive plate started same grooves used original assembly use stack washers hex screws pull drive plate way down stop shaft Recheck drive plate runs true no wobble Note specify hex-head screw because requires no pushing turned got screwdriver three stitches deep palm hand trying standard slotted screw warned engine apart examine parts damage wear needed use piston reset tool tighten up piston ball socket good time consider removing accumulated varnish cylinder walls see below Reassemble engine good grade oil WD-40 Marvel Mystery 3-InOne seem work OK After-run oils should good preference BreakFreea gun oil Teflon particles wont say sure improvement can bit Teflon hurt Varnish Removal As engine runs certain amount burned oil will accumulate cylinder walls varnish does two things reduces clearance between cylinder piston may generate heat tends get sticky heats up result engine suddenly has difficult time being run up peak rpm holding seems exactly though engine unbroken-in remove varnish coating remove cylinder head head gasket cylinder engine Get pad 000-grade steel wool Wrap strip steel wool around clean dowel scour inside cylinder bore until completely silvery again very difficult harm cylinder bore technique steel wool softer steel cylinder its much harder varnish Clean cylinder solvent Use brush assure residue wool hairs have removed reassemble engine above Piston Resetting technique allows tighten fit between conrod ball socket piston Allowing fit get too loose can cause vibration inaccurate timing breakage find socket usually needs tightened once twice life engine metal eventually wears very smooth work-hardens itself fit eventually remains constant using socket-setter use hammer gently first keep moving position tool around socket key tighten socket evenly possible Keep checking resulting fit achieved no noticeable slop between ball socket no bind Clean piston rod oil socket before reassembling engine Storage keep engines sealed metal box Prior storage get liberal dousing inside out oil again favorite Break-Free would excellent idea throw bag desiccant engines stop rust Miscellaneous Thoughts Keep screws tight Plastic can cold-flow check screws remain snugly tight Tee Dee Medallion engines check carburetor body retaining nut silver ring behind prop drive snug Air leaks place another source starting problems Glow heads loosen up themselves check tightness run gasket looks worn torn replace Look plastic parts cracks rubber Hycar washers back tank can harden should replaced 38 Model Aviation RT HINGE POINTS AND CONTROL HORNS. look suspicious Backplates rotary-valve engines can also loosen themselves Castor oil gums up engine used expect have clean out fuel system run full tank through engine slow speed fire up again Fuel absorbs water amazing rate keep fuel can sealed well between flights Engine Repair isnt really much can repair model engine Generally situation finding problem replacing parts hobby shop cant get parts distributor tell Cox has no-minimum policy part purchases dealers addition can purchase parts direct Cox through Customer Service toll-free hot line 800 451-0339 Some things worth knowing about servicing engines can free up old gunky engine warming film-shrinking iron boiling water can clean almost anything off old engine boiling dishwasher detergent screws Cox engines standard sizes2-56 3-48 4-40 5-40 etc None other threads used anyone else get all-custom taps Customer Service has list thread definitions just have have Glow heads can bad variety reasons obvious dont glow also possible upper seals leak element have aluminum coating fused will limit ability catalyze combustion process doubt look element under microscope element shiny like jewelry probably shot usually good idea keep pistons cylinders matched pairs Once parts have broken together lose fit sport flying can mix performance will vary wildly LDM Industries Model Accessories Universal Servo Tray measures 23 42 inches designed hold over 50 different standard mid-size servos 2 yle tray features adjustable mounting brackets molded tough glass filled nylon durability Part #6000 . Universal Servo Tray .. $495 Con-Do-It Con-Do-It clear PVC tubing withal /2 outside diameter 023 wall thickness Con-Do-It provides neat simple way running servo lead extensions fuel lines air lines wiring harnesses through model package contains two 24 pieces Con-Do-It Part #7500Con-Do-It$495 Model Chocks lock place models axles prevent model rolling around car during transport flying field packaged sets two designed fit 5/32 axles up 3 diameter wheels Part #7000Model Chocks$395 order send check money order including $400 S&H LDM Industries Inc PO Box 292396 Tampa FL 33687-2396 Phone 813 991-4277 Fax 813 991-4810 Florida residents add 6% sales tax VISA and MASTER CARD Accepted 1996 LDM Industries Inc A~[W IN Pa N 4161 IIU INN IN 4 .This product am going use time go flying Dick Pettit RC Report .I have using Advanced Aero Fueler past several months problems associated fuel have gone away~ Paul Tradelius Model