f you have examined the accompanying photos you might be

thinking, “Hey, this airplane looks familiar.” And it should be

familiar. The Wildman 60 design of 1950 was strongly influenced

by a Control Line (CL) Precision Aerobatics, or Stunt, airplane

called the Dragon. It was the design of a young man named J.C.

Yates, and the construction article for it was published in the

November 1947 Air World magazine.

The Dragon was powered by a big Orwick .73 engine on spark

ignition. Its wing was a rectangular planform of only 475 square

inches, with a rather thin airfoil called NACA 99. The Dragon was

an immediate success, most likely because of its graceful lines in an

era when many CL Stunt models were simple “barn door” models

designed for maximum performance and good looks were

secondary.

The haphazard CL Stunt routine of the late 1940s was difficult

for judges and pilots. To bring some sort of order out of chaos,

George Aldrich and his colleagues proposed a new AMA Stunt

pattern with set maneuvers which everyone was obliged to fly.

Some of these maneuvers, such as the Wingover, Vertical Dive, and

Square Loop, required the model to dive toward the ground and

suddenly pull out to level flight. This clearly signaled the need for a

new type of aircraft.

Bob Palmer discovered that a lightweight model with wing flaps

would make a CL airplane turn better. His Go-Devil, Chief, and

Smoothie turned fliers away from high-powered, heavy, and fast

Stunters. Bob flew five-second laps with a glow Veco .29 barely

running at a slow four-stroke setting.

Most of my friends abandoned the old ways and followed Bob

Palmer’s example. I decided to make one last attempt using my

usual power package of an Orwick .64 and spark ignition. My

immediate problem was that the Orwick .64 engine and spark coil

and battery pack weighs 16 ounces. How could I design a CL model

to meet the demands of the new Stunt pattern?

My best solution was to design a larger airplane to carry the dead

weight of my power unit with a reasonable wing loading.

Since I had admired the sleek lines of the J.C. Yates Dragon, I

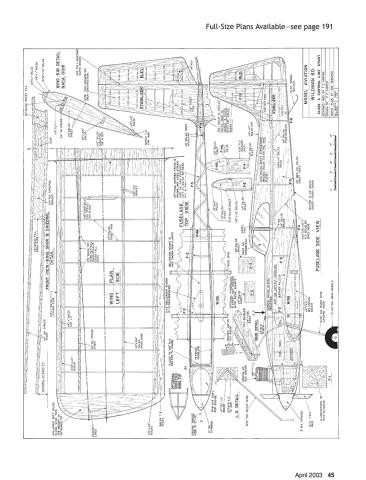

Wildman 60

■ Floyd Carter

Blast from the past for Old-Time Ignition CL Stunt events

I

The Wildman 60 design was heavily influenced by J.C.

“Madman” Yates’ Dragon, but it is a substantially larger

model.

Type: Old-Time Ignition CL Stunt

Wingspan: 591⁄2 inches

Engine: Ignition .60

Flying weight: 60-65 ounces

Construction: Balsa and plywood

Covering/finish: Silk and dope

Wildman 60

42 MODEL AVIATION

04sig2.QXD 1.24.03 8:38 am Page 42

designed Wildman 60 in the spring of 1950 with the Dragon in the

back of my mind. I settled on a wing planform of 60 x 12 inches

with a thick airfoil and a design weight less than 31⁄2 pounds.

I flew the prototype Wildman 60 in the Southern California

Plymouth meet at Redondo Beach, California, in 1950 and in

Phoenix in 1951. I earned no trophies for these efforts, but my

model flew much better than its pilot. I knew I had something good

going, but the judges at that time were more impressed with the

Bob Palmer style of slow flying.

CONSTRUCTION

The fuselage begins with a simple balsa-and-plywood box,

similar to many modern Stunters. But first you must select an

engine, because the fuselage front end is built around the engine of

choice.

If an Orwick .64 is not part of your collection, consider the

Cunningham Blue Streak .64 produced by RJL Industries (address

at end of text). The Blue Streak spark-ignition engine is similar to

an Orwick .64, but it features radial mounting and beam-mounting

lugs with a ball-bearing crankshaft. Suitable alternatives include the

Anderson Spitfire, the Super Cyclone, the McCoy .60, and other

strong engines.

The radial-mounting version of the Wildman 60 uses a hefty

plywood firewall securely tied into the fuselage and wing structure.

Beam mounting should utilize 1⁄2 x 5⁄8-inch hard-maple bearers

extending back to the wing cutout in the fuselage sides. Either

option begins with making identical fuselage sides from 1⁄8

medium-hard balsa sheet with matching wing cutouts. Plywood

doublers made from 0.8-millimeter or 1⁄32 birch plywood are glued

to the inside surface of each fuselage side.

April 2003 43

This shot with the top hatch removed shows the tank and coil

placement. Notice the modern Deans-type connectors.

The Orwick .64 is among the most beautiful of the ignition

engines, with its metallic-green-painted case.

Another view of the engine bay shows the clean lines of the nose

shape and the fine workmanship by Floyd Carter.

The author with his original design in 1950. He flew it in

competition then and now at Vintage Stunt Championships.

In-flight photo courtesy Elwyn Aud Graphic Design by Lydia Whitehead

04sig2.QXD 1.24.03 8:41 am Page 43

46 MODEL AVIATION

The radial-mount firewall F1 is epoxied

in place with the straight top of the

fuselage sides pinned to your building

board. Use a T-square to ensure that the

firewall will provide 0-0 engine thrust, and

glue in former F2 to establish the slight

taper, front to rear, of the fuselage sides.

Further bracing of the radial-mount

firewall to the fuselage sides is required,

using spruce triangular pieces behind the

firewall.

The plans show a molded plywood Ubrace

to further strengthen the firewallfuselage

interface, but this brace requires

building a male/female pine fixture to bend

and laminating the thin sheets of plywood

to make the U-brace. An alternate and

satisfactory method is to lay in fiberglass

cloth and epoxy to strengthen this joint.

For beam mounting, drill the maple

engine bearers and install T-nuts. Bolt the

engine to the engine bearers, keeping the

bearers parallel. This establishes the width

of firewall F1, which can be 1⁄8 birch

plywood for this option. If F1 turns out to

be different from what is shown on the

plans, the remainder of the fuselage

formers must also be adjusted to keep the

fuselage sides parallel back to the end of

the engine bearers and to establish the

required curve of the fuselage sides. If a

smoother taper in the fuselage top view is

desired, the engine bearers can be

narrowed aft of the firewall.

With the firewall epoxied in place and a

balsa fill-in between the engine bearers to

keep them parallel, this engine-mount

assembly can be epoxied to the plywood of

the fuselage sides. It is easier to epoxy the

engine-mount assembly to the fuselage one

side at a time. This gives you room to see

that the maple engine bearers are parallel

with the top of the fuselage and to use

weights on the engine-mount assembly to

ensure good contact with the fuselage side.

Epoxy the second fuselage side in place

with the fuselage sides turned upside down

on your flat building surface.

With the fuselage still mounted upsidedown

on the building board, glue in place

the remainder of the fuselage spacers,

formers, and doublers, and pull the

fuselage together at the tail post. Take care

to keep the fuselage curve symmetrical and

without any twist.

Build the fuselage turtledeck and top

block. The turtledeck on the 1993 Wildman

60 was made from two layers of 1⁄32 balsa

sheet laminated on a pine mold with a layer

of silkspan paper between. This requires

building a mold, but the result is light and

strong. Conventional construction is shown

on the plans.

The top hatch must be removable for

access to the spark-ignition components

and fuel tank. The removable hatch may

also include the simulated “cockpit,” or the

cockpit can be permanently glued to the

fuselage with the hatch separation line just

ahead of the cockpit. Either option will

provide enough access to the interior.

Notice that the fuselage gets no

torsional support from the top block. The

fuselage sides will be firmly anchored to

the wing center sheeting to stiffen the

fuselage in the absence of a glued-on top

block.

Tail Group: The prototype Wildman 60

had light 1⁄16 balsa covering over the builtup

tail. The 1993 model did not use balsa

covering. The tail group is a 3⁄8 x 1⁄2-inch

balsa outline. Double-glue the pieces

together and install 3⁄8-inch gussets at all

corners (not shown on the plans).

Cloth “over-and-under” hinges are

authentic and also seal the hinge gap for

better control response. Rayon taffeta

material works best. The tail group is

plenty strong with silk or heavy silkspan

covering.

The long tail moment and generous

stabilizer area provide authoritative pitch

control. Therefore, your bellcrank and

elevator horn geometry should be planned

for not more than 30° of elevator

movement up and down.

Wing: Build the spars with doublers first.

Draw your own dihedral template on a

large piece of plywood. Both wing panels

are the same length. Assemble the main

Hughes RC 1-800-786-0802 www.hughesrc.com

The CHARGE+ glow start charger

makes your pocket glow starter

as good as your power panel.

