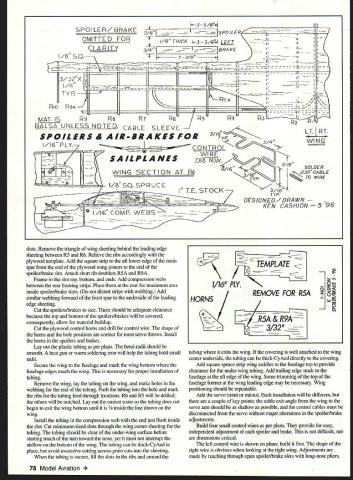

U Ken Cashion couple decades ago Frank Zaic gave such good advice about spoilers put placard model shop Dons t go too high want come down huny Getting models back down easy disconcerting maintain visual contact sun reflecting fluttering wings Yes getting down easy stress sometimes difficult Spoilers air-brakes permit models come down huny safely Just significant allow us cruise way up just below frantic altitude Adding spoilers model during construction isnt difficult what about already-built modelthe real good almost lost last Sunday started working League Electric Soarings Right Achievement Program flying Goldberg Electra too high again soT decided needed spoilers might well add air-brakes have used configuration sailplanes Spoilers Spoil Lot Spoilers may operate like think spoilers raised small amount spoil lift over section wing model still weighs same less wing developing lift wing-loading has effectively increased spoiler eight inches long much wing lost Sixteen inches No turbulence four ends spoilers also reduces lift flight-tested different spoiler shapes sizes 12-foot sailplane appeared turbulence messed up about inch wing spoiler end Therefore using eight-inch spoilers about 20 inches wing no longer developing much lift Right quite two other factors Spoilers create lots drag slowing model consequently wing area still producing lift producing less lift because lower airspeed spoilers located widest wing section losing inch wingspan involves lot area toward tip So much wing lost aerodynamic realm fly have told Knowing Engineers three-to-one good ratio Whoa Eight-inch spoilers eliminate 48 inches wing lam too sure believe point spoilers dump lot lift might first think Hying Modifications Become familiar positions transmitter spoiler control produces h-inch spoiler deployment half deployment full deployment low altitude practice flying spoiler positions spoilers will needed such high altitudes flier will able see what model doingbased low-altitude practice will have know Learn fly comfortably first position high-altitude cruising position because later model strong lift tiny cross overhead spoiler position might used lot Full spoiler/brake deployment isnt necessary below 1000 feet unless flier precision competition showing off lightalng getting close Modification Procedure applicable almost built-up wing providing mounts top fuselage modifications added ounce wing 3/4 ounce fuselage no apparent CG shift canopy still fit Spoilers brakes could added both Review models original construction plans Modify left right wing same time used thick thin cyanoacrylate CyA Remove plastic wing covering R4 Rb exposing six rib baystop bottom both wings Remove covering wing bottom between R3 R4 between front rear spars careful score wood removing covering Use covering iron remove colored adhesive left wing Make plywood template per drawing Cut four short rib doublers two R5A R9A end ribs spoiler/brake 76 Model Aviation s Authors Goldberg Electra prior modification Process took about nine working hours complete Wing underside slots framed tubing installed brake sitting place Tubing does disturb airflow Top left wing shows slot framing compression webbingPreparing flight tests Servo installation does affect fit brake horn adjustable control wirecanopy Mini micro servos can used April 1997 77 Electra spoilers air-brakes full deployment position often neededpractice low altitude first Internal control wires ensure spoilers brakes held flush wing Pic 5/32X TYF P 9A MAT IS Ps BALSA UNLESS 1/8 K k33/8A LEFT - ----- - ________ P7 kiOTFfl CABLE TIII II-I Y.P5A_______J --\_____ ____ II ________-II1i P6P5RP2 Ri SLEEVE SPOIL ERS& AIR-BRAKES FOR /16 PLY 6 3/Id TYR WIRE SAILPLANES 018MW /16 K~SOLDER WING SECTION AT PG3/16 TYP23O CABLE 3/16 T YP KEN CASH/ON - --------- ..DESIGNED/DRAWN 01/16 COMP WEDS -o slots Remove tnangle wing sheeting behind leading edge sheeting between R5 R6 Relieve ribs accordingly plywood template Add square strip aft lower edge main spar end plywood wing joiners end spoiler/brake slot Attach short rib doublers R5A R9A Frame-in slot top bottom ends Add compression webs between rear framing strips Place rear maximum area inside spoiler/brake slots distort strips webbing Add similar webbing forward front spar underside leading edge sheeting Cut spoilers/brakes size should adequate clearance because top bottom spoilers/brakes will covered consequently allow material buildup Cut plywood control horns drill control wire shape horns hole