Aviation Safe easy use Advanced Aero Fueler will enhance modelers flight kit Helps prevent fuel evaporation moisture absorption possible spills may lead fires explosions Gas glow bottles cans $1495 22nd Century Aero Products 2763 West Ave L Suite 295 Lancaster CA 93536 800 273-AERO Distributed Horizon Hobby Distributors Ask local retailer order direct Please add $400 S/H July1996 39 Universal Servo Tray Model Chocks SERVO SLOW MAY SAVE YOUR PLANE lOSxs Servo Slow feature allows adjustment servo speed electronically its fastest speed down 10/sec rate flaps brakes canopies naturals Servo Slow other applications may provide great benefit creative modelers possibility throttle fire walling throttle takeoff sudden increase torque can cause plane ground loop worse rudder added too little too late difficult coordination maneuver compounded because things happen fast Now lets slow throttle servo down After throttle response made linear using lOSx Lo-Base feature can digitally reduce servo speed Experimentation will provide answer right speed application sport taildragger choose 400/sec rate gave 3 second transit advantage obvious After firewalling throttle steering adjust ments made stick against stop Since airplane accelerates smooth ly rudder corrections infinitely easier air smoother throttle helped flying over landing minor throttle adjustments happen fast enough servo slow unnoticeable Try Servo Slow JR technology makes modeling enjoyable JR Customizing Any modfication Ccx engine voids warranty Read section own risk Several modifications mentioned can work done right will always make engine warranty kaput two types engine rework best type simply assemble engine need specific application correct set parts second type hop-up tuning will deal topics separately Custom Setups trick understand what need application know what parts available let achieve result few standard applications get given below Control Line Stunt need engine good power key achieve ultimate steady running usually necessary muffle engine too Two examples shown photograph engine use Me-109 stunter other set up flying fully competitive Stunt model Engine uses crankcase crankshaft cylinder piston Killer Bee smooth out run increase ability run large prop standard ready-to-fly product backplate substituted bored-out provided Killer Bee Again achieve steady run under varied loads plus provide extra cooling head Texaco engine substituted high-compression head normally found Killer Bee second engine started Tee Dee R/C 05 Control Line venturi substituted RC carburetor Texaco head substituted same reasons before addition steadier run can achieved tapping muffler pressure tank still power needed drill out venturi bigger diameter use side tap engine per free flight engine instructions Diesel Several diesel-type conversions shown photo two heads currently available RJL Box 5 Sierra Madre CA 91025 Davis Diesel Box 141 Milford CT 06460 RJL uses 0-ring seal Davis uses Teflon disks destructible seal RJL has lock arm fix compression lever Davis uses spring system knob Both work just fine both will instantly void warranty engine keys successful diesel operation pick adequately strong components use absolutely fresh fuel high ether content Small diesels need lots etherup 50% engines shown Venom Medallion crankshafts engines least likely break under mistreatment dished out diesel operation Since goal running diesel get long duration swing large props ideal engine would Venom front end Texaco tank backplate Venom will punch out power durable Texaco tank backplate have small venturi maximum duration smooth running low speeds couple words about using mufflers exhaust restrictors RC throttling As mentioned first engine article thing exhaust ports called sub-piston induction SPI piston uncovers bottom exhaust port top-dead-center some air allowed go under piston crankcase used open-exhaust engines get last little bit performance SPI instant death running muffler exhaust restriction throttle system going use muffler sure select cylinder no SPI using muffler SPI exhaust gas pumped down crankcase good 2000 3000 lost rpm Longer Runs addition running diesel couple techniques get longer engine-run times first use tank Dragonfly has 11cc capacity compared Black WidowNenomlTexaco capacity 8cc addition shown photo tank extender Kavan available through Hobby Lobby International 5614 Franklin Pike Circle Brentwood TN 37027 Tel [615] 373-1444 Different Heads least four manufacturers heads allow use standard glow plugs special plugs Cox engines units may used economy sport engines higher performance competition depending unit selected RJL Charlies conversions allow use short regular plugs GloBee Galbreath heads allow use GloBee inserts Nelson plugs pay money get out tachometer start experimenting find what best GloBee heads available number distributors Galbreath heads available Doug Galbreath 3408 Topsail P1 Davis CA 95616 Hop-Ups practical hop-up average individual carefully tune combination bead gaskets nitro content prop match airplane