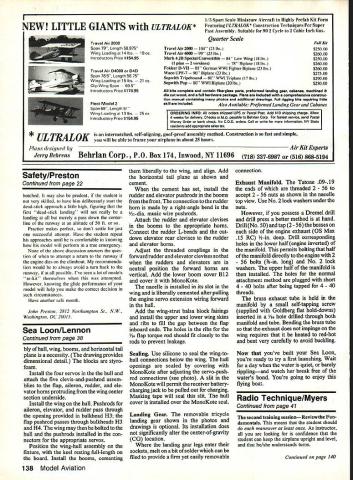

NO OCR TEXT NO OCR TEXT Note details transition point normal leading edge drooped lead ing edge bottom view th wing trim depend hull design welldesigned hull assisted some wing lift obtains dynamic lift its planing action water speed increases elevators become effective trim angles may controlled effect hull proportions angles control both hump trim humo resis So its just confined water can show off its great flying habits local club flying field detailing included plans three removable landing gear wheels Left NACA cooling scoop exhaust stack add detailing engine nacelle though inverted engines start easily thats important modei diffIcult handle upelde dewn Right Bottom wing revealing proper slot flap Left removable landing gear fitted holes according plans Nose wheel steerable though Note hull bottom pointed steps boom front Right Note leading edge droop crucial models outstanding flight performance tance may theorize fact hump trim wing must stalled stalled wing exhibits increased air drag loss effectiveness ailerons compounded hump resistance characteristics could prevent takeoff partic ularly engine power marginal full-scale flying boats problem Hump trims 150 conjunction wing airfoils stall 2O provide healthy margin models howeverparticularly small light air craft fly low speeds low Reynolds Numbersscale effect has major impact stalling angles low teens addition during takeoff model flying boat operating ground effect reduces angle stall Deployed flaps further reduce stall angle model hull design should tailored suit wings stall character istics turn depend airfoil section aspect ratio plan form Eppler 193 airfoil used Sea Loon gives wing gentle stall Adjusted aspect ratio plan form will stall 160 Ground effect half flap deployment 26 Model Aviation BY G LENNON 1/32 BALSA SHEET 1Op -AND BOTTOM 32 SKIN-S TOP S BOT 7 1/32 BALSA SHEET BOTH SIDES 1/16 BALSA SHEET SIDES 1/8 SQ BALSA 1/16 BALSA TOP B 7 1/16 BALSA 3/32 1/32 BALSA SKIN PLYBALSA BLOCK\ 7~TOP AND BOTTOM DIA WHEEL V1-3/4BALSA BLOCK VI6 BALSA SKIN 1DP AND BOTTOM 3/32 BALSA 77 7 BALSA BLOCK. 1 1/16 PLY SPLASH RAIL 1/16 PLY 77 completed hull except bottom sheeting Note location bulkheads servo mounts Du-Bro quick switch assembly left right nacelle sides p re-bent soaking liquid ammonia Note details NACA engine-cooling scoops form fiberglass epoxy cowl ing spinner ring its companion ply wood piece included assembly 200 out maximum deflection 40 reduce 120 hull designed 80 stern post angle see drawing twin afterbodies slightly longer hull forebody result hump trim angle estimated 80 measured forebody keeL Since wing must rotate 120 before stalling hump trim leaves healthy margin below stall wing set 00 incidence keel level 1A16 BALSA SHIN 500MB BASTOMWINGPLAN AERIALIii SALASHHSHRISE HYTAi OHIIt SALAEH tVJBEMAL AlEI LOS SHL~SHji__ F w0 132 BALSA SKIN 12__HIHEWOL F EII lYRHA BALSA8-10 B-BS BALSA SCAdS2 ci~jIiH IYR HIA EBBS BliNK I H LENGTH 0132 NA HURE-NOLBERHALL TOP HO LB LEOSPRAY AS NSAHASH DIN SLY IBALSAN-IA AS PLY H lAO MAPLEAR HA OHILL SC AR BALSA HNLRB 574-ASS JHH /oA SOSHANALS LS OoASNBASH COSHACH SHUESHCHALISA LEAS 55 ATO-ARSSESAY j0HAHAlASH ELbAI-I-IlSALSABALSH ~Y----- H-SB SHYAS zzZhE ABOA84-13B HNASHOT KB JACSHBAA ALHYRPASA BIRINA----1IY II NALTRERO AH2 PLYBURECESORII7AA BALSA BLOHEIL ANAHEY LISP-RAHLEI UFHAM -CRAHHEBHIPAHABA / 'I 1-514 HIA OHEEL J FUSELAGE SIDE VIEW HIPV4SN flight speed 45 mph 00 angle attack will support model Once past hump wing lift increases Planing action water wing lift cause hull rise elevators aided pusher prop slipstream become effective plane now rides hull rear boom ends touch up elevator takeoff occurs Drooped 200 wings slotted flaps shorten takeoff run deployed 40 permit landings 20 mph Flap deployment produces very little change longitudinal trim provide beam loading ounces weight per inch maximum beam com mensurate Sea Loons wing loading 22 oz per sq ft wing area beam 2 selected Sea Loon wing incorporates outboard leading edge droop illustrated drawing again based NACA 28 Model Aviation Nacelle assembly begins Installing engine mount Note slot servo wir ing servo extension cord will needed assembled nacelle engine cowling Sana pyion streamline cross section IU PLY SUPPORT BOOR F Ifi IiI i rI BASSIITIFiAjj __ I7VT01- B/SOBS fl S/BJ[BR TUBE CEVBRBR LOEfbO TOE FAIRIRIAJTLINE- TUBA SRBP1 -r 1AILERHOS iIiUBEISsz BR ROE SO P110 B FLAP A5 ~L1BL itIAF CJ S0211 4I.A\OTIDIISAIIFL 100CRASCTRIAIR BALSaIlLSIllSLAIR SORUEQER BALSABALSAFLAyI/B BALSA AERIAL7-- BALSA BE TAP B BATROB jRZ4ICCHL~1fiI&2BLAT SE RHO ORALS FLOE LOWS AERIALPLYALSr ALL O/BHBHO-~ _________________________20 1/AB/ALI/B PLA AERIALPIASTAG FLAP BEFOBIY IABECOAFEEHA TAP Bis-ss- UBSA BALSA POPHERETI II 2- BEiI/SBALHAIlOAN ______ISHEET TAPBROTHS II I/BBOLHAJI 000000 ASH BOTTLELCOTYHMBES1REI/B BALSA HORNIIBE /-UTB BALSA BREETIJ~jlz0A IL RIGHT H LEFTBLOCSI---]Ej _- A-IIF I/A SRI SIHE ALEBELEVATOR BAIRN IIIIIASOCOABSIDL womBIIFLAP BARS fISOININS h S S/B DOABLE BOTE S*AAB SECT EB BALL BOWL BAR OAT 0/ill~OLBLA I16J21JA MABS 151 BLBAE AOEA ROOF H-r -A BEET FLAP LEERN ALLI/HA BOASH HOT 100 AlL BABN flASA MAHO 101 HBLARAO HARDWARE DETALL -IFVIISOSBIOYA IL -___I H 1OILEBON---SECT S _______________________________________ ''''' FFIN IIL/LA BALSA J NOCET BARB r0— - $ECTAL T SLOE IIi1[v32]S0Ii357~RO I/TA BAISAlIBo~LBrOR III ______I/BBECJJSC _______-11001 COTTLOB ISOI 4HORIZONTAL TAILELANEI/TBBIBIABECT 0NUB 0 FORILLSO BRBS0/YB BBL I/LA BALSAOCLAP INNIOEBNLSCRRil-aRAE A-SOS/SD BALSA ABSO BALSA5/ABEI- SO N-ID RI~"0-BB-Ni/IICA BLALE IAN BE II --- - ii H-I IR I/IS BALSA _ BALSA II ISISA CTUEB-HO-IH-BH -IITt1I-- ____________I SCARF 1/10 BASA 'SIlO BA BALSA S/SO BALSA ELEEF__IIII H RAS USANEPOOTCHINE'SPBAT STOP -SEULAKEELI/B IA BALSAooEsB-SO COLASREAL SIB TE [CI ALSA LAN BLAHO ISS PLAICOAJ PLO PLY _____Li mORLAL HO USTRI N-IDIRISULNA COUNTBREDSN-B _LIRROLSA oego rr--i IBARBSNBSOORTORED BBILIRE ULoCI LLCAS LOROR00 DRABALAA TAB ALSAI -BESLEY N-ISIRA IBOLARNOPOLNISI-OASA1 /LIBA B-I TELA BALSACOTYB LI IBAJJ CAFABRO932 BATORHsAL - 1flSAfl fl-BZ S/BCO HIS RB0 OR50EHALEH-H1B-hR-NBALSA _ORBACH/11 AL0020WON1111 IHIRAE BE-4RA LEOI OR BA DIE PLY A___ B H/A ~ TLRL-R ISO DOD RE RB SOS RBASTLCRIGHT BGOIL 1BIS-B/LN I0-OLE02-LAN BAtHS EL/fl IRB1JL U -=- F_ rBHLTLAN TRL 71j PLY HDOLOCOCO LA COW FORMER00 0 SORO OPEHEBI flNBJDDER RIBS MODEL AVIATION SEA LOON-FLYING BOAT DESIGNED B DRAWN BY 0 LENRN TRACING BY JOE DEMARCO Left With keel 1/8-in sq chine strips place sand keel hull sides conform hulls V cross section add right left spray sheets spray strips Right completed hull including cover drawings reflect recent modification cover now ends wing leading edge balsa faring extends back cover See text water-proofing hints October 1987 29 Y9REEOICEB SOBIUIB BALSA BOBU F LAHIALTAP ABA COTROB BALLS SOPYLHB BLAT Full-Size Plans Available. See Page 188 Left The completed covered wing Note area thats left uncovered fairing will glue Right Boom construction Pre assembled bulkheads glued side -triangle stock outer control cable tubes should installed time Left Attach right left fins booms Note location cable sheath shown upper boom Right Assemble rudders shown again pinning pieces