Charges at 1.6A, yet takes only

600mA from your field battery.

Use at home with AC adapter.

Peaks at highest voltage.

Rejuvenates older depressed

batteries. Get full details at our

website, or call toll-free.

12 ft., 37 lb. Cub, Col. M., Bossier City, LA

CHARGE+ the GRANDSTAND

The GRANDSTAND is great for

.60 size to 40% scale. Made of

HEAVY-DUTY PVC, it is strong,

lightweight and folds for easy

storage and transport. Why pay

more for heavy, old fashioned

stands? See it in action on our

website.

The BATTERY TENDER,

Jr. keeps your 12 volt

gel cell or lead acid field

battery topped off with

microprocessor

controlled float charge

system. Plug it in and

leave it. No more

guessing and no more

down batteries.

Increases battery life too.

Full technical

specifications at our

website.

ONLY $39 95_

ONLY $3995

+S&H

ONLY $4995

+S&H

BATTERY TENDER Jr.

04sig2.QXD 1.23.03 1:20 pm Page 46

spar over your dihedral template, and glue

on the one-piece filler of 1⁄4 balsa and the

plywood doublers. Build the rear spar over

the main spar to duplicate the dihedral

angle and prevent a crooked wing. Cut out

the slot for the bellcrank to move through

the main spar now, before you forget.

Make a wing-rib template of plywood

or aluminum so that all ribs will be cut and

sanded exactly the same. If you use a wing

fixture featuring 1⁄4-inch-diameter steel

rods, these holes should be included on the

wing-rib template. The 1⁄4-inch holes will

be used to align the wing on the fixture,

but also pay attention to the leading edge

and trailing edge lineup, in case the wingrib

holes are not quite accurate.

With the basic wing frame completed,

install the plywood bellcrank mount,

bellcrank, pushrod wire, and leadouts. The

wing center-section sheeting on the top of

the wing should be joined at the centerline

between panels, and it should be reinforced

with silk and epoxy. The bottom centersection

sheeting of 3-inch-wide balsa

should be in continuous pieces across the

fuselage centerline wherever possible.

The wingtips on the prototype were

balsa blocks, but a built-up and sheetcovered

tip is suitable, less expensive, and

easier. An extra rib that is slightly smaller

than the airfoil ribs must be installed to

provide a two-step “break” in the tip

design. An outboard wingtip weight box is

recommended, but adjustable line guides

are not required if leadout position is per

the plans.

Final Assembly: Assemble the wing and

tail group to the fuselage, taking great care

to keep everything symmetrical and

square. It is important that the

wing/fuselage joint be secure. If the wing

does not fit the fuselage wing cutout

exactly, use scrap balsa packing to get

good contact.

Lash the landing-gear wire to its

plywood mount using copper wire and

epoxy. This is plenty strong. Install the

landing-gear mount by cutting out enough

wing bottom center planking to insert the

plywood gear mount. It is important to

epoxy the landing-gear mount to the

fuselage sides and to the bellcrank

plywood mount. This ties everything

together.

Leather triangular pattern-makers’

fillets are no longer generally available. A

good substitute is very soft triangular

balsa, wetted in ammonia, heated, and

carefully bent to shape. After gluing in

place, sand the fillets to a concave shape

using sandpaper wrapped around a short

length of birch dowel. The epoxy putty

normally used these days for fillets will be

heavy if laid down to the required

thickness. Besides, it is difficult to get a

smooth fillet with epoxy. The model will

April 2003 47

PERFORMANCE SPECIALTIES

PO Box 3146 • Gardnerville, NV 89410

Phone: 775-265-7523 • Fax: 775-265-7522

Performance Specialties makes your 4 stroke installations

easier with a great variety of new mufflers

and elbows for YS and OS engines.

Our unique new "Twister" allows the

user to rotate the muffler

through 150 degrees then

lock it down in the desired

position. The elbows are

available in 30, 45,

75 and 90 degree

versions to fit

virtually any installation.

The muffler/elbow

combinations and

the "Twister" are

available for OS 70/91/120,

YS 53/63/91/120/140, and

Saito 65/80/91/100/120/150/

180 engines.

VISIT US AT WWW.PSPEC.COM.

DEALER INQUIRIES WELCOME!

Take a look at the chart below. An UltraThrust

Muffler will add power without the hassle of tuned

pipes. No Hangers, No Couplers, No Problems!

Don’t limit your performance or your fun . . .

Fly with an UltraThrust Muffler.

Stock Ultra Thrust

Muffler Muffler

K&B 48 14,800 16,300

OS32 FX 15,500 16,500

OS40 FX 13,700 15,000

OS46 FX 14,400 15,800

OS46 SF 14,000 15,700

OS61 FX 11,700 13,000

OS91 FX 10,500 12,000

ST GS 40 13,600 15,000

ST GS 45 ABC 14,600 16,300

TT Pro 46 14,000 15,100

TT Pro 61 11,400 12,300

Webra 40 GT 13,800 15,200

Webra 50 GT 14,600 15,900

OS 32 FX tested on APC 9/6 prop. All 40-50’s tested on APC 10/6 prop. All 61’s on APC 11/7

prop. OS 91 FX on APC 13/8 prop. 15% Nitro Fuel. Your results may vary with local conditions.

ALSO

AVAILABLE

FOR OTHER

ENGINES

CALL

FOR

DETAILS!

Our Twister

lets you

position

the muffler

where YOU

want to!

PISTON/CYLINDER

ASSEMBLIES

Complete engine and muffler packages are available

from Performance Specialties.

ULTRATHRUST

MUFFLERS

NEED A LITTLE

ELBOW ROOM?

OUR TRUE CHROME PLATED PISTON/CYLINDER

ASSEMBLIES ARE GUARANTEED NOT TO PEEL!

• CUSTOM PORTING.

• TIMING OPTIONS

AVAILABLE ON

SOME VERSIONS.

• FACTORY

INSTALLATION

AVAILABLE.

Also Available:

Vor tech Adapter Nuts

To avoid the problem of long screws, which tend to

flex and break at the point where they enter the adapter

nut, we make 4 lengths of adapter nuts:

Short, Long, Extra Long & Extra-Extra Long.

This allows for the use of shorter screws, which don’t

flex and break.

FIBER- FILLED MOTOR MOUNTS•VIBRA-DAMP ISOLATION MOUNTS•SOUTHERN

PRO RETRACTS•MICRO-BALLOONS•SOUTHERN’S SORGHUM•TX-POSER•HUSH-CLAMP PIPE MOUNT•STRABILIZER TX TRAY•FIBERGLASS PUSHRODS•CORDLESS STARTER PACK•FLEX-ALL•CARBON

FIBER TAPE•CARBON FIBRE STRIP•TRIMSEAL•SKYLOFT•C/APPLICATOR SIX SHOOTER FUEL PUMPS•HOLSTER•POUR’N’PUMP FUELING SYSTEMS•LITE FLITE WHEELS•TREADED LITE FLITE WHEELS•LECTRA LITE WHEELS•TREADED LECTRA LITE WHEELS•BIG LITE WHEELS•TREADED BIG LITE WHEELS•R/C

FLIGHT SIMULA TORS FOR IBM COMPUTERS•TUNED PIPE MOUNT•VORTECH SPINNERS

4560 Layhigh Rd, Hamilton, OH 45013

513.738.1576 • www.dbproducts.com

Do You Need A Spinner

With Special Cutouts?

NO PROBLEM!

•Sizes up to 6 inches.

•Standard, Parabolic &

Ultimate styles.

•CNC machined to the

highest tolerances

•Strong, yet very light-weight

•Spun from Aluminum using

the same techniques used

for full-scale aircraft.

•Individually hand polished

& inspected

•Made in the USA.

There’s nothing better than having a beautiful, lightweight

spinner custom cut for your airplane. We cut our Vortech

Spinners to meet special requirements everyday.

Need a spinner for your multi-bladed prop? Maybe

something to fit a that special prop? No problem - give us a

call and we’ll be glad to help.

04sig2.QXD 1.23.03 1:21 pm Page 47

48 MODEL AVIATION

have a rather crude look without these

generous wing fillets.

Finishing: Silk covering is my material of

choice. This wing is plenty strong for G

forces, but it depends on the covering for

torsional stability. Silk or heavy silkspan

covering is necessary.

Center of Gravity (CG): With the model

assembled and covered, and with most of

the paint applied, the CG can be adjusted by

positioning the flight battery. Hopefully this

step can eliminate the addition of lead for

balance. The 1950 model had the battery aft

of the CG. The 1993 model has the flight

battery installed under the fuel tank. One

never knows until the last minute!

Spark Ignition: There is no need to fear

spark ignition! Modern electronics and Ni-

Cd flight cells all but eliminate sparkignition

problems. I use the transistorized

spark coil made by Aero Ply Research Co.