will get 90% way next-most-effective procedure set up pressure fuel system drill out venturi allow air enter engine will get 98% maximum possible performance Beyond get pro stuff Serious engine hop-up involves lots experimentation scrapped parts 40 Model Aviation ER SEVEN IN SERIES Experience testing patience deep wallet main requirements success casual modeler doesnt record results experiments really own Any stuff will void warranty often will hop-down engine rather hop up An entire new article expert engine hop-up would needed really cover subject will describe types true modifications people Hop-ups usually start custom fitting parts selection lapping techniques people modify timing cylinder ports crankshaft ports Shimming cylinder up down achieve timing changes way done Another technique timing changes actually machine dimensions parts differently Extreme hop-ups involve engine re-design use such things full Schnuerle porting ball bearings People machine own cylinders crankcases tuned-pipe systems depends what want much time expertise money have Conclusions First can have terrific amount fun small engines Cox leader worldwide currently about dozen Cox 049 variations suit possible needs hobby exact combination need isnt available can put together what want Second get satisfactory peiformance small engines need care big enginesnot less rarely get kind careful attention need Think flying engine after crash just slosh fuel hose off dirt similar pouring cup sand down Weber carbs Ferrari Third best performance what need easy sensible stuff 95% what need know nutshell Cleanliness Have realistic understanding what engines can dont overprop over rev Select right engine airplane Choose fuel high enough nitro oil content few items will make seem instant expert point hobby have fun Learning get out engines will make lot easier have fun hope pair articles has provided basics need piqued interest learning about fascinating bits running jewelry y Renger 13182 Sutton St Cerritos CA 90703 Wh&s&Wmg Orders Only Please ft Wont Undersold see lower price call! Shipping 495! Futaba ml 6VAS19999 4NBF $13999 4NBL 1~lQQ S-148 SPECIAL rnrn 3 3999 1299 en addI eutana ervos S132H Sl48w/Hdwe S300 I/metal S3002Mini S3003 SId 53101 micro S3002mini 53302 114 53303 l/4Mtl S5IOIBB 55102 Micro BB 59101 RB MS S9102 BB LP S9202 BB SHT 59203 RB S9303 RB MG MT 59402 BB HS S9601 BR Mini 3594 1694 2594 5794 1594 3594 5594 5694 5794 4294 5594 5694 7994 5594 9494 6994 9494 5694 Futaba Accessories CiystalsCall AileronExt594to79 AECI3 V Harness9.9 Tx RX batteries froml59 Trainer Cordl39 Glow Plug Speeiaia Fox RIC Long 6for 1299 l2for 1799 K&B R/C Long 6 1499 12 2299 McDaniel NiStarters 101/2011999/2299 Coverite 21st Century Iron 2899 Sullivan 600/6013299/3599 Dynatron5299 JR Radios XF-62226494 F-40015894 XP783FM38894 XP783PCM44894 PCMIOS 899 Free shipping JR Servos 5071794 5172394 3413894 41316494 47216994 HiteclRCD Servos 0300S SId 1199 0422 Pro 1699 0605 Ultra 3599 0705 Giants 4299 Specify Air Fut Jr qp MIDWEST g paomucrS CO. INC Super Hots 8999 Malibu 5799 Aero-Star 406999 Aero-Star 6011699 Mustng/Mssrschmt 7399 Sukhoi 8299 Mustang 6011599 Corsair 408599 Cherokee 409699 AT6/Extra30023499 ~ARL GOLDBERG Electra Dlx Mirage 550 Falcon Ill Super Chipnmk Ultimate Ripe Extra 300 Eagle2 Sophistd Lady Gentle Lady Anniver Cub Tiger 2 40 Tiger 2 60 Sukhoi Float Kit 5199 5999 6199 10899 13299 12699 5499 3499 2899 6699 6199 8899 14399 3799 I20% Off Retail @miiu Lanier RC SIG US Air Coree will honor advertised price magazine! call other models 3 Ril5pdal 3Ragfm $2199 Ultracote Jltracote99 earls & Flrscnt139 Jtracote Plus114 Jitracote PIs FIr139 AoKoTE paque 92 earls/Metallics 119 eons 139 25 3 799/4599/ 479 Coverite 21st Century film 889 21st Cent fabric 1389 21st Fabric 15 JetSuper Slow 2 oz $679 Buy 3 & Save 60 ea 3 S1857 NHP CA Glues Thin Medium Thick oz28 oz49 Guaranteed freshest Epoxies 6 0 Minute 9 ounce 699 A-50 18494 A-65 19394 A-80 21394 A-9lS 24494 A-l20S 34894 Salto 150 L Retail Onh $599953699 Upgrade Golden Knight $17 f shipping GP 15ABC4994 GP 25ARC5694 GP 40ARC5994 GP6IABC9494 PRO2SABC8494 PR036ABC8994 PRO4OARC9494 PR046 ARC9994 PRO6I ARC14894 PRO9I22494 prices include shipping rn 05 45 FP 5794 0565 PP10494 0540 SF9994 0546 SF4694 0546 ASC15594 OS 61SF 21594 prices include shipping coil other models webra Silverline40 6994 Silverilne 61 9894 Speed 120 24994 Fox 40 BR STD 7799 40 SB DLX 8794 46 RB ARC 9794 MAcfl 45 Sportster 65 Sportster 40 w/mfi 61 R/C w/m 6499 6799 6799 8499 Add 5495 5 H & ins up en 56 0/S pkgs mis S795 2nd day & Next Day available COD orders available continental USA add $595 COD fee PricesarecaslspricexCCsurclsg i9% Money Ordon ship withouc delay Allow 14 days personal checks clear Due advertising deadlines & circumstances beyond ourcontrol availability specs & prices subject change merchandise cames tisanufacisseers wamuty Retssnts subject restocking fee Wheels & Wings etca 7620 LyndaleAveS MinneapolisMN 55423 1-800-896-2582 Orders Only Please! Information other inquiries call 1-612-861-6261 Name _____________ Order City _________________St_____ Zip CodePhone_________ Form ItemDescrlolionPrice CCMO/Check_____Subtotal_________ Credit Card#_________________ SalesTax:________ SignatureTOTAL $ July1996 43