positions correct servo throws Install horns spoilers brakes Lay out plastic tubing per plans bend-radii should smooth heat gun warm soldering iron will help tubing hold small radii Secure wing fuselage mark wing bottom fuselage edges touch wing necessary proper installation tubing Remove wing lay tubing wing make holes webbing end tubing Push tubing hole mark ribs tubing feed-through locations R6 R5 will drilled others will notched Lay out easiest route tubing does begin exit wing bottom until inside line drawn wing Install tubing compression web end just flush inside slot Cut minimum-sized slots through wing center sheeting tubing tubing should clear under-wing surface before starting much turn toward nose yet must interrupt airflow bottom wing tubing can thick-CyAed place avoid excessive cutting across-grain cuts sheeting tubing secure fill slots ribs around tubing exits wing covering well attached wing center underside tubing can thick-CyAed directly covering Add square spruce strip wing saddles fuselage top provide clearance under-wing tubing Add trailing edge stock fuselage aft edge wing Some trimming top fuselage former wing leading edge may necessary Wing positiomng should repeatable Add servo mim micro installation will different couple key points cable exit-angle wing servo arm should shallow possible control cables must disconnected servo major alterations spoiler/brake adjustments Build four small control wires per plans provide easy independent adjustment spoiler brake difficult nor dimensions critical left control wire shown plans build first shape right wire obvious looking right wing Adjustments made reaching through open spoiler/brake slots long-nose pliers 78 Model Aviation T WING 5 96 1/16 PLY REMOVE FOR R5A HORNS R5A&R9A shape also helps prevent overloading servo extreme ends servo throw holds spoilers/brakes closed under spring compression Solder control wires control cable cut cable slightly overlength solder end cut cable prevent fraying clean off flux Install cables through slots temporarily attach spoilers/brakes respective control wires Slight bending control wires will let spoiler/brake surfaces sit flush Almost tape can used temporary hinge Check spoiler throw select appropriate horn hole connect cable servo arm short piece tubing over cables will prevent excessive cable flexing small collar can used between servo control horn wing clamp cables together after everything has adjusted reasons greater servo throw needed distance control horns must travel no problem reduces criticality dimensions Adjust control wires attachment servo until operate properly wing can removed reinstalled easily proceed until can done everything operating properly wing spoilers brakes can covered may necessary retrim seating position spoilers/brakes agalnst ribs because added covering thicknessuse emery boards Doping sealing exposed balsa plywood horns would good idea time Add Y32 balsa tape close all-open rib bays restricting movement control wires horns Add hinges used TrimKote Thin cardboard shims can used ends trailing edge spoiler/brake slots hinges can properly positioned Total work time nine hours three minutes have questions about conversion League Electric Soaring please write AiEaftPa INCORPORATED WORLDS LARGEST MANUFACTURER OF SUPERIOR EPOXY-GLASS COWLS WHEEL PANTS 8 ACCESSORIES CALL NOW 810 677-0213 FAX 810 677-0414 orders U U iU 451 WN .1VU EM Ia. ana oniy rive minutes can upgraae stan dard Futaba Airtronics servos ball bearing servos new EMS Ball Bearing Conversion Kit New case tops accurately molded super tough glass filled fuel-proof Celcon include top quality stainless steel ball bearing servo output shaft * Stops case top andlor plastic bushing wear * Prevents output gear shaft shimmy * Reduces friction improves servo centering * Enhances performance airplanes boats & cars * Mandatory helicopter servos * Free output arm provided case top * Guaranteed against breakage year * pay $3995 $2995 BC-i Fits FUTABA S28/St28 S38/S138 S48/St48 Servos set 4$2595 -2As above set I$695 i-3Fits AIRTRONICS 94102 Servos set 4$2595 1X4As above set I$695 BBC-5BaIt Bearing Only JR 501 507 RCDAPOLLO 05 10 FOCUS HS300 HS500 ACE 330342 342HS TOWER TS-5 Servos set 4$1995 Add $3 00 Shipping Handling ail orders 92-1393 Info Only California Residents Add 775% Sates Tax 800 845-8978 Orders OnlyVISA MASTERCARD Accepted April 1997 81 Send $100 forOpen $200 C. Monday Friday $300 outside USA10 am 4 pm EST Ken Cashion 157 Tennyson Cove Picayune MS 39466 YUIUO LII lUd Ut