(address at end of text). As a bonus, the

transistorized spark-ignition units reduce

the current flowing through the engine

timer points to 1⁄50 ampere, with no

sparking. This means that your engine

points will never burn out or wear out. I

typically start an ignition engine in less

time than most people can start a Fox .35 or

an O.S. engine.

I use a homemade, rectangular fuel tank

made from K&S tin sheet stock. It is 1.9

inches wide, 3 inches long, and 1 inch high,

with uniflow venting, giving nearly three

ounces capacity. This will run the Orwick

.64 for roughly seven minutes on fuel

consisting of three parts Coleman lantern

fuel and one part Castrol 70 motorcycle oil.

Be sure to time your engine’s fuel

consumption for the correct tank volume.

I prefer rectangular fuel tanks because

they provide maximum volume in the space

available. In addition, a rectangular tank

takes approximately three laps of coughing

and wheezing before the engine stops

completely. I will not get caught in an

overhead maneuver with a suddenly dead

engine. It is a good idea to make your fuel

tank removable for maintenance. Solder

brackets to the tank, and secure the tank

with small wood screws.

Flying: This model flies best on 66-foot

braided lines of .018 diameter. With the

long wing, the radius of flight is nearly 70

feet. MA

Floyd E. Carter

2029 Crist Dr.

Los Altos CA 94024

Sources:

Cunningham Blue Streak engine:

RJL Industries

Box 5

Sierra Madre CA 91025

Spark ignition:

Aero Ply Research Co.

2029 Crist Dr.

Los Altos CA 94024

www.gcbmrc.com Catalog: $5.00 Direct Sales Only.

FLAIR PRODUCTS

SCOUT SERIES

WE CARRY ...

• 1⁄4 SCALE STEARMAN

• 1⁄4 SCALE TIGER MOTH

• 1⁄5 SCALE F2B BRISTOL

IN .40 2/S TO .61 4/S:

• SE5-A

• LEGIONAIRE

(NIEUPORT 17)

• BARONETTE

(FOKKER TRI-PLANE)

• SOPWITH PUP

• MAGNATILLA

• HARVARD / AT-6 TEXAN

GREAT MAGNUM

ENGINE/KIT COMBOS!

Flair Fokker D-VII (61” WS, .40 2/S, .60 4/S)

THEY’RE NOT ARFS...

5009 FAIRDALE

PASADENA, TX 77505

ORDERS: 800-609-7951

TECHLINE: 281-998-2529

THANK HEAVENS!!!

Tell them you saw it in “Modeler’s Mall”

04sig2.QXD 1.23.03 1:21 pm Page 48

Edition: Model Aviation - 2003/04

Page Numbers: 42,43,45,46,47,48

Edition: Model Aviation - 2003/04

Page Numbers: 42,43,45,46,47,48

f you have examined the accompanying photos you might be

thinking, “Hey, this airplane looks familiar.” And it should be

familiar. The Wildman 60 design of 1950 was strongly influenced

by a Control Line (CL) Precision Aerobatics, or Stunt, airplane

called the Dragon. It was the design of a young man named J.C.

Yates, and the construction article for it was published in the

November 1947 Air World magazine.

The Dragon was powered by a big Orwick .73 engine on spark

ignition. Its wing was a rectangular planform of only 475 square

inches, with a rather thin airfoil called NACA 99. The Dragon was

an immediate success, most likely because of its graceful lines in an

era when many CL Stunt models were simple “barn door” models

designed for maximum performance and good looks were

secondary.

The haphazard CL Stunt routine of the late 1940s was difficult

for judges and pilots. To bring some sort of order out of chaos,

George Aldrich and his colleagues proposed a new AMA Stunt

pattern with set maneuvers which everyone was obliged to fly.

Some of these maneuvers, such as the Wingover, Vertical Dive, and

Square Loop, required the model to dive toward the ground and

suddenly pull out to level flight. This clearly signaled the need for a

new type of aircraft.

Bob Palmer discovered that a lightweight model with wing flaps

would make a CL airplane turn better. His Go-Devil, Chief, and

Smoothie turned fliers away from high-powered, heavy, and fast

Stunters. Bob flew five-second laps with a glow Veco .29 barely

running at a slow four-stroke setting.

Most of my friends abandoned the old ways and followed Bob

Palmer’s example. I decided to make one last attempt using my

usual power package of an Orwick .64 and spark ignition. My

immediate problem was that the Orwick .64 engine and spark coil

and battery pack weighs 16 ounces. How could I design a CL model

to meet the demands of the new Stunt pattern?

My best solution was to design a larger airplane to carry the dead

weight of my power unit with a reasonable wing loading.

Since I had admired the sleek lines of the J.C. Yates Dragon, I

Wildman 60

■ Floyd Carter

Blast from the past for Old-Time Ignition CL Stunt events

I

The Wildman 60 design was heavily influenced by J.C.

“Madman” Yates’ Dragon, but it is a substantially larger

model.

Type: Old-Time Ignition CL Stunt

Wingspan: 591⁄2 inches

Engine: Ignition .60

Flying weight: 60-65 ounces

Construction: Balsa and plywood

Covering/finish: Silk and dope

Wildman 60

42 MODEL AVIATION

04sig2.QXD 1.24.03 8:38 am Page 42

designed Wildman 60 in the spring of 1950 with the Dragon in the

back of my mind. I settled on a wing planform of 60 x 12 inches

with a thick airfoil and a design weight less than 31⁄2 pounds.

I flew the prototype Wildman 60 in the Southern California

Plymouth meet at Redondo Beach, California, in 1950 and in

Phoenix in 1951. I earned no trophies for these efforts, but my

model flew much better than its pilot. I knew I had something good

going, but the judges at that time were more impressed with the

Bob Palmer style of slow flying.

CONSTRUCTION

The fuselage begins with a simple balsa-and-plywood box,

similar to many modern Stunters. But first you must select an

engine, because the fuselage front end is built around the engine of

choice.

If an Orwick .64 is not part of your collection, consider the

Cunningham Blue Streak .64 produced by RJL Industries (address

at end of text). The Blue Streak spark-ignition engine is similar to

an Orwick .64, but it features radial mounting and beam-mounting

lugs with a ball-bearing crankshaft. Suitable alternatives include the

Anderson Spitfire, the Super Cyclone, the McCoy .60, and other

strong engines.

The radial-mounting version of the Wildman 60 uses a hefty

plywood firewall securely tied into the fuselage and wing structure.

Beam mounting should utilize 1⁄2 x 5⁄8-inch hard-maple bearers

extending back to the wing cutout in the fuselage sides. Either

option begins with making identical fuselage sides from 1⁄8

medium-hard balsa sheet with matching wing cutouts. Plywood

doublers made from 0.8-millimeter or 1⁄32 birch plywood are glued

to the inside surface of each fuselage side.

April 2003 43

This shot with the top hatch removed shows the tank and coil

placement. Notice the modern Deans-type connectors.

The Orwick .64 is among the most beautiful of the ignition

engines, with its metallic-green-painted case.

Another view of the engine bay shows the clean lines of the nose

shape and the fine workmanship by Floyd Carter.

The author with his original design in 1950. He flew it in

competition then and now at Vintage Stunt Championships.

In-flight photo courtesy Elwyn Aud Graphic Design by Lydia Whitehead

04sig2.QXD 1.24.03 8:41 am Page 43

46 MODEL AVIATION

The radial-mount firewall F1 is epoxied

in place with the straight top of the

fuselage sides pinned to your building

board. Use a T-square to ensure that the

firewall will provide 0-0 engine thrust, and

glue in former F2 to establish the slight

taper, front to rear, of the fuselage sides.

Further bracing of the radial-mount

firewall to the fuselage sides is required,

using spruce triangular pieces behind the

firewall.

The plans show a molded plywood Ubrace

to further strengthen the firewallfuselage

interface, but this brace requires

building a male/female pine fixture to bend

and laminating the thin sheets of plywood

to make the U-brace. An alternate and

satisfactory method is to lay in fiberglass

cloth and epoxy to strengthen this joint.

For beam mounting, drill the maple

engine bearers and install T-nuts. Bolt the

engine to the engine bearers, keeping the

bearers parallel. This establishes the width

of firewall F1, which can be 1⁄8 birch

plywood for this option. If F1 turns out to

be different from what is shown on the

plans, the remainder of the fuselage

formers must also be adjusted to keep the

fuselage sides parallel back to the end of

the engine bearers and to establish the

required curve of the fuselage sides. If a

smoother taper in the fuselage top view is

desired, the engine bearers can be

narrowed aft of the firewall.

With the firewall epoxied in place and a

balsa fill-in between the engine bearers to

keep them parallel, this engine-mount

assembly can be epoxied to the plywood of

the fuselage sides. It is easier to epoxy the

engine-mount assembly to the fuselage one

side at a time. This gives you room to see

that the maple engine bearers are parallel

with the top of the fuselage and to use

weights on the engine-mount assembly to

ensure good contact with the fuselage side.