Edition: Model Aviation - 1996/07

Page Numbers: 35, 36, 37, 38, 39, 40, 43

Running Tips Care Repair Customizing EE.EE EE...E n Part June 1996 issue author provided background history Cox E engines Now can learn about care feeding Engine Running Tips essential points consider running Cox engines Choice fuelU Choice propeller Prop balancingU Mounting Starting battery andU Fuel filtration glow-plug clip systemU Cleanliness Break-in COX ENGINES U COX ENGINES U COX ENGINES U 0 0 x m z 0 z m CD U 0 0 x m z 0 ni CD U 0 0 x ENGINES U COX ENGINES U COX ENGIN U.. ENS care & PART II IN feed II I ing Pistonlrod socket tightener Work out aggressions hammer July1996 35 U COX U 41 Fuels Cox recommends use minimum 15% nitromethane mixed volume weight No cheating Cox fuels have 18% oilall castor oil Cox engines seem like pure synthetic oils least half oil fuel should castor Note Cox fuels very good magic other equivalent fuels top quality run Cox fuels because know exactly what does seem upper limit much nitromethane can run Cox engine usually run Cox Racing 30% interested peak performance will switch Aerodyne 500Pa 50%-intro mix propylene oxide added competing would probably go way up 65% nitro Remember once run engine high-nitro fuel will heat-cycled run way will lose power drop back lower-nitro fuels ideal break engine fuel intend run forever balance must met top performance necessary hit correct combination fuel propeller compression ratio weather conditions glow plug element heat get ultimate performance out engine Only tachometer accurate enough kind experimentationIn general high nitro goes small props cold plugs low compression benefit maximum power output Low intro needs heat higher compression payoff lugging power greater fuel efficiency Propellers ties fuel choice must select correct prop type flying doing break engine m run prop Choice brand up balanced correctly no prop will damage engine unless allows rpm above structural redline engine Some engines like Killer Bees tuned run small props high-nitro fuel run will very erratic other combinations Select correct engine airplane correct prop fuel combination safe bet props Cox 5 x 3 6 x 3 sizes other will well 80% situations competition several other choices seem have established consistent winning ways 36 Model Aviation filter must least filter fuel going tank Front Davis diesel head Middle Venom 049 RJL best filter again between tank engine conversion head Rear Medallion rare Lofquist diesel head number custom accessories available adapt Cox ultra-long runs Kavan tank extender Available long engines variety installations uses short-bolt versions Babe Bee Black Widow Texaco events typically use props large size starting 7 x 35 8 x 4 props other end scale Nostalgia Free Flight fliers seem prefer very small propsliketheTomado5x3andAPC55x2 Mouse Racers Combat fliers seem like Tornado 5 x 4 Prop Balancing very important running Cox engines Small models need power can get engine will put out oomph technical term itis running smoothly addition extra power engine airplane will last longer prefer Top Flite magnetic balancer head-and-shoulders better rest Second-best large-wheel variety typified Du-Bro Generally anything better nothing though balancing across knife blade really close worse-than-nothing Balancers will never wear out can used engine prop own Mounting solidly engine mounted faster will run Soft mounts intended reduce noise damageto airframe soft mount always costs rpm unnecessary small engine Use correct size screws large head possible spread loads out Very important mounting surface must flat Any mounting distortion will least cost power worst may trash engine Starting Battery Clips starting system use should provide mediumorange glow glow plug filament times plug just has little visible glow bottom element guaranteed have hard-starting engine Plugs take high current flow poor battery thin wires dirty wealdy attached clip will cause lots grief glow-driver system best because will adapt weather battery charge flooding etc still fire up engine glow driver will overcome poor wiring connections some extent simplest system find effective pair alkaline D-cells soldered parallel cable clip should lamp cord clip must clean provide both friction spring force assure high current flow Fuel Filtration Yes filter fuelwithout qualification fuel passages Cox engine tiny takes almost nothing plug up needle valve will either prevent running make run erratic ideal filter fuel can tank again between tank engine Cox fuel cans have built-in filter Break-In Break-in process both polishing parts mate other stress-relieving parts heat-cycling As prop fuel break-in technique depends use engine Casual flying requires casual break-in full performance requires closer attention sport flying need run engine