corkboard jig left-side sheeting plywood water rudders still added research wing design spin resis tance configuration increases stalling angle drooped portion good 100 also provides effective aileron response high angles attack third design author has incor porated such leading edge droop three confirm NACA research As drawings show Sea Loon incorporates some beneficial modifications original design hull has lengthened inch mainly move flap servo forward easier access also avoid nose ballast NACA low-drag air scoop inlets outlet have en larged slightly better engine cooling ground block wing tips extend drooped leading edge Note offset servo wheel aileron servo hull feature provides aileron differential much greater up ward downward aileron deflection result smooth banked turns adverse yaw hence no rudder action Engine Starting inverted engine its nacelle position easily started electric starter room between spinner horizontal tail plane permit However after priming engine flip prop hand several times make certain no fuel trapped between piston cylinder head unusual resis tance felt tip model Tatone manifold downward permitting trapped fuel drain out through cylinders exhaust opening Trying start engine model inverted engine upright awkward recommended Flying small model Waves three four inches height would have impact comparable three- fourfoot waves full-scale shipthat would make takeoffs dangerous im possible Sea Loon therefore successful water takeoffs require dead calm gentle ripple condition positive side models small size light weight permit hand launching wing tip droop paid off couple authors bad hand launches upward instead level slightly down Good piloting plus good aileron control averted otherwise inevitable crash Water takeoffs will shortened half flap deployment Landings flaps fully deployed can made water grass removable tricycle landing gear 30 Model Aviation Left Spray strips sharp corners help reduce spray thrown up hull Above Wing assembly done jig made 1/8-in corkboard 1/2-in plywood Mylar strips prevent glue adhering cork Note authors antenna installation Len I ne stab elevator assemwies strip trailing edge stock holds lower stab sheeting against front . ht underside horizontal tail plane right hand balsa tip block reveals location rear elevator control smurn Left The simple Jig used assemble hull wing booms horizontal tail plane Text drawings provide additional details Right FInal assembly point four hull servos have installed elevator rudder pushrods connected proper surfaces shown drawing optional Basically its needed landings made pavement nose wheel steer able onboard glow plug heating arrange ment really works No in-flight inverted engine quits have occurred Note both throttle lever trim lever down position engine shut down glow plug heating circuit deacti vated full throttle circuit also deactivated Recently flew larger flying boat shore large lake pickup boat standing glow plug arrange ment inverted engine identical Sea Loon After six- sevenflight session taxied model back shore under its own power delib erately shut engine down Three fellow RC club members John Jeffrey Dick Murray Ken Sharkey have flown Sea Loonand backed up its virtues comment Its good airplane Construction Sea Loons structure based stressed skin concept surfaces sheet balsa minimum internal components construction light yet surprisingly strong Note true-lengths curved surfaces such hull sides nacelle sides etc shown drawing Build components according guidelines drawing Detailed instruc dons assembly major component follow Nacelle Successful nacelle assembly de pends correct sequence operations followsContinued page 32 October 1987 31 Left Flap assembly two sections left complete two right missing upper sheeting detail rib locations Upper sheeting attached end wrapped over ribs glued piace outer ply ribs indented provide space 1/64 brass torque arms Right finished flaps torque rods arms plywood supports Aligning flap leading edges -in strip open nacelle reveals engine servo switch on-board battery Note piece toothpick CyAed servo prevent roller lever jamming servo arm Assemble engine mount cut slot servo wiring Solder wiring see diagram Radio Shackiack mount its ply base Rough-shape balsa nose block hollow out Epoxy jack mount position Install bulkhead Ni add sides Install servo extension cable through slot nacelle strut Using contact cement attach fitted tank foam pads Using three outlet holes tank plugfor engine fuel manifold pressure fuelingis recom mended Plug open end fueling tubing rivet small screw Mount Radio Shack battery holder ply base using 356 bolts nuts Complete soldering connections glow plug wiring see wiring diagram Mount battery holder its base using epoxy Install servo mount again using epoxy Install servo connect servo extension mount engine Connect 045-in music wire pushrod mini-link clevis both servo engine throttle arms Using cyanoacrylate glue CyA attach Radio Shack roller lever switch servo shown Attach nacelle cover components nacelle Make cowling laying up two layers medium-weight fiberglass form see photo drawing Assemble ply spinner ring its companion piece using Hobby Poxy #2 adhesive has cured dissolve styrofoam core acetone gasoline trim cut cowl parting line Epoxy top portion cowling bulkhead #2 align spinner ring spinner Note 3A2-in plywood washer engine crankshaft Position rear cowl plywood making sure flat attach hold-down assembly *2 shoulder screw Install lower cowling fit rear cowl hold-down assembly cowl ing closes properly Positioning both nacelle epoxy cowl rear holddown assembly prevent bonding lower cowl bulkhead #2 insert waxed paper between hold-down assembly bulkhead Finally sand nacelle shape Hull Prebend hull sides using liquid ammonia Arrange weights supports hold sides bent position until dry subassembly bulkheads parts Hi H2 H4 H4A H5 Install 3/16-insq servo mounts -in-sq balsa sides Assemble sides top front bulkheads switch used X Acto clamps operation Install ply servo mounts keel Install l-in-sq balsa chines Sand keel chines meet N bulkhead bottoms Fit bottom planking right left sides keel cement itto keel bulkheads chines Add nose block sand shape Continued page 34 Weve known put out great catalog literally best business Because take AC seriously years catalog no exception Packed over 200 pages lull color action photographs 1988 Catalog next best thing favorite RC dealer contains everything Robbe makesboats cars planes gliders accessories beginners barnstormers over 450 products 1988 Catalog can bring right home Youll find Robbes 1988 Catalog AC dealer now use coupon send yours today Just $500 Plus youll receive $400 certificate good towards next Robbe purchase EUUEUEUUEUEEEUUEUUUUU Rush Robbes new cetaleg. Enclmd $5J10 I] Cheek 0 Money Order U U U U U U U U U U U U U City/State/Zip Mail Robbe Modelsport 180 Township Line Rd. BeUe Mead NJ 08502 Cectificate expires 12/31187 Good purchases $50 over direct Robbe 7 ego ezect4e daud FROM THE 20S. Y FAVORITE OF THE GOLDEN ERA OF FLIGHT WITH THE 05 ELECTRIC POWERED SPORT-SCALE 54 SPAN 425 SQ AREA WEIGHT 5 OZ WITH 3 CHANNELS ALL DAVEY SYSTEMS ELECTRIC KITS ARE NOW AVAILABLE WITH OR WITHOUT THE MOTOR AND/OR GEARBOX AND FROM THE 40SBRING