Epoxy the second fuselage side in place

with the fuselage sides turned upside down

on your flat building surface.

With the fuselage still mounted upsidedown

on the building board, glue in place

the remainder of the fuselage spacers,

formers, and doublers, and pull the

fuselage together at the tail post. Take care

to keep the fuselage curve symmetrical and

without any twist.

Build the fuselage turtledeck and top

block. The turtledeck on the 1993 Wildman

60 was made from two layers of 1⁄32 balsa

sheet laminated on a pine mold with a layer

of silkspan paper between. This requires

building a mold, but the result is light and

strong. Conventional construction is shown

on the plans.

The top hatch must be removable for

access to the spark-ignition components

and fuel tank. The removable hatch may

also include the simulated “cockpit,” or the

cockpit can be permanently glued to the

fuselage with the hatch separation line just

ahead of the cockpit. Either option will

provide enough access to the interior.

Notice that the fuselage gets no

torsional support from the top block. The

fuselage sides will be firmly anchored to

the wing center sheeting to stiffen the

fuselage in the absence of a glued-on top

block.

Tail Group: The prototype Wildman 60

had light 1⁄16 balsa covering over the builtup

tail. The 1993 model did not use balsa

covering. The tail group is a 3⁄8 x 1⁄2-inch

balsa outline. Double-glue the pieces

together and install 3⁄8-inch gussets at all

corners (not shown on the plans).

Cloth “over-and-under” hinges are

authentic and also seal the hinge gap for

better control response. Rayon taffeta

material works best. The tail group is

plenty strong with silk or heavy silkspan

covering.

The long tail moment and generous

stabilizer area provide authoritative pitch

control. Therefore, your bellcrank and

elevator horn geometry should be planned

for not more than 30° of elevator

movement up and down.

Wing: Build the spars with doublers first.

Draw your own dihedral template on a

large piece of plywood. Both wing panels

are the same length. Assemble the main

Hughes RC 1-800-786-0802 www.hughesrc.com

The CHARGE+ glow start charger

makes your pocket glow starter

as good as your power panel.

Charges at 1.6A, yet takes only

600mA from your field battery.

Use at home with AC adapter.

Peaks at highest voltage.

Rejuvenates older depressed

batteries. Get full details at our

website, or call toll-free.

12 ft., 37 lb. Cub, Col. M., Bossier City, LA

CHARGE+ the GRANDSTAND

The GRANDSTAND is great for

.60 size to 40% scale. Made of

HEAVY-DUTY PVC, it is strong,

lightweight and folds for easy

storage and transport. Why pay

more for heavy, old fashioned

stands? See it in action on our

website.

The BATTERY TENDER,

Jr. keeps your 12 volt

gel cell or lead acid field

battery topped off with

microprocessor

controlled float charge

system. Plug it in and

leave it. No more

guessing and no more

down batteries.

Increases battery life too.

Full technical

specifications at our

website.

ONLY $39 95_

ONLY $3995

+S&H

ONLY $4995

+S&H

BATTERY TENDER Jr.

04sig2.QXD 1.23.03 1:20 pm Page 46

spar over your dihedral template, and glue

on the one-piece filler of 1⁄4 balsa and the

plywood doublers. Build the rear spar over

the main spar to duplicate the dihedral

angle and prevent a crooked wing. Cut out

the slot for the bellcrank to move through

the main spar now, before you forget.

Make a wing-rib template of plywood

or aluminum so that all ribs will be cut and

sanded exactly the same. If you use a wing

fixture featuring 1⁄4-inch-diameter steel

rods, these holes should be included on the

wing-rib template. The 1⁄4-inch holes will

be used to align the wing on the fixture,

but also pay attention to the leading edge

and trailing edge lineup, in case the wingrib

holes are not quite accurate.

With the basic wing frame completed,

install the plywood bellcrank mount,

bellcrank, pushrod wire, and leadouts. The

wing center-section sheeting on the top of

the wing should be joined at the centerline

between panels, and it should be reinforced

with silk and epoxy. The bottom centersection

sheeting of 3-inch-wide balsa

should be in continuous pieces across the

fuselage centerline wherever possible.

The wingtips on the prototype were

balsa blocks, but a built-up and sheetcovered

tip is suitable, less expensive, and

easier. An extra rib that is slightly smaller

than the airfoil ribs must be installed to

provide a two-step “break” in the tip

design. An outboard wingtip weight box is

recommended, but adjustable line guides

are not required if leadout position is per

the plans.

Final Assembly: Assemble the wing and

tail group to the fuselage, taking great care

to keep everything symmetrical and

square. It is important that the

wing/fuselage joint be secure. If the wing

does not fit the fuselage wing cutout

exactly, use scrap balsa packing to get

good contact.

Lash the landing-gear wire to its

plywood mount using copper wire and

epoxy. This is plenty strong. Install the

landing-gear mount by cutting out enough

wing bottom center planking to insert the

plywood gear mount. It is important to

epoxy the landing-gear mount to the

fuselage sides and to the bellcrank

plywood mount. This ties everything

together.

Leather triangular pattern-makers’

fillets are no longer generally available. A

good substitute is very soft triangular

balsa, wetted in ammonia, heated, and

carefully bent to shape. After gluing in

place, sand the fillets to a concave shape

using sandpaper wrapped around a short

length of birch dowel. The epoxy putty

normally used these days for fillets will be

heavy if laid down to the required

thickness. Besides, it is difficult to get a

smooth fillet with epoxy. The model will

April 2003 47

PERFORMANCE SPECIALTIES

PO Box 3146 • Gardnerville, NV 89410

Phone: 775-265-7523 • Fax: 775-265-7522

Performance Specialties makes your 4 stroke installations

easier with a great variety of new mufflers

and elbows for YS and OS engines.

Our unique new "Twister" allows the

user to rotate the muffler

through 150 degrees then

lock it down in the desired

position. The elbows are

available in 30, 45,

75 and 90 degree

versions to fit

virtually any installation.

The muffler/elbow

combinations and

the "Twister" are

available for OS 70/91/120,

YS 53/63/91/120/140, and

Saito 65/80/91/100/120/150/

180 engines.

VISIT US AT WWW.PSPEC.COM.

DEALER INQUIRIES WELCOME!

Take a look at the chart below. An UltraThrust

Muffler will add power without the hassle of tuned

pipes. No Hangers, No Couplers, No Problems!

Don’t limit your performance or your fun . . .

Fly with an UltraThrust Muffler.

Stock Ultra Thrust

Muffler Muffler

K&B 48 14,800 16,300

OS32 FX 15,500 16,500

OS40 FX 13,700 15,000

OS46 FX 14,400 15,800

OS46 SF 14,000 15,700

OS61 FX 11,700 13,000

OS91 FX 10,500 12,000

ST GS 40 13,600 15,000

ST GS 45 ABC 14,600 16,300

TT Pro 46 14,000 15,100

TT Pro 61 11,400 12,300

Webra 40 GT 13,800 15,200

Webra 50 GT 14,600 15,900

OS 32 FX tested on APC 9/6 prop. All 40-50’s tested on APC 10/6 prop. All 61’s on APC 11/7

prop. OS 91 FX on APC 13/8 prop. 15% Nitro Fuel. Your results may vary with local conditions.

ALSO

AVAILABLE

FOR OTHER

ENGINES

CALL

FOR

DETAILS!

Our Twister

lets you

position

the muffler

where YOU

want to!

PISTON/CYLINDER

ASSEMBLIES

Complete engine and muffler packages are available

from Performance Specialties.

ULTRATHRUST

MUFFLERS

NEED A LITTLE

ELBOW ROOM?

OUR TRUE CHROME PLATED PISTON/CYLINDER

ASSEMBLIES ARE GUARANTEED NOT TO PEEL!

• CUSTOM PORTING.

• TIMING OPTIONS

AVAILABLE ON

SOME VERSIONS.

• FACTORY

INSTALLATION

AVAILABLE.

Also Available:

Vor tech Adapter Nuts

To avoid the problem of long screws, which tend to

flex and break at the point where they enter the adapter

nut, we make 4 lengths of adapter nuts:

Short, Long, Extra Long & Extra-Extra Long.

This allows for the use of shorter screws, which don’t

flex and break.

FIBER- FILLED MOTOR MOUNTS•VIBRA-DAMP ISOLATION MOUNTS•SOUTHERN

PRO RETRACTS•MICRO-BALLOONS•SOUTHERN’S SORGHUM•TX-POSER•HUSH-CLAMP PIPE MOUNT•STRABILIZER TX TRAY•FIBERGLASS PUSHRODS•CORDLESS STARTER PACK•FLEX-ALL•CARBON

FIBER TAPE•CARBON FIBRE STRIP•TRIMSEAL•SKYLOFT•C/APPLICATOR SIX SHOOTER FUEL PUMPS•HOLSTER•POUR’N’PUMP FUELING SYSTEMS•LITE FLITE WHEELS•TREADED LITE FLITE WHEELS•LECTRA LITE WHEELS•TREADED LECTRA LITE WHEELS•BIG LITE WHEELS•TREADED BIG LITE WHEELS•R/C

FLIGHT SIMULA TORS FOR IBM COMPUTERS•TUNED PIPE MOUNT•VORTECH SPINNERS

4560 Layhigh Rd, Hamilton, OH 45013

513.738.1576 • www.dbproducts.com

Do You Need A Spinner

With Special Cutouts?