Edition: Model Aviation - 1997/04

Page Numbers: 76, 77, 78, 81

U Ken Cashion couple decades ago Frank Zaic gave such good advice about spoilers put placard model shop Dons t go too high want come down huny Getting models back down easy disconcerting maintain visual contact sun reflecting fluttering wings Yes getting down easy stress sometimes difficult Spoilers air-brakes permit models come down huny safely Just significant allow us cruise way up just below frantic altitude Adding spoilers model during construction isnt difficult what about already-built modelthe real good almost lost last Sunday started working League Electric Soarings Right Achievement Program flying Goldberg Electra too high again soT decided needed spoilers might well add air-brakes have used configuration sailplanes Spoilers Spoil Lot Spoilers may operate like think spoilers raised small amount spoil lift over section wing model still weighs same less wing developing lift wing-loading has effectively increased spoiler eight inches long much wing lost Sixteen inches No turbulence four ends spoilers also reduces lift flight-tested different spoiler shapes sizes 12-foot sailplane appeared turbulence messed up about inch wing spoiler end Therefore using eight-inch spoilers about 20 inches wing no longer developing much lift Right quite two other factors Spoilers create lots drag slowing model consequently wing area still producing lift producing less lift because lower airspeed spoilers located widest wing section losing inch wingspan involves lot area toward tip So much wing lost aerodynamic realm fly have told Knowing Engineers three-to-one good ratio Whoa Eight-inch spoilers eliminate 48 inches wing lam too sure believe point spoilers dump lot lift might first think Hying Modifications Become familiar positions transmitter spoiler control produces h-inch spoiler deployment half deployment full deployment low altitude practice flying spoiler positions spoilers will needed such high altitudes flier will able see what model doingbased low-altitude practice will have know Learn fly comfortably first position high-altitude cruising position because later model strong lift tiny cross overhead spoiler position might used lot Full spoiler/brake deployment isnt necessary below 1000 feet unless flier precision competition showing off lightalng getting close Modification Procedure applicable almost built-up wing providing mounts top fuselage modifications added ounce wing 3/4 ounce fuselage no apparent CG shift canopy still fit Spoilers brakes could added both Review models original construction plans Modify left right wing same time used thick thin cyanoacrylate CyA Remove plastic wing covering R4 Rb exposing six rib baystop bottom both wings Remove covering wing bottom between R3 R4 between front rear spars careful score wood removing covering Use covering iron remove colored adhesive left wing Make plywood template per drawing Cut four short rib doublers two R5A R9A end ribs spoiler/brake 76 Model Aviation s Authors Goldberg Electra prior modification Process took about nine working hours complete Wing underside slots framed tubing installed brake sitting place Tubing does disturb airflow Top left wing shows slot framing compression webbingPreparing flight tests Servo installation does affect fit brake horn adjustable control wirecanopy Mini micro servos can used April 1997 77 Electra spoilers air-brakes full deployment position often neededpractice low altitude first Internal control wires ensure spoilers brakes held flush wing Pic 5/32X TYF P 9A MAT IS Ps BALSA UNLESS 1/8 K k33/8A LEFT - ----- - ________ P7 kiOTFfl CABLE TIII II-I Y.P5A_______J --\_____ ____ II ________-II1i P6P5RP2 Ri SLEEVE SPOIL ERS& AIR-BRAKES FOR /16 PLY 6 3/Id TYR WIRE SAILPLANES 018MW /16 K~SOLDER WING SECTION AT PG3/16 TYP23O CABLE 3/16 T YP KEN CASH/ON - --------- ..DESIGNED/DRAWN 01/16 COMP WEDS -o slots Remove tnangle wing sheeting behind leading edge sheeting between R5 R6 Relieve ribs accordingly plywood template Add square strip aft lower edge main spar end plywood wing joiners end spoiler/brake slot Attach short rib doublers R5A R9A Frame-in slot top bottom ends Add compression webs between rear framing strips Place rear maximum area inside spoiler/brake slots distort strips webbing Add similar webbing forward front spar underside leading edge sheeting Cut spoilers/brakes size should adequate clearance because top bottom spoilers/brakes will covered consequently allow material buildup Cut plywood control horns drill control wire shape horns