BACK THE NOSTALGIA OF THE FABU LOUS PIPER PA-I 2 SUPER CRUISER WITH MAJESTIC SCALE-LIKE PERFORMANCE 1/5 SCALE FOR 60 2 CYCLE OR 90 4 CYCLE ENGINES 85 SPAN 1040 SQ AREA 9-10 LBS WITH 4 CHANNELS DAVEY SYSTEMS CORPORATION pleased announce acquisition CHAMPION MODEL AEROPLANE COMPANY line fine model kits addition CHAMPIONS extensive variety high quality kits including trainers old timers pattern scale WW II DAVEY SYSTEMS can now offer modeler complete line Whatever preference engine powered sailplane electric. have HIAVEY YSTEMS ORPORATION 675 TOWER LANE WEST CHESTER PA 19380 215-430-8645 Carry Largest Only Stock Kraft Parts World .. Kraft alive working KRAFT MIDWEST LL FLY WHAT FIX Autboejoed Warranty Service PREQUENCY CONVERSION $1000 Diecoont Reguler Repair Moat Make Modola Converted Tuning Done Spectrum Analyzer Also Service ACE El/CjjiiSha Only Full Time Servicenter Midwest 117 East Main St Northvilte Michin 48167 Level M8StbPhone 1-313-348-0085 Add spray strips sand contours shown bulkhead portion drawing accompanying photos Attach cover components hull radius corners Wing Assemble rudder-elevator torque tubes aileron torque tubes Note A-in-dia elevator tube rides -in-dia rudder tube Study draw ing carefully torque tubes hinges transfer output single elevator single rudder servos two sets pushrods necessary operate twin elevators rudders Solder bushings inside Y6-in-dla tube ends complete hinges stops /s2-dia soldered both sets tubes prevent end-play %z dia bearings supported /16 ply plates Both ply bearings epoxiedto ribs K&S Engineering brass tubing -in brass strips used Solder horns securely tubes Make jig -in corkboard -in plywood n strip balsa cemented jig shown cater slight undercamber E-193 wing section Mark rib locations three lower wing skins Pin skins jig shown Cement -in trailing edges TE position Position lower -insq spar three sets torque tubes skins rib cutouts will locate Install ribs epoxy ply bearing supports seven Add upper -in-sq spar /16 balsa webbing between ribs Add balsa ply dihedral joint reinforcements -rn triangular stock Install three drilled blocks wing hold-down antenna installed along brass tubing coupling composed -in lengths 6 /32 tubing shown drawing However necessary cut antenna before installation join two pieces later coupling made up two -in lengths brass tubing Vs6 brass tube section free-sliding fit /32 tube section bit solder should melted onto Y16 tube filed down good tight electrical connectionyet still permits us readily disconnect two sections Measure antenna carefully before cutting point four inches receiver After soldering coupling halves both sections using heat-shrink tubing over solder joints joining measure again will necessary cut bit far end antenna compen sate coupling important antenna same length before first cut have used procedure five models its own antenna permanently installed either fuselage wing absolutely no problem permits moving receiver model model easily Install aileron outboard pushrod devises horns run out through ply guides aileron pushContinued page 36 34 Model Aviation ATT- CHEIC1 ON-Board Battery Tester Saves Time. Saves Models BAiTCHEK RX-1 eIn $1495 USA Install RC Models Check receiver battery status press button Small Light 1/2 oz Precise Rugged ORDER TODAY dealer Protune Corp 914 462-6452 PO Box 1808 Poughkeepaie NY 12601 SUPERIOR DESIGN________ & CRAFTSMANSHIP DEL-A IR& 01 need easy handling superior acrobatic modern looking sport exhibitIon biplane has filled SelAir ee kit parts biplane fine line kits machine cut asslat building real show atopper Set-Air 60 has fully aummetriosi wing aectiona Thia gives greatest potential aerobatic performance either upright inverted Thia ship capable very slow close-in type flight right up rigorous acrobatic schedule can muster 60 52 935 0 40 IFICATIONS Fuselage Width Weight Range Wing Loading Range 35, 6 75 lbs 148 185 207-490-1881 Visa MasterCard Accepted 4 NORTHEAST AERODYNAMICS Inc_______ SiC LEBANON STREET SANFORD E 04073 S7246018S1 Finest Kits Youll Ever Buy Build Train-Air 20 Train-Air 40 Sport-AIr 40 Bel-Air 40 40 Hydro-Floats rods Y32-dia music wire attached mini-link clevis using aded portion 2-56 coupling sup plied No 507 cable sets soldered music wire permit adjustment ailerons trim purposes tap mini-link 2-56 threaded coupling will turn reasonably freely clevis access holes outboard skins lower wing purpose rear elevator clevis shortened mini-link connected elevator cable using aded coupling drilled its full length carbu retor clevis attached 045-in-dia music wire pushrod similar fashion brass coupling must drilled 344 dia accommodate wire Bend pin lower wing skin leading edge LE rib contour cement securely Cement center-section upper wing skin spars ribs except LE Fit outboard upper wing skins inner ribs Cement spars ribs again except LE Using -in masking tape hold skin place cement upper skins ribs lower skin done placing three-inch lengths tape along chord sheeting 1 -in centers hold wing skin leading edges cement setting up Install triangular cross-sectioned strips onto rear spar positioned front both ailerons flaps four pieces latter sanded formthe flap slot lid Booms Assemble bulkheads install ing landing gear lace epoxy piece Yt6-sq brass tubing bulkhead B2 Cement both -in triangular stock -in-sq strips four boom sides Attach bulkheads boom sides install plastic tube sheath ele vator rudder Add top bottom boom sheeting Note bottom sheeting compared shown photo has shortened front pertnit access elevator rudder horns Add pieces B8 B9 BlO BL 1 Defer installation ofBl2 lower forward skin order provide access rudder elevator horns during final assembly Add balsa nose blocks sand shape Sand top corners add -in ply skeg lower rear end boom Fins Install fin spars correct angle 92 shown drawing bottom skin Add right-hand skins ribs Rl R2 R3 R7 rib added right-hand side well elevator tube casing attached CyA Add left-hand skins cement LE liberally tape masking tape wing LE Add blocks R9 sand LE radius Add R4 Rudders Assemble right-hand skins Continued page 38 36 Model Aviation NEW Engine Requirement Wing Span Wing Area Fuesiage Length race flexible push rod serves servo best nothing beats Gold-N-Rod Sullivan Products Because Gold-N-Rods unique design allows lowest friction accurate transfer motion around curves push rod market Heres Etclusive spline design dramatically reduces friction between inner outer rod Sullivans demanding quality control insures tight fit minimal play between inner outer rods Gold-N-Rods special temperature-resistant resins help keep model trim comes convenient applications Gold-N-Rod soars above competition Youll find installation snap adjustments easier using Gold-N-Rods complete kit push rods studs Gold-N-Clevises So dont get thrown curve Instead go gold Gold-N-Rod Sullivan 77FF34fR 70E2V& LE spars ribs shown Note /16 ply rudder horn/rib Add left-hand skins sand shape Add 146 ply water rudder Flaps Assemble solder center /16 music wire pivot /32 brass tube /32 inboard horn two ply flap supports two brass flap horns Check solder joints carefully adequate strength Use hot soldering iron thoroughly clean areas soldered Assemble boom 146 music wire pivots two piy flap supports