NO PROBLEM!

•Sizes up to 6 inches.

•Standard, Parabolic &

Ultimate styles.

•CNC machined to the

highest tolerances

•Strong, yet very light-weight

•Spun from Aluminum using

the same techniques used

for full-scale aircraft.

•Individually hand polished

& inspected

•Made in the USA.

There’s nothing better than having a beautiful, lightweight

spinner custom cut for your airplane. We cut our Vortech

Spinners to meet special requirements everyday.

Need a spinner for your multi-bladed prop? Maybe

something to fit a that special prop? No problem - give us a

call and we’ll be glad to help.

04sig2.QXD 1.23.03 1:21 pm Page 47

48 MODEL AVIATION

have a rather crude look without these

generous wing fillets.

Finishing: Silk covering is my material of

choice. This wing is plenty strong for G

forces, but it depends on the covering for

torsional stability. Silk or heavy silkspan

covering is necessary.

Center of Gravity (CG): With the model

assembled and covered, and with most of

the paint applied, the CG can be adjusted by

positioning the flight battery. Hopefully this

step can eliminate the addition of lead for

balance. The 1950 model had the battery aft

of the CG. The 1993 model has the flight

battery installed under the fuel tank. One

never knows until the last minute!

Spark Ignition: There is no need to fear

spark ignition! Modern electronics and Ni-

Cd flight cells all but eliminate sparkignition

problems. I use the transistorized

spark coil made by Aero Ply Research Co.

(address at end of text). As a bonus, the

transistorized spark-ignition units reduce

the current flowing through the engine

timer points to 1⁄50 ampere, with no

sparking. This means that your engine

points will never burn out or wear out. I

typically start an ignition engine in less

time than most people can start a Fox .35 or

an O.S. engine.

I use a homemade, rectangular fuel tank

made from K&S tin sheet stock. It is 1.9

inches wide, 3 inches long, and 1 inch high,

with uniflow venting, giving nearly three

ounces capacity. This will run the Orwick

.64 for roughly seven minutes on fuel

consisting of three parts Coleman lantern

fuel and one part Castrol 70 motorcycle oil.

Be sure to time your engine’s fuel

consumption for the correct tank volume.

I prefer rectangular fuel tanks because

they provide maximum volume in the space

available. In addition, a rectangular tank

takes approximately three laps of coughing

and wheezing before the engine stops

completely. I will not get caught in an

overhead maneuver with a suddenly dead

engine. It is a good idea to make your fuel

tank removable for maintenance. Solder

brackets to the tank, and secure the tank

with small wood screws.

Flying: This model flies best on 66-foot

braided lines of .018 diameter. With the

long wing, the radius of flight is nearly 70

feet. MA

Floyd E. Carter

2029 Crist Dr.

Los Altos CA 94024

Sources:

Cunningham Blue Streak engine:

RJL Industries

Box 5

Sierra Madre CA 91025

Spark ignition:

Aero Ply Research Co.

2029 Crist Dr.

Los Altos CA 94024

www.gcbmrc.com Catalog: $5.00 Direct Sales Only.

FLAIR PRODUCTS

SCOUT SERIES

WE CARRY ...

• 1⁄4 SCALE STEARMAN

• 1⁄4 SCALE TIGER MOTH

• 1⁄5 SCALE F2B BRISTOL

IN .40 2/S TO .61 4/S:

• SE5-A

• LEGIONAIRE

(NIEUPORT 17)

• BARONETTE

(FOKKER TRI-PLANE)

• SOPWITH PUP

• MAGNATILLA

• HARVARD / AT-6 TEXAN

GREAT MAGNUM

ENGINE/KIT COMBOS!

Flair Fokker D-VII (61” WS, .40 2/S, .60 4/S)

THEY’RE NOT ARFS...

5009 FAIRDALE

PASADENA, TX 77505

ORDERS: 800-609-7951

TECHLINE: 281-998-2529

THANK HEAVENS!!!

Tell them you saw it in “Modeler’s Mall”

04sig2.QXD 1.23.03 1:21 pm Page 48

Edition: Model Aviation - 2003/04

Page Numbers: 42,43,45,46,47,48

f you have examined the accompanying photos you might be

thinking, “Hey, this airplane looks familiar.” And it should be

familiar. The Wildman 60 design of 1950 was strongly influenced

by a Control Line (CL) Precision Aerobatics, or Stunt, airplane

called the Dragon. It was the design of a young man named J.C.

Yates, and the construction article for it was published in the

November 1947 Air World magazine.

The Dragon was powered by a big Orwick .73 engine on spark

ignition. Its wing was a rectangular planform of only 475 square

inches, with a rather thin airfoil called NACA 99. The Dragon was

an immediate success, most likely because of its graceful lines in an

era when many CL Stunt models were simple “barn door” models

designed for maximum performance and good looks were

secondary.

The haphazard CL Stunt routine of the late 1940s was difficult

for judges and pilots. To bring some sort of order out of chaos,

George Aldrich and his colleagues proposed a new AMA Stunt

pattern with set maneuvers which everyone was obliged to fly.

Some of these maneuvers, such as the Wingover, Vertical Dive, and

Square Loop, required the model to dive toward the ground and

suddenly pull out to level flight. This clearly signaled the need for a

new type of aircraft.

Bob Palmer discovered that a lightweight model with wing flaps

would make a CL airplane turn better. His Go-Devil, Chief, and

Smoothie turned fliers away from high-powered, heavy, and fast

Stunters. Bob flew five-second laps with a glow Veco .29 barely

running at a slow four-stroke setting.

Most of my friends abandoned the old ways and followed Bob

Palmer’s example. I decided to make one last attempt using my

usual power package of an Orwick .64 and spark ignition. My

immediate problem was that the Orwick .64 engine and spark coil

and battery pack weighs 16 ounces. How could I design a CL model

to meet the demands of the new Stunt pattern?

My best solution was to design a larger airplane to carry the dead

weight of my power unit with a reasonable wing loading.

Since I had admired the sleek lines of the J.C. Yates Dragon, I

Wildman 60

■ Floyd Carter

Blast from the past for Old-Time Ignition CL Stunt events

I

The Wildman 60 design was heavily influenced by J.C.

“Madman” Yates’ Dragon, but it is a substantially larger

model.

Type: Old-Time Ignition CL Stunt

Wingspan: 591⁄2 inches

Engine: Ignition .60

Flying weight: 60-65 ounces

Construction: Balsa and plywood

Covering/finish: Silk and dope

Wildman 60

42 MODEL AVIATION

04sig2.QXD 1.24.03 8:38 am Page 42

designed Wildman 60 in the spring of 1950 with the Dragon in the

back of my mind. I settled on a wing planform of 60 x 12 inches

with a thick airfoil and a design weight less than 31⁄2 pounds.

I flew the prototype Wildman 60 in the Southern California

Plymouth meet at Redondo Beach, California, in 1950 and in

Phoenix in 1951. I earned no trophies for these efforts, but my

model flew much better than its pilot. I knew I had something good

going, but the judges at that time were more impressed with the

Bob Palmer style of slow flying.

CONSTRUCTION

The fuselage begins with a simple balsa-and-plywood box,

similar to many modern Stunters. But first you must select an

engine, because the fuselage front end is built around the engine of

choice.

If an Orwick .64 is not part of your collection, consider the

Cunningham Blue Streak .64 produced by RJL Industries (address

at end of text). The Blue Streak spark-ignition engine is similar to

an Orwick .64, but it features radial mounting and beam-mounting

lugs with a ball-bearing crankshaft. Suitable alternatives include the

Anderson Spitfire, the Super Cyclone, the McCoy .60, and other

strong engines.

The radial-mounting version of the Wildman 60 uses a hefty

plywood firewall securely tied into the fuselage and wing structure.

Beam mounting should utilize 1⁄2 x 5⁄8-inch hard-maple bearers

extending back to the wing cutout in the fuselage sides. Either

option begins with making identical fuselage sides from 1⁄8

medium-hard balsa sheet with matching wing cutouts. Plywood

doublers made from 0.8-millimeter or 1⁄32 birch plywood are glued

to the inside surface of each fuselage side.

April 2003 43

This shot with the top hatch removed shows the tank and coil

placement. Notice the modern Deans-type connectors.

The Orwick .64 is among the most beautiful of the ignition

engines, with its metallic-green-painted case.

Another view of the engine bay shows the clean lines of the nose

shape and the fine workmanship by Floyd Carter.