hole positions correct servo throws Install horns spoilers brakes Lay out plastic tubing per plans bend-radii should smooth heat gun warm soldering iron will help tubing hold small radii Secure wing fuselage mark wing bottom fuselage edges touch wing necessary proper installation tubing Remove wing lay tubing wing make holes webbing end tubing Push tubing hole mark ribs tubing feed-through locations R6 R5 will drilled others will notched Lay out easiest route tubing does begin exit wing bottom until inside line drawn wing Install tubing compression web end just flush inside slot Cut minimum-sized slots through wing center sheeting tubing tubing should clear under-wing surface before starting much turn toward nose yet must interrupt airflow bottom wing tubing can thick-CyAed place avoid excessive cutting across-grain cuts sheeting tubing secure fill slots ribs around tubing exits wing covering well attached wing center underside tubing can thick-CyAed directly covering Add square spruce strip wing saddles fuselage top provide clearance under-wing tubing Add trailing edge stock fuselage aft edge wing Some trimming top fuselage former wing leading edge may necessary Wing positiomng should repeatable Add servo mim micro installation will different couple key points cable exit-angle wing servo arm should shallow possible control cables must disconnected servo major alterations spoiler/brake adjustments Build four small control wires per plans provide easy independent adjustment spoiler brake difficult nor dimensions critical left control wire shown plans build first shape right wire obvious looking right wing Adjustments made reaching through open spoiler/brake slots long-nose pliers 78 Model Aviation T WING 5 96 1/16 PLY REMOVE FOR R5A HORNS R5A&R9A shape also helps prevent overloading servo extreme ends servo throw holds spoilers/brakes closed under spring compression Solder control wires control cable cut cable slightly overlength solder end cut cable prevent fraying clean off flux Install cables through slots temporarily attach spoilers/brakes respective control wires Slight bending control wires will let spoiler/brake surfaces sit flush Almost tape can used temporary hinge Check spoiler throw select appropriate horn hole connect cable servo arm short piece tubing over cables will prevent excessive cable flexing small collar can used between servo control horn wing clamp cables together after everything has adjusted reasons greater servo throw needed distance control horns must travel no problem reduces criticality dimensions Adjust control wires attachment servo until operate properly wing can removed reinstalled easily proceed until can done everything operating properly wing spoilers brakes can covered may necessary retrim seating position spoilers/brakes agalnst ribs because added covering thicknessuse emery boards Doping sealing exposed balsa plywood horns would good idea time Add Y32 balsa tape close all-open rib bays restricting movement control wires horns Add hinges used TrimKote Thin cardboard shims can used ends trailing edge spoiler/brake slots hinges can properly positioned Total work time nine hours three minutes have questions about conversion League Electric Soaring please write AiEaftPa INCORPORATED WORLDS LARGEST MANUFACTURER OF SUPERIOR EPOXY-GLASS COWLS WHEEL PANTS 8 ACCESSORIES CALL NOW 810 677-0213 FAX 810 677-0414 orders U U iU 451 WN .1VU EM Ia. ana oniy rive minutes can upgraae stan dard Futaba Airtronics servos ball bearing servos new EMS Ball Bearing Conversion Kit New case tops accurately molded super tough glass filled fuel-proof Celcon include top quality stainless steel ball bearing servo output shaft * Stops case top andlor plastic bushing wear * Prevents output gear shaft shimmy * Reduces friction improves servo centering * Enhances performance airplanes boats & cars * Mandatory helicopter servos * Free output arm provided case top * Guaranteed against breakage year * pay $3995 $2995 BC-i Fits FUTABA S28/St28 S38/S138 S48/St48 Servos set 4$2595 -2As above set I$695 i-3Fits AIRTRONICS 94102 Servos set 4$2595 1X4As above set I$695 BBC-5BaIt Bearing Only JR 501 507 RCDAPOLLO 05 10 FOCUS HS300 HS500 ACE 330342 342HS TOWER TS-5 Servos set 4$1995 Add $3 00 Shipping Handling ail orders 92-1393 Info Only California Residents Add 775% Sates Tax 800 845-8978 Orders OnlyVISA MASTERCARD Accepted April 1997 81 Send $100 forOpen $200 C. Monday Friday $300 outside USA10 am 4 pm EST Ken Cashion 157 Tennyson Cove Picayune MS 39466 YUIUO LII lUd Ut