two / brass horns Solder carefully above Epoxy 146 music wire outboard pivots outboard ply flap ribs After covering flaps used MonoKate assemble shown carefully aligning flap leading edges epoxying brass horns ply end ribs Note ply flap supports position width two outboard spaces must clear boom sides free flap operation Ailerons Assembly similar elevator Note aileron ply inboard rib extends aileron LE provide aileron horn Stabilizer Elevator See two accompanying photos clear illustration stabilizer elevator construction Note -in balsa rib near right-hand end elevator 146-dia music wire elevator torque rod inserted rib spar grooved rod submerged balsa structure photos see right-hand stabilizer tip block stabilizer end elevator brass horn visible Covering Installing Hinges chose MonoKote covering took care leave generous -in overlap seams prevent leakage Ailerons rudders elevator side hinged using double MonoKote procedure shown right-hand end wing portion drawing provid ing both hinging gap-seal method affords effective oontrol sure surfaces operate freely both directions Leave underside wing bare booms make contact balsa-to-balsa cementing can take place Cement stabilizer end blocks stabilizer shape Drilling Tapping suggested three drilled holes wing hull nacelle hold-down blocks used align mating holes hull nacelle maple blocks Ensure wing hull alignment correct before drilling same applies two covers Use No 29 drill 8-32 threads aNo 50 drill 2 56 tap holes accord ingly Final Assembly simple jig assem Continued page 138 38 Model Aviation push comes shove Sullivans Gold-N-Rod smoothest around curves P00 DUCTS Dee Noih Have, S,ee ox 5166 Blmore MD 21224 732-3500 DJly .hInnporn Made USA NEW LITTLE GIANTS ULTRALOK* Travel Air 2000 Span 79 Length 58875 Wing Loading 14 lbs 19 oz Introductory Price $15495 Travel Air 04000 D4D Span 785 Length 5675 Wing Loading 15 lbs 21 oz Clip Wing Span 695 Introductory Price $17495 Fleet Model 2 Span 68 Length 51 Wing Loading 13 lbs z Introductory Price $15495 1/5 Sport Scale Miniature Aircraft Highly Prefab Kit Form Featuring UL TRALOK Construction Techniques Super Fast Assembly Suitable 90 2 Cycle 2 Cubic Inch Gas Quarter Scale Travel Air 2000 23 lbs Travel Air 40009925 lbs Mark 4JB Special Convertible ow Wing IS lbs plan 2 versions 78 Biplane 18 lbs Fokker D-VlI 88 German WWI Fighter Biplane 23 lbs Waco UPF-7 iplane 23 lbs Sopwith Tripehound 80 WWI Triplane 17 lbs Sopwith Pup 80 WWI Biplane 20 lbs kIts complete contaIn fiberglass parts preformed landIng gear cabanes machIned & dl cut wood full hardware package Plans Included wIth comprehensIve construc sIan manual contaIning photoa addItIonal drawlnga Full rIggIng kIts requirIng lIttla akIll IncludadAlso Available Preformed Landing Gear Cabanes ORDERING INFO orders shipped UPS Parcel Post Add *iO shipping charge Allow 4 weeks delivery Checks MO payable Behrlan Corp fastest service send Postal Mortey Order bank cheqk No COD orders Call write information NV State reaiderta add appropriate seles tea * ITT 7DAJIIlr internotched self-aligning goof-proof assembly method Construction fast simple UI-i 1I&tIIjLI1 will able frame airplane about 25 hours Air Kit Experts Jerry Behrens Behrlan Corp PO Box 174 Inwood NY 11696 718 337-6987 516 868-5194 Safety/Preston Continued page 22 botched may also prudent student very skilled have him deliberately start dead-stick approach little high figuring first dead-stick landing will really landing merely pass down center line runway altitude 50 ft Practice makes perfect dont settle just successful attempt Have student repeat approaches until comfortable knowing model will perform true emergency None above discussion answers ques tion attempt return runway engine dies climbout recommenda tion would always avoid turn hack runway possible Ive seen lot models re-kit themselves attempted However knowing glide performance model will help make correct decision such circumstances Have another safe month Joht Preson 2812 Northampton St NW Washington DC 20015 Sea Loon/Lennon Continued page 38 bly hull wing booms horizontal tail plane necessity drawing provides dimensional detail blocks styro foam Install four servos the hull attach five clevis-and-pushrod assem blies flap aileron rudder ele vator horns protruding wing center Section underside Install wing hull Pushrods aileron elevator rudder pass through opening provided bulkhead H3 flap pushrod passes through bulkheads H3 H4 wing may bolted hull pushrods installed con nectors appropriate servos Position wing-hull assembly fixture keel resting full-length board Install booms cementing liberally wing align Add horizontal tail plane shown cement cement has set install rudder elevator pushrods booms front connection rudder horn made right-angle bend /32-dia music wire pushrods Attach rudder elevator devises booms appropriate horns Connect rudder L-bends cutdown elevator rear devises rudder elevator horns Adjust threaded couplings forward rudder elevator devises rudders elevators neutral position forward horns vertical Add lower boom cover B 12 cover MonoKote nacelle installed its slot wing liberally cemented after pulling engine servo extension wiring forward hull Add wing-strut balsa block fairings install upper lower wing skins ribs fill gap between flap inboard ends holes ribs Ae flap torque rod should fit closely rods prevent leakage Sealing Use silicone seal wing-to hull connections below wing hull openings sealed covering MonoKote after adjusting servopush rod connections see photo slit MonoKote will permit receiver batterycharging jack pulled out charging Masking tape will seal slit hull cover installed over MonoKote seal Landing Gear removable tricycle landing gear shown photos drawings optional Its installation does significantly alter center-of-gravity CG location landing gear legs enter sockets melt bit solder can filed provide firm yet easily removable connection Exhaust Manifold Tatone 09- 19 ends threaded 2 56 accept 2 56 nuts shown nacelle top view Use No2 lock washers under nuts However possess Dremel drill drill press better method hand Drill No 50 tap 2- 56 bosses side engine exhaust OS Max 15 RC -in deep Drill corresponding holes lower half engine inverted manifold permits bolting half manifold directly engine 2 56 bolts li-in long No 2 lock washers upper half manifold installed holes normal attachment method plugged short 4 40 bolts after being tapped 4 40 threads brass exhaust tube held manifold small self-tapping screw supplied Goldberg flat hold-downs inserted 6 hole drilled through both manifold tube Bending brass tube exhaust does impinge wing requires heated red-hot bent very carefully avoid buckling Now youve built Sea Loon youre ready try first launching Wait day water quiet barely ripplingand watch break free waters bond Youre going enjoy flying boat Radio Technique/Myers Continued page 41 second training sessionReview Fun damentals means student should maneuver least once As instructor looking confidence student can keep airplane upright level he/she understands turns Continued page 140 138 Model Aviation Full Kit $25000 $26000 $25000 $26000 $26000 $27500 $29000 $25000

Edition: Model Aviation - 1987/10

Page Numbers: 24, 25, 26, 27, 28, 29, 30, 31, 32, 34, 36, 38, 138