The author with his original design in 1950. He flew it in

competition then and now at Vintage Stunt Championships.

In-flight photo courtesy Elwyn Aud Graphic Design by Lydia Whitehead

04sig2.QXD 1.24.03 8:41 am Page 43

46 MODEL AVIATION

The radial-mount firewall F1 is epoxied

in place with the straight top of the

fuselage sides pinned to your building

board. Use a T-square to ensure that the

firewall will provide 0-0 engine thrust, and

glue in former F2 to establish the slight

taper, front to rear, of the fuselage sides.

Further bracing of the radial-mount

firewall to the fuselage sides is required,

using spruce triangular pieces behind the

firewall.

The plans show a molded plywood Ubrace

to further strengthen the firewallfuselage

interface, but this brace requires

building a male/female pine fixture to bend

and laminating the thin sheets of plywood

to make the U-brace. An alternate and

satisfactory method is to lay in fiberglass

cloth and epoxy to strengthen this joint.

For beam mounting, drill the maple

engine bearers and install T-nuts. Bolt the

engine to the engine bearers, keeping the

bearers parallel. This establishes the width

of firewall F1, which can be 1⁄8 birch

plywood for this option. If F1 turns out to

be different from what is shown on the

plans, the remainder of the fuselage

formers must also be adjusted to keep the

fuselage sides parallel back to the end of

the engine bearers and to establish the

required curve of the fuselage sides. If a

smoother taper in the fuselage top view is

desired, the engine bearers can be

narrowed aft of the firewall.

With the firewall epoxied in place and a

balsa fill-in between the engine bearers to

keep them parallel, this engine-mount

assembly can be epoxied to the plywood of

the fuselage sides. It is easier to epoxy the

engine-mount assembly to the fuselage one

side at a time. This gives you room to see

that the maple engine bearers are parallel

with the top of the fuselage and to use

weights on the engine-mount assembly to

ensure good contact with the fuselage side.

Epoxy the second fuselage side in place

with the fuselage sides turned upside down

on your flat building surface.

With the fuselage still mounted upsidedown

on the building board, glue in place

the remainder of the fuselage spacers,

formers, and doublers, and pull the

fuselage together at the tail post. Take care

to keep the fuselage curve symmetrical and

without any twist.

Build the fuselage turtledeck and top

block. The turtledeck on the 1993 Wildman

60 was made from two layers of 1⁄32 balsa

sheet laminated on a pine mold with a layer

of silkspan paper between. This requires

building a mold, but the result is light and

strong. Conventional construction is shown

on the plans.

The top hatch must be removable for

access to the spark-ignition components

and fuel tank. The removable hatch may

also include the simulated “cockpit,” or the

cockpit can be permanently glued to the

fuselage with the hatch separation line just

ahead of the cockpit. Either option will

provide enough access to the interior.

Notice that the fuselage gets no

torsional support from the top block. The

fuselage sides will be firmly anchored to

the wing center sheeting to stiffen the

fuselage in the absence of a glued-on top

block.

Tail Group: The prototype Wildman 60

had light 1⁄16 balsa covering over the builtup

tail. The 1993 model did not use balsa

covering. The tail group is a 3⁄8 x 1⁄2-inch

balsa outline. Double-glue the pieces

together and install 3⁄8-inch gussets at all

corners (not shown on the plans).

Cloth “over-and-under” hinges are

authentic and also seal the hinge gap for

better control response. Rayon taffeta

material works best. The tail group is

plenty strong with silk or heavy silkspan

covering.

The long tail moment and generous

stabilizer area provide authoritative pitch

control. Therefore, your bellcrank and

elevator horn geometry should be planned

for not more than 30° of elevator

movement up and down.

Wing: Build the spars with doublers first.

Draw your own dihedral template on a

large piece of plywood. Both wing panels

are the same length. Assemble the main

Hughes RC 1-800-786-0802 www.hughesrc.com

The CHARGE+ glow start charger

makes your pocket glow starter

as good as your power panel.

Charges at 1.6A, yet takes only

600mA from your field battery.

Use at home with AC adapter.

Peaks at highest voltage.

Rejuvenates older depressed

batteries. Get full details at our

website, or call toll-free.

12 ft., 37 lb. Cub, Col. M., Bossier City, LA

CHARGE+ the GRANDSTAND

The GRANDSTAND is great for

.60 size to 40% scale. Made of

HEAVY-DUTY PVC, it is strong,

lightweight and folds for easy

storage and transport. Why pay

more for heavy, old fashioned

stands? See it in action on our

website.

The BATTERY TENDER,

Jr. keeps your 12 volt

gel cell or lead acid field

battery topped off with

microprocessor

controlled float charge

system. Plug it in and

leave it. No more

guessing and no more

down batteries.

Increases battery life too.

Full technical

specifications at our

website.

ONLY $39 95_

ONLY $3995

+S&H

ONLY $4995

+S&H

BATTERY TENDER Jr.

04sig2.QXD 1.23.03 1:20 pm Page 46

spar over your dihedral template, and glue

on the one-piece filler of 1⁄4 balsa and the

plywood doublers. Build the rear spar over

the main spar to duplicate the dihedral

angle and prevent a crooked wing. Cut out

the slot for the bellcrank to move through

the main spar now, before you forget.

Make a wing-rib template of plywood

or aluminum so that all ribs will be cut and

sanded exactly the same. If you use a wing

fixture featuring 1⁄4-inch-diameter steel

rods, these holes should be included on the

wing-rib template. The 1⁄4-inch holes will

be used to align the wing on the fixture,

but also pay attention to the leading edge

and trailing edge lineup, in case the wingrib

holes are not quite accurate.

With the basic wing frame completed,

install the plywood bellcrank mount,

bellcrank, pushrod wire, and leadouts. The

wing center-section sheeting on the top of

the wing should be joined at the centerline

between panels, and it should be reinforced

with silk and epoxy. The bottom centersection

sheeting of 3-inch-wide balsa

should be in continuous pieces across the

fuselage centerline wherever possible.

The wingtips on the prototype were

balsa blocks, but a built-up and sheetcovered

tip is suitable, less expensive, and

easier. An extra rib that is slightly smaller

than the airfoil ribs must be installed to

provide a two-step “break” in the tip

design. An outboard wingtip weight box is

recommended, but adjustable line guides

are not required if leadout position is per

the plans.

Final Assembly: Assemble the wing and

tail group to the fuselage, taking great care

to keep everything symmetrical and

square. It is important that the

wing/fuselage joint be secure. If the wing

does not fit the fuselage wing cutout

exactly, use scrap balsa packing to get

good contact.

Lash the landing-gear wire to its

plywood mount using copper wire and

epoxy. This is plenty strong. Install the

landing-gear mount by cutting out enough

wing bottom center planking to insert the

plywood gear mount. It is important to

epoxy the landing-gear mount to the

fuselage sides and to the bellcrank

plywood mount. This ties everything

together.

Leather triangular pattern-makers’

fillets are no longer generally available. A

good substitute is very soft triangular

balsa, wetted in ammonia, heated, and

carefully bent to shape. After gluing in

place, sand the fillets to a concave shape

using sandpaper wrapped around a short

length of birch dowel. The epoxy putty

normally used these days for fillets will be

heavy if laid down to the required

thickness. Besides, it is difficult to get a

smooth fillet with epoxy. The model will

April 2003 47

PERFORMANCE SPECIALTIES

PO Box 3146 • Gardnerville, NV 89410

Phone: 775-265-7523 • Fax: 775-265-7522

Performance Specialties makes your 4 stroke installations

easier with a great variety of new mufflers

and elbows for YS and OS engines.

Our unique new "Twister" allows the

user to rotate the muffler

through 150 degrees then

lock it down in the desired

position. The elbows are

available in 30, 45,

75 and 90 degree

versions to fit

virtually any installation.

The muffler/elbow

combinations and

the "Twister" are

available for OS 70/91/120,

YS 53/63/91/120/140, and

Saito 65/80/91/100/120/150/

180 engines.

VISIT US AT WWW.PSPEC.COM.

DEALER INQUIRIES WELCOME!

Take a look at the chart below. An UltraThrust

Muffler will add power without the hassle of tuned

pipes. No Hangers, No Couplers, No Problems!

Don’t limit your performance or your fun . . .

Fly with an UltraThrust Muffler.

Stock Ultra Thrust

Muffler Muffler

K&B 48 14,800 16,300

OS32 FX 15,500 16,500

OS40 FX 13,700 15,000

OS46 FX 14,400 15,800

OS46 SF 14,000 15,700

OS61 FX 11,700 13,000

OS91 FX 10,500 12,000

ST GS 40 13,600 15,000

ST GS 45 ABC 14,600 16,300

TT Pro 46 14,000 15,100

TT Pro 61 11,400 12,300

Webra 40 GT 13,800 15,200

Webra 50 GT 14,600 15,900

OS 32 FX tested on APC 9/6 prop. All 40-50’s tested on APC 10/6 prop. All 61’s on APC 11/7

prop. OS 91 FX on APC 13/8 prop. 15% Nitro Fuel. Your results may vary with local conditions.