rich opening needle valve add fuel fuel/air mixture minute begin leaning out closing needle valve somewhat bit time Listen engine attempting sag off overheating suddenly slowing down richen up let cool few moments before leaning out again As soon will hold solid two-cycle peak ready fly will find engine will gain performance over period time probably sacrifice small amount peak performance sport flying cares get peak performance out engine competition may need bit careful break-in first phase let parts polish themselves bit avoid galling scuffing like using low-intro fuel 15% slightly smaller prop planned run bit rich side plan get rpm close final planned range engine lightly loaded running cool About five minutes running way should give surfaces imtial polish clean out assembly oil may have left engine during manufacturing attempting minimize heat stress initial run reason running engine speed finally hope achieve have inertial vibration levels correct rockin-and-rollin happening same running flat-out point need begin heatcycle engine get parts final relaxed shape recommend switching final nitro prop fur type running part run seems like sport breakin intensified Start engine lean out scream Immediately back off rich setting Re-lean engine run high speed few moments longer Continue process longer longer peaks until engine will hold full steady high rpm no tendency sag time peak engine builds heat metal moves bit wear factor goes up engine repolishes itself extra heat generated reason engine will suddenly try sag-off lean Too much heat heating cooling cycles longer heat periods run closer metal will settle its final shape continuous re-fitting process cannot achieved factory During break-in process never let engine sag off lean Dont just let engine run itself Break-in boring process requires constant attention Again engine under maximum stress want rpm roughly will finally run engine properly broken-in engine will easier start will last longer will less sensitive needlevalve setting Basically engine has blueprinted itself Cox tried grinding engine precise fit piston/cylinder tapers Precision Power Tools power better n.Iitv Rip Fence lade Guard Mitre-Guide Cooled Motor Blades Cuts wood up 1/4 thick Tools require Minicraft Power Supply Universal Van-Speed Transformer 1 tool MB730$3495 3 tools MB750$7195 Minicraft tools available oar new home page Internet HTTPJMrWWCFORCCOM/HANGAR Send 2 Minicraft 20 nane Color Catalon Wing span WingArea2455q1n Length ngine049 099 2-4 Ch Mini Radio Req d HOBBY HANGAR 1862 Petersburg Rd Hebron KY 41048 1-800-611-3880 Orders Only 606-334-4330 Customer Serve 606-334-4333 FaxTITh Prices Subject Change Any Time July1996 37 $12995 MB490 with a 5mm Safety Stroke sturdy Die Cast construction y Blade Position Balsa up to 1 5/8 thick & Plywood up 1/2 thick e Size 7 1/2 x 7 1/2 Cooled Motor uIpuvu Iuqu au dsage Lightweight Keyless Chuck Speed Extendable cable st ways keep cool 0 maintain control ROBART HINGE POINTS Simply best hinging system available application Drill hole add drop glue Hinge Point youre hinged DON TEFA ROBART CONTROL HORNS accurate on-center control linkage No need bent kinked control lines use horns built-in rotating ball link Reach other tine ROBART products hobby dealers nationwide ROBART MFG POBOX 1247 STCHARLES IL 60174 708-584-7616 really good-running well-broken-rn engine result awful As soon engine run promptly changed shape wore some other fit didnt work well Cleanliness As fuel filtration must small engines A engine has half larger engines clearance between piston cylinder makes dust dirt twice big hit dirt engine take home clean properly alternative will lose significant amount performance engines life first part next run Engine Care Cleaning clean engine remove backplate head cylinder piston rotating crankshaft Usually necessary pull crankshaft case rotary engine crashed really fine dust tear engine down completely Use good solvent like denatured alcohol kerosene model fuel Use brushes paper towels physically remove dirt just sloshing part solvent somewhat effective necessary remove crankshaft removal reassembly procedure Removal screw size crankshaft 5 x 40 commonly found hobby shops standard hardware size Purchase some hex-head /2-inch 5 x 40 machine screws matching hex wrench After removing backplate cylinder piston engine insert screws shaft far will go Place crankcase rear-end down sheet cardboard cement floor cement solid backing cardboard crankcase wont marred Whup puppy hammer until shaft slides free drive washer Keep screw just removing shafts Reinstallation bit tricky After thoroughly cleaning oiling parts slip shaft engine gently reassemble thrust washer used prop drive plate onto shaft Get drive plate started same grooves used original assembly use stack washers hex screws pull drive plate way down stop shaft Recheck drive plate runs true no wobble Note specify hex-head screw because requires no pushing turned got screwdriver three stitches deep palm hand trying standard slotted screw warned engine