NO OCR TEXT NO OCR TEXT Note details transition point normal leading edge drooped lead ing edge bottom view th wing trim depend hull design welldesigned hull assisted some wing lift obtains dynamic lift its planing action water speed increases elevators become effective trim angles may controlled effect hull proportions angles control both hump trim humo resis So its just confined water can show off its great flying habits local club flying field detailing included plans three removable landing gear wheels Left NACA cooling scoop exhaust stack add detailing engine nacelle though inverted engines start easily thats important modei diffIcult handle upelde dewn Right Bottom wing revealing proper slot flap Left removable landing gear fitted holes according plans Nose wheel steerable though Note hull bottom pointed steps boom front Right Note leading edge droop crucial models outstanding flight performance tance may theorize fact hump trim wing must stalled stalled wing exhibits increased air drag loss effectiveness ailerons compounded hump resistance characteristics could prevent takeoff partic ularly engine power marginal full-scale flying boats problem Hump trims 150 conjunction wing airfoils stall 2O provide healthy margin models howeverparticularly small light air craft fly low speeds low Reynolds Numbersscale effect has major impact stalling angles low teens addition during takeoff model flying boat operating ground effect reduces angle stall Deployed flaps further reduce stall angle model hull design should tailored suit wings stall character istics turn depend airfoil section aspect ratio plan form Eppler 193 airfoil used Sea Loon gives wing gentle stall Adjusted aspect ratio plan form will stall 160 Ground effect half flap deployment 26 Model Aviation BY G LENNON 1/32 BALSA SHEET 1Op -AND BOTTOM 32 SKIN-S TOP S BOT 7 1/32 BALSA SHEET BOTH SIDES 1/16 BALSA SHEET SIDES 1/8 SQ BALSA 1/16 BALSA TOP B 7 1/16 BALSA 3/32 1/32 BALSA SKIN PLYBALSA BLOCK\ 7~TOP AND BOTTOM DIA WHEEL V1-3/4BALSA BLOCK VI6 BALSA SKIN 1DP AND BOTTOM 3/32 BALSA 77 7 BALSA BLOCK. 1 1/16 PLY SPLASH RAIL 1/16 PLY 77 completed hull except bottom sheeting Note location bulkheads servo mounts Du-Bro quick switch assembly left right nacelle sides p re-bent soaking liquid ammonia Note details NACA engine-cooling scoops form fiberglass epoxy cowl ing spinner ring its companion ply wood piece included assembly 200 out maximum deflection 40 reduce 120 hull designed 80 stern post angle see drawing twin afterbodies slightly longer hull forebody result hump trim angle estimated 80 measured forebody keeL Since wing must rotate 120 before stalling hump trim leaves healthy margin below stall wing set 00 incidence keel level 1A16 BALSA SHIN 500MB BASTOMWINGPLAN AERIALIii SALASHHSHRISE HYTAi OHIIt SALAEH tVJBEMAL AlEI LOS SHL~SHji__ F w0 132 BALSA SKIN 12__HIHEWOL F EII lYRHA BALSA8-10 B-BS BALSA SCAdS2 ci~jIiH IYR HIA EBBS BliNK I H LENGTH 0132 NA HURE-NOLBERHALL TOP HO LB LEOSPRAY AS NSAHASH DIN SLY IBALSAN-IA AS PLY H lAO MAPLEAR HA OHILL SC AR BALSA HNLRB 574-ASS JHH /oA SOSHANALS LS OoASNBASH COSHACH SHUESHCHALISA LEAS 55 ATO-ARSSESAY j0HAHAlASH ELbAI-I-IlSALSABALSH ~Y----- H-SB SHYAS zzZhE ABOA84-13B HNASHOT KB JACSHBAA ALHYRPASA BIRINA----1IY II NALTRERO AH2 PLYBURECESORII7AA BALSA BLOHEIL ANAHEY LISP-RAHLEI UFHAM -CRAHHEBHIPAHABA / 'I 1-514 HIA OHEEL J FUSELAGE SIDE VIEW HIPV4SN flight speed 45 mph 00 angle attack will support model Once past hump wing lift increases Planing action water wing lift cause hull rise elevators aided pusher prop slipstream become effective plane now rides hull rear boom ends touch up elevator takeoff occurs Drooped 200 wings slotted flaps shorten takeoff run deployed 40 permit landings 20 mph Flap deployment produces very little change longitudinal trim provide beam loading ounces weight per inch maximum beam com mensurate Sea Loons wing loading 22 oz per sq ft wing area beam 2 selected Sea Loon wing incorporates outboard leading edge droop illustrated drawing again based NACA 28 Model Aviation Nacelle assembly begins Installing engine mount Note slot servo wir ing servo extension cord will needed assembled nacelle engine cowling Sana pyion streamline cross section IU PLY SUPPORT BOOR F Ifi IiI i rI BASSIITIFiAjj __ I7VT01- B/SOBS fl S/BJ[BR TUBE CEVBRBR LOEfbO TOE FAIRIRIAJTLINE- TUBA SRBP1 -r 1AILERHOS iIiUBEISsz BR ROE SO P110 B FLAP A5 ~L1BL itIAF CJ S0211 4I.A\OTIDIISAIIFL 100CRASCTRIAIR BALSaIlLSIllSLAIR SORUEQER BALSABALSAFLAyI/B BALSA AERIAL7-- BALSA BE TAP B BATROB jRZ4ICCHL~1fiI&2BLAT SE RHO ORALS FLOE LOWS AERIALPLYALSr ALL O/BHBHO-~ _________________________20 1/AB/ALI/B PLA AERIALPIASTAG FLAP BEFOBIY IABECOAFEEHA TAP Bis-ss- UBSA BALSA POPHERETI II 2- BEiI/SBALHAIlOAN ______ISHEET TAPBROTHS II I/BBOLHAJI 000000 ASH BOTTLELCOTYHMBES1REI/B BALSA HORNIIBE /-UTB BALSA BREETIJ~jlz0A IL RIGHT H LEFTBLOCSI---]Ej _- A-IIF I/A SRI SIHE ALEBELEVATOR BAIRN IIIIIASOCOABSIDL womBIIFLAP BARS fISOININS h S S/B DOABLE BOTE S*AAB SECT EB BALL BOWL BAR OAT 0/ill~OLBLA I16J21JA MABS 151 BLBAE AOEA ROOF H-r -A BEET FLAP LEERN ALLI/HA BOASH HOT 100 AlL BABN flASA MAHO 101 HBLARAO HARDWARE DETALL -IFVIISOSBIOYA IL -___I H 1OILEBON---SECT S _______________________________________ ''''' FFIN IIL/LA BALSA J NOCET BARB r0— - $ECTAL T SLOE IIi1[v32]S0Ii357~RO I/TA BAISAlIBo~LBrOR III ______I/BBECJJSC _______-11001 COTTLOB ISOI 4HORIZONTAL TAILELANEI/TBBIBIABECT 0NUB 0 FORILLSO BRBS0/YB BBL I/LA BALSAOCLAP INNIOEBNLSCRRil-aRAE A-SOS/SD BALSA ABSO BALSA5/ABEI- SO N-ID RI~"0-BB-Ni/IICA BLALE IAN BE II --- - ii H-I IR I/IS BALSA _ BALSA II ISISA CTUEB-HO-IH-BH -IITt1I-- ____________I SCARF 1/10 BASA 'SIlO BA BALSA S/SO BALSA ELEEF__IIII H RAS USANEPOOTCHINE'SPBAT STOP -SEULAKEELI/B IA BALSAooEsB-SO COLASREAL SIB TE [CI ALSA LAN BLAHO ISS PLAICOAJ PLO PLY _____Li mORLAL HO USTRI N-IDIRISULNA COUNTBREDSN-B _LIRROLSA oego rr--i IBARBSNBSOORTORED BBILIRE ULoCI LLCAS LOROR00 DRABALAA TAB ALSAI -BESLEY N-ISIRA IBOLARNOPOLNISI-OASA1 /LIBA B-I TELA BALSACOTYB LI IBAJJ CAFABRO932 BATORHsAL - 1flSAfl fl-BZ S/BCO HIS RB0 OR50EHALEH-H1B-hR-NBALSA _ORBACH/11 AL0020WON1111 IHIRAE BE-4RA LEOI OR BA DIE PLY A___ B H/A ~ TLRL-R ISO DOD RE RB SOS RBASTLCRIGHT BGOIL 1BIS-B/LN I0-OLE02-LAN BAtHS EL/fl IRB1JL U -=- F_ rBHLTLAN TRL 71j PLY HDOLOCOCO LA COW FORMER00 0 SORO OPEHEBI flNBJDDER RIBS MODEL AVIATION SEA LOON-FLYING BOAT DESIGNED B DRAWN BY 0 LENRN TRACING BY JOE DEMARCO Left With keel 1/8-in sq chine strips place sand keel hull sides conform hulls V cross section add right left spray sheets spray strips Right completed hull including cover drawings reflect recent modification cover now ends wing leading edge balsa faring extends back cover See text water-proofing hints October 1987 29 Y9REEOICEB SOBIUIB BALSA BOBU F LAHIALTAP ABA COTROB BALLS SOPYLHB BLAT Full-Size Plans Available. See Page 188 Left The completed covered wing Note area thats left uncovered fairing will glue Right Boom construction Pre assembled bulkheads glued side -triangle stock outer control cable tubes should installed time Left Attach right left fins booms Note location cable sheath shown upper boom Right Assemble rudders shown again pinning pieces corkboard jig left-side