ALSO

AVAILABLE

FOR OTHER

ENGINES

CALL

FOR

DETAILS!

Our Twister

lets you

position

the muffler

where YOU

want to!

PISTON/CYLINDER

ASSEMBLIES

Complete engine and muffler packages are available

from Performance Specialties.

ULTRATHRUST

MUFFLERS

NEED A LITTLE

ELBOW ROOM?

OUR TRUE CHROME PLATED PISTON/CYLINDER

ASSEMBLIES ARE GUARANTEED NOT TO PEEL!

• CUSTOM PORTING.

• TIMING OPTIONS

AVAILABLE ON

SOME VERSIONS.

• FACTORY

INSTALLATION

AVAILABLE.

Also Available:

Vor tech Adapter Nuts

To avoid the problem of long screws, which tend to

flex and break at the point where they enter the adapter

nut, we make 4 lengths of adapter nuts:

Short, Long, Extra Long & Extra-Extra Long.

This allows for the use of shorter screws, which don’t

flex and break.

FIBER- FILLED MOTOR MOUNTS•VIBRA-DAMP ISOLATION MOUNTS•SOUTHERN

PRO RETRACTS•MICRO-BALLOONS•SOUTHERN’S SORGHUM•TX-POSER•HUSH-CLAMP PIPE MOUNT•STRABILIZER TX TRAY•FIBERGLASS PUSHRODS•CORDLESS STARTER PACK•FLEX-ALL•CARBON

FIBER TAPE•CARBON FIBRE STRIP•TRIMSEAL•SKYLOFT•C/APPLICATOR SIX SHOOTER FUEL PUMPS•HOLSTER•POUR’N’PUMP FUELING SYSTEMS•LITE FLITE WHEELS•TREADED LITE FLITE WHEELS•LECTRA LITE WHEELS•TREADED LECTRA LITE WHEELS•BIG LITE WHEELS•TREADED BIG LITE WHEELS•R/C

FLIGHT SIMULA TORS FOR IBM COMPUTERS•TUNED PIPE MOUNT•VORTECH SPINNERS

4560 Layhigh Rd, Hamilton, OH 45013

513.738.1576 • www.dbproducts.com

Do You Need A Spinner

With Special Cutouts?

NO PROBLEM!

•Sizes up to 6 inches.

•Standard, Parabolic &

Ultimate styles.

•CNC machined to the

highest tolerances

•Strong, yet very light-weight

•Spun from Aluminum using

the same techniques used

for full-scale aircraft.

•Individually hand polished

& inspected

•Made in the USA.

There’s nothing better than having a beautiful, lightweight

spinner custom cut for your airplane. We cut our Vortech

Spinners to meet special requirements everyday.

Need a spinner for your multi-bladed prop? Maybe

something to fit a that special prop? No problem - give us a

call and we’ll be glad to help.

04sig2.QXD 1.23.03 1:21 pm Page 47

48 MODEL AVIATION

have a rather crude look without these

generous wing fillets.

Finishing: Silk covering is my material of

choice. This wing is plenty strong for G

forces, but it depends on the covering for

torsional stability. Silk or heavy silkspan

covering is necessary.

Center of Gravity (CG): With the model

assembled and covered, and with most of

the paint applied, the CG can be adjusted by

positioning the flight battery. Hopefully this

step can eliminate the addition of lead for

balance. The 1950 model had the battery aft

of the CG. The 1993 model has the flight

battery installed under the fuel tank. One

never knows until the last minute!

Spark Ignition: There is no need to fear

spark ignition! Modern electronics and Ni-

Cd flight cells all but eliminate sparkignition

problems. I use the transistorized

spark coil made by Aero Ply Research Co.

(address at end of text). As a bonus, the

transistorized spark-ignition units reduce

the current flowing through the engine

timer points to 1⁄50 ampere, with no

sparking. This means that your engine

points will never burn out or wear out. I

typically start an ignition engine in less

time than most people can start a Fox .35 or

an O.S. engine.

I use a homemade, rectangular fuel tank

made from K&S tin sheet stock. It is 1.9

inches wide, 3 inches long, and 1 inch high,

with uniflow venting, giving nearly three

ounces capacity. This will run the Orwick

.64 for roughly seven minutes on fuel

consisting of three parts Coleman lantern

fuel and one part Castrol 70 motorcycle oil.

Be sure to time your engine’s fuel

consumption for the correct tank volume.

I prefer rectangular fuel tanks because

they provide maximum volume in the space

available. In addition, a rectangular tank

takes approximately three laps of coughing

and wheezing before the engine stops

completely. I will not get caught in an

overhead maneuver with a suddenly dead

engine. It is a good idea to make your fuel

tank removable for maintenance. Solder

brackets to the tank, and secure the tank

with small wood screws.

Flying: This model flies best on 66-foot

braided lines of .018 diameter. With the

long wing, the radius of flight is nearly 70

feet. MA

Floyd E. Carter

2029 Crist Dr.

Los Altos CA 94024

Sources:

Cunningham Blue Streak engine:

RJL Industries

Box 5

Sierra Madre CA 91025

Spark ignition:

Aero Ply Research Co.

2029 Crist Dr.

Los Altos CA 94024

www.gcbmrc.com Catalog: $5.00 Direct Sales Only.

FLAIR PRODUCTS

SCOUT SERIES

WE CARRY ...

• 1⁄4 SCALE STEARMAN

• 1⁄4 SCALE TIGER MOTH

• 1⁄5 SCALE F2B BRISTOL

IN .40 2/S TO .61 4/S:

• SE5-A

• LEGIONAIRE

(NIEUPORT 17)

• BARONETTE

(FOKKER TRI-PLANE)

• SOPWITH PUP

• MAGNATILLA

• HARVARD / AT-6 TEXAN

GREAT MAGNUM

ENGINE/KIT COMBOS!

Flair Fokker D-VII (61” WS, .40 2/S, .60 4/S)

THEY’RE NOT ARFS...

5009 FAIRDALE

PASADENA, TX 77505

ORDERS: 800-609-7951

TECHLINE: 281-998-2529

THANK HEAVENS!!!

Tell them you saw it in “Modeler’s Mall”

04sig2.QXD 1.23.03 1:21 pm Page 48

Edition: Model Aviation - 2003/04

Page Numbers: 42,43,45,46,47,48

f you have examined the accompanying photos you might be

thinking, “Hey, this airplane looks familiar.” And it should be

familiar. The Wildman 60 design of 1950 was strongly influenced

by a Control Line (CL) Precision Aerobatics, or Stunt, airplane

called the Dragon. It was the design of a young man named J.C.

Yates, and the construction article for it was published in the

November 1947 Air World magazine.

The Dragon was powered by a big Orwick .73 engine on spark

ignition. Its wing was a rectangular planform of only 475 square

inches, with a rather thin airfoil called NACA 99. The Dragon was

an immediate success, most likely because of its graceful lines in an

era when many CL Stunt models were simple “barn door” models

designed for maximum performance and good looks were

secondary.

The haphazard CL Stunt routine of the late 1940s was difficult

for judges and pilots. To bring some sort of order out of chaos,

George Aldrich and his colleagues proposed a new AMA Stunt

pattern with set maneuvers which everyone was obliged to fly.

Some of these maneuvers, such as the Wingover, Vertical Dive, and

Square Loop, required the model to dive toward the ground and

suddenly pull out to level flight. This clearly signaled the need for a

new type of aircraft.

Bob Palmer discovered that a lightweight model with wing flaps

would make a CL airplane turn better. His Go-Devil, Chief, and

Smoothie turned fliers away from high-powered, heavy, and fast

Stunters. Bob flew five-second laps with a glow Veco .29 barely

running at a slow four-stroke setting.

Most of my friends abandoned the old ways and followed Bob

Palmer’s example. I decided to make one last attempt using my

usual power package of an Orwick .64 and spark ignition. My

immediate problem was that the Orwick .64 engine and spark coil

and battery pack weighs 16 ounces. How could I design a CL model

to meet the demands of the new Stunt pattern?

My best solution was to design a larger airplane to carry the dead

weight of my power unit with a reasonable wing loading.

Since I had admired the sleek lines of the J.C. Yates Dragon, I

Wildman 60

■ Floyd Carter

Blast from the past for Old-Time Ignition CL Stunt events

I

The Wildman 60 design was heavily influenced by J.C.

“Madman” Yates’ Dragon, but it is a substantially larger

model.

Type: Old-Time Ignition CL Stunt

Wingspan: 591⁄2 inches

Engine: Ignition .60

Flying weight: 60-65 ounces

Construction: Balsa and plywood

Covering/finish: Silk and dope

Wildman 60

42 MODEL AVIATION

04sig2.QXD 1.24.03 8:38 am Page 42

designed Wildman 60 in the spring of 1950 with the Dragon in the

back of my mind. I settled on a wing planform of 60 x 12 inches

with a thick airfoil and a design weight less than 31⁄2 pounds.