apart examine parts damage wear needed use piston reset tool tighten up piston ball socket good time consider removing accumulated varnish cylinder walls see below Reassemble engine good grade oil WD-40 Marvel Mystery 3-InOne seem work OK After-run oils should good preference BreakFreea gun oil Teflon particles wont say sure improvement can bit Teflon hurt Varnish Removal As engine runs certain amount burned oil will accumulate cylinder walls varnish does two things reduces clearance between cylinder piston may generate heat tends get sticky heats up result engine suddenly has difficult time being run up peak rpm holding seems exactly though engine unbroken-in remove varnish coating remove cylinder head head gasket cylinder engine Get pad 000-grade steel wool Wrap strip steel wool around clean dowel scour inside cylinder bore until completely silvery again very difficult harm cylinder bore technique steel wool softer steel cylinder its much harder varnish Clean cylinder solvent Use brush assure residue wool hairs have removed reassemble engine above Piston Resetting technique allows tighten fit between conrod ball socket piston Allowing fit get too loose can cause vibration inaccurate timing breakage find socket usually needs tightened once twice life engine metal eventually wears very smooth work-hardens itself fit eventually remains constant using socket-setter use hammer gently first keep moving position tool around socket key tighten socket evenly possible Keep checking resulting fit achieved no noticeable slop between ball socket no bind Clean piston rod oil socket before reassembling engine Storage keep engines sealed metal box Prior storage get liberal dousing inside out oil again favorite Break-Free would excellent idea throw bag desiccant engines stop rust Miscellaneous Thoughts Keep screws tight Plastic can cold-flow check screws remain snugly tight Tee Dee Medallion engines check carburetor body retaining nut silver ring behind prop drive snug Air leaks place another source starting problems Glow heads loosen up themselves check tightness run gasket looks worn torn replace Look plastic parts cracks rubber Hycar washers back tank can harden should replaced 38 Model Aviation RT HINGE POINTS AND CONTROL HORNS. look suspicious Backplates rotary-valve engines can also loosen themselves Castor oil gums up engine used expect have clean out fuel system run full tank through engine slow speed fire up again Fuel absorbs water amazing rate keep fuel can sealed well between flights Engine Repair isnt really much can repair model engine Generally situation finding problem replacing parts hobby shop cant get parts distributor tell Cox has no-minimum policy part purchases dealers addition can purchase parts direct Cox through Customer Service toll-free hot line 800 451-0339 Some things worth knowing about servicing engines can free up old gunky engine warming film-shrinking iron boiling water can clean almost anything off old engine boiling dishwasher detergent screws Cox engines standard sizes2-56 3-48 4-40 5-40 etc None other threads used anyone else get all-custom taps Customer Service has list thread definitions just have have Glow heads can bad variety reasons obvious dont glow also possible upper seals leak element have aluminum coating fused will limit ability catalyze combustion process doubt look element under microscope element shiny like jewelry probably shot usually good idea keep pistons cylinders matched pairs Once parts have broken together lose fit sport flying can mix performance will vary wildly LDM Industries Model Accessories Universal Servo Tray measures 23 42 inches designed hold over 50 different standard mid-size servos 2 yle tray features adjustable mounting brackets molded tough glass filled nylon durability Part #6000 . Universal Servo Tray .. $495 Con-Do-It Con-Do-It clear PVC tubing withal /2 outside diameter 023 wall thickness Con-Do-It provides neat simple way running servo lead extensions fuel lines air lines wiring harnesses through model package contains two 24 pieces Con-Do-It Part #7500Con-Do-It$495 Model Chocks lock place models axles prevent model rolling around car during transport flying field packaged sets two designed fit 5/32 axles up 3 diameter wheels Part #7000Model Chocks$395 order send check money order including $400 S&H LDM Industries Inc PO Box 292396 Tampa FL 33687-2396 Phone 813 991-4277 Fax 813 991-4810 Florida residents add 6% sales tax VISA and MASTER CARD Accepted 1996 LDM Industries Inc A~[W IN Pa N 4161 IIU INN IN 4 .This product am going use time go flying Dick Pettit RC Report .I have using Advanced Aero Fueler past several months problems associated fuel have gone away~ Paul Tradelius Model Aviation Safe easy use Advanced Aero Fueler will enhance modelers flight kit Helps prevent fuel evaporation moisture absorption possible spills may lead fires explosions Gas glow bottles cans $1495 22nd Century Aero Products 2763 West Ave L Suite 295 Lancaster CA 93536 800 273-AERO Distributed Horizon Hobby