sheeting plywood water rudders still added research wing design spin resis tance configuration increases stalling angle drooped portion good 100 also provides effective aileron response high angles attack third design author has incor porated such leading edge droop three confirm NACA research As drawings show Sea Loon incorporates some beneficial modifications original design hull has lengthened inch mainly move flap servo forward easier access also avoid nose ballast NACA low-drag air scoop inlets outlet have en larged slightly better engine cooling ground block wing tips extend drooped leading edge Note offset servo wheel aileron servo hull feature provides aileron differential much greater up ward downward aileron deflection result smooth banked turns adverse yaw hence no rudder action Engine Starting inverted engine its nacelle position easily started electric starter room between spinner horizontal tail plane permit However after priming engine flip prop hand several times make certain no fuel trapped between piston cylinder head unusual resis tance felt tip model Tatone manifold downward permitting trapped fuel drain out through cylinders exhaust opening Trying start engine model inverted engine upright awkward recommended Flying small model Waves three four inches height would have impact comparable three- fourfoot waves full-scale shipthat would make takeoffs dangerous im possible Sea Loon therefore successful water takeoffs require dead calm gentle ripple condition positive side models small size light weight permit hand launching wing tip droop paid off couple authors bad hand launches upward instead level slightly down Good piloting plus good aileron control averted otherwise inevitable crash Water takeoffs will shortened half flap deployment Landings flaps fully deployed can made water grass removable tricycle landing gear 30 Model Aviation Left Spray strips sharp corners help reduce spray thrown up hull Above Wing assembly done jig made 1/8-in corkboard 1/2-in plywood Mylar strips prevent glue adhering cork Note authors antenna installation Len I ne stab elevator assemwies strip trailing edge stock holds lower stab sheeting against front . ht underside horizontal tail plane right hand balsa tip block reveals location rear elevator control smurn Left The simple Jig used assemble hull wing booms horizontal tail plane Text drawings provide additional details Right FInal assembly point four hull servos have installed elevator rudder pushrods connected proper surfaces shown drawing optional Basically its needed landings made pavement nose wheel steer able onboard glow plug heating arrange ment really works No in-flight inverted engine quits have occurred Note both throttle lever trim lever down position engine shut down glow plug heating circuit deacti vated full throttle circuit also deactivated Recently flew larger flying boat shore large lake pickup boat standing glow plug arrange ment inverted engine identical Sea Loon After six- sevenflight session taxied model back shore under its own power delib erately shut engine down Three fellow RC club members John Jeffrey Dick Murray Ken Sharkey have flown Sea Loonand backed up its virtues comment Its good airplane Construction Sea Loons structure based stressed skin concept surfaces sheet balsa minimum internal components construction light yet surprisingly strong Note true-lengths curved surfaces such hull sides nacelle sides etc shown drawing Build components according guidelines drawing Detailed instruc dons assembly major component follow Nacelle Successful nacelle assembly de pends correct sequence operations followsContinued page 32 October 1987 31 Left Flap assembly two sections left complete two right missing upper sheeting detail rib locations Upper sheeting attached end wrapped over ribs glued piace outer ply ribs indented provide space 1/64 brass torque arms Right finished flaps torque rods arms plywood supports Aligning flap leading edges -in strip open nacelle reveals engine servo switch on-board battery Note piece toothpick CyAed servo prevent roller lever jamming servo arm Assemble engine mount cut slot servo wiring Solder wiring see diagram Radio Shackiack mount its ply base Rough-shape balsa nose block hollow out Epoxy jack mount position Install bulkhead Ni add sides Install servo extension cable through slot nacelle strut Using contact cement attach fitted tank foam pads Using three outlet holes tank plugfor engine fuel manifold pressure fuelingis recom mended Plug open end fueling tubing rivet small screw Mount Radio Shack battery holder ply base using 356 bolts nuts Complete soldering connections glow plug wiring see wiring diagram Mount battery holder its base using epoxy Install servo mount again using epoxy Install servo connect servo extension mount engine Connect 045-in music wire pushrod mini-link clevis both servo engine throttle arms Using cyanoacrylate glue CyA attach Radio Shack roller lever switch servo shown Attach nacelle cover components nacelle Make cowling laying up two layers medium-weight fiberglass form see photo drawing Assemble ply spinner ring its companion piece using Hobby Poxy #2 adhesive has cured dissolve styrofoam core acetone gasoline trim cut cowl parting line Epoxy top portion cowling bulkhead #2 align spinner ring spinner Note 3A2-in plywood washer engine crankshaft Position rear cowl plywood making sure flat attach hold-down assembly *2 shoulder screw Install lower cowling fit rear cowl hold-down assembly cowl ing closes properly Positioning both nacelle epoxy cowl rear holddown assembly prevent bonding lower cowl bulkhead #2 insert waxed paper between hold-down assembly bulkhead Finally sand nacelle shape Hull Prebend hull sides using liquid ammonia Arrange weights supports hold sides bent position until dry subassembly bulkheads parts Hi H2 H4 H4A H5 Install 3/16-insq servo mounts -in-sq balsa sides Assemble sides top front bulkheads switch used X Acto clamps operation Install ply servo mounts keel Install l-in-sq balsa chines Sand keel chines meet N bulkhead bottoms Fit bottom planking right left sides keel cement itto keel bulkheads chines Add nose block sand shape Continued page 34 Weve known put out great catalog literally best business Because take AC seriously years catalog no exception Packed over 200 pages lull color action photographs 1988 Catalog next best thing favorite RC dealer contains everything Robbe makesboats cars planes gliders accessories beginners barnstormers over 450 products 1988 Catalog can bring right home Youll find Robbes 1988 Catalog AC dealer now use coupon send yours today Just $500 Plus youll receive $400 certificate good towards next Robbe purchase EUUEUEUUEUEEEUUEUUUUU Rush Robbes new cetaleg. Enclmd $5J10 I] Cheek 0 Money Order U U U U U U U U U U U U U City/State/Zip Mail Robbe Modelsport 180 Township Line Rd. BeUe Mead NJ 08502 Cectificate expires 12/31187 Good purchases $50 over direct Robbe 7 ego ezect4e daud FROM THE 20S. Y FAVORITE OF THE GOLDEN ERA OF FLIGHT WITH THE 05 ELECTRIC POWERED SPORT-SCALE 54 SPAN 425 SQ AREA WEIGHT 5 OZ WITH 3 CHANNELS ALL DAVEY SYSTEMS ELECTRIC KITS ARE NOW AVAILABLE WITH OR WITHOUT THE MOTOR AND/OR GEARBOX AND FROM THE 40SBRING BACK THE NOSTALGIA