Edition: Model Aviation - 1997/04

Page Numbers: 76, 77, 78, 81

U Ken Cashion couple decades ago Frank Zaic gave such good advice about spoilers put placard model shop Dons t go too high want come down huny Getting models back down easy disconcerting maintain visual contact sun reflecting fluttering wings Yes getting down easy stress sometimes difficult Spoilers air-brakes permit models come down huny safely Just significant allow us cruise way up just below frantic altitude Adding spoilers model during construction isnt difficult what about already-built modelthe real good almost lost last Sunday started working League Electric Soarings Right Achievement Program flying Goldberg Electra too high again soT decided needed spoilers might well add air-brakes have used configuration sailplanes Spoilers Spoil Lot Spoilers may operate like think spoilers raised small amount spoil lift over section wing model still weighs same less wing developing lift wing-loading has effectively increased spoiler eight inches long much wing lost Sixteen inches No turbulence four ends spoilers also reduces lift flight-tested different spoiler shapes sizes 12-foot sailplane appeared turbulence messed up about inch wing spoiler end Therefore using eight-inch spoilers about 20 inches wing no longer developing much lift Right quite two other factors Spoilers create lots drag slowing model consequently wing area still producing lift producing less lift because lower airspeed spoilers located widest wing section losing inch wingspan involves lot area toward tip So much wing lost aerodynamic realm fly have told Knowing Engineers three-to-one good ratio Whoa Eight-inch spoilers eliminate 48 inches wing lam too sure believe point spoilers dump lot lift might first think Hying Modifications Become familiar positions transmitter spoiler control produces h-inch spoiler deployment half deployment full deployment low altitude practice flying spoiler positions spoilers will needed such high altitudes flier will able see what model doingbased low-altitude practice will have know Learn fly comfortably first position high-altitude cruising position because later model strong lift tiny cross overhead spoiler position might used lot Full spoiler/brake deployment isnt necessary below 1000 feet unless flier precision competition showing off lightalng getting close Modification Procedure applicable almost built-up wing providing mounts top fuselage modifications added ounce wing 3/4 ounce fuselage no apparent CG shift canopy still fit Spoilers brakes could added both Review models original construction plans Modify left right wing same time used thick thin cyanoacrylate CyA Remove plastic wing covering R4 Rb exposing six rib baystop bottom both wings Remove covering wing bottom between R3 R4 between front rear spars careful score wood removing covering Use covering iron remove colored adhesive left wing Make plywood template per drawing Cut four short rib doublers two R5A R9A end ribs spoiler/brake 76 Model Aviation s Authors Goldberg Electra prior modification Process took about nine working hours complete Wing underside slots framed tubing installed brake sitting place Tubing does disturb airflow Top left wing shows slot framing compression webbingPreparing flight tests Servo installation does affect fit brake horn adjustable control wirecanopy Mini micro servos can used April 1997 77 Electra spoilers air-brakes full deployment position often neededpractice low altitude first Internal control wires ensure spoilers brakes held flush wing Pic 5/32X TYF P 9A MAT IS Ps BALSA UNLESS 1/8 K k33/8A LEFT - ----- - ________ P7 kiOTFfl CABLE TIII II-I Y.P5A_______J --\_____ ____ II ________-II1i P6P5RP2 Ri SLEEVE SPOIL ERS& AIR-BRAKES FOR /16 PLY 6 3/Id TYR WIRE SAILPLANES 018MW /16 K~SOLDER WING SECTION AT PG3/16 TYP23O CABLE 3/16 T YP KEN CASH/ON - --------- ..DESIGNED/DRAWN 01/16 COMP WEDS -o slots Remove tnangle wing sheeting behind leading edge sheeting between R5 R6 Relieve ribs accordingly plywood template Add square strip aft lower edge main spar end plywood wing joiners end spoiler/brake slot Attach short rib doublers R5A R9A Frame-in slot top bottom ends Add compression webs between rear framing strips Place rear maximum area inside spoiler/brake slots distort strips webbing Add similar webbing forward front spar underside leading edge sheeting Cut spoilers/brakes size should adequate clearance because top bottom spoilers/brakes will covered consequently allow material buildup Cut plywood control horns drill control wire shape