Distributors Ask local retailer order direct Please add $400 S/H July1996 39 Universal Servo Tray Model Chocks SERVO SLOW MAY SAVE YOUR PLANE lOSxs Servo Slow feature allows adjustment servo speed electronically its fastest speed down 10/sec rate flaps brakes canopies naturals Servo Slow other applications may provide great benefit creative modelers possibility throttle fire walling throttle takeoff sudden increase torque can cause plane ground loop worse rudder added too little too late difficult coordination maneuver compounded because things happen fast Now lets slow throttle servo down After throttle response made linear using lOSx Lo-Base feature can digitally reduce servo speed Experimentation will provide answer right speed application sport taildragger choose 400/sec rate gave 3 second transit advantage obvious After firewalling throttle steering adjust ments made stick against stop Since airplane accelerates smooth ly rudder corrections infinitely easier air smoother throttle helped flying over landing minor throttle adjustments happen fast enough servo slow unnoticeable Try Servo Slow JR technology makes modeling enjoyable JR Customizing Any modfication Ccx engine voids warranty Read section own risk Several modifications mentioned can work done right will always make engine warranty kaput two types engine rework best type simply assemble engine need specific application correct set parts second type hop-up tuning will deal topics separately Custom Setups trick understand what need application know what parts available let achieve result few standard applications get given below Control Line Stunt need engine good power key achieve ultimate steady running usually necessary muffle engine too Two examples shown photograph engine use Me-109 stunter other set up flying fully competitive Stunt model Engine uses crankcase crankshaft cylinder piston Killer Bee smooth out run increase ability run large prop standard ready-to-fly product backplate substituted bored-out provided Killer Bee Again achieve steady run under varied loads plus provide extra cooling head Texaco engine substituted high-compression head normally found Killer Bee second engine started Tee Dee R/C 05 Control Line venturi substituted RC carburetor Texaco head substituted same reasons before addition steadier run can achieved tapping muffler pressure tank still power needed drill out venturi bigger diameter use side tap engine per free flight engine instructions Diesel Several diesel-type conversions shown photo two heads currently available RJL Box 5 Sierra Madre CA 91025 Davis Diesel Box 141 Milford CT 06460 RJL uses 0-ring seal Davis uses Teflon disks destructible seal RJL has lock arm fix compression lever Davis uses spring system knob Both work just fine both will instantly void warranty engine keys successful diesel operation pick adequately strong components use absolutely fresh fuel high ether content Small diesels need lots etherup 50% engines shown Venom Medallion crankshafts engines least likely break under mistreatment dished out diesel operation Since goal running diesel get long duration swing large props ideal engine would Venom front end Texaco tank backplate Venom will punch out power durable Texaco tank backplate have small venturi maximum duration smooth running low speeds couple words about using mufflers exhaust restrictors RC throttling As mentioned first engine article thing exhaust ports called sub-piston induction SPI piston uncovers bottom exhaust port top-dead-center some air allowed go under piston crankcase used open-exhaust engines get last little bit performance SPI instant death running muffler exhaust restriction throttle system going use muffler sure select cylinder no SPI using muffler SPI exhaust gas pumped down crankcase good 2000 3000 lost rpm Longer Runs addition running diesel couple techniques get longer engine-run times first use tank Dragonfly has 11cc capacity compared Black WidowNenomlTexaco capacity 8cc addition shown photo tank extender Kavan available through Hobby Lobby International 5614 Franklin Pike Circle Brentwood TN 37027 Tel [615] 373-1444 Different Heads least four manufacturers heads allow use standard glow plugs special plugs Cox engines units may used economy sport engines higher performance competition depending unit selected RJL Charlies conversions allow use short regular plugs GloBee Galbreath heads allow use GloBee inserts Nelson plugs pay money get out tachometer start experimenting find what best GloBee heads available number distributors Galbreath heads available Doug Galbreath 3408 Topsail P1 Davis CA 95616 Hop-Ups practical hop-up average individual carefully tune combination bead gaskets nitro content prop match airplane will get 90% way next-most-effective procedure set up pressure fuel system drill out venturi allow air enter engine will get 98% maximum possible performance Beyond get pro stuff Serious engine hop-up involves lots experimentation scrapped parts 40 Model Aviation ER SEVEN IN SERIES Experience testing patience