OF THE FABU LOUS PIPER PA-I 2 SUPER CRUISER WITH MAJESTIC SCALE-LIKE PERFORMANCE 1/5 SCALE FOR 60 2 CYCLE OR 90 4 CYCLE ENGINES 85 SPAN 1040 SQ AREA 9-10 LBS WITH 4 CHANNELS DAVEY SYSTEMS CORPORATION pleased announce acquisition CHAMPION MODEL AEROPLANE COMPANY line fine model kits addition CHAMPIONS extensive variety high quality kits including trainers old timers pattern scale WW II DAVEY SYSTEMS can now offer modeler complete line Whatever preference engine powered sailplane electric. have HIAVEY YSTEMS ORPORATION 675 TOWER LANE WEST CHESTER PA 19380 215-430-8645 Carry Largest Only Stock Kraft Parts World .. Kraft alive working KRAFT MIDWEST LL FLY WHAT FIX Autboejoed Warranty Service PREQUENCY CONVERSION $1000 Diecoont Reguler Repair Moat Make Modola Converted Tuning Done Spectrum Analyzer Also Service ACE El/CjjiiSha Only Full Time Servicenter Midwest 117 East Main St Northvilte Michin 48167 Level M8StbPhone 1-313-348-0085 Add spray strips sand contours shown bulkhead portion drawing accompanying photos Attach cover components hull radius corners Wing Assemble rudder-elevator torque tubes aileron torque tubes Note A-in-dia elevator tube rides -in-dia rudder tube Study draw ing carefully torque tubes hinges transfer output single elevator single rudder servos two sets pushrods necessary operate twin elevators rudders Solder bushings inside Y6-in-dla tube ends complete hinges stops /s2-dia soldered both sets tubes prevent end-play %z dia bearings supported /16 ply plates Both ply bearings epoxiedto ribs K&S Engineering brass tubing -in brass strips used Solder horns securely tubes Make jig -in corkboard -in plywood n strip balsa cemented jig shown cater slight undercamber E-193 wing section Mark rib locations three lower wing skins Pin skins jig shown Cement -in trailing edges TE position Position lower -insq spar three sets torque tubes skins rib cutouts will locate Install ribs epoxy ply bearing supports seven Add upper -in-sq spar /16 balsa webbing between ribs Add balsa ply dihedral joint reinforcements -rn triangular stock Install three drilled blocks wing hold-down antenna installed along brass tubing coupling composed -in lengths 6 /32 tubing shown drawing However necessary cut antenna before installation join two pieces later coupling made up two -in lengths brass tubing Vs6 brass tube section free-sliding fit /32 tube section bit solder should melted onto Y16 tube filed down good tight electrical connectionyet still permits us readily disconnect two sections Measure antenna carefully before cutting point four inches receiver After soldering coupling halves both sections using heat-shrink tubing over solder joints joining measure again will necessary cut bit far end antenna compen sate coupling important antenna same length before first cut have used procedure five models its own antenna permanently installed either fuselage wing absolutely no problem permits moving receiver model model easily Install aileron outboard pushrod devises horns run out through ply guides aileron pushContinued page 36 34 Model Aviation ATT- CHEIC1 ON-Board Battery Tester Saves Time. Saves Models BAiTCHEK RX-1 eIn $1495 USA Install RC Models Check receiver battery status press button Small Light 1/2 oz Precise Rugged ORDER TODAY dealer Protune Corp 914 462-6452 PO Box 1808 Poughkeepaie NY 12601 SUPERIOR DESIGN________ & CRAFTSMANSHIP DEL-A IR& 01 need easy handling superior acrobatic modern looking sport exhibitIon biplane has filled SelAir ee kit parts biplane fine line kits machine cut asslat building real show atopper Set-Air 60 has fully aummetriosi wing aectiona Thia gives greatest potential aerobatic performance either upright inverted Thia ship capable very slow close-in type flight right up rigorous acrobatic schedule can muster 60 52 935 0 40 IFICATIONS Fuselage Width Weight Range Wing Loading Range 35, 6 75 lbs 148 185 207-490-1881 Visa MasterCard Accepted 4 NORTHEAST AERODYNAMICS Inc_______ SiC LEBANON STREET SANFORD E 04073 S7246018S1 Finest Kits Youll Ever Buy Build Train-Air 20 Train-Air 40 Sport-AIr 40 Bel-Air 40 40 Hydro-Floats rods Y32-dia music wire attached mini-link clevis using aded portion 2-56 coupling sup plied No 507 cable sets soldered music wire permit adjustment ailerons trim purposes tap mini-link 2-56 threaded coupling will turn reasonably freely clevis access holes outboard skins lower wing purpose rear elevator clevis shortened mini-link connected elevator cable using aded coupling drilled its full length carbu retor clevis attached 045-in-dia music wire pushrod similar fashion brass coupling must drilled 344 dia accommodate wire Bend pin lower wing skin leading edge LE rib contour cement securely Cement center-section upper wing skin spars ribs except LE Fit outboard upper wing skins inner ribs Cement spars ribs again except LE Using -in masking tape hold skin place cement upper skins ribs lower skin done placing three-inch lengths tape along chord sheeting 1 -in centers hold wing skin leading edges cement setting up Install triangular cross-sectioned strips onto rear spar positioned front both ailerons flaps four pieces latter sanded formthe flap slot lid Booms Assemble bulkheads install ing landing gear lace epoxy piece Yt6-sq brass tubing bulkhead B2 Cement both -in triangular stock -in-sq strips four boom sides Attach bulkheads boom sides install plastic tube sheath ele vator rudder Add top bottom boom sheeting Note bottom sheeting compared shown photo has shortened front pertnit access elevator rudder horns Add pieces B8 B9 BlO BL 1 Defer installation ofBl2 lower forward skin order provide access rudder elevator horns during final assembly Add balsa nose blocks sand shape Sand top corners add -in ply skeg lower rear end boom Fins Install fin spars correct angle 92 shown drawing bottom skin Add right-hand skins ribs Rl R2 R3 R7 rib added right-hand side well elevator tube casing attached CyA Add left-hand skins cement LE liberally tape masking tape wing LE Add blocks R9 sand LE radius Add R4 Rudders Assemble right-hand skins Continued page 38 36 Model Aviation NEW Engine Requirement Wing Span Wing Area Fuesiage Length race flexible push rod serves servo best nothing beats Gold-N-Rod Sullivan Products Because Gold-N-Rods unique design allows lowest friction accurate transfer motion around curves push rod market Heres Etclusive spline design dramatically reduces friction between inner outer rod Sullivans demanding quality control insures tight fit minimal play between inner outer rods Gold-N-Rods special temperature-resistant resins help keep model trim comes convenient applications Gold-N-Rod soars above competition Youll find installation snap adjustments easier using Gold-N-Rods complete kit push rods studs Gold-N-Clevises So dont get thrown curve Instead go gold Gold-N-Rod Sullivan 77FF34fR 70E2V& LE spars ribs shown Note /16 ply rudder horn/rib Add left-hand skins sand shape Add 146 ply water rudder Flaps Assemble solder center /16 music wire pivot /32 brass tube /32 inboard horn two ply flap supports two brass flap horns Check solder joints carefully adequate strength Use hot soldering iron thoroughly clean areas soldered Assemble boom 146 music wire pivots two piy flap supports two / brass horns