I flew the prototype Wildman 60 in the Southern California

Plymouth meet at Redondo Beach, California, in 1950 and in

Phoenix in 1951. I earned no trophies for these efforts, but my

model flew much better than its pilot. I knew I had something good

going, but the judges at that time were more impressed with the

Bob Palmer style of slow flying.

CONSTRUCTION

The fuselage begins with a simple balsa-and-plywood box,

similar to many modern Stunters. But first you must select an

engine, because the fuselage front end is built around the engine of

choice.

If an Orwick .64 is not part of your collection, consider the

Cunningham Blue Streak .64 produced by RJL Industries (address

at end of text). The Blue Streak spark-ignition engine is similar to

an Orwick .64, but it features radial mounting and beam-mounting

lugs with a ball-bearing crankshaft. Suitable alternatives include the

Anderson Spitfire, the Super Cyclone, the McCoy .60, and other

strong engines.

The radial-mounting version of the Wildman 60 uses a hefty

plywood firewall securely tied into the fuselage and wing structure.

Beam mounting should utilize 1⁄2 x 5⁄8-inch hard-maple bearers

extending back to the wing cutout in the fuselage sides. Either

option begins with making identical fuselage sides from 1⁄8

medium-hard balsa sheet with matching wing cutouts. Plywood

doublers made from 0.8-millimeter or 1⁄32 birch plywood are glued

to the inside surface of each fuselage side.

April 2003 43

This shot with the top hatch removed shows the tank and coil

placement. Notice the modern Deans-type connectors.

The Orwick .64 is among the most beautiful of the ignition

engines, with its metallic-green-painted case.

Another view of the engine bay shows the clean lines of the nose

shape and the fine workmanship by Floyd Carter.

The author with his original design in 1950. He flew it in

competition then and now at Vintage Stunt Championships.

In-flight photo courtesy Elwyn Aud Graphic Design by Lydia Whitehead

04sig2.QXD 1.24.03 8:41 am Page 43

46 MODEL AVIATION

The radial-mount firewall F1 is epoxied

in place with the straight top of the

fuselage sides pinned to your building

board. Use a T-square to ensure that the

firewall will provide 0-0 engine thrust, and

glue in former F2 to establish the slight

taper, front to rear, of the fuselage sides.

Further bracing of the radial-mount

firewall to the fuselage sides is required,

using spruce triangular pieces behind the

firewall.

The plans show a molded plywood Ubrace

to further strengthen the firewallfuselage

interface, but this brace requires

building a male/female pine fixture to bend

and laminating the thin sheets of plywood

to make the U-brace. An alternate and

satisfactory method is to lay in fiberglass

cloth and epoxy to strengthen this joint.

For beam mounting, drill the maple

engine bearers and install T-nuts. Bolt the

engine to the engine bearers, keeping the

bearers parallel. This establishes the width

of firewall F1, which can be 1⁄8 birch

plywood for this option. If F1 turns out to

be different from what is shown on the

plans, the remainder of the fuselage

formers must also be adjusted to keep the

fuselage sides parallel back to the end of

the engine bearers and to establish the

required curve of the fuselage sides. If a

smoother taper in the fuselage top view is

desired, the engine bearers can be

narrowed aft of the firewall.

With the firewall epoxied in place and a

balsa fill-in between the engine bearers to

keep them parallel, this engine-mount

assembly can be epoxied to the plywood of

the fuselage sides. It is easier to epoxy the

engine-mount assembly to the fuselage one

side at a time. This gives you room to see

that the maple engine bearers are parallel

with the top of the fuselage and to use

weights on the engine-mount assembly to

ensure good contact with the fuselage side.

Epoxy the second fuselage side in place

with the fuselage sides turned upside down

on your flat building surface.

With the fuselage still mounted upsidedown

on the building board, glue in place

the remainder of the fuselage spacers,

formers, and doublers, and pull the

fuselage together at the tail post. Take care

to keep the fuselage curve symmetrical and

without any twist.

Build the fuselage turtledeck and top

block. The turtledeck on the 1993 Wildman

60 was made from two layers of 1⁄32 balsa

sheet laminated on a pine mold with a layer

of silkspan paper between. This requires

building a mold, but the result is light and

strong. Conventional construction is shown

on the plans.

The top hatch must be removable for

access to the spark-ignition components

and fuel tank. The removable hatch may

also include the simulated “cockpit,” or the

cockpit can be permanently glued to the

fuselage with the hatch separation line just

ahead of the cockpit. Either option will

provide enough access to the interior.

Notice that the fuselage gets no

torsional support from the top block. The

fuselage sides will be firmly anchored to

the wing center sheeting to stiffen the

fuselage in the absence of a glued-on top

block.

Tail Group: The prototype Wildman 60

had light 1⁄16 balsa covering over the builtup

tail. The 1993 model did not use balsa

covering. The tail group is a 3⁄8 x 1⁄2-inch

balsa outline. Double-glue the pieces

together and install 3⁄8-inch gussets at all

corners (not shown on the plans).

Cloth “over-and-under” hinges are

authentic and also seal the hinge gap for

better control response. Rayon taffeta

material works best. The tail group is

plenty strong with silk or heavy silkspan

covering.

The long tail moment and generous

stabilizer area provide authoritative pitch

control. Therefore, your bellcrank and

elevator horn geometry should be planned

for not more than 30° of elevator

movement up and down.

Wing: Build the spars with doublers first.

Draw your own dihedral template on a

large piece of plywood. Both wing panels

are the same length. Assemble the main

Hughes RC 1-800-786-0802 www.hughesrc.com

The CHARGE+ glow start charger

makes your pocket glow starter

as good as your power panel.

Charges at 1.6A, yet takes only

600mA from your field battery.

Use at home with AC adapter.

Peaks at highest voltage.

Rejuvenates older depressed

batteries. Get full details at our

website, or call toll-free.

12 ft., 37 lb. Cub, Col. M., Bossier City, LA

CHARGE+ the GRANDSTAND

The GRANDSTAND is great for

.60 size to 40% scale. Made of

HEAVY-DUTY PVC, it is strong,

lightweight and folds for easy

storage and transport. Why pay

more for heavy, old fashioned

stands? See it in action on our

website.

The BATTERY TENDER,

Jr. keeps your 12 volt

gel cell or lead acid field

battery topped off with

microprocessor

controlled float charge

system. Plug it in and

leave it. No more

guessing and no more

down batteries.

Increases battery life too.

Full technical

specifications at our

website.

ONLY $39 95_

ONLY $3995

+S&H

ONLY $4995

+S&H

BATTERY TENDER Jr.

04sig2.QXD 1.23.03 1:20 pm Page 46

spar over your dihedral template, and glue

on the one-piece filler of 1⁄4 balsa and the

plywood doublers. Build the rear spar over

the main spar to duplicate the dihedral

angle and prevent a crooked wing. Cut out

the slot for the bellcrank to move through

the main spar now, before you forget.

Make a wing-rib template of plywood

or aluminum so that all ribs will be cut and

sanded exactly the same. If you use a wing

fixture featuring 1⁄4-inch-diameter steel

rods, these holes should be included on the

wing-rib template. The 1⁄4-inch holes will

be used to align the wing on the fixture,

but also pay attention to the leading edge

and trailing edge lineup, in case the wingrib

holes are not quite accurate.

With the basic wing frame completed,

install the plywood bellcrank mount,

bellcrank, pushrod wire, and leadouts. The

wing center-section sheeting on the top of

the wing should be joined at the centerline

between panels, and it should be reinforced

with silk and epoxy. The bottom centersection

sheeting of 3-inch-wide balsa

should be in continuous pieces across the

fuselage centerline wherever possible.

The wingtips on the prototype were

balsa blocks, but a built-up and sheetcovered

tip is suitable, less expensive, and

easier. An extra rib that is slightly smaller

than the airfoil ribs must be installed to

provide a two-step “break” in the tip

design. An outboard wingtip weight box is

recommended, but adjustable line guides

are not required if leadout position is per

the plans.

Final Assembly: Assemble the wing and

tail group to the fuselage, taking great care

to keep everything symmetrical and

square. It is important that the

wing/fuselage joint be secure. If the wing

does not fit the fuselage wing cutout

exactly, use scrap balsa packing to get

good contact.

Lash the landing-gear wire to its

plywood mount using copper wire and

epoxy. This is plenty strong. Install the

landing-gear mount by cutting out enough

wing bottom center planking to insert the

plywood gear mount. It is important to

epoxy the landing-gear mount to the

fuselage sides and to the bellcrank

plywood mount. This ties everything

together.

Leather triangular pattern-makers’

fillets are no longer generally available. A

good substitute is very soft triangular