deep wallet main requirements success casual modeler doesnt record results experiments really own Any stuff will void warranty often will hop-down engine rather hop up An entire new article expert engine hop-up would needed really cover subject will describe types true modifications people Hop-ups usually start custom fitting parts selection lapping techniques people modify timing cylinder ports crankshaft ports Shimming cylinder up down achieve timing changes way done Another technique timing changes actually machine dimensions parts differently Extreme hop-ups involve engine re-design use such things full Schnuerle porting ball bearings People machine own cylinders crankcases tuned-pipe systems depends what want much time expertise money have Conclusions First can have terrific amount fun small engines Cox leader worldwide currently about dozen Cox 049 variations suit possible needs hobby exact combination need isnt available can put together what want Second get satisfactory peiformance small engines need care big enginesnot less rarely get kind careful attention need Think flying engine after crash just slosh fuel hose off dirt similar pouring cup sand down Weber carbs Ferrari Third best performance what need easy sensible stuff 95% what need know nutshell Cleanliness Have realistic understanding what engines can dont overprop over rev Select right engine airplane Choose fuel high enough nitro oil content few items will make seem instant expert point hobby have fun Learning get out engines will make lot easier have fun hope pair articles has provided basics need piqued interest learning about fascinating bits running jewelry y Renger 13182 Sutton St Cerritos CA 90703 Wh&s&Wmg Orders Only Please ft Wont Undersold see lower price call! Shipping 495! Futaba ml 6VAS19999 4NBF $13999 4NBL 1~lQQ S-148 SPECIAL rnrn 3 3999 1299 en addI eutana ervos S132H Sl48w/Hdwe S300 I/metal S3002Mini S3003 SId 53101 micro S3002mini 53302 114 53303 l/4Mtl S5IOIBB 55102 Micro BB 59101 RB MS S9102 BB LP S9202 BB SHT 59203 RB S9303 RB MG MT 59402 BB HS S9601 BR Mini 3594 1694 2594 5794 1594 3594 5594 5694 5794 4294 5594 5694 7994 5594 9494 6994 9494 5694 Futaba Accessories CiystalsCall AileronExt594to79 AECI3 V Harness9.9 Tx RX batteries froml59 Trainer Cordl39 Glow Plug Speeiaia Fox RIC Long 6for 1299 l2for 1799 K&B R/C Long 6 1499 12 2299 McDaniel NiStarters 101/2011999/2299 Coverite 21st Century Iron 2899 Sullivan 600/6013299/3599 Dynatron5299 JR Radios XF-62226494 F-40015894 XP783FM38894 XP783PCM44894 PCMIOS 899 Free shipping JR Servos 5071794 5172394 3413894 41316494 47216994 HiteclRCD Servos 0300S SId 1199 0422 Pro 1699 0605 Ultra 3599 0705 Giants 4299 Specify Air Fut Jr qp MIDWEST g paomucrS CO. INC Super Hots 8999 Malibu 5799 Aero-Star 406999 Aero-Star 6011699 Mustng/Mssrschmt 7399 Sukhoi 8299 Mustang 6011599 Corsair 408599 Cherokee 409699 AT6/Extra30023499 ~ARL GOLDBERG Electra Dlx Mirage 550 Falcon Ill Super Chipnmk Ultimate Ripe Extra 300 Eagle2 Sophistd Lady Gentle Lady Anniver Cub Tiger 2 40 Tiger 2 60 Sukhoi Float Kit 5199 5999 6199 10899 13299 12699 5499 3499 2899 6699 6199 8899 14399 3799 I20% Off Retail @miiu Lanier RC SIG US Air Coree will honor advertised price magazine! call other models 3 Ril5pdal 3Ragfm $2199 Ultracote Jltracote99 earls & Flrscnt139 Jtracote Plus114 Jitracote PIs FIr139 AoKoTE paque 92 earls/Metallics 119 eons 139 25 3 799/4599/ 479 Coverite 21st Century film 889 21st Cent fabric 1389 21st Fabric 15 JetSuper Slow 2 oz $679 Buy 3 & Save 60 ea 3 S1857 NHP CA Glues Thin Medium Thick oz28 oz49 Guaranteed freshest Epoxies 6 0 Minute 9 ounce 699 A-50 18494 A-65 19394 A-80 21394 A-9lS 24494 A-l20S 34894 Salto 150 L Retail Onh $599953699 Upgrade Golden Knight $17 f shipping GP 15ABC4994 GP 25ARC5694 GP 40ARC5994 GP6IABC9494 PRO2SABC8494 PR036ABC8994 PRO4OARC9494 PR046 ARC9994 PRO6I ARC14894 PRO9I22494 prices include shipping rn 05 45 FP 5794 0565 PP10494 0540 SF9994 0546 SF4694 0546 ASC15594 OS 61SF 21594 prices include shipping coil other models webra Silverline40 6994 Silverilne 61 9894 Speed 120 24994 Fox 40 BR STD 7799 40 SB DLX 8794 46 RB ARC 9794 MAcfl 45 Sportster 65 Sportster 40 w/mfi 61 R/C w/m 6499 6799 6799 8499 Add 5495 5 H & ins up en 56 0/S pkgs mis S795 2nd day & Next Day available COD orders available continental USA add $595 COD fee PricesarecaslspricexCCsurclsg i9% Money Ordon ship withouc delay Allow 14 days personal checks clear Due advertising deadlines & circumstances beyond ourcontrol availability specs & prices subject change merchandise cames tisanufacisseers wamuty Retssnts subject restocking fee Wheels & Wings etca 7620 LyndaleAveS MinneapolisMN 55423 1-800-896-2582 Orders Only Please! Information other inquiries call 1-612-861-6261 Name _____________ Order City _________________St_____ Zip CodePhone_________ Form ItemDescrlolionPrice CCMO/Check_____Subtotal_________ Credit Card#_________________ SalesTax:________ SignatureTOTAL $ July1996 43

Edition: Model Aviation - 1996/07

Page Numbers: 35, 36, 37, 38, 39, 40, 43