Solder carefully above Epoxy 146 music wire outboard pivots outboard ply flap ribs After covering flaps used MonoKate assemble shown carefully aligning flap leading edges epoxying brass horns ply end ribs Note ply flap supports position width two outboard spaces must clear boom sides free flap operation Ailerons Assembly similar elevator Note aileron ply inboard rib extends aileron LE provide aileron horn Stabilizer Elevator See two accompanying photos clear illustration stabilizer elevator construction Note -in balsa rib near right-hand end elevator 146-dia music wire elevator torque rod inserted rib spar grooved rod submerged balsa structure photos see right-hand stabilizer tip block stabilizer end elevator brass horn visible Covering Installing Hinges chose MonoKote covering took care leave generous -in overlap seams prevent leakage Ailerons rudders elevator side hinged using double MonoKote procedure shown right-hand end wing portion drawing provid ing both hinging gap-seal method affords effective oontrol sure surfaces operate freely both directions Leave underside wing bare booms make contact balsa-to-balsa cementing can take place Cement stabilizer end blocks stabilizer shape Drilling Tapping suggested three drilled holes wing hull nacelle hold-down blocks used align mating holes hull nacelle maple blocks Ensure wing hull alignment correct before drilling same applies two covers Use No 29 drill 8-32 threads aNo 50 drill 2 56 tap holes accord ingly Final Assembly simple jig assem Continued page 138 38 Model Aviation push comes shove Sullivans Gold-N-Rod smoothest around curves P00 DUCTS Dee Noih Have, S,ee ox 5166 Blmore MD 21224 732-3500 DJly .hInnporn Made USA NEW LITTLE GIANTS ULTRALOK* Travel Air 2000 Span 79 Length 58875 Wing Loading 14 lbs 19 oz Introductory Price $15495 Travel Air 04000 D4D Span 785 Length 5675 Wing Loading 15 lbs 21 oz Clip Wing Span 695 Introductory Price $17495 Fleet Model 2 Span 68 Length 51 Wing Loading 13 lbs z Introductory Price $15495 1/5 Sport Scale Miniature Aircraft Highly Prefab Kit Form Featuring UL TRALOK Construction Techniques Super Fast Assembly Suitable 90 2 Cycle 2 Cubic Inch Gas Quarter Scale Travel Air 2000 23 lbs Travel Air 40009925 lbs Mark 4JB Special Convertible ow Wing IS lbs plan 2 versions 78 Biplane 18 lbs Fokker D-VlI 88 German WWI Fighter Biplane 23 lbs Waco UPF-7 iplane 23 lbs Sopwith Tripehound 80 WWI Triplane 17 lbs Sopwith Pup 80 WWI Biplane 20 lbs kIts complete contaIn fiberglass parts preformed landIng gear cabanes machIned & dl cut wood full hardware package Plans Included wIth comprehensIve construc sIan manual contaIning photoa addItIonal drawlnga Full rIggIng kIts requirIng lIttla akIll IncludadAlso Available Preformed Landing Gear Cabanes ORDERING INFO orders shipped UPS Parcel Post Add *iO shipping charge Allow 4 weeks delivery Checks MO payable Behrlan Corp fastest service send Postal Mortey Order bank cheqk No COD orders Call write information NV State reaiderta add appropriate seles tea * ITT 7DAJIIlr internotched self-aligning goof-proof assembly method Construction fast simple UI-i 1I&tIIjLI1 will able frame airplane about 25 hours Air Kit Experts Jerry Behrens Behrlan Corp PO Box 174 Inwood NY 11696 718 337-6987 516 868-5194 Safety/Preston Continued page 22 botched may also prudent student very skilled have him deliberately start dead-stick approach little high figuring first dead-stick landing will really landing merely pass down center line runway altitude 50 ft Practice makes perfect dont settle just successful attempt Have student repeat approaches until comfortable knowing model will perform true emergency None above discussion answers ques tion attempt return runway engine dies climbout recommenda tion would always avoid turn hack runway possible Ive seen lot models re-kit themselves attempted However knowing glide performance model will help make correct decision such circumstances Have another safe month Joht Preson 2812 Northampton St NW Washington DC 20015 Sea Loon/Lennon Continued page 38 bly hull wing booms horizontal tail plane necessity drawing provides dimensional detail blocks styro foam Install four servos the hull attach five clevis-and-pushrod assem blies flap aileron rudder ele vator horns protruding wing center Section underside Install wing hull Pushrods aileron elevator rudder pass through opening provided bulkhead H3 flap pushrod passes through bulkheads H3 H4 wing may bolted hull pushrods installed con nectors appropriate servos Position wing-hull assembly fixture keel resting full-length board Install booms cementing liberally wing align Add horizontal tail plane shown cement cement has set install rudder elevator pushrods booms front connection rudder horn made right-angle bend /32-dia music wire pushrods Attach rudder elevator devises booms appropriate horns Connect rudder L-bends cutdown elevator rear devises rudder elevator horns Adjust threaded couplings forward rudder elevator devises rudders elevators neutral position forward horns vertical Add lower boom cover B 12 cover MonoKote nacelle installed its slot wing liberally cemented after pulling engine servo extension wiring forward hull Add wing-strut balsa block fairings install upper lower wing skins ribs fill gap between flap inboard ends holes ribs Ae flap torque rod should fit closely rods prevent leakage Sealing Use silicone seal wing-to hull connections below wing hull openings sealed covering MonoKote after adjusting servopush rod connections see photo slit MonoKote will permit receiver batterycharging jack pulled out charging Masking tape will seal slit hull cover installed over MonoKote seal Landing Gear removable tricycle landing gear shown photos drawings optional Its installation does significantly alter center-of-gravity CG location landing gear legs enter sockets melt bit solder can filed provide firm yet easily removable connection Exhaust Manifold Tatone 09- 19 ends threaded 2 56 accept 2 56 nuts shown nacelle top view Use No2 lock washers under nuts However possess Dremel drill drill press better method hand Drill No 50 tap 2- 56 bosses side engine exhaust OS Max 15 RC -in deep Drill corresponding holes lower half engine inverted manifold permits bolting half manifold directly engine 2 56 bolts li-in long No 2 lock washers upper half manifold installed holes normal attachment method plugged short 4 40 bolts after being tapped 4 40 threads brass exhaust tube held manifold small self-tapping screw supplied Goldberg flat hold-downs inserted 6 hole drilled through both manifold tube Bending brass tube exhaust does impinge wing requires heated red-hot bent very carefully avoid buckling Now youve built Sea Loon youre ready try first launching Wait day water quiet barely ripplingand watch break free waters bond Youre going enjoy flying boat Radio Technique/Myers Continued page 41 second training sessionReview Fun damentals means student should maneuver least once As instructor looking confidence student can keep airplane upright level he/she understands turns Continued page 140 138 Model Aviation Full Kit $25000 $26000 $25000 $26000 $26000 $27500 $29000 $25000

Edition: Model Aviation - 1987/10

Page Numbers: 24, 25, 26, 27, 28, 29, 30, 31, 32, 34, 36, 38, 138