horns hole positions correct servo throws Install horns spoilers brakes Lay out plastic tubing per plans bend-radii should smooth heat gun warm soldering iron will help tubing hold small radii Secure wing fuselage mark wing bottom fuselage edges touch wing necessary proper installation tubing Remove wing lay tubing wing make holes webbing end tubing Push tubing hole mark ribs tubing feed-through locations R6 R5 will drilled others will notched Lay out easiest route tubing does begin exit wing bottom until inside line drawn wing Install tubing compression web end just flush inside slot Cut minimum-sized slots through wing center sheeting tubing tubing should clear under-wing surface before starting much turn toward nose yet must interrupt airflow bottom wing tubing can thick-CyAed place avoid excessive cutting across-grain cuts sheeting tubing secure fill slots ribs around tubing exits wing covering well attached wing center underside tubing can thick-CyAed directly covering Add square spruce strip wing saddles fuselage top provide clearance under-wing tubing Add trailing edge stock fuselage aft edge wing Some trimming top fuselage former wing leading edge may necessary Wing positiomng should repeatable Add servo mim micro installation will different couple key points cable exit-angle wing servo arm should shallow possible control cables must disconnected servo major alterations spoiler/brake adjustments Build four small control wires per plans provide easy independent adjustment spoiler brake difficult nor dimensions critical left control wire shown plans build first shape right wire obvious looking right wing Adjustments made reaching through open spoiler/brake slots long-nose pliers 78 Model Aviation T WING 5 96 1/16 PLY REMOVE FOR R5A HORNS R5A&R9A shape also helps prevent overloading servo extreme ends servo throw holds spoilers/brakes closed under spring compression Solder control wires control cable cut cable slightly overlength solder end cut cable prevent fraying clean off flux Install cables through slots temporarily attach spoilers/brakes respective control wires Slight bending control wires will let spoiler/brake surfaces sit flush Almost tape can used temporary hinge Check spoiler throw select appropriate horn hole connect cable servo arm short piece tubing over cables will prevent excessive cable flexing small collar can used between servo control horn wing clamp cables together after everything has adjusted reasons greater servo throw needed distance control horns must travel no problem reduces criticality dimensions Adjust control wires attachment servo until operate properly wing can removed reinstalled easily proceed until can done everything operating properly wing spoilers brakes can covered may necessary retrim seating position spoilers/brakes agalnst ribs because added covering thicknessuse emery boards Doping sealing exposed balsa plywood horns would good idea time Add Y32 balsa tape close all-open rib bays restricting movement control wires horns Add hinges used TrimKote Thin cardboard shims can used ends trailing edge spoiler/brake slots hinges can properly positioned Total work time nine hours three minutes have questions about conversion League Electric Soaring please write AiEaftPa INCORPORATED WORLDS LARGEST MANUFACTURER OF SUPERIOR EPOXY-GLASS COWLS WHEEL PANTS 8 ACCESSORIES CALL NOW 810 677-0213 FAX 810 677-0414 orders U U iU 451 WN .1VU EM Ia. ana oniy rive minutes can upgraae stan dard Futaba Airtronics servos ball bearing servos new EMS Ball Bearing Conversion Kit New case tops accurately molded super tough glass filled fuel-proof Celcon include top quality stainless steel ball bearing servo output shaft * Stops case top andlor plastic bushing wear * Prevents output gear shaft shimmy * Reduces friction improves servo centering * Enhances performance airplanes boats & cars * Mandatory helicopter servos * Free output arm provided case top * Guaranteed against breakage year * pay $3995 $2995 BC-i Fits FUTABA S28/St28 S38/S138 S48/St48 Servos set 4$2595 -2As above set I$695 i-3Fits AIRTRONICS 94102 Servos set 4$2595 1X4As above set I$695 BBC-5BaIt Bearing Only JR 501 507 RCDAPOLLO 05 10 FOCUS HS300 HS500 ACE 330342 342HS TOWER TS-5 Servos set 4$1995 Add $3 00 Shipping Handling ail orders 92-1393 Info Only California Residents Add 775% Sates Tax 800 845-8978 Orders OnlyVISA MASTERCARD Accepted April 1997 81 Send $100 forOpen $200 C. Monday Friday $300 outside USA10 am 4 pm EST Ken Cashion 157 Tennyson Cove Picayune MS 39466 YUIUO LII lUd Ut

Edition: Model Aviation - 1997/04

Page Numbers: 76, 77, 78, 81

U Ken Cashion couple decades ago Frank Zaic gave such good advice about spoilers put placard model shop Dons t go too high want come down huny Getting models back down easy disconcerting maintain visual contact sun reflecting fluttering wings Yes getting down easy stress sometimes difficult Spoilers air-brakes permit models come down huny safely Just significant allow us cruise way up just below frantic altitude Adding spoilers model during construction isnt difficult what about already-built modelthe real good almost lost last Sunday started working League Electric Soarings Right Achievement Program flying Goldberg Electra too high again soT decided needed spoilers might well add air-brakes have used configuration sailplanes Spoilers Spoil Lot Spoilers may operate like think spoilers raised small amount spoil lift over section wing model still weighs same less wing developing lift wing-loading has effectively increased spoiler eight inches long much wing lost Sixteen inches No turbulence four ends spoilers also reduces lift flight-tested different spoiler shapes sizes 12-foot sailplane appeared turbulence messed up about inch wing spoiler end Therefore using eight-inch spoilers about 20 inches wing no longer developing much lift Right quite two other factors Spoilers create lots drag slowing model consequently wing area still producing lift producing less lift because lower airspeed spoilers located widest wing section losing inch wingspan involves lot area toward tip So much wing lost aerodynamic realm fly have told Knowing Engineers three-to-one good ratio Whoa Eight-inch spoilers eliminate 48 inches wing lam too sure believe point spoilers dump lot lift might first think Hying Modifications Become familiar positions transmitter spoiler control produces h-inch spoiler deployment half deployment full deployment low altitude practice flying spoiler positions spoilers will needed such high altitudes flier will able see what model doingbased low-altitude practice will have know Learn fly comfortably first position high-altitude cruising position because later model strong lift tiny cross overhead spoiler position might used lot Full spoiler/brake deployment isnt necessary below 1000 feet unless flier precision competition showing off lightalng getting close Modification Procedure applicable almost built-up wing providing mounts top fuselage modifications added ounce wing 3/4 ounce fuselage no apparent CG shift canopy still fit Spoilers brakes could added both Review models original construction plans Modify left right wing same time used thick thin cyanoacrylate CyA Remove plastic wing covering R4 Rb exposing six rib baystop bottom both wings Remove covering wing bottom between R3 R4 between front rear spars careful score wood removing covering Use covering iron remove colored adhesive left wing Make plywood template per drawing Cut four short rib doublers two R5A R9A end ribs spoiler/brake 76 Model Aviation s Authors Goldberg Electra prior modification Process took about nine working hours complete Wing underside slots framed tubing installed brake sitting place Tubing does disturb airflow Top left wing shows slot framing compression webbingPreparing flight tests Servo installation does affect fit brake horn adjustable control wirecanopy Mini micro servos can used April 1997 77 Electra spoilers air-brakes full deployment position often neededpractice low altitude first Internal control wires ensure spoilers brakes held flush wing Pic 5/32X TYF P 9A MAT IS Ps BALSA UNLESS 1/8 K k33/8A LEFT - ----- - ________ P7 kiOTFfl CABLE TIII II-I Y.P5A_______J --\_____ ____ II ________-II1i P6P5RP2 Ri SLEEVE SPOIL ERS& AIR-BRAKES FOR /16 PLY 6 3/Id TYR WIRE SAILPLANES 018MW /16 K~SOLDER WING SECTION AT PG3/16 TYP23O CABLE 3/16 T YP KEN CASH/ON - --------- ..DESIGNED/DRAWN 01/16 COMP WEDS -o slots Remove tnangle wing sheeting behind leading edge sheeting between R5 R6 Relieve ribs accordingly plywood template Add square strip aft lower edge main spar end plywood wing joiners end spoiler/brake slot Attach short rib doublers R5A R9A Frame-in slot top bottom ends Add compression webs between rear framing strips Place rear maximum area inside spoiler/brake slots distort strips webbing Add similar webbing forward front spar underside leading edge sheeting Cut spoilers/brakes size should adequate clearance because top bottom spoilers/brakes will covered consequently allow material buildup Cut plywood control horns drill control wire shape horns hole positions correct servo throws Install horns spoilers brakes Lay out plastic tubing per plans bend-radii should smooth heat gun warm soldering iron will help tubing hold small radii Secure wing fuselage mark wing bottom fuselage edges touch wing necessary proper installation tubing Remove wing lay tubing wing make holes webbing end tubing Push tubing hole mark ribs tubing feed-through locations R6 R5 will drilled others will notched Lay out easiest route tubing does begin exit wing bottom until inside line drawn wing Install tubing compression web end just flush inside slot Cut minimum-sized slots through wing center sheeting tubing tubing should clear under-wing surface before starting much turn toward nose yet must interrupt airflow bottom wing tubing can thick-CyAed place avoid excessive cutting across-grain cuts sheeting tubing secure fill slots ribs around tubing exits wing covering well attached wing center underside tubing can thick-CyAed directly covering Add square spruce strip wing saddles fuselage top provide clearance under-wing tubing Add trailing edge stock fuselage aft edge wing Some trimming top fuselage former wing leading edge may necessary Wing positiomng should repeatable Add servo mim micro installation will different couple key points cable exit-angle wing servo arm should shallow possible control cables must disconnected servo major alterations spoiler/brake adjustments Build four small control wires per plans provide easy independent adjustment spoiler brake difficult nor dimensions critical left control wire shown plans build first shape right wire obvious looking right wing Adjustments made reaching through open spoiler/brake slots long-nose pliers 78 Model Aviation T WING 5 96 1/16 PLY REMOVE FOR R5A HORNS R5A&R9A shape also helps prevent overloading servo extreme ends servo throw holds spoilers/brakes closed under spring compression Solder control wires control cable cut cable slightly overlength solder end cut cable prevent fraying clean off flux Install cables through slots temporarily attach spoilers/brakes respective control wires Slight bending control wires will let spoiler/brake surfaces sit flush Almost tape can used temporary hinge Check spoiler throw select appropriate horn hole connect cable servo arm short piece tubing over cables will prevent excessive cable flexing small collar can used between servo control horn wing clamp cables together after everything has adjusted reasons greater servo throw needed distance control horns must travel no problem reduces criticality dimensions Adjust control wires attachment servo until operate properly wing can removed reinstalled easily proceed until can done everything operating properly wing spoilers brakes can covered may necessary retrim seating position spoilers/brakes agalnst ribs because added covering thicknessuse emery boards Doping sealing exposed balsa plywood horns would good idea time Add Y32 balsa tape close all-open rib bays restricting movement control wires horns Add hinges used TrimKote Thin cardboard shims can used ends trailing edge spoiler/brake slots hinges can properly positioned Total work time nine hours three minutes have questions about conversion League Electric Soaring please write AiEaftPa INCORPORATED WORLDS LARGEST MANUFACTURER OF SUPERIOR EPOXY-GLASS COWLS WHEEL PANTS 8 ACCESSORIES CALL NOW 810 677-0213 FAX 810 677-0414 orders U U iU 451 WN .1VU EM Ia. ana oniy rive minutes can upgraae stan dard Futaba Airtronics servos ball bearing servos new EMS Ball Bearing Conversion Kit New case tops accurately molded super tough glass filled fuel-proof Celcon include top quality stainless steel ball bearing servo output shaft * Stops case top andlor plastic bushing wear * Prevents output gear shaft shimmy * Reduces friction improves servo centering * Enhances performance airplanes boats & cars * Mandatory helicopter servos * Free output arm provided case top * Guaranteed against breakage year * pay $3995 $2995 BC-i Fits FUTABA S28/St28 S38/S138 S48/St48 Servos set 4$2595 -2As above set I$695 i-3Fits AIRTRONICS 94102 Servos set 4$2595 1X4As above set I$695 BBC-5BaIt Bearing Only JR 501 507 RCDAPOLLO 05 10 FOCUS HS300 HS500 ACE 330342 342HS TOWER TS-5 Servos set 4$1995 Add $3 00 Shipping Handling ail orders 92-1393 Info Only California Residents Add 775% Sates Tax 800 845-8978 Orders OnlyVISA MASTERCARD Accepted April 1997 81 Send $100 forOpen $200 C. Monday Friday $300 outside USA10 am 4 pm EST Ken Cashion 157 Tennyson Cove Picayune MS 